Growing number of adult orthodontic patients and their demand for less visible appliances encouraged the clinicians to improve the aesthetic values. By the help of recent advances several aesthetic appliances including ceramic brackets, coated arch wires and tooth colored ligatures have been introduced.

Most fixed orthodontic appliances are metallic which although provide adequate mechanical properties, their appearance is a major disadvantage [1]. Also, conventionally used orthodontic arch wires which are made up of metal such as stainless steel, Nickel Titanium (Ni-Ti) etc., have excellent mechanical properties, produce aesthetic compromise.

In response to patient demands for better aesthetics in orthodontics, aesthetic brackets made of ceramic or composite have been developed [2]. In terms of arch wires, three types of aesthetic arch wires have been introduced i.e., Optiflex, which has been reported to have undesirable mechanical properties [3], fiber-reinforced composite arch wires which are still at laboratory level [4], and coated metallic arch wires such as coated Ni-Ti arch wires which are available aesthetic wires in clinical practice. Materials used in the coating process are polymers such a synthetic fluorine-containing resin, Teflon®, epoxy resin, etc., [5].

These aesthetic arch wires although seem very attractive especially to use with clear brackets, they are not yet considered routine for daily practice since the evidence lacks enough data to confirm their efficacy, also there is lack of clinicians’ familiarity with this material.

In addition to the stability of coating materials, it is necessary that a coated arch wire represent enough mechanical properties. The process of applying the coating material to the arch wire includes some surface treatment which might cause negative effects on mechanical properties including load deflection rate, frictional properties, corrosion and color stability of the arch wire [6,7].

The aim of this study was to make comparative evaluation, by means of the load-deflection ratio of the force released by coated and uncoated conventional Ni-Ti arch wires when ligated to conventional and metal-insert ceramic brackets. Load-deflection characteristics are important because they determine the biological nature of orthodontic tooth movement [8].

Materials and Methods

This in-vitro experimental study was conducted on three types of orthodontic arch wires: conventional uncoated super elastic Ni-Ti (Rematitian Lite; Dentaurum, Ispringen, Germany), HUBIT (Teflon Coated, Korea), G&H (Epoxy Coated, Greenwood, Ind, USA) in 0.016inch size and the form of maxillary arch. Two types of standard ceramic brackets with the slot size of 0.022×0.028 inches were used. Both ceramic bracket systems, conventional and metal-insert type, were manufactured by Ortho Technology (Ortho Technology, Tampa, Florida, USA).

All three types of wire were tested in each of the two bracket types. Based on the results of pilot study, sample size was determined to be of 30 wires. Five pieces of each type of wire were tested in each of the six experimental groups.

Ethical approval for this research was obtained by the ethical committee of Yazd University, Iran.

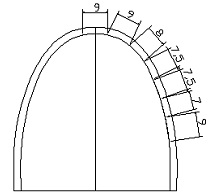

Before the mechanical tests, a simulation device was fabricated similar to ortho small maxillary arch form (Ormco) to resemble a model of human dental arch which makes it possible to measure the magnitude of exerted force to malaligned tooth. To make this simulated model, two stainless steel discs with diameter of 80mm were made and 11 steel bars with a diameter of 5mm and a height of 200mm, each one belonging to a maxillary tooth were welded between the two discs on specific spots, but the upper right lateral bar was not welded therefore malocclusion, by lingual displacement of upper right lateral incisor, was simulated [Table/Fig-1]. To set the brackets in proper position without any irregularity in bracket position Wilkinson bracket positioning and inter bracket distance was used [9]. Auto CAD (Autodesk 2002) software was used to determine the exact position and distance between the brackets on the bars by creating the model on software [Table/Fig-2].

Three-point bending test of mounted arch wires in a water bath at a constant temperature of 35.5oC.

Location of each tooth on the arch form.

Next, ceramic and metal insert ceramic brackets were affixed on the bars. To achieve strong bracket-model connection laser welding was used.

The wires were placed and engaged into the brackets of the device by means of elastomeric chain (Elastomeric modules, Sanities Silver, GAC Dentsply International, USA) in a standard configuration.

A three-point bending test was conducted in the buccolingual plane similar to first-order wire deflection using the universal testing machine (Zwick GmbH & Co., KG., Ulm, Germany) in Metallurgy and Material Engineering Department, University of Tehran, Tehran, Iran.

In this test, force was exerted vertically on midpoint of the wire between central incisor and canine at a crosshead speed of 1mm/minute pressure from metal blade. Each sample was loaded until a deflection of 3.0mm was produced. Then the samples were unloaded at the same cross head speed until the force became zero. The same procedure was performed for five times each with a new piece of wire. The whole procedure was performed in a water bath at a constant temperature of 35.5°C±0.5°C which was controlled by a digital thermometer.

