Previous studies have shown that 20-30% of denture users have been dissatisfied with their dentures [1,2]. Ideal denture base material, should distribute uniform stress on the underlying tissues [3]. Several materials, such as silicone, acrylic resin, and fluoroethylene, have been used as resilient denture liners which exhibit various viscoelastic properties.

To obtain stresses and displacements, FEA has been illustrated as computational tool. Since the early 1960’s, the FEA has been used in the aerospace industry and later it was applied in dentistry in 1970’s [4]. FEA is capable of providing detailed quantitative data at any location within a mathematical model, so is a valuable analytical tool in dentistry [4,5]. The power of FEA exists principally in its versatility with respect to a range of physical problems [5]. The structure which is to be analyzed can have a random shape, loads, and supporting conditions. In addition, the mesh can mix elements of divergent types, shapes, and physical properties. A single computer program encloses all these substantial versatility and the type, geometry, boundary conditions, and element choice are controlled by user-prepared input data [5].

This study was conducted with the aim to observe and analyze the stress distribution under complete denture lined with elastic and viscoelastic liners using 3D FEA and objectives were to correlate this with a clinical study where patients were given dentures lined with elastic or viscoelastic liners to assess the effect of liners on the quality of life of patients and which liner is suitable for which type of food.

Materials and Methods

This study was conducted in in-vitro and in-vivo phases. Ethical clearance was granted by the ethical clearance committee of the Career Post-Graduate Institute of Dental Sciences, Lucknow, Uttar Pradesh, India.

Phase 1: Finite Element Model (In-vitro)

FEA was carried out at “Lelogistix Design” in Delhi using the following computer characteristics:

Ansys level 11.0 version for strain analysis

Software Pentium IV

Memory 320GB

RAM 3GB

Solid Works 2009 for parametric model creation

White-light scanning systems (Imetric 3D GmbH) for scanning the physical model.

Three virtual models were fabricated: One depicting a maxillary denture with an acrylic resin liner, another with a silicone liner, and a third depicting a heat-cured acrylic resin denture resting on the mucosa. The fabrication of virtual models and study of load pattern included the following steps:

1. Scanning the physical casts and denture models to create geometric models: The casts and dentures were made in the laboratory and in these pre-fabricated physical models of dentures and casts most appropriate defect free model was used to initiate the project. This physical model was scanned using a white-light scanner. The structured light 3D scanner (Imetric 3D GmbH) was used for contactless digitalization of the denture and cast. The scanner projects a pattern of light on the subject and assesses the pattern of deformation on the subject. The data obtained using this scanner exhibited better quality, precision, and speed than that obtained using other scanners. Instead of scanning one point at a time, the structured 3D light scanner scanned multiple points at once for a wide range of applications. After scanning the model, virtual point cloud data were obtained. The point cloud data were transformed into x, y, and z co-ordinate points and assessed using FEA to create geometric models of the cast and denture. These geometric models were analogous with the physical models but were non-parametric. Therefore, they were transferred to Solid Works 2009 for creating a 3D Computer Aided Design (CAD) model.

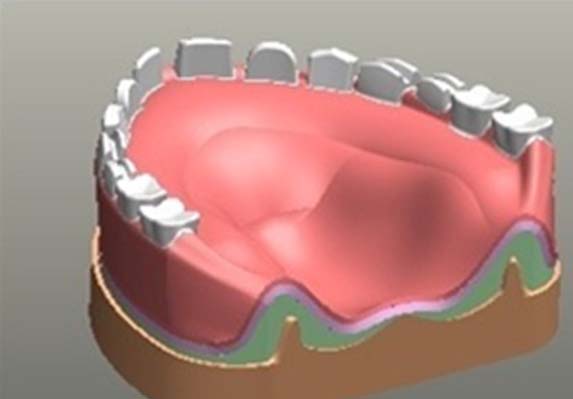

2. Creating 3D–CAD parametric models using geometric models: Parametric models for cast and denture were developed using the models received from the previous process [Table/Fig-1]. The 3D finite element models that matched to the geometric models were produced using the Ansys pre-processor [6].

