In the era of evidence based medicine, it is not surprising that, a significantly large amount of clinical decision making is based on investigatory findings. Of all the diagnostic modalities used, biochemistry investigations form a major portion and account for significant percentage of healthcare expenses. There are many factors which finally decide the cost of an investigation, like operational profit, value of the investigation, complexity of the investigation, instrument and reagent costs etc. A competent management of the laboratory is essential for optimizing the cost of testing [1]. Printing of reports is invariably viewed as an additional cost in most laboratories. In corporate sector, where the quality of reports serves as a brand ambassador, glossy and patient appealing printouts are issued to the patients as the costs involved in printing such attractive reports is factored into the patient’s final bill. However, in the government sector and in small private laboratories, printing such results is perceived as a waste of expenditure. The debate of printing attractive reports and costs cutting becomes a critical issue. When a laboratory compromises on the quality of the printout (sometime issuing handwritten reports), it leaves the patients with a feeling that reports are not as hi-tech as the corporate sector and hence, sub-standard. This significantly affects the psychology of the clientele. The option of sending reports as emails/pdf files or making them available online (by ensuring login privacy) is in vogue, but has restricted utility especially while dealing with clientèle of lower socio-economic strata who are the most common group of patients visiting government sector hospitals. Hence, it becomes the duty of the doctors to guide the system into most cost effective algorithm wherein cost cutting is ensured without depreciation in clientele satisfaction. Although material managers will continue to perform their traditional functions of cutting costs, it will become necessary for clinicians to guide them in selecting clinically relevant, cost-effective technologies through the technology assessment process [2]. While it is possible to get an estimate of the theoretical output possible from a inkjet cartridge or laser printer toner from the manufacturer’s web-site, the information on the volume of data printed in these pages is missing and hence, the information is often misleading. Budgeting on the basis of the information provided by the manufacture’s may be misleading.

We undertook this study to critically evaluate the various printings options available to a biochemistry laboratory for printing out the reports and provide firm data to organizations for making informed decision on choosing the best option available to them to print reports.

Materials and Methods

This prospective study was done in the biochemistry section of a tertiary care hospital over a period of two months where on an average more than 200 reports were generated per day. All the reports of a given day were printed on a single printing platform to calculate printing cost. The study was done over a period of 2 months. The department has a Laboratory Information System (LIS) in place and the data from the biochemistry analysers were available centrally on a computer. This data was then used to print out the patient reports. We tested four printing devices, namely the Laser Printer (HP p1007 laser printer), an Inkjet printer (HP Ink advantage 2010 K010 printer), a dotmatrix printer (Epson LX 100+) and a Thermal Printer (Star TSP 800 II).

Printing using the Laser Printer (LP)

Initially all the reports were printed on the laser printer. Before the start of the study, the laser printer was loaded with a fresh printer cartridge. Reports were printed in economy mode till they became faint. When the reports became faint, the printing mode was changed to normal printing mode. This was continued till the quality of print was not acceptable. Then the toner was refilled and reused. The total number of satisfactory reports printed from one toner with one refill was evaluated for working out the economics of printing.

Printing using the Inkjet Printer (IP)

After obtaining statistics from the laser printer, the similar task was done with the inkjet printer. All the reports were printed on a fresh black inkjet cartridge, and when the report quality became unacceptably faint, the cartridge was re-inked. The total number of reports that were printed out from one new cartridge with one re-inking was used to workout the economics of printing.

Printing using Dotmatrix Printer (DMP)

A brand new printer ribbon cartridge was put on the DMP. Using visual basic codes, the output of the LIS was sent to the DMP for DOS printing. DOS printing is a technique where the data from the computer is sent to the printer in text form [3]. The number of reports printed from one ribbon was calculated. Later a new ribbon was replaced in the cartridge and once again reports were printed. The total number of reports printed using two ribbons was used to calculate the economics of printing reports using the DMP.

Printing using Thermal Printer (TP)

As the thermal printer did not require any additional consumables apart from the printer roll, 10 thermal printer rolls were used to calculate the amount of reports that could be printed on them. This was then used to calculate the cost of printing of one single report using thermal printer.

