It is neither promising nor advantageous to make patterns for fixed dental prosthesis directly in the mouth. That’s why, for obtaining a precise cast an impression of the teeth and surrounding structures is always essential [1]. Along with proper impression material, rigid impression trays and precise impression techniques are required for an exact registration of hard and soft tissues of oral cavity [2]. In fixed partial denture fabrication many impression techniques have been stated for obtaining clinically acceptable impressions [3]. Getz in 1951 used a water cooled tray with a reversible hydrocolloid for dual arch impression technique [4]. Wilson and Werrin described the dual-arch impression technique which is practical in that the obligatory maxillary and mandibular impressions, over and above the interocclusal record can be recorded in single procedure [5]. The foremost benefit of this technique is that it can lessen errors and the call for occlusal adjustment [6]. The rationale of this research was to compare the preciseness of working dies made from impressions with quadrant metal and plastic dual-arch trays and full arch stock metal rim lock trays when two diverse viscosities (rigid and monophase) of impression tray material were used, and altering which side (working /nonworking) of the dual-arch impression was poured first. The null hypotheses was that there was no difference in die materials for plastic against metal trays, for monophase against rigid impression material, and for pouring opposing against the working side of the impression first.

Materials and Methods

The present study was conducted for the period of three years in the Department of Prosthodontics including Crown and Bridge and Implantology of Government Dental College and Hospital, Ahmedabad in assistance with Reproductive Cytotoxicity Department, National Institute of Occupational Health (NIOH), Ahmedabad, Gujarat, India.

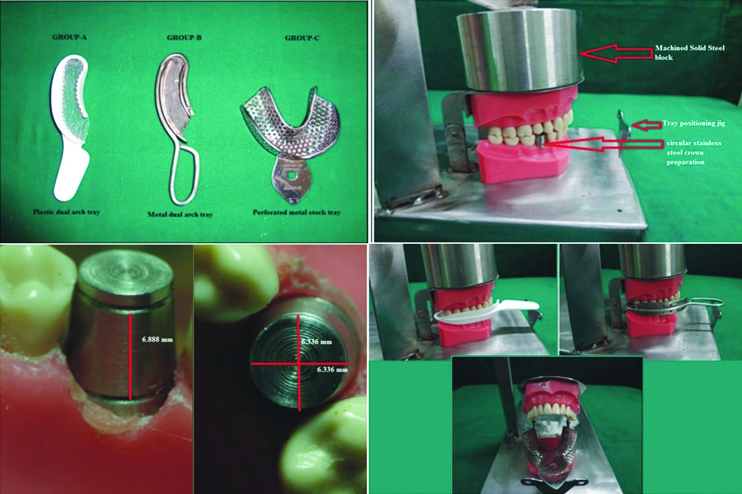

There were three variables that could have an effect on accuracy of working dies obtained: type of trays [Table/Fig-1] used, impression material viscosity, and order of pour of the impression arches.

Impression trays used in the study, and articulated master model in maximum intercuspation with reproducible reference grooves and points for measuring occluso-gingival, mesio-distal and bucco-lingual distance.

An unbiased (even-handed or balanced) design with independent samples was used to study these three variables. There was sample size discrepancy between Group C and Group A and B because Group A and B have working and nonworking sides while the Group C has only working side but at the same time subgroups of each group had same sample size that is 30 each. Though in previous studies sample size was small, but in present study sample size was large for getting more authentic statistical results. A sample size of 30 was kept in each subgroup yielding a total 300 impressions in ten subgroups or three groups (120 Group A, 120 Group B and 60 Group C) [7].

Impressions recorded by sectional dual arch impression trays (plastic and metal) and full arch metal stock trays were divided into three groups and 10 subgroups.

Grounding of the Master Model [Table/Fig-1]

The typhodont teeth were rooted in the maxillary and mandibular API model bases. In place of right mandibular second premolar a machined, rounded stainless steel crown preparation was used. Grooves were made on the occlusal and gingival surface of the stainless steel die to act as reproducible allusion points for the intention of assessment [8] Then API models were mounted in maximum intercuspation on a custom made stainless steel holder [9], using machined concrete customary steel block of 1.5 kg. A tray positioning jig was attached to the custom made stainless steel holder so that the position of the impression tray was steady and reproducible between the trials [7,9].