Layering of the mucosa: The mating surface of the cast (intaglio surface) was used as the primary surface for mucosa modelling. The main requirement for modelling was to maintain the varying thickness of the mucosa. The modulus of elasticity was assumed to be homogeneous at 10Pa and Poisson’s ratio at 0.40.

Layering of liners: A layer of the liner was added on the tissue surface of the denture with a uniform thickness of 1.5mm. The model depicting acrylic resin liner was incorporated with the modulus of elasticity of 3.1GPa. The model with silicone lining had a modulus of elasticity of 1.7GPa and the model depicting the heat- cured acrylic resin denture had a modulus of elasticity of 3.6GPa.

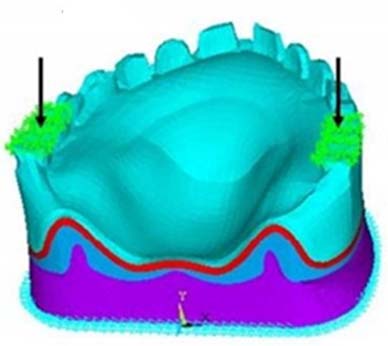

3. Preparing a finite element mesh: The 3D finite element models corresponding to the geometric models were generated using the Ansys pre-processor. During meshing, the elements were carefully concentrated in the region of the greatest interest in the stress distribution pattern.

A quadratic displacement behaviour element which was of higher order i.e., 3-D 10 node element, was selected as default element size using the SOLID 187 element. This was well-matched for modeling asymmetrical meshes (such as those formed by CAD-CAM systems). The element was described as 10 nodes, with three degrees of freedom on every node. The elements were constructed such that their size aspect ratio yielded reasonable solution accuracy. The completed anatomic model consisted of 123620 nodes and 74756 elements and had an element size of 4.2mm.

These geometric models were transmitted to Solid Works 2009 for 3D-CAD model creation using the Ansys pre-processor [7]. Surfaces of the models were used to develop parametric surfaces. These surfaces were knitted together to complete the solid models for casts, dentures, mucosa and liners [Table/Fig-2].

4. Applying material property: The living tissues of concerned area (mucosa, bone, acrylic resin, and denture teeth) were supposed to be linearly elastic, isotropic, and homogenous [6]. Although, cortical bone exhibits anisotropic material characteristics and possesses regional stiffness variations, the dentures were modelled isotropically because sufficient data were unavailable and establishing the principal axis of anisotropy was difficult. The mechanical properties, such as Young’s modulus© and Poisson’s ratio (δ), of the cortical bone (250 MPa and 0.30), mucosa (10Pa and 0.40), and the denture base resin (27Gpa and 0.35) were determined according to literature survey [4,7–10]. Any viscoelastic material behaviour is highly non-linear in nature, time-dependent changes in Young’s modulus are represented by loss modulus. The loss modulus describes energy dissipation through the loss tangent of the material. The damping factor or loss tangent (tan δ) is defined as a ratio of storage to loss modulus, which can indicate the amount of energy absorbed by the material [7,8]. Visco-elastic material modelling was available in the software. The loss tangent and Young’s modulus were used to define the viscoelastic material behaviour in the software. The storage modulus, loss modulus and damping factor for the elastic and viscoelastic liners were 3.12 and 4.45, 0.093 and 0.187, and 0.03 and 0.04 respectively.

5. Applying boundary conditions: For the boundary condition of the model, a supporting system was set up. Symmetrical boundary conditions were imposed at the basal bone region of the maxilla.

