Light cured composite resins are one of the direct aesthetic restorative materials used in restorative dentistry to restore form and function of anterior and posterior teeth [1]. The development of composite resins dates back to 1960 when the introduction of BIS-GMA system by Dr. R Bowen (1962) and acid etching technique by Dr. Michael G Buonocore (1955) brought about a transformation in restorative dentistry [2].

With the advent of new technology in material sciences in recent years, the quality of composite resin restorations have been improved. However, discolouration and wear of composite resin materials remains to be a major problem in long-term clinical studies [3]. Filler particle-related features such as the concentration, size of the filler reinforcement and resin formulation is a known factor to affect the wear and discolouration of composites [4].

Depth-sensing indentation technique, which involves the continuous tracking of load and corresponding penetration depth, has been commonly used to determine the plastic (hardness) and elastic (modulus) properties of materials especially in thin films and micro-electronics industries [5,6]. In dentistry, the depth-sensing indentation test has been employed recently to determine the mechanical properties of dental hard tissues and composite resins.

Newer composites like G aenial Universal Flo are flowable, light cured, radiopaque restorative material. As per the manufacturer’s data, G aenial Universal Flo has higher strength, higher wear resistance and higher gloss retention when compared to currently available leading flowable and conventional composites. [7]. The aim of this study was to comparatively evaluate the CS and surface hardness of G aenial Universal Flo with other methacrylate based nano packable composite (Filtek Z350XT and Tetric N Ceram). Null Hypothesis: The CS and surface hardness of methacrylate based nano flowable composite (G aenial Universal Flo) is not better than that of methacrylate based nano packable composite (Filtek Z350XT and Tetric N Ceram).

Materials and Methods

This in vitro study was conducted in the Department of Conservative Dentistry and Endodontics, Bapuji Dental College and Hospital, Davangere, Karnataka, India. Ethical clearance was obtained from the Institutional Review Board.

The composition and the manufacturer information of the resin composite materials used in this study are listed in the [Table/Fig-1].

Composition of the materials used in the study.

| S. No | Material | Composition | Manufacture |

|---|

| Matrix | Filler | Initiator |

|---|

| 1. | Filtek Z350XT | UDMA, Bis-GMA, PEGDMA, Bis-EMA, TEGDMA | Silica, Zirconia | Additives, Stabilizers, Catalysts | 3M ESPE |

| 2. | Tetric N Ceram | UDMA, Bis-GMA, Ethoxylated Bis-EMA, TEGDMA | Barium Glass, Yitterbium Triflouride, Silicon dioxide | Additives, Stabilizers, Catalysts | Ivoclar Vivadent |

| 3. | G aenial Universal Flo | UDMA, Bis-MEPP, TEGDMA | Silicon dioxide, Strontium Glass, Pigment | Photoinitiator | GC India |

Forty eight disc shaped specimens were prepared from three different resin composite materials (G aenial Universal Flo, Filtek Z350XT and Tetric N Ceram) with the dimensions of 10 mm diameter and 2 mm thickness according to manufacturer instructions using teflon mould [8,9], as shown in [Table/Fig-2]. Following polymerization, the specimens were removed from the mould and were polished with Sof-Lex polishing kit (3M ESPE). Digital calliper was used to check the specimen dimensions. The specimens with voids, defects or incorrect dimensions were discarded. Specimens were then stored for 24 hours in distilled water in a dark container, at room temperature for complete polymerization.

Specimens were divided into two groups of CS and VH and then subdivided into three sub groups (eight specimens in each sub group) of Filtek Z350XT, Tetric N Ceram and G aenial Universal Flo. Specimens were divided as follows [Table/Fig-3].