The parameters evaluated for computing the economics of printing included the cost of printing each report, the cost of stationary involved and the time taken for printing the report. Also, 20 doctors and 100 clientèle were shown 10 reports printed in each format and were asked to evaluate the visual quality of the report in a score of 1 to 5. The modal core was taken as a consensus figure for the overall grading.

Results

Cost of printing reports

A single LP cartridge 88A was purchased for Rs 2640 and the cost of refilling it once was Rs 375. A total of 4200 reports (2900 reports in economy mode and 1300 in normal mode thereafter) could be printed from a new cartridge. After refilling it, there was a significant decrease in the number of satisfactory reports as only 1100 satisfactory reports could be printed from a re-toned cartridge. Effectively 5300 reports could be printed with an investment of Rs 3015 (cartridge + re-filling charges), making the cost per report to be Rs 0.57. Information on the internet on the output of HP 88A cartridge suggested that, 1500 papers could be printed from one cartridge [4] making an approximate print capability of 3000 reports.

A single inkjet cartridge (with one refill) could print 1002 satisfactory reports (736 reports on a fresh cartridge and 266 reports after being refilled). The cost of one black cartridge was Rs 375 and that for reinking was Rs 100. Based on the above data, the cost of printing one report was estimated to be Rs 0.470 per report. Information from the manufacturers of HP 704 inkjet cartridge suggested that, a total of 500 [5] sheets could be printed from a single cartridge, making a theoretical possibility of 1000 reports per cartridge.

The cost of a new DMP cartridge was Rs 200. A single ribbon could print 820 satisfactory reports. The cost of a new ribbon was Rs 50. After changing the ribbon, we were able to print 835 satisfactory reports on the new ribbon. There was no effect of the cartridge case and it could be reused many times (unlike the toner/inkjet cartridge), and hence, we did not factor the cost of the case while calculating the economics of printing one single report from the DMP. The final cost for printing one report on the DMP was estimated to be Rs 0.06. TP did not require any ink/cartridge for printing. Hence, there was no cost involved in printing a report in Thermal Printer.

Cost of Stationary involved

The LP and IP used A4 size papers. The print output was standardised to printing two reports per A4 size paper. The cost of 500 sheets of A4 paper was Rs 180, making the cost of stationary for printing one report to be Rs 0.18.

Two kinds of stationary were used for the DMP. The first was an 80 column single ply continuous feed computer stationary. The cost of 1000 sheets of such paper was Rs 300. In a single sheet two reports could be printed making the cost of stationary for one report to be Rs 0.15. In the second method, a printer roll 210 mm x 45 mts was used to print the report. A single roll costs Rs 17. In a single roll, nearly 120 reports could be printed. Hence, the cost per report using the paper roll was calculated to be Rs 0.14. A single roll of thermal paper could print 80 reports. The cost of one thermal paper roll was Rs 75. Hence, the cost of stationary for one report using thermal paper was Rs 0.93. The net cost involved in printing a single report by the four printing modalities is shown in [Table/Fig-1].

Net cost involved for printing reports by the four printing modalities.

| Printer | Cost of printer | Cost of printing one report | Cost of printing 36500 reports (@ 100 reports per day for one year) | Cost of printing 73000 reports (@ 200 reports per day for one year) |

|---|

| Print | Stationary | Total |

|---|

| Laser Printer | 6500 | 0.57 | 0.18 | 0.75 | 27375 | 54750 |

| Inkjet printer | 3750 | 0.47 | 0.18 | 0.65 | 23725 | 47450 |

| Dot Matrix printer with Single ply paper | 7400 | 0.06 | 0.15 | 0.21 | 7665 | 15330 |

| Dot Matrix printer with paper roll | 7400 | 0.06 | 0.14 | 0.20 | 7300 | 14600 |

| Thermal Printer | 7500 | 0 | 0.93 | 0.93 | 33945 | 67890 |

Time taken for printing out a report

We calculated the time taken to print out a report from all the modalities. Laser printer and inkjet printers are known to have a delayed startup time while printing the first report, after which its speed increases. So, we tested the time taken to print one report and the time taken to print a batch of 30 reports. [Table/Fig-2] shows the information on the time taken to print out a single report and a batch of 30 reports.