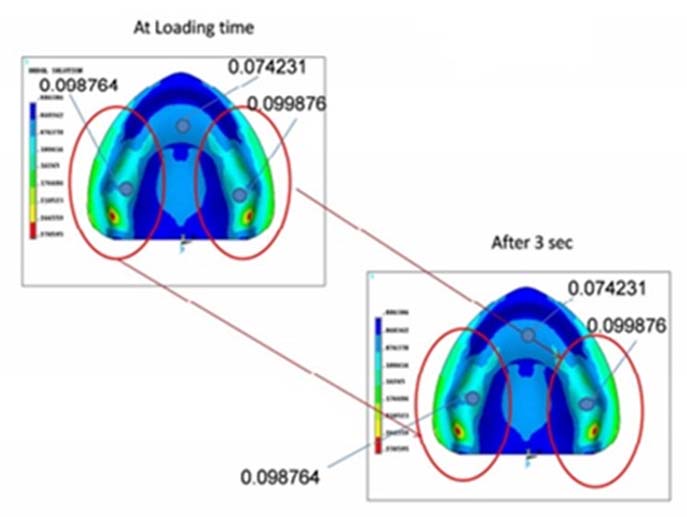

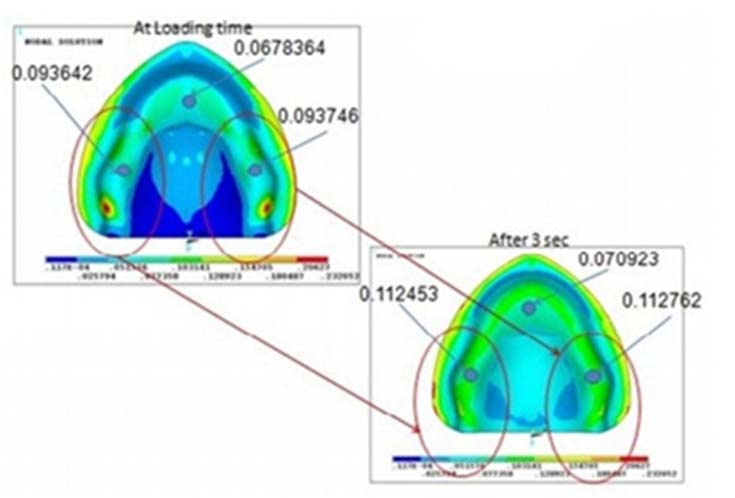

6. Applying load: A constant bilateral force of 166N was applied at the 2nd premolar and 1st molar regions [Table/Fig-3]. The direction of force was parallel to the long axis of the teeth. The load was applied at a constant rate for 3 seconds. The stress pattern was measured at the beginning and 3 seconds after loading.

7. Analyzing stress pattern: The models were analyzed by the processor and displayed by the post processor of the finite element software (Ansys, Version 11.0) using Von Mises stress analysis. Von Mises stress values defined the beginning of deformation of viscoelastic materials, such as denture liners [11].

Phase 2: Clinical Study (In-vivo)

The study was reviewed and approved by the ethical committee of the institute. The questionnaire was given to all the participants selected from the outpatient department of the Department of Prosthodontics. The given questionnaires were in conjunction with previous studies conducted by Albaker AM and Kimoto S [1,3]. The questionnaires were in English language (since the population selected was educated up to graduate level and simple English was used, more over if needed, translator was provided) and its validity and reliability were assessed previously with pilot study following a pre-test in the related population. In this cross-sectional clinical assessment, 20 patients were evaluated three times. The inclusion criteria were first time denture users who had a minimum edentulous period of 6 months and healthy oral mucosa, with no bony spicules. Patients had to be cooperative. Dentures were fabricated with heat- cured acrylic resin (DPI Mumbai, India) and relined successively with silicone and acrylic liners at 2-month intervals.

Conventional complete dentures with bilaterally balanced occlusion were fabricated using material-A (DPI Mumbai, India) for all 20 patients. After 2 months, each patient was recalled and requested to complete a denture assessment questionnaire and food eating ability questionnaire based on his/her denture experiences. The responses of the patients with dentures made of material-A were designated as Group-I for all 20 patients.

The denture assessment questionnaire included 12 questions related to the functional, aesthetic, and psychological demands of complete dentures each question was graded from 1 to 4. (1 correlated with extreme difficulty and 4 with no difficulty). Based on the total score, the evaluation was scaled as poor=12-23, fair=24-35, and good=36-48. The total score was compiled and maintained for further reference. Another questionnaire was based on patient’s ability to eat food with different consistencies. This questionnaire categorized food on the basis of texture as soft, firm, hard and fibrous. Each food item was again scaled from 1 to 4 (1=cannot eat, 2=eat with difficulty, 3=eat with relative ease and 4=eat with no difficulty). The total score for each food type was compiled and maintained for further reference.