Impressions [Table/Fig-1-3]

Groups and subgroups of samples.

| Group A: Impressions made in plastic quadrant dual arch trays. | Group B: Impressions made in metal quadrant dual arch trays. | Group C: Impressions made in full arch metal stock trays. |

| Subgroup A1: Impressions made in plastic quadrant dual arch trays with rigid impression material and pouring working side first (30 samples). | Subgroup B1: Impressions made in metal quadrant dual arch trays with rigid impression material and pouring working side first (30 samples). | Group C1: Impressions made in full arch metal stock trays with rigid impression material (30 samples). |

| Subgroup A2: Impressions made in plastic quadrant dual arch trays with rigid impression material and pouring nonworking side first (30 samples). | Subgroup B2: Impressions made in metal quadrant dual arch trays with rigid impression material and pouring nonworking side first (30 samples). | Group C2: Impressions made in full arch metal stock trays with monophase impression material (30 samples). |

| Subgroup A3: Impressions made in plastic quadrant dual arch trays with monophase impression material and pouring working side first (30 samples). | Subgroup B3: Impressions made in metal quadrant dual arch trays with monophase impression material and pouring working side first (30 samples). | - |

| Subgroup A4: Impressions made in plastic quadrant dual arch trays with monophase impression material and pouring nonworking side first (30 samples). | Subgroup B4: Impressions made in metal quadrant dual arch trays with monophase impression material and pouring nonworking side first (30 samples). | - |

Note: In Group C there was only one side (working side) that’s why the total sample size of this group was 60.

Impression making and completed impressions of rigid and monophase impression materials with light body in three different type of trays.

Group A impressions: Plastic quadrant dual-arch trays (Alfa triple tray, Premier Dental Products, Canada) were used to make the impressions via one step technique [10]. A dual mix technique was used where tray material was hand mixed and low viscosity materials were auto mixed concurrently [10]. The impressions were poured in gypsum 60 minutes later [7]

A total of 120 impressions were made in this group. Half the impressions (60) were poured on the working side first (Subgroup A1 and A3) and then the non-working side was poured. In the supplementary half of the impressions (60) the non-working side (Subgroup A2 and A4) was poured first as suggested by the manufacturers of the tray, and also as suggested by Wilson and Werrin [11]. After an hour passed the working side of the impression was poured.

Group B impressions: A metal quadrant dual-arch tray was used to make the impressions using a one-step technique [10]. The method was similar to that performed in Group A (first pouring of Subgroup B1 and B3 and then Subgroup B2 and B4) impressions apart from that a five metal dual-arch trays were used to make all the impressions.

Group C impressions: Full-arch dentulous stock metal trays were used to make the impressions using a two step putty reline technique in this group [12]. A total of 60 PVS tray material (Reprosil-putty and Aquasil monophase) and light body impressions were made (Subgroup C1 and C2) [13,14].

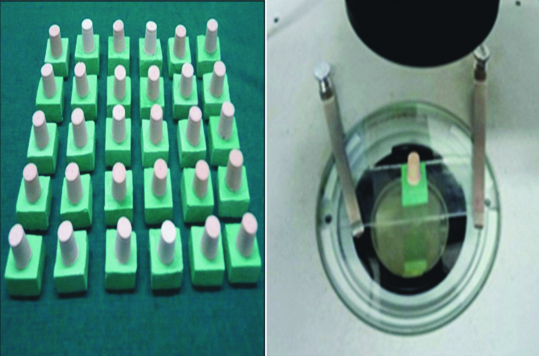

Preparation of the Master Dies [Table/Fig-4]

Obtained working dies, and measurement of working dies under measuring microscope.

A 100 gm of improved dental stone (type IV) Elite rock, Sandy Brown, Zhermack-Italy) was used with 20 ml of distilled water and was hand mixed for 10 seconds. Later the stone was automatically mixed under vacuum in a vacuum mixer for 40 seconds [7]. After pouring the casts, the impression trays were poised in a tray holder for 60 minutes allocated for the gypsum to set. All casts were allowed to set for 24 hours at room temperature before removal from the impressions [7]. The casts were then sectioned with a diamond disc (6934; Brasseler USA, Savannah, Ga) to form individual gypsum dies of the stainless steel standard and were labeled as per group.

Measuring method: Measurements were done by the measuring microscope (Olympus, Japan) with accuracy of 0.001 mm. The gypsum working dies were measured at a fixed, reproducible position under the microscope with inbuilt jig [Table/Fig-4]. For the assessment of 3-dimensional accuracy (buccolingual, mesiodistal, and occlusogingival), each die was measured with a measuring microscope. Each dimension of the working dies was measured three times at three different magnifications (8X, 10X, 12.5X) and the mean was used for the sample value. The same three aspects of the stainless steel standard die were measured multiple times, first prior to and then at the conclusion of measuring all working dies, to turn up at the three standard values to which all working dies means were compared.

Statistical Analysis

Descriptive statistics like mean, Standard Deviation (SD) were calculated for all the groups and for differences with Master Model (MM). One-way Analysis of Variance (ANOVA) was used for multiple group comparisons. Differences from the master model were analysed by paired t-test, an intergroup comparison by unpaired t-test. A p-value of 0.05 or less was considered for statistical significance. A statistical software IBM SPSS Statistics versions 22.0 was used.