Time taken to print out reports using the four printers.

| Printer | Time taken to print (in sec) |

|---|

| Single report | 30 reports |

|---|

| Laser | 12 | 162 |

| Inkjet | 20 | 193 |

| Dot matrix | 7 | 210 |

| Thermal | 2 | 60 |

Quality of printout

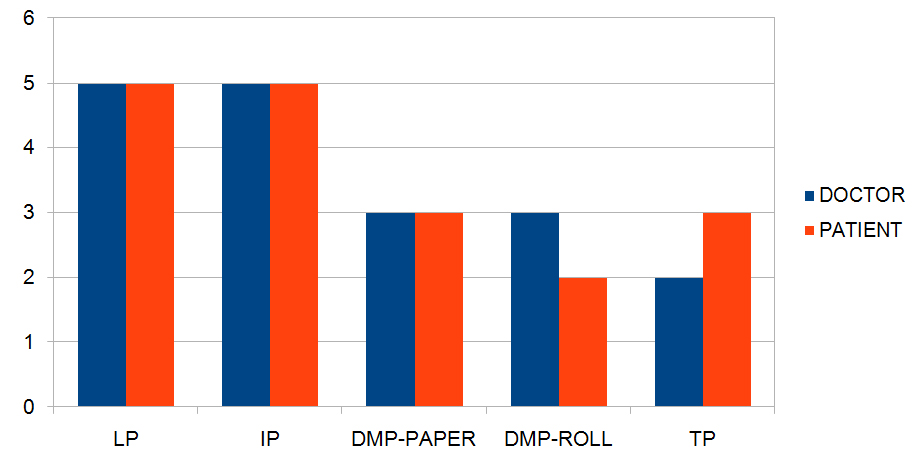

Ten reports from the LP, IP, DMP (computer stationary and printer roll) and TP were given to 20 doctors and asked to score the quality of report on a scale of 1 to 5. Similarly 100 patients were asked to score the reports on the similar format. The modal score was assigned to the overall quality of the report. [Table/Fig-3] shows the scores obtained by all the modalities of printout.

Modal score of the quality of report as assessed by doctors and patients.

Overall assessment of the four modalities of printings is summarised in [Table/Fig-4].

Strength and Limitation analysis of the various modes of printing.

| Printing mode | Strength | Limitation |

|---|

| Laser printer | Quality of printoutSpeed of printoutCapability of printing figures and graphsDurability | Cost of printing single report |

| Inkjet printer | Quality of printoutAbility of colour outputSpeed of printoutCapability of printing figures and graphs | Cost of printing.Have limitations when handling large quantity of printing at a regular basis. |

| Dot Matrix printer | Economy of printing reportDurability of printerSpeed of printing single report | Noise during printing.Limited capability of glamorizing reports with special effects (use of fonts etc). |

| Thermal Printer | Very fast printoutNo additional requirement for printing (toner/cartridge etc) | Cost of printingReports tend to fade out over a period of time.Scratches or rough handling of the reports could affect clarity of print.Paper size limited to printer rolls. |

Discussion

This issue of cost cutting in printing is not only limited to laboratories but extends to all corporate offices and companies. As early as 1980s, efforts were undertaken to use electronic media as a mode of communication and a view to reduce ‘paper-work’ by creating a ‘Paper Less Office’ [6]. Unfortunately, this vision has not yet been materialized, and it is estimated that the average employee in US uses 10,000 sheets of paper a year [7]. Sadly, but true is the fact that most of clinicians as well as patients are more comfortable with hard copies of reports thus, making printing reports especially laboratory reports inescapable.