After completing the questionnaire assessment, each patient was asked to not wear the dentures for a week to reduce the factor of adaptability. After 1 week, the dentures were relined (chair side) using material-B (chair side soft denture reline material; Tokuyama Dental Corporation, Taitouku, Tokyo, Japan). After 2 months, the same procedure was performed for evaluation and the results of material-B assessment were aggregated as Group-II. Material-C (chair side acrylic resin denture liner; Permasoft, Dentsply International Inc.) was similarly assessed and the results were grouped as Group-III. The scores obtained were tabulated and statistically analyzed using the analysis of variance of the mean Quality of Life (QOL) score among the three groups. For the various groups, the differences in the QOL scores were assessed using Tukey’s HSD test. This test was selected to minimize the Type I (α) error.

Results

The results were determined in two parts:

Part I: FEA modelling

Part II: QOL assessment and suitability for different foods

Part I: FEA modelling: For each tested liner (materials B and C), the stress plots were obtained for the mucosa at and 3 seconds after loading at points A, B and C. The values of the strain were indicated by different colour contours. Red represented the highest tensile value, and blue represented the highest compressive value [7]. For material B, the maximum concentration was observed near the tuberosity region whereas, the incisive region exhibited minimum stresses. In contrast to material B, the stress pattern for material C revealed lower values with the highest concentration at the tuberosity region [Table/Fig-4,5]. However, after loading the stress values increased in the incisive region, and reduced in the tuberosity region. Stress values obtained at and 3 seconds after loading on all three reference points are tabulated in [Table/Fig-6].

Stress plot for material-B.

Stress plot for material-C.

| Point A | Point B | Point C |

|---|

| Material B | 0.074231 | 0.098764 | 0.099876 |

| Material C | 0.0678364 | 0.093642 | 0.093746 |

| Loading value at t * =0 secs |

| Material B | 0.074231 | 0.098764 | 0.099876 |

| Material C | 0.070923 | 0.112453 | 0.112762 |

| Loading value at t * =3 secs |

* t- time

Part II: QOL assessment and suitability for different foods: The mean QOL scores were 23.65±4.00 (Group-I), 29.50±5.08 (Group-II), and 33.10±6.15 (Group-III). The minimum QOL score was 17 for a patient in Group I; whereas, the maximum was 42 for a patient in Group III. The analysis of the variance of mean QOL scores in different groups is presented in [Table/Fig-7].

Mean QOL score and analysis of variance of mean QOL scores in different groups.

| Group | No. of Cases | Mean | SD * | Minimum | Maximum | F | Sig. |

|---|

| I | 20 | 23.65 | 4.00 | 17 | 31 | 17.136 | <0.001 |

| II | 20 | 29.50 | 5.08 | 21 | 39 |

| III | 20 | 33.10 | 6.15 | 21 | 42 |

* *SD- standard deviation, Test applied- Analysis of variance; p <0.05 Significant

Mean difference was found to be maximum between Groups I and III (9.45±1.63) and minimum between Groups II and III (3.60±1.63) as shown in [Table/Fig-8] where Post-Hoc Tests (Tukey-HSD) was used. Statistically, the difference was significant between Groups I and II and between Groups I and III. The difference was not statistically significant between Groups II and III (p=0.078). The QOL scores for different groups were in the following order:

Group I < Group II ~ Group III

Between group differences for mean QOL scores in different groups (Tukey HSD).