Results [Table/Fig-5-11]:

The occlusogingival, mesiodistal, and buccolingual dimensions in the stainless steel master model (die) were found to be 6.888 mm, 6.336 mm, and 6.336 mm respectively to which the three groups were compared [Table/Fig-5]. The mean standard deviation associated with the stainless steel standard was 0.001 mm [Table/Fig-5] and that for the working dies ranged from 0.002 mm to 0.047 mm [Table/Fig-12]. Statistical analysis was done to assess the accuracy of the impressions within the group and between the groups. Side/group and group/viscosity cross-product interactions were significant (p<0.05) in occlusogingival direction, while in mesiodistal and buccolingual directions group/viscosity interaction was significant (p<0.05) [Table/Fig-6,7,8]. Result shows that when:

Occlusogingival, mesiodistal, and bucco-lingual dimensions of stainless steel master model (die).

| Master Model (MM) | OG | MD | BL |

|---|

| 6.888 (0.001)mm | 6.336 (0.001) mm | 6.336 (0.001) mm |

Results of 3-factor ANOVA for occlusogingival dimensions (OG).

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. | Noncent. Parameter | Observed Power(a) |

|---|

| Corrected Model | 0.008 | 9 | 0.001 | 8.843 | 0.000 | 79.587 | 1.000 |

| Intercept | 13,454.717 | 1 | 13,454.717 | 136,677, 456.653 | 0.000 | 136,677, 456.653 | 1.000 |

| GROUP | 0.001 | 2 | 0.000 | 3.995 | 0.019 | 7.991 | 0.712 |

| SIDE | 0.000 | 1 | 0.000 | 1.195 | 0.275 | 1.195 | 0.193 |

| VISC | 0.000 | 1 | 0.000 | 3.756 | 0.054 | 3.756 | 0.489 |

| SIDE * GROUP | 0.000 | 1 | 0.000 | 4.951 | 0.027 | 4.951 | 0.602 |

| GROUP * VISC | 0.004 | 2 | 0.002 | 20.977 | 0.000 | 41.954 | 1.000 |

| SIDE * VISC | 0.000 | 1 | 0.000 | 0.299 | 0.585 | 0.299 | 0.085 |

| SIDE * GROUP * VISC | 0.000 | 1 | 0.000 | 1.281 | 0.259 | 1.281 | 0.204 |

| Error | 0.029 | 290 | 0.000 | | | | |

| Total | 14,223.565 | 300 | | | | | |

| Corrected Total | 0.036 | 299 | | | | | |

Test of between- Subjects Effects: a. Computed using alpha = 0.05 b. R Squared =.215 (Adjusted R Squared = 0.191)

Results of 3-factor ANOVA for mesiodistal dimensions (MD).

| Source | Type III Sum ofSquares | df | MeanSquare | F | Sig. | Noncent.Parameter | ObservedPower(a) |

|---|

| Corrected Model | 0.424 | 9 | 0.047 | 413.665 | 0.000 | 3,722.982 | 1.000 |

| Intercept | 11,243.379 | 1 | 11,243.379 | 98,774,022.005 | 0.000 | 98,774,022.005 | 1.000 |

| GROUP | 0.359 | 2 | 0.180 | 1,577.848 | 0.000 | 3,155.696 | 1.000 |

| SIDE | 0.001 | 1 | 0.001 | 7.813 | 0.006 | 7.813 | 0.796 |

| VISC | 0.003 | 1 | 0.003 | 28.410 | 0.000 | 28.410 | 1.000 |

| SIDE * GROUP | 0.000 | 1 | 0.000 | 0.012 | 0.913 | 0.012 | 0.051 |

| GROUP * VISC | 0.007 | 2 | 0.003 | 29.356 | 0.000 | 58.712 | 1.000 |

| SIDE * VISC | 0.000 | 1 | 0.000 | 0.427 | 0.514 | 0.427 | 0.100 |

| SIDE * GROUP * VISC | 0.000 | 1 | 0.000 | 2.325 | 0.128 | 2.325 | 0.330 |

| Error | 0.033 | 290 | 0.000 | | | | |

| Total | 11,907.495 | 300 | | | | | |

| Corrected total | 0.457 | 299 | | | | | |

Test of between- Subjects Effects

a. Computed using alpha = 0.05

b. R Squared =.928 (Adjusted R Squared = .925)

Results of 3-factor ANOVA for buccolingual dimensions (BL).