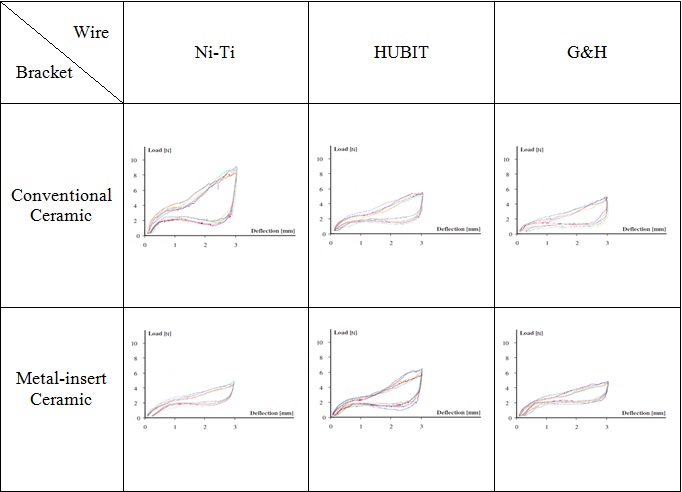

The loading and unloading forces were recorded and load- deflection diagrams were drawn from the available data by a computer connected to the apparatus [Table/Fig-3]. Also, maximum load deflection, characteristics of plateau phase in unloading curve such as mean values of unloading force and length of the plateau were measured during the test.

Loading and unloading curves of coated and uncoated wires in conventional and metal-insert ceramic brackets.

Data were analyzed using SPSS version of 11 for windows (SPSS Inc, Chicago, III). The Shapiro-Wilk test was used to assess the normality of the data. Two-way ANOVA was applied for overall comparison of groups while Tukey’s post-hoc test was used for pair wise comparisons. All statistical analysis were undertaken at the p<0.05 level of significance.

Results

In this study maximum loading and unloading forces, the average plateau force and plateau length were comparatively evaluated for using three types of arch wire and two types of bracket. Descriptive statistics of the variable force according to the type of brackets are presented in [Table/Fig-4]. Mean values of maximum loading force, unloading forces and length of the plateau with standard deviation of measured variables are illustrated in [Table/Fig-5]. Results of analysis of variance for each variable and their interaction are presented in [Table/Fig-6].

Descriptive statistics of the variable force according to the types of brackets.

| DependentVariable | Bracket Type | Mean(N)* | Std. Error | 95% Confidence Interval |

|---|

| Lower Bound | Upper Bound |

|---|

| Mean values of max loading force | Conventional Ceramic | 6.387 | 0.187 | 6.001 | 6.772 |

| Metal-insert Ceramic Bracket | 5.037 | 0.187 | 4.651 | 5.422 |

| Mean values of unloading force | Conventional Ceramic | 2.333 | 0.071 | 2.186 | 2.481 |

| Metal-insert Ceramic Bracket | 1.787 | 0.071 | 1.639 | 1.934 |

| Length of plateau phase | Conventional Ceramic | 2.110 | 0.046 | 2.015 | 2.205 |

| Metal-insert Ceramic Bracket | 2.257 | 0.046 | 2.162 | 2.352 |

newton*

The means and standard deviation of the maximum load, average plateau load and plateau length for each group at the deflection of 3mm.

| Bracket Type | Wire type | Max Loading Force(N)*mean±SD | Unloading Force(N)mean±SD | Plateau Length(mm)**mean±SD |

|---|

| Conventional Ceramic | HUBIT | 5.48±0.54 | 2.40±0.26 | 2.12±0.27 |

| Ni-Ti | 8.50±0.42 | 2.52±0.25 | 1.79±0.07 |

| G&H | 5.18±0.63 | 2.08±0.13 | 2.42±0.23 |

| TOTAL | 6.38±1.63 | 2.33±0.28 | 2.11±0.33 |

| Metal-insert Ceramic Bracket | HUBIT | 6.31±0.55 | 1.46±0.16 | 2.16±0.11 |

| Ni-Ti | 4.47±1.35 | 2.16±0.08 | 2.21±0.15 |

| G&H | 4.33±0.32 | 1.73±0.51 | 2.39±0.10 |

| TOTAL | 5.03±1.23 | 1.78±0.41 | 2.25±0.15 |

| Total | HUBIT | 5.89±0.67 | 1.93±0.53 | 2.14±0.20 |

| Ni-Ti | 6.48±2.32 | 2.34±0.25 | 2.00±0.25 |

| G&H | 4.75±0.65 | 1.90±0.40 | 2.40±0.17 |

| TOTAL | 5.71±1.57 | 2.06±0.44 | 2.18±0.26 |

newton*, millimeter**

Results of analysis of variance for each variables and their interaction.