| S. No. | Comparison | Mean Difference | SE | p-value |

|---|

| 1. | Group I v/s Group II | -5.85 | 1.63 | 0.002 |

| 2. | Group I v/s Group III | -9.45 | 1.63 | <0.001 |

| 3. | Group II v/s Group III | -3.60 | 1.63 | 0.078 |

Test applied- Post-Hoc Tests (Tukey-HSD), p <0.05 Significant

For all the food items, Group I exhibited the minimum mean score; whereas, Group III exhibited the maximum. The analysis of variance of the mean scores for different groups is presented in [Table/Fig-9]. Inter-group comparison for different foods revealed maximum mean differences between Groups I and III. For soft, hard and fibrous food, a minimum difference was observed between Groups II and III. In the firm food category, Groups I and II exhibited a minimum difference. The mean differences were statistically significant, except those between Groups II and III for fibrous food (p=0.076) [Table/Fig-10]. On the basis of the aforementioned assessment, the order of scores was as follows:

Group I < Group II < Group III

Analysis of variance of mean dietary scores in different groups.

| Sum of Squares | df | Mean Square | F | Sig. |

|---|

| Soft Foods |

| Between Groups | 535.03 | 2 | 267.52 | 25.082 | <0.001 |

| Within Groups | 607.95 | 57 | 10.67 | | |

| Total | 1142.98 | 59 | | | |

| Firm Foods |

| Between Groups | 342.43 | 2 | 171.22 | 16.470 | <0.001 |

| Within Groups | 592.55 | 57 | 10.40 | | |

| Total | 934.98 | 59 | | | |

| Hard Foods |

| Between Groups | 246.43 | 2 | 123.22 | 22.103 | <0.001 |

| Within Groups | 317.75 | 57 | 5.57 | | |

| Total | 564.18 | 59 | | | |

| Fibrous Foods |

| Between Groups | 249.73 | 2 | 124.87 | 24.029 | <0.001 |

| Within Groups | 296.20 | 57 | 5.20 | | |

| Total | 545.93 | 59 | | | |

Test applied- Analysis of variance; p <0.05 Significant

Between group comparisons of mean scores for different food items.

| Food Item | Group I v/s Group II | Group I v/s Group III | Group II v/s Group III |

|---|

| MD | SE | p- value | MD | SE | p- value | MD | SE | p- value |

|---|

| Soft food | -4.05 | 1.03 | 0.001 | -7.30 | 1.03 | <0.001 | -3.25 | 1.03 | 0.007 |

| Firm food | -2.80 | 1.02 | 0.022 | -5.85 | 1.02 | <0.001 | -3.05 | 1.02 | 0.011 |

| Hard food | -2.80 | 0.75 | 0.001 | -4.95 | 0.75 | <0.001 | -2.15 | 0.75 | 0.015 |

| Fibrous food | -3.30 | 0.72 | <0.001 | -4.90 | 0.72 | <0.001 | -1.60 | 0.72 | 0.076 |

Test applied- Test applied- Analysis of variance; p <0.05 Significant

Discussion

Conventional acrylic resin dentures act as a hard non-resilient material with no capacity to absorb or dissipate pressure. Therefore, applying resilient denture liners to the denture base enables the absorption of stresses, thereby reducing the load on the supporting tissues. The load is distributed over the denture-bearing area by avoiding localized areas of stress concentration [8]. Contemporary resilient liner materials are of two types: acrylic resin-based, and silicone-based.

Acrylic resin- based resilient liners exhibit considerably higher rates of stress relaxation than silicone- based liners. They exhibit viscoelastic behaviour; whereas, silicone-based resilient liners exhibit elastic behaviour. Acrylic resin-based resilient liners demonstrate greater changes in viscoelasticity over time than silicone and polyolephin liners [12,13].

Various methods can be used to measure the pressure under dentures, such as direct measurement in the oral cavity using pressure sensors, indirect measurement using simulation models, photo elastic analysis, and FEA. Direct measurement in the oral cavity has limitations because of the reduced sensitivity of the method [5]. In the indirect measurement model, pressure sensors are attached to the casts and dentures. The human bones have different mechanical properties and mechanical properties of models were different from it. Thus, the pressures recorded didn’t present the true pressures [14]. Good qualitative information is imparted by photo elasticity pertaining to the overall location of the stresses; but only restricted quantitative information is provided by it [15].