| Source | Type III Sum of Squares | df | Mean Square | f | Sig. | Noncent.Parameter | Observed Power(a) |

|---|

| Corrected Model | 0.182 | 9 | 0.020 | 98.472 | 0.000 | 886.246 | 1.000 |

| Intercept | 11,279.424 | 1 | 11,279.424 | 55,042,595.388 | 0.000 | 55,042,595.388 | 1.000 |

| GROUP | 0.096 | 2 | 0.048 | 233.578 | 0.000 | 467.155 | 1.000 |

| SIDE | 0.000 | 1 | 0.000 | 0.264 | 0.608 | 0.264 | 0.081 |

| VISC | 0.025 | 1 | 0.025 | 123.184 | 0.000 | 123.184 | 1.000 |

| SIDE * GROUP | 0.000 | 1 | 0.000 | 0.089 | 0.766 | 0.089 | 0.060 |

| GROUP * VISC | 0.042 | 2 | 0.021 | 101.913 | 0.000 | 203.826 | 1.000 |

| SIDE * VISC | 0.000 | 1 | 0.000 | 0.165 | 0.685 | 0.165 | 0.069 |

| SIDE * GROUP * VISC | 0.000 | 1 | 0.000 | 0.897 | 0.344 | 0.897 | 0.157 |

| Error | 0.059 | 290 | 0.000 | | | | |

| Total | 11,934.965 | 300 | | | | | |

| Corrected total | 0.241 | 299 | | | | | |

Test of between- Subjects Effects

a. Computed using alpha = 0.05

b. R Squared =.753 (Adjusted R Squared = .746)

Comparison of Group A, B, and C in occlusogingival (OG), mesiodistal (MD), and buccolingual (BL) dimensions.

| Descriptives | A v/s B, A v/s C, B v/s C | Master Model |

|---|

| GROUP | N | Mean | Std.Deviation | Std.Error | Min | Max | Comparison | MeanDifference | t-value | p-value | MeanDifference | %Difference | t-value | p-value |

|---|

| OG | A | 120 | 6.883 | 0.005 | 0.000 | 6.874 | 6.892 | A v/s B | -0.003 | 5.097 | <0.0001 | -0.005 | -0.07 | 10.003 | <0.0001 |

| B | 120 | 6.887 | 0.005 | 0.000 | 6.878 | 6.898 | A v/s C | -0.004 | 1.851 | 0.066 | -0.001 | -0.02 | 2.294 | 0.024 |

| C | 60 | 6.887 | 0.022 | 0.003 | 6.860 | 6.940 | B v/s C | -0.001 | 0.246 | 0.806 | -0.001 | -0.01 | 0.209 | 0.835 |

| Total | 300 | 6.886 | 0.011 | 0.001 | 6.860 | 6.940 | | | | | -0.002 | -0.03 | 4.231 | 0.031 |

| MD | A | 120 | 6.314 | 0.006 | 0.001 | 6.302 | 6.332 | A v/s B | -0.008 | 8.365 | <0.0001 | -0.022 | -0.34 | 36.964 | <0.0001 |

| B | 120 | 6.323 | 0.008 | 0.001 | 6.307 | 6.335 | A v/s C | 0.088 | 39.606 | <0.0001 | -0.014 | -0.21 | 17.633 | <0.0001 |

| C | 60 | 6.226 | 0.023 | 0.003 | 6.175 | 6.304 | B v/s C | 0.096 | 42.218 | <0.0001 | -0.110 | -1.76 | 37.402 | <0.0001 |

| Total | 300 | 6.300 | 0.039 | 0.002 | 6.175 | 6.335 | | | | | -0.036 | -0.57 | 14.563 | <0.0001 |

| BL | A | 120 | 6.318 | 0.005 | 0.000 | 6.304 | 6.340 | A v/s B | 0.003 | 4.235 | <0.0001 | -0.018 | -0.28 | 36.568 | <0.0001 |

| B | 120 | 6.316 | 0.004 | 0.000 | 6.309 | 6.324 | A v/s C | 0.050 | 11.751 | <0.0001 | -0.020 | -0.32 | 60.261 | <0.0001 |

| C | 60 | 6.269 | 0.046 | 0.006 | 6.209 | 6.329 | B v/s C | 0.047 | 11.237 | <0.0001 | -0.067 | -1.07 | 11.404 | <0.0001 |

| Total | 300 | 6.307 | 0.028 | 0.002 | 6.209 | 6.340 | | | | | -0.029 | -0.45 | 7.238 | <0.0001 |

Comparison of rigid and monophase impression material in occlusogingival (OG), mesiodistal (MD), and buccolingual (BL) dimensions.

| Descriptives | Rigid v/s Monophase | Master Model |

|---|

| VISCOSITY | N | Mean | Std.Deviation | Std. Error | MeanDifference | t-value | p-value | MeanDifference | %difference | t-value | p-value |