| Groups | Colour Stability (CS) | Vickers Hardness (VH) |

|---|

| Subgroup 1 | Filtek Z350XT (CS 1) | Filtek Z350XT (VH 1) |

| Subgroup 2 | Tetric N Ceram (CS 2) | Tetric N Ceram (VH 2) |

| Subgroup 3 | Gaenial Universal Flo (CS 3) | Gaenial Universal Flo (VH 3) |

Evaluation of Colour Stability

Before colour testing, the spectrophotometer (Perkin Elmer Lambda 750 UV visible spectrophotometer) was calibrated with a specified calibration plate. The CIE-L*a*b* colour system, which is defined as a 3-dimensional (3D) measurement system, was applied. ‘L’ indicates the brightness, ‘a’ red-green, and ‘b’ the yellow-blue proportion of the colour. The specimens were immersed in a staining solution. The staining solution was prepared by adding five ounces (approximately 142 g) of instant coffee to 750 ml of boiling water. After 72 hours, specimens were thoroughly washed under tap water and were subjected to 10 strokes of brushing using soft-grade toothbrush. The specimens were then dried gently with delicate paper napkins. Colour measurements were obtained again using the spectrophotometer, as described above. The above described colour measuring process was repeated using freshly prepared staining solution every 72 hours for three weeks. All measurements were taken three times and their means were taken as final values.

Specific colour coordinate differences (ΔL, Δa, Δb) were calculated between baseline, day 3, day 6, day 9, day 12, day 15, day 18 and day 21.

Total colour differences (ΔE) were calculated by following formula [10]:

ΔE= ((ΔL)2+(Δa)2+ (Δb)2)1/2

These values were automatically stored digitally by a computer connected to the spectrophotometer.

Repeated measures ANOVA was used to assess and compare the difference in the colour stability of three different composites at baseline, day 3, day 6, day 9, day 12, day 15, day 18 and day 21.

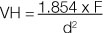

Evaluation of Vicker’s Hardness

The VH evaluation was done using microhardness tester (Zwick/Roell Vicker’s Microhardness Tester, UK). VH numbers were determined from indentation made under 10 N load for 15 seconds by the arithmetic mean of three indentation values randomly performed for each specimen and testing condition.

The formula for calculating VHN is the applied load (kgf) divided by the surface area of the indentation (mm2) [11].

Where F = load in kgf

d = arithmetic mean of two diagonals d1 and d2 in mm

VH = Vickers hardness

Statistical Analysis

One-way ANOVA was employed to determine the difference in hardness of the three different composites between three groups under consideration. Tukey’s post-hoc analysis was employed if any significant difference was observed between the groups under consideration.

Results

Comparison of colour stability among the three study groups at each time interval is presented in [Table/Fig-4]. Statistically significant difference was found in comparison of colour stability at different time interval in each study Groups (p<0.001). Group CS 1 showed least discolouration followed by group CS 2 and highest colour change in Group CS 3 after immersion for 21 days.

Comparison of colour stability among the three study groups at each time interval.

| Group | Mean | Std. Deviation | N | F(df1, df2) | p-value |

|---|

| CS 1 (Filtek Z350XT) | Baseline | 0 | 0 | 8 | 5684.01(2.23, 15.64) | <0.001* |

| Day3 | 5.41 | 0.095 | 8 |

| Day6 | 5.77 | 0.167 | 8 |

| Day9 | 6.37 | 0.210 | 8 |

| Day12 | 7.10 | 0.225 | 8 |

| Day15 | 7.59 | 0.168 | 8 |

| Day18 | 8.20 | 0.171 | 8 |

| Day21 | 8.63 | 0.226 | 8 |

| CS 2 (Tetric N Ceram) | Baseline | 0 | 0 | 8 | 4142.69(2.03, 14.24) | <0.001* |

| Day3 | 4.97 | 0.271 | 8 |

| Day6 | 5.50 | 0.231 | 8 |

| Day9 | 6.16 | 0.224 | 8 |

| Day12 | 6.93 | 0.261 | 8 |

| Day15 | 7.60 | 0.170 | 8 |

| Day18 | 8.22 | 0.102 | 8 |

| Day21 | 8.80 | 0.138 | 8 |

| CS 3(G aenial Universal Flo) | Baseline | 0 | 0 | 8 | 8194.26(2.32, 16.26) | <0.001* |

| Day3 | 4.83 | 0.152 | 8 |

| Day6 | 5.25 | 0.095 | 8 |

| Day9 | 5.85 | 0.176 | 8 |

| Day12 | 6.47 | 0.174 | 8 |

| Day15 | 7.27 | 0.127 | 8 |

| Day18 | 7.86 | 0.201 | 8 |

| Day21 | 8.45 | 0.165 | 8 |

* significant

When comparing the three groups, the greatest colour stability was seen with Filtek Z350XT, followed by Tetric N Ceram and lastly G aenial Universal Flo.

