In the direct bonding of orthodontic attachments to the teeth, nature of the enamel surface, the conditioning procedure, the type of adhesive and the design of the bracket base may influence the bond strength [1].

Ceramic orthodontic brackets were introduced in dentistry in the 1980s to satisfy the aesthetic needs of patients and have been available for clinical use since 1987 [2,3]. All currently available ceramic orthodontic brackets are composed of aluminium oxides [4,5] which have many advantages such as biocompatibility, good aesthetics, resistance to temperature and chemical changes, and good bond strength that is higher or equal to that of stainless steel brackets [6–9]. Ceramic bracket bonding mechanisms are divided into three groups: mechanically retentive bases, silane-treated chemically retentive bases, and both mechanically and chemically retentive bases. Various studies have shown that the bond strength between the ceramic and composite in a silane treated chemically retentive bracket is more as compared to a mechanically retentive ceramic bracket. This high bond strength is almost equal to the strength of enamel, making enamel fractures more likely to occur [9–15]. Therefore, mechanically retentive ceramic bracket base designs are more desirable than chemically retentive ceramic brackets [16].

For mechanical retention, various base designs, such as micro-crystalline, mechanical ball, dovetail, dimpled, mechanical, buttons, and polymeric bases are available from many manufacturers. Furthermore, these designs are claimed to have more consistent bond strengths and debonding characteristics than conventional stainless steel brackets which have a mesh welded to the bracket base to provide mechanical retention [3,17,18].

Bonding can be done either by using precoated bracket system or by manually applying adhesive to the bracket base prior to placement [19]. Precoated brackets were available as both metallic and ceramic types. Cooper RB et al., in their study claimed the advantages of adhesive precoated brackets which include consistent quality and quantity of light cure adhesives, easier clean-up following bonding, faster bonding procedure and lesser chair side time [20]. In both systems, complete removal of flash is advocated. Leaving behind flash exposes a rough surface of composite which acts as a critical site of plaque accumulation [19,21–23]. This plaque accumulation can lead to enamel deminera-lization and white spot lesions which will compromise the final aesthetic outcome of the treatment [24,25]. The company 3M Unitek (Monrovia, California) has developed a new APC Flash-free Adhesive Coated Appliance System as an attempt to eliminate the need for flash removal. In this system optimal amount of adhesive is pre-pasted on each bracket base allowing the clinician to cure the composite without flash removal [26].

The aims and objectives of the present study were the following: To evaluate the effect of base designs of different ceramic brackets on SBS; comparison of the SBS among various currently available ceramic brackets, SBS between the APC Flash-Free Adhesive coated brackets and the manually pasted ceramic brackets, SBS between different ceramic brackets and mechanical mesh base metal brackets, and to determine the fracture site after debonding.

Materials and Methods

The sample comprising of 50 extracted maxillary premolars was collected from the patients who reported to the Department of Orthodontics, Institute of Dental Sciences, Bareilly, Uttar Pradesh, India, requiring orthodontic treatment. An informed and written consent from the patients and their guardians was obtained.

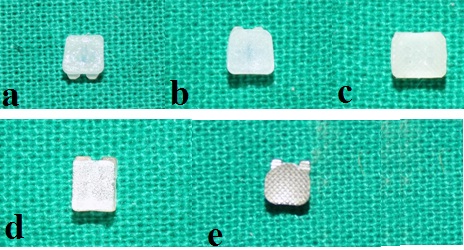

Five groups of direct-bonded maxillary premolar brackets (4 ceramic and 1 metal) with different base designs were obtained from different manufacturers. Ten brackets were taken in each group. Identification of brackets is shown in [Table/Fig-1,2a-e].

Identification of brackets.

| Group | Name of Bracket | Manufacturer | Type | Base Design | Area of Base (mm2) |

|---|

| 1. | Clarity Advanced (APC Flash-free) | Unitek/3M Monrovia, California | Polycrystalline | Adhesive Precoated (APC) | 11.69 |

| 2. | Clarity Advanced | Unitek/3M, Monrovia, California | Polycrystalline | Microcry-stalline mechanical | 11.69 |

| 3. | InVu | TP Orthodontics La Porte, IN, USA | Polycrystalline | Polymer mesh | 14.90 |

| 4. | Inspire Ice | Ormco, Glendora California | Monocrystalline with Sapphire | Patented bead ball | 11.50 |

| 5. | Gemini | Unitek/3M, Monrovia, California | Metal | Mechanical mesh | 11.98 |

(a) Adhesive precoated base of Clarity advanced (APC Flash-free) ceramic bracket; (b) Microcrystalline base of Clarity advanced ceramic bracket; (c) Polymer mesh base of InVu ceramic bracket; (d) Patented bead ball base of Inspire Ice ceramic bracket; (e) Mechanical mesh base of Gemini metal bracket.

The teeth were cleaned with tap water to remove soft tissue and debris and placed in 0.1% thymol solution (an anti-microbial solution for inhibition of bacterial growth) for one week and then stored in distilled water until use [27].

The criteria for tooth selection were as follows:

(1) The teeth with intact crown, unattrited and free from hypoplastic areas, cracks, gross irregularities, decays and fractures.

(2) Teeth without pre-treatment with chemical agents, such as hydrogen peroxide, formalin, or fluoride.

The samples were randomly divided into five groups (Group 1-5) each consisting of ten teeth. Each tooth was placed in a metal mold and roots were embedded in self-curing acrylic resin (width=15mm; breadth=7mm; height =18mm) upto 1mm apical to cementoenamel junction. The long axis of the tooth was kept parallel to the long axis of the metal mold. Crowns were kept exposed to facilitate surface treatment and bracket bonding on buccal surface [28].

Before bonding, the facial surface of each premolar was cleaned for 10 seconds with a mixture of water and fluoride-free pumice in a rubber polishing cup using a low-speed contra-angle hand piece. The enamel surface was water rinsed to remove pumice or debris and then dried with an oil-free compressed air [29].

Instructions of the manufacturer were carefully followed for the bonding of the bracket using light-cured orthodontic adhesive Transbond XT (Unitek/3M) consisting of an orthodontic bonding paste and an enamel bonding sealing resin. The buccal surface of the teeth was etched with 37% phosphoric acid gel, Scotchbond (3M) ESPE, for 30 seconds [30,31] followed by thorough washing and drying until a characteristic frosty white etched area was observed. A thin layer of primer (Transbond XT primer, 3M Dental Products) was applied on the etched enamel, and polymerized for five seconds. The adhesive (Transbond XT 3M Unitek) was placed on bracket base.

The bracket was placed firmly on the tooth to desired position and angulation. The excess composite resin was removed carefully from the bracket margin with a dental probe to eliminate any increase in nominal base area and were then light cured by light curing unit for ten seconds on the mesial and 10 seconds on the distal side [32] (total cure time is 20 seconds). All 50 teeth in each five groups with various types of brackets used the same type of bonding technique.

After bonding, all samples were stored in distilled water at room temperature for 24 hours and subsequently tested in shear mode on a universal testing machine (Model 3382; Instron Corp., Canton, Massachusetts, USA) at a cross head speed of 1mm/minute connected to a computer that recorded the results of each test [Table/Fig-3].

Universal testing machine with mounted specimen.