|---|

| OG | RIGID | 150 | 6.887 | 0.010 | 0.001 | 0.003 | 2.665 | 0.008 | -0.001 | -0.01 | 0.821 | 0.413 |

| MONOPHASE | 150 | 6.884 | 0.011 | 0.001 | -0.004 | -0.06 | 4.369 | <0.0001 |

| TOTAL | 300 | 6.886 | 0.011 | 0.001 | -0.002 | -0.03 | 0.645 | 0.354 |

| MD | RIGID | 150 | 6.297 | 0.039 | 0.003 | -0.006 | 1.380 | 0.169 | -0.039 | -0.62 | 12.224 | <0.0001 |

| MONOPHASE | 150 | 6.303 | 0.039 | 0.003 | -0.033 | -0.52 | 10.358 | <0.0001 |

| TOTAL | 300 | 6.300 | 0.039 | 0.002 | -0.036 | -0.57 | 11.638 | <0.0001 |

| BL | RIGID | 150 | 6.300 | 0.035 | 0.003 | -0.015 | 4.825 | <0.0001 | -0.036 | -0.58 | 12.630 | <0.0001 |

| MONOPHASE | 150 | 6.315 | 0.016 | 0.001 | -0.021 | -0.33 | 15.938 | <0.0001 |

| TOTAL | 300 | 6.307 | 0.028 | 0.002 | -0.029 | -0.45 | 12.764 | <0.0001 |

Comparison of working and non-working side in Group A and B for occlusogingival (OG), mesiodistal (MD), and buccolingual (BL) dimensions.

| MM | GROUP | SIDE | Mean | N | Std. Deviation | MeanDifference | p value | Results |

|---|

| OG | 6.888 | A | Working | 6.886 | 120 | 0.003 | -0.002 | <0.001 | S |

| B |

| OG | 6.888 | A | Non-working | 6.884 | 120 | 0.003 | -0.004 | <0.001 | S |

| B |

| MD | 6.336 | A | Working | 6.320 | 120 | 0.005 | -0.016 | <0.001 | S |

| B |

| MD | 6.336 | A | Non-working | 6.317 | 120 | 0.003 | -0.019 | <0.001 | S |

| B |

| BL | 6.336 | A | Working | 6.317 | 120 | 0.004 | -0.019 | <0.001 | S |

| B |

| BL | 6.336 | A | Non-working | 6.317 | 120 | 0.003 | -0.019 | <0.001 | S |

| B |

Working side table for Group A, B, and C with mean values and standard deviations for rigid and monophase impression material.

| VISCOSITY | GROUP | N | Mean | Std. Deviation | Std. Error | 95% Confidence Interval for Mean | Minimum | Maximum |

|---|

| OG_RIGID | GROUP A | 30 | 6.88510 | 0.002510 | 0.000458 | 6.88416 | 6.88604 | 6.881 | 6.889 |

| GROUP B | 30 | 6.89350 | 0.002921 | 0.000533 | 6.89241 | 6.89459 | 6.889 | 6.898 |

| GROUP C | 30 | 6.88070 | 0.020944 | 0.003824 | 6.87288 | 6.88852 | 6.860 | 6.920 |

| Total | 90 | 6.88643 | 0.013277 | 0.001399 | 6.88365 | 6.88921 | 6.860 | 6.920 |

| MD_RIGID | GROUP A | 30 | 6.31830 | 0.002231 | 0.000407 | 6.31747 | 6.31913 | 6.315 | 6.322 |

| GROUP B | 30 | 6.31850 | 0.002921 | 0.000533 | 6.31741 | 6.31959 | 6.314 | 6.323 |

| GROUP C | 30 | 6.22040 | 0.016031 | 0.002927 | 6.21441 | 6.22639 | 6.175 | 6.230 |

| Total | 90 | 6.28573 | 0.047396 | 0.004996 | 6.27581 | 6.29566 | 6.175 | 6.323 |

| BL_RIGID | GROUP A | 30 | 6.31850 | 0.002374 | 0.000434 | 6.31761 | 6.31939 | 6.315 | 6.322 |

| GROUP B | 30 | 6.31350 | 0.002921 | 0.000533 | 6.31241 | 6.31459 | 6.309 | 6.318 |

| GROUP C | 30 | 6.23490 | 0.029870 | 0.005454 | 6.22375 | 6.24605 | 6.209 | 6.321 |

| Total | 90 | 6.28897 | 0.042161 | 0.004444 | 6.28014 | 6.29780 | 6.209 | 6.322 |

| OG_MONOPHASE | GROUP A | 30 | 6.88040 | 0.004903 | 0.000895 | 6.87857 | 6.88223 | 6.874 | 6.890 |

| GROUP B | 30 | 6.88450 | 0.002921 | 0.000533 | 6.88341 | 6.88559 | 6.880 | 6.889 |

| GROUP C | 30 | 6.89410 | 0.021721 | 0.003966 | 6.88599 | 6.90221 | 6.880 | 6.940 |

| Total | 90 | 6.88633 | 0.014060 | 0.001482 | 6.88339 | 6.88928 | 6.874 | 6.940 |

| MD_MONOPHASE | GROUP A | 30 | 6.31430 | 0.010161 | 0.001855 | 6.31051 | 6.31809 | 6.302 | 6.332 |

| GROUP B | 30 | 6.33050 | 0.002921 | 0.000533 | 6.32941 | 6.33159 | 6.326 | 6.335 |

| GROUP C | 30 | 6.23190 | 0.026973 | 0.004925 | 6.22183 | 6.24197 | 6.203 | 6.304 |

| Total | 90 | 6.29223 | 0.046457 | 0.004897 | 6.28250 | 6.30196 | 6.203 | 6.335 |