Comparison of microhardness among the three study groups is presented in [Table/Fig-5]. Mean microhardness value of Group VH 1 is found to be significantly different from Group VH 2 (p<0.001*) and Group VH 3 (p<0.001*). No significant difference was found between the microhardness mean value in Group VH 2 and Group VH 3 (p=0.15). Group VH 1 yielded the highest microhardness mean of VHN 101.62, while Group VH 3 presented the lowest microhardness mean of VHN 56.75.

Comparison of microhardness among the three study groups.

| Groups | N | Mean | Std. Deviation | ANOVA |

|---|

| F(df1,df2) | p-value |

|---|

| Filtek Z350XT | 8 | 101.62 | 4.94 | 90.52(2,21) | <0.001* |

| Tetric N Ceram | 8 | 63.74 | 10.90 |

| G aenial universal flo | 8 | 56.75 | 3.35 |

*p<0.001 statistically significant

When comparing the three groups, the greatest VH was seen with Filtek Z350XT (VH 1), followed by Tetric N Ceram (VH 2) and lastly G aenial Universal Flo (VH 3).

Pairwise comparison of microhardness and CS among the three study groups is presented in [Table/Fig-6]. Mean microhardness value of Filtek Z350 XT is found to be significantly different from Tetric N Ceram (p<0.001) and G aenial universal Flo (p<0.001).

Pairwise comparison of microhardness and color stability among the three study groups.

| MICROHARDNESS |

|---|

| (I) Group | (J) Group | Mean Difference(I-J) | Std.Error | p-value | 95% Confidence Interval |

|---|

| Lower Bound | Upper Bound |

|---|

| Filtek Z350 XT | Tetric N Ceram | 37.87 | 3.58 | <0.001* | 28.83 | 46.92 |

| G aenial universal Flo | 44.87 | 3.58 | <0.001* | 35.83 | 53.92 |

| Tetric N Ceram | G aenial universal Flo | 6.99 | 3.58 | 0.15(NS) | -2.04 | -28.83 |

| Color Stability (at Day 21) |

| Filtek Z350 XT | Tetric N Ceram | -0.17 | 0.09 | 0.168 | -0.39 | 0.05 |

| G aenial universal Flo | 0.18 | 0.09 | 0.135 | -0.04 | 0.40 |

| Tetric N Ceram | G aenial universal Flo | 0.35 | 0.09 | 0.002 | 0.12 | 0.57 |

Tukey Post Hoc Test, *p<0.05 statistically significant, p<0.001 significant, p>0.05 not significant CNS

Discussion

Colour stability is an important in vitro analysis to evaluate the performance of an aesthetic material in clinical situations. Discolouration of dental materials may be caused by intrinsic and extrinsic factors. The intrinsic factors include insufficient polymerization or immersion in water for long periods, polymer quality, filler type, and amount and photo initiator system. Extrinsic factors include staining by adsorption and absorption of colourants [12].

To assess the surface hardness, in vitro studies have been conducted using the Vicker’s and Knoop hardness tests. VH test is also referred as microhardness test and is based on optical measurement system. This test is mostly used for small parts and thin sections. In Vicker’s scale, pyramid shaped square base diamond is used for testing. The microhardness test procedure, ASTM E-384, identifies a range of light loads using a diamond indenter to make an indentation which is measured and converted to a hardness value. It is very useful for testing on a wide type of materials as long as test samples are carefully prepared. The filler particle-related features, like the concentration and size of the filler reinforcement and resin formulation determines the surface hardness of the composite [5,13].

Flowable composites have been introduced in the market with high expectations to overcome the limitations of packable composites like adaptation of the material. These flowable composites have low filler loading and high monomer content, which permit these materials to flow, but often at the expense of inferior physical properties [14].

Available data about the material properties of the new universal flowable resin composite (G aenial Universal Flo) is scarce. Hence, this study was initiated with an aim to compare and evaluate the colour stability and microhardness of G aenial Universal Flo with non flowable composites, Filtek Z350XT and Tetric N Ceram. For the present study the resin composite materials used were G aenial Universal Flo, Filtek Z350XT and Tetric N Ceram. These are methacrylate based nano hybrid composites. Nano hybrid composite have been the focus of much recent research. These nano hybrid composites are potential alternative to conventional composites because of their advantage of better strength, gloss and lower shrinkage. All the materials selected for the study were of shade A2 as it is the most commonly used shade [13–17].