| Term | Dependent Variable | F-value | Sig. |

|---|

| Bracket | Mean values of max loading force | 26.110 | 0.019* |

| Length of plateau phase | 5.134 | 0.076 |

| Mean values of unloading force | 29.330 | 0.012* |

| Wire | Mean values of max loading force | 14.774 | 0.037* |

| Length of plateau phase | 13.600 | 0.043* |

| Mean values of unloading force | 17.884 | 0.025* |

| Bracket× Wire | Mean values of max loading force | 29.095 | 0.014* |

| Length of plateau phase | 4.482 | 0.088 |

| Mean values of unloading force | 13.719 | 0.040* |

p-value < 0.05 indicates a significant result

Effects of bracket type: Two-way ANOVA [Table/Fig-6] revealed statistically significant differences between two types of brackets regarding the mean values of maximum loading and unloading forces (p<0.05). The highest values belonged to conventional ceramic brackets (6.387N for loading and 2.333N for unloading force) which was significantly higher than metal-insert ceramic brackets (5.037N for loading and 1.787N for unloading force) [Table/Fig-4,5]. The average clinical plateau length of metal-insert ceramic brackets was higher which was not significantly different from conventional ceramic brackets (p>0.05).

Effects of arch wire type: The mean values of maximum loading force were significantly different based on the type of arch wire. Ni-Ti arch wire had the highest force (6.485N) and G&H arch wire had the lowest force (4.755N) while there were no significant differences between HUBIT and Ni-Ti arch wires [Table/Fig-5,6 and 7].

Results of Post hoc Tukey’s test to compare each type of wires.

| Wire | Wires | p-value Maximum load | p-value Plateau Length | p-value Average Plateau load |

|---|

| HUBIT | Ni-Ti | 0.211 | 0.225 | 0.001* |

| G&H | 0.007* | 0.011* | 0.976 |

| Ni-Ti | G&H | 0.023* | 0.018* | 0.018* |

p-value < 0.05 indicates a significant result after post hoc Tukey’s test

Tukey’s post-hoc test showed that the highest unloading force belonged to Ni-Ti wire (2.343N) and the lowest to G&H (1.905N) which were statistically significant (p-value<0.05) [Table/Fig-5,7].

According to the Tukey’s post-hoc test, G&H wire showed the highest (2.409mm) plateau length while the lowest length of plateau belonged to Ni-Ti (2.000mm) which was significantly different (p value<0.05) [Table/Fig-5,7].

Discussion

The present study used three-point test for assessing the physical properties of different types of aesthetic arch wires and brackets which offers reproducibility; thus, facilitating comparison among studies available in the literature [10]. Most of the studies on the load - deflection characteristics of Ni-Ti arch wires were performed on the free-end, simple three point bending test but in the present study, the bending test was carried on an arch model simulating the orthodontic treatment of the malaligned upper right lateral by palatal deflection. Based on the available evidences, at the low amount of irregularity, the exerted force levels might not reach the super elastic plateau, and the force would not be independent of deflection [11,12], therefore, in this study, 3.0mm irregularity was created. Results of this study showed that ceramic brackets exhibited higher level of force than that of metal-insert ceramic brackets against all three types of wires at loading and unloading. This finding was similar to the study conducted by Alavi S et al., [13], who reported that Ni-Ti and poly-coated wires required higher force when engaged in ceramic brackets during loading phase and illustrated lower force in unloading phase in comparison with metal-insert ceramic bracket. The reason might be contributed to the higher frictional force between ceramic bracket and these two types of wire. According to the report of Cacciafesta V et al., conventional ceramic brackets showed a loading and unloading force more than metal insert types which confirms the results of this study [14]. In the study conducted by Hemingway R et al., bending test was used to evaluate force delivery of Ni-Ti arch wires with size of 0.014 inch [15]. According to their results, ceramic brackets, metal insert ceramic brackets, metal brackets and self ligating type represented highest forces respectively which is in line with this study result.