To determine and analyze stresses and deformations of any given geometry, FEA is a numerical method which is used. The structure to analyze is discretized into the “finite elements” connected through nodes [10,11]. The type, arrangement, and total number of elements affect the accuracy of the results.

Previous studies conducted by Sato and Kawano using FEA to assess the pressure distribution under a lined denture, included a 2D model to simulate the denture-bearing unit (less sensitivity) [10,16]. The first use of 3D FEA under lined denture has been used by Shim JS. He assessed the pattern of stress concentration in the mandibular denture to study the areas of breakage of lower lined denture. Although this study did not assess stress distribution under denture, it concluded that 3D FEA was a fairly accurate tool to depict clinical situation [17]. In this study the time interval chosen to assess the loading pattern, which depicted the points of intercuspation and final loading, was set at 3 seconds before and after which the stress patterns remained identical. The major drawback of FEA is the inability to mimic the mechanical properties of histological tissues, such as mucosa, periosteum and hard tissues in their complete entirety, after considering the diverse variation in mean values.

For the silicone liners, the stresses at and after 3 seconds of loading were highest near maxillary tuberosity bilaterally. This can be attributed to the fact that the silicone liners did not deform under compression or dissipate stress uniformly and instead behaved more like a stiff material. At loading, the acrylic soft liners displayed lesser stress than the silicone liners, which suggests that acrylic soft liners absorbed the loading stress because of a higher damping factor (energy absorption ability). This was supported by the findings of the study conducted by Taguchi and Yoneyama, wherein they concluded that for a 1mm silicone liner, the difference between highest and lowest pressure reading was marked, where as for acrylic soft liner the readings for highest and lowest pressure were almost similar [14,18].

Resilient denture materials have been used for decades and actively studied in the dental materials and bacteriologic fields. However, only a few valid reports on their clinical efficacy have been published. Kimoto S performed a clinical trial on edentulous patients to determine satisfaction with resilient denture liners and concluded that there were no significant differences in patient satisfaction and mostly patients preferred dentures with a resilient liner [3].

Clinically, the overall patient satisfaction scores were higher for acrylic soft-lined dentures than for silicone or conventional dentures. Of the conventional and silicone relined dentures, patients were more comfortable using silicone lined dentures. For acrylic and silicone liners the patient satisfaction data were not statistically significant. Patients with conventional hard dentures were the least comfortable with soft, firm, hard or fibrous foods. Patients with acrylic lined dentures were most comfortable. The clinical results of silicone and acrylic liner were statistically similar. It must be emphasized that liners do exhibit some drawbacks, such as debonding of the liner from the denture surface, increased probability of fungal infections, and reduced structural durability of the denture base. The operator must consider these drawbacks and address them appropriately. In addition patient’s adaptation to each liner must not be ignored because it may influence the results of questionnaire-based analysis. This study has high clinical implication as it proves that denture liners help in uniform distribution of stress, in that viscoelastic liners are better than others.

Limitation

The limitation of the study were, in the FEA viscoelastic material behaviour is highly non-linear in nature, time and temperature dependent in real situation. In the present scope of the FEA the diametric models which were created to simulate the mucosa and bone but more realistic and accurate modelling in future in this field may enhance the quality of models to assess living tissues more precisely. A study with large sample and long term will always be useful in assessing the results.

Conclusion

Within the limitations of this study, viscoelastic liners provided the most uniform stress distribution. Both denture soft liners significantly improved the QOL of the patients, with the viscoelastic liner being more acceptable among the patients. Both liners were more effective with different types of food (hard, soft, firm and fibrous) than the conventional heat-cured acrylic dentures. The viscoelastic liners performed better than the elastic liners with hard, firm and soft foods. The performance of both liners was similar for fibrous food.

* t- time

* *SD- standard deviation, Test applied- Analysis of variance; p <0.05 Significant

Test applied- Post-Hoc Tests (Tukey-HSD), p <0.05 Significant

Test applied- Analysis of variance; p <0.05 Significant

Test applied- Test applied- Analysis of variance; p <0.05 Significant