The specimens prepared were made in accordance to previous studies where the dimensions used were (10±0.1mm in diameter and 2±0.1 mm in thickness) for colour stability and microhardness evaluation [8,15,18].

The light curing was performed using Bluedent, for 20 seconds with the intensity of 1200 mW/cm2. Aging of light curing bulb reduces the intensity of the curing unit. To monitor and maintain the optimal intensity of the bulb, radiometer is used [2]. In the present study, radiometer was not used which may have influenced the results as there might be variation in the polymerization among different specimens.

For the evaluation of CS, spectrophotometer (Perkin Elmer LAMBDA) was used. The spectrophotometer is usually used in the UV and visible regions of the spectrum and uses Commision Internationale de l’Eclairage (CIA) L*a*b* colour system. The system is a recommended method for dental purposes and characterizes a colour based on the human perception [8,9].

The least colour difference was observed in Filtek Z350XT when compared to Tetric N Ceram and G aenial Universal Flo. CS is related to the structure of the resin matrix, characteristics of the filler particles and the interaction between the two. The filler particles in Filtek Z350XT are zirconia and silica which when coupled, improves the filler attachment to the matrix, thereby, improving its physical properties. The fillers in Tetric N Ceram and G aenial Universal Flo are barium and strontium respectively, they have inferior physical properties like hardness, solubility, and these are difficult to attach to the resin matrix, when compared with zirconia. This would explain why the Tetric N Ceram and G aenial Universal Flo have got lower colour stability [2,19].

Also, as Filtek Z350XT has better filler loading (78.5 %vol), it achieves superior finish after polishing and better wear resistance when compared with Tetric N Ceram (63% vol) and G aenial Universal Flo (50% vol) [17,20,21].

The result of this study for CS testing is comparably similar with previous studies where authors have reported less surface roughness and colour change for Filtek Z350XT when compared to Tetric N Ceram [22].

The VH for the materials tested in the study is as follows: FiltekZ350XT-101.62 VHN, Tetric N Ceram-63.74 VHN and G aenial Universal Flo-56.75 VHN. The results can be attributed to the filler particle size. The higher microhardness value of Filtek Z350XT in the present study might be attributed to the presence of nanofillers and nanoclusters which could affect the light reflection and hence the degree of conversion. The zirconia and silica fillers in the Filtek Z350XT have greater hardness and less solubility when compared with fillers in Tetric N Ceram (barium) and G aenial Universal Flow (strontium) [21,23]. Strontium and barium fillers do not attach to the matrix readily in comparison to Filtek Z350XT where matrix filler complex are better adapted [2,21].

The other factor that affects microhardness could be the presence of different filler particle size. This can affect degree of composite polymerization as the light beam is scattered and reflected within the composite material, leading to lower microhardness values. Larger filler size variation in G aenial Universal Flo (16-200nm) and Tetric N Ceram (40-160nm) might explain lesser microhardness value when compared to Filtek Z350XT (4-20nm) [21]. The results are in accordance with previous studies where authors have reported increased microhardness in composite with uniform distribution of filler content when compared to composite in which mixture of irregular and rounded filler particles was incorporated [24,25].

In the present study, samples were not subjected to thermocycling to avoid complexity in the study. The influence of thermocycling may affect the results of the study. The staining technique used in this study was concentrated solution of coffee which may over estimate the results.

To summarize, according to the results obtained, null hypothesis is accepted as there is significant difference between the colour stability and microhardness of Filtek Z350XT (3MESPE, India) G aenial Universal Flo (GC India) and Tetric N Ceram (Ivoclar Vivadent).

Conclusion

The greater CS and VH was seen with Filtek Z350XT, followed by Tetric N Ceram and lastly G aenial Universal Flo. Within the limitations of this study, it can be concluded that the properties of G aenial Universal Flo are inferior to the existing conventional packable composites.

* significant

*p<0.001 statistically significant

Tukey Post Hoc Test, *p<0.05 statistically significant, p<0.001 significant, p>0.05 not significant CNS