In the present study, elastomeric ligation was used for maintaining the wires into the bracket slots. Kasuya S et al., evaluated the effect of ligation on mechanical properties of Ni-Ti arch wires with three bracket bending test and demonstrated that the ligation with elastomeric ligature can affect loading and unloading plateau adversely [16]. They suggested that the internal changes in wires can occur by using elastomeric ligature between wire and bracket; however, in this study loading and unloading was observed in both of uncoated and coated Ni-Ti arch wires. Some authors reported that metal ligatures produced less friction as compared with elastomeric ones, the loading force generated during the placement of the metal ligature is subjective, and could vary based on the orthodontist [17].

Loading curve illustrates the force applied to insert the wire in the bracket on the malaligned teeth; thus, the force is usually recorded at the last deflection of loading curve; whereas, the unloading curve represents the force delivered to teeth during treatment and usually is recorded in several deflection points. In this study G&H arch wire showed lower force while the Ni-Ti and HUBIT wires presented higher force levels in both loading and unloading phases. This could be explained by the fact that the Teflon (HUBIT) layer adds a minimal thickness of 0.0008 to 0.001inch while the thickness of epoxy resin coating arch wire is approximately 0.002 inch. Therefore, coating of these wires may result in a smaller Ni-Ti inner core compared to the conventional Ni-Ti arch wires [18]. Alavi S et al., evaluated the load-deflection and surface properties of coated and conventional super elastic orthodontic arch wires in conventional and metal-insert ceramic brackets [13]. According to their result the least force required in loading and generated during unloading belonged to epoxy resin arch wire which is in accordance with the present study results despite some differences. Doshi UH et al., investigated a comparison of the load deflection characteristics of aesthetic and metal orthodontic wires on ceramic brackets using three point bending test [19]. According to their result coated arch wires represented lower force in loading and unloading phase than that of uncoated Ni-Ti and Stainless Steel wires which is in line with the present study results. Elayyan F et al., stated that ultra aesthetic coated arch wires (G&H, Greenwood, Indiana, USA) produced lower loading and unloading forces than uncoated wires of the same nominal dimensions, this result is in accord with the present study findings [1]. The loading curve resembles the force needed to engage the wire in the bracket and the unloading curve has more interesting clinical value, because it represents the forces which act on the dental elements. In this study G&H arch wires presented the longest plateau length while Ni-Ti arch wire was at the minimum length. The best clinical performances are exhibited by wires with longer clinical plateaus which are classified as true super-elastic and provide relatively stable forces [12]. The clinical advantage of using these types of wires is the possibility of having relatively low and stable force levels for the first phase of fixed orthodontic treatment. The wires with a longer clinical plateau in combination with greater application forces are indicated for derotational procedures. In agreement with the above findings are the results of Andreasen GF et al., who reported that the large Nitinol arch wires should be used to correct and maintain leveling and rotations while minimizing the patient’s discomfort [20]. True super-elastic wires as above mentioned are those which presented a clinical plateau length of ≥0.5mm [12]. In this study all the wires demonstrated plateau length more than 0.5mm; therefore, these wires could be recommended especially for the treatment of adult patients with mild to moderate crowding.

Clinical implication: The present study showed that coated arch wires exerted lower force than coated Ni-Ti arch wires which allow them to express their super-elasticity characters at lower deflections. With the same size, coated arch wires can make the fuller engagement into bracket slot compared to uncoated arch wires which can minimize the risk of delivering excessive force in primary phases of treatment. This is particularly important in treating severe malocclusion cases and adults with periodontal disease.

Limitation

In this laboratory trial study elastomeric ligature were used to tie the arch wires to the brackets. This could evoke friction between the wire and bracket slot during tooth movement which in turn, might have an affect on elasticity characteristics of the samples. One of the limitations of this study was, therefore, not including self ligating brackets.

Also, no attempt was made to simulate the effects of oral environ-ment to assess coating stability and surface characteristics of coated arch wires. This study investigated the arch wire characteristics only under lubricating effects of water. Physical and chemical effects of saliva (such as corrosion) might have impacts on the results which were not considered in this study.

Conclusion

Load deflection characteristics of wires vary based on bracket type. Conventional ceramic brackets produced higher force than metal-insert ceramic bracket against Ni-Ti, HUBIT and G&H wires. Generally, coated G&H wires (Epoxy Coated, Greenwood, Indiana, USA) produced lower forces compared to conventional uncoated super-elastic Ni-Ti (Rematitian lite; Dentaurum, Ispringen, Germany), HUBIT (Teflon Coated, Korea) arch wires in both loading and unloading phase. All the wires showed hysteresis in their load deflection curves where G&H wires showed the widest loading-unloading deflection curves.

newton*

newton*, millimeter**

p-value < 0.05 indicates a significant result

p-value < 0.05 indicates a significant result after post hoc Tukey’s test