| BL_MONOPHASE | GROUP A | 30 | 6.31840 | 0.009726 | 0.001776 | 6.31477 | 6.32203 | 6.304 | 6.340 |

| GROUP B | 30 | 6.31950 | 0.002921 | 0.000533 | 6.31841 | 6.32059 | 6.315 | 6.324 |

| GROUP C | 30 | 6.30240 | 0.031763 | 0.005799 | 6.29054 | 6.31426 | 6.212 | 6.329 |

| Total | 90 | 6.31343 | 0.020593 | 0.002171 | 6.30912 | 6.31775 | 6.212 | 6.340 |

1. Occlusogingival Dimensions were Measured

Groups (Trays): Metal stock full-arch trays were more precise. Mean difference from metal-dual arch tray was 0.001 which was non-significant [Table/Fig-9].

Viscosities: Rigid impression material was more exact. Mean difference from monophase impression material 0.003 which was significant [Table/Fig-10].

Sides: Working side was more accurate than nonworking side of the impression on pouring and the mean difference with non-working side was 0.002 that was not statistically significant [Table/Fig-13].

Comparison of working and non-working side in group A, B, and C for occlusogingival (OG), mesiodistal (MD), and buccolingual dimensions (BL).

| Descriptives | Working v/s Non Working Side | Master Model |

|---|

| SIDE | N | Mean | Std.Deviation | Std. Error | Minimum | Maximum | MeanDifference | t-value | p-value | MeanDifference | %Difference | t-value | p-value |

|---|

| OG | Working Side | 180 | 6.886 | 0.014 | 0.001 | 6.860 | 6.940 | 0.002 | 1.471 | 0.142 | -0.002 | -0.02 | 1.591 | 0.113 |

| Non Working Side | 120 | 6.884 | 0.005 | 0.000 | 6.875 | 6.893 | -0.004 | -0.05 | 7.907 | <0.001 |

| Total | 300 | 6.886 | 0.011 | 0.001 | 6.860 | 6.940 | -0.002 | -0.03 | 1.635 | 0.146 |

| MD | Working Side | 180 | 6.289 | 0.047 | 0.003 | 6.175 | 6.335 | -0.028 | 6.368 | <0.001 | -0.047 | -0.75 | 13.447 | <0.001 |

| Non Working Side | 120 | 6.317 | 0.008 | 0.001 | 6.304 | 6.333 | -0.019 | -0.31 | 25.712 | <0.001 |

| Total | 300 | 6.300 | 0.039 | 0.002 | 6.175 | 6.335 | -0.036 | -0.57 | 12.985 | <0.001 |

| BL | Working Side | 180 | 6.301 | 0.035 | 0.003 | 6.209 | 6.340 | -0.015 | 4.742 | <0.001 | -0.035 | -0.55 | 13.231 | <0.001 |

| Non Working Side | 120 | 6.317 | 0.003 | 0.000 | 6.310 | 6.325 | -0.019 | -0.31 | 66.038 | <0.001 |

| Total | 300 | 6.307 | 0.028 | 0.002 | 6.209 | 6.340 | -0.029 | -0.45 | 10.756 | <0.001 |

2. Mesiodistal Dimensions were Measured

Groups (Trays): Metal dual-arch trays were more exact. Mean difference from plastic dual arch tray was 0.008 which was significant [Table/Fig-9].

Viscosities: Monophase impression material was more precise. Mean difference from rigid impression material was 0.006 which was non-significant [Table/Fig-10].

Sides: Non-working side was more accurate than working side of the impression on pouring and the mean difference with working side was 0.028 that was statistically significant [Table/Fig-13].

3. Buccolingual Dimensions were Measured

Groups (Trays): Plastic dual-arch trays were more exact. Mean difference from metal dual arch tray was 0.003 which was significant [Table/Fig-9].

Viscosities: Monophase impression material was more precise. Mean difference from rigid impression material was 0.015 which was significant [Table/Fig-10].

Sides: Non-working side was more accurate than working side of the impression on pouring and the mean difference with working side was 0.015 that was statistically significant [Table/Fig-13].

Discussion

Making a perfect impression in fixed prosthodontics is an exigent task. It depends upon the type of impression material, the impression tray, the technique of impression and methods of sequence of pour [2]. Distortion is a 3-dimensional setback that is inherent in all of the steps involved in fabricating an indirect dental restoration [15]. There are several impression techniques to improve the accuracy of impressions used in fabrication of crowns and fixed partial dentures. Dual-arch impression technique has significant advantages over conventional impression techniques in the fabrication of fixed prosthesis [16]. Factors those causing the occlusal error are, flexure of the mandible that occurs after 28% of maximum opening in conventional impression procedure, and discrepancy in opposing casts and their articulation can be eliminated by dual arch impression technique. So, need for occlusal adjustment can be reduced [6].