Automation in the field of clinical chemistry has come as a big boon to laboratories in augmenting their abilities to keep up with the ever increasing demand from the clinicians. Increased work load has translated to increased profit for commercial laboratories, which ends up as a win-win situation for both the clinicians as was the laboratory. When a laboratory report is printed directly from an analyser/LIS, a significant amount of technical man hours is saved because the laboratory technician can then focus on the task of operating the machine and ensuring quality of reports. Not only does printing reports increase the productivity of the laboratory in terms on number of samples run, it also significantly reduces the transcriptional errors that could occur. Viewed holistically, printing of laboratory reports improves the efficiency of the laboratory both tangibly and intangibly and hence, should be adopted universally.

Unfortunately in government sector and in small laboratories, where the feel-good factor of the patient may not play a major role, printing of reports is still considered as a wasteful cost, and being dispensed with on the pretext of cost cutting. Reports are still being handwritten, a concept that derails the power of automation and one that is fraught with the risk of generating post-analytical errors (transcriptional errors) [8,9]. In a study done by Black et al., they found that in an ICU setting, complete and accurate transcription was seen in only 67.6% of the cases [8]. Even though cutting cost is always welcome by any laboratory management team, it equally becomes their responsibility to ensure that the cutting costs do not affect the quality of the report and that the patient’s satisfaction should always be kept in mind [2].

The debate on the choice of the optimal printing media needs to be addressed over multiple factors, namely cost of the printer, cost of the stationary and the running cost for printing. The cost of the IP is significantly lower than LP, DMP or TP. The cost of stationary in the LP, IP and DMP are comparable to each other while the cost of stationary of TP is significantly higher. TP however has a low to negligible printing cost. Cost analysis of the four printing options available in the laboratory is shown in [Table/Fig-1]. Critical analysis of the merits and demerits of the various modalities of printing is shown in [Table/Fig-4]. From the data in both the tables, it is evident that the most economical option for printing reports in a laboratory is DMP in DOS mode printing.

In the conventional method of printing on DMPs from MS office applications such as MS Word or MS Access, data is sent to the printer as a graphics output. The DMPs have limited capability of handling graphics output and hence, appears to be slow in printing. For this reason, DMPs have fallen into disrepute. DOS printing is a technique where the data from the computer is sent to the printer in text form [3]. DMPs have an inherent capability of handling text data efficiently and print them at a fast speed. Also, ‘Esc P codes’ [10] are available which can enhance print options (bold, underline, itallic, double height, double width printing) of the DMP and could be resorted to if required. In a biochemistry report, most of the output data is plain text and numbers. Hence, a slight compromise on the print quality translates into a significant gain the print speed.

The importance of resorting to printing biochemistry reports is essential to reduce transcriptional errors as well as increase in the productivity of the laboratory. The most economical printing option is the DMP with DOS printing. However, we found that the difference of printing reports on a laser printer and that of a DMP is only Rs 0.50 per report. Extrapolating this data, the net difference in the cost of printing over 200 reports a day annually would be around Rs 36500 which we feel would be an insignificant expense especially considering the revenue earned by the laboratory in processing so many samples. In government sectors where the treatment to the clientèle is offered free of cost, there is a strong case for switching to at least DMP with DOS printing option, with a view to harness the full potentials of automation as well as significantly reduce the risk of patient harm due to transcription errors. Whatever the option chosen for printing report, the one unifying factor is that it is essential to print reports directly from the LIS using an option tailor-made for that institution.

Limitation

This study used the models of laser and inkjet printer available at the author’s disposal. These were the common mode of printers normally seen in any office. However, there are more sophisticated printers with different printing economics/time of printing and hence, the data of this study is limited to type of printers used in this study.

Conclusion

The most economical printing option for biochemistry reports is DMP with DOS printing. The most appealing as far as clientele is concerned is of LP and IP but these are costly. The difference of cost between Laser printing and DMP- DOS printing is actually not as heavy as is perceived and if the institution is not very starved for funds, laser printing can be resorted to for better clientele satisfaction. Thermal printing is costly as well as found to be unsatisfactory among clients.