As per Wilson and Werrin [5] dual arch impression technique, maxillary arch, mandibular arch, and inter-occlusal record can be recorded in one step [7,17]. There are many techniques for making an impression with dual-arch trays, acrylic custom trays, and stock metal trays. Most popular are the one step and two- step techniques [10,18-21].

In the past lots of studies had been conducted by number of authors to evaluate the accuracy of dies obtained by using the different types of trays with different viscosities of impression materials and by changing the sequence of pour of the impressions.

Reddy JM et al., concluded that metal dual arch trays were more accurate than plastic dual arch trays followed by stock metal trays while measuring the inter-abutment distance and on pouring nonworking side was more accurate than working side [22]. Drawback of their study was that they had investigated only single aspect linear relationship in same side of the arch.

George S et al., conducted a study in which they had used metal and plastic dual arch trays and customized acrylic trays to evaluate the accuracy of the dies obtained from impressions. Results of their study indicated that dies obtained from all impression combinations were of increased dimensions than the control group [23]. Among all the trays studied full arch acrylic resin trays were more accurate. Drawbacks of their study were that only buccolingual dimensions were measured and only working side was poured.

Reddy N R et al., concluded in their study that metal dual arch trays are more accurate than plastic dual arch trays, and on pouring working side first resulted in more accurate dimensions [24]. In this study only buccolingual parameter was considered similar to the study conducted by George S et al., [23].

Considering the limitations of the previous studies in the present study all the three dimensions of the dies have been evaluated. Till now, no scientific data has been published regarding the comparison of accuracy of metal and plastic quadrant dual-arch trays, and full- arch stock metal rim lock trays along with the use of different viscosities of impression materials in all three dimensions, while keeping in mind the sequence of pour of the impressions.

From the previous studies although it has been cleared that metal dual arch trays are more accurate than plastic dual arch trays, but to minimize distortion in working dies there is a lack of harmony among the authors of different articles about which side of the dual-arch impression should be poured first. Investigation of these parameters would also help in planning an anticipated clinical trial.

In the present study to evaluate the variation of the die in a mesiodistal, buccolingual, and occlusogingival direction machined circular stainless steel standard die was used. In machined stainless steel standard die for reducing measurement error well-defined, clearly observable, and reproducible reference grooves and points were incorporated for measuring occluso-gingival, mesio-distal and bucco-lingual distance under the microscope.

Dies obtained in this study were smaller in size than the standard die. The probable reason of attaining smaller gypsum dies in all three dimensions was not having used tray adhesive because all three tray types had mechanically retentive features. As the impression material shrink toward the centre of mass during the polymerization reaction, use of tray adhesive would redirect this shrinkage toward the impression tray walls and resulting in a die larger in diameter and smaller in height [25].

The relationship between the change in buccolingual and mesiodistal dimensions of the gypsum dies were allowed to be observed by the circular nature of the standard. In this study when buccolingual and mesiodistal dimensions were measured, dies obtained from plastic trays using rigid and regular body impression material showed large variation (smaller dies). Seating of the tray with impression material on the prepared tooth may cause tray being flexed outward and then any spring back on removal of the impression may result in a reduced buccolingual and mesiodistal dimensions [9,26]. Gypsum dies were narrower mesiodistally than buccolingually because the plastic trays have the tendency to change the size of gypsum dies from a circular shape into an ovoid shape [7]. Within this study plastic dual arch trays were more precise in buccolingual dimensions than mesiodistal dimensions. Thus, the findings of the present study were in agreement with the study conducted by Ceyhan JA et al., [7].

Stone dies were supposed to be more accurate and resulted in precise casting with the poly vinyl siloxane putty/wash 2-step impression technique [27].

For the fabrication of stone dies metal stock trays have been proved to be more accurate whilst using a putty wash impression technique [28], but in Reddy JM et al., study metal dual arch trays were more accurate during measurement of the inter-abutment distance [22] and in George S et al., [23] study full arch acrylic resin trays were more accurate during measurement of buccolingual dimension. While in the present study, full arch stock metal trays were more accurate in occlusogingival dimension than the metal and plastic quadrant dual arch trays. The possible explanation for the critical factor that influences the accuracy may be that in full arch stock metal trays two stage putty wash technique was employed with controlled wash bulk while in metal and plastic quadrant dual arch trays one stage putty wash technique without controlled wash bulk was employed.

Results of the present study were based on the observation of Chugh A et al., study, in that two-step putty-wash technique was more accurate with 1 and 2 mm spacer thickness than one step technique [29].

But, why full arch stock metal trays were not accurate in mesiodistal and buccolingual dimensions with the two stage putty wash technique, this could not be explained in this study. Possible explanation might be that, full arch stock metal trays were not accurately fit on stainless steel standard in typhodont in mesiodistal and buccolingual dimensions owing to interference of buccal and lingual flanges of the tray, and the other reason could be the polymerization shrinkage of the poly vinyl siloxane impression material, as the material shrinks towards the center of the mass during polymerization reaction [12,14,30-32].

Researcher of this study noted that when rigid impression material was used with metal quadrant dual arch trays and full arch stock metal trays, dies were more accurate in occlusogingival dimensions when working sides were poured first, but the difference with the nonworking side was no significant. Same way when monophase impression material was used with metal quadrant dual arch trays, dies were more accurate in mesiodistal dimensions when non working sides were poured first, and when monophase impression material was used with plastic quadrant dual arch trays, dies were more accurate in buccolingual dimensions when non working sides were poured first. This may be explained by the protocol of Wilson and Werrin [11] of “always pouring the counter-impression before pouring the working side impression.”

It was noted in Ceyhan JA and Johnson GH study, that by using the monophase tray material with the plastic dual arch trays, larger standard deviation for all three dimensions were observed when the working side of the impression was poured first. Results of the present study were also in agreement with the study conducted by Ceyhan JA and Johnson GH [3,7].

Reddy NR et al., concluded in their study that by pouring working side first resulted in more accurate dimensions [24]. While in present study, in Group A and B it was observed that by pouring the nonworking side first resulted in more accurate dies than pouring the working side first. This could be due to the compensation of polymerization shrinkage by the die stone expansion. Sequence of the pouring in the Group A, and B author concluded that for all three dimensions in Group A there was no difference in the sequence of the pouring, but in the Group B working side was more accurate than nonworking side.

The variation in results between plastic and metal dual-arch groups could be due to the flexibility of the plastic dual arch trays in association to the metal dual arch trays and viscosity of the impression material used. In present study author also compared the viscosity of the impression material in the Group A, B, and C and concluded that in Group A rigid was more accurate than monophase and in Group B, and C monophase was more accurate than rigid impression material. In Reddy NR et al., study heavy body and light body combination is more accurate than monophase impression material in buccolingual dimension [24]. As the measurements of stone dies are also affected by the setting expansion of the dental stone used. While pouring opposite side first dies were more accurate in occlusogingival dimension obtained from the rigid impression material in metal trays because of the setting expansion of the stone in occlusogingival direction [33]. In a study by Campbell SD the thickness of one coat of die spacer can vary from 8 to 40 μm [34]. In order to compensate for the narrower dimension mesiodistally, it may be advisable to include an extra coat of die spacer on the interproximal surfaces [7]. To end with, this investigation capitulated to some statistically significant differences between tray type and impression material viscosity, though, the differences were of a magnitude that would most likely have little clinical significance. “Last but foremost” apart of clinician’s skill, tray type, material viscosity, and pouring sequence of the dual and single arch impressions are the factors which can affect the accuracy of fixed prosthesis in prosthodontics. All the same, further clinical trials are suggested to validate the results of this study.

Limitation

In the present study, distortion had been observed for only single crown preparation in occlusogingival, mesiodistal, and buccolingual dimensions, but pertaining to multiple crown preparations distortion in alignment of adjacent abutments and inter-abutment distance might be present that had not been evaluated in this study.

Authors of this study suggests that in vivo study should be done for evaluating the effects of the occlusal forces more than 1.5 kg and effects of saliva and other soft tissues on the impression material.

Clinical Implication of The Study

As an accurate impression is necessary for the fabrication of any fixed partial denture prosthesis, results of the present study can help dentists in selecting the tray type and material viscosity for obtaining an accurate impression to ensure success of the treatment. Author recommends that a clinically acceptable impression can be obtained with the use of rigid or monophase impression materials either in plastic trays or in metal dual arch trays.

Conclusion

According to the results of this study the following conclusions were made. The gypsum dies produced from the dual arch impressions were generally smaller in all three dimensions than the stainless steel standard die. Plastic dual-arch trays were more accurate with rigid impression material and there was no statistically significant difference for sequence of pouring (Subgroup A1, A2). Metal dual-arch trays were more accurate with monophase impression material and working side was more accurate (Subgroup B3). Stock metal full arch trays were more accurate for monophase impression material (Subgroup C2). For occlusogingival dimension among all three variables metal stock full-arch trays, rigid impression material, and working side were more accurate, for mesiodistal dimension metal dual-arch tray, monophase impression material, and non-working side were more accurate, and for buccolingual dimension plastic dual-arch tray, monophase impression material, and non-working side were more accurate.

Test of between- Subjects Effects: a. Computed using alpha = 0.05 b. R Squared =.215 (Adjusted R Squared = 0.191)

Test of between- Subjects Effects

a. Computed using alpha = 0.05

b. R Squared =.928 (Adjusted R Squared = .925)

Test of between- Subjects Effects

a. Computed using alpha = 0.05

b. R Squared =.753 (Adjusted R Squared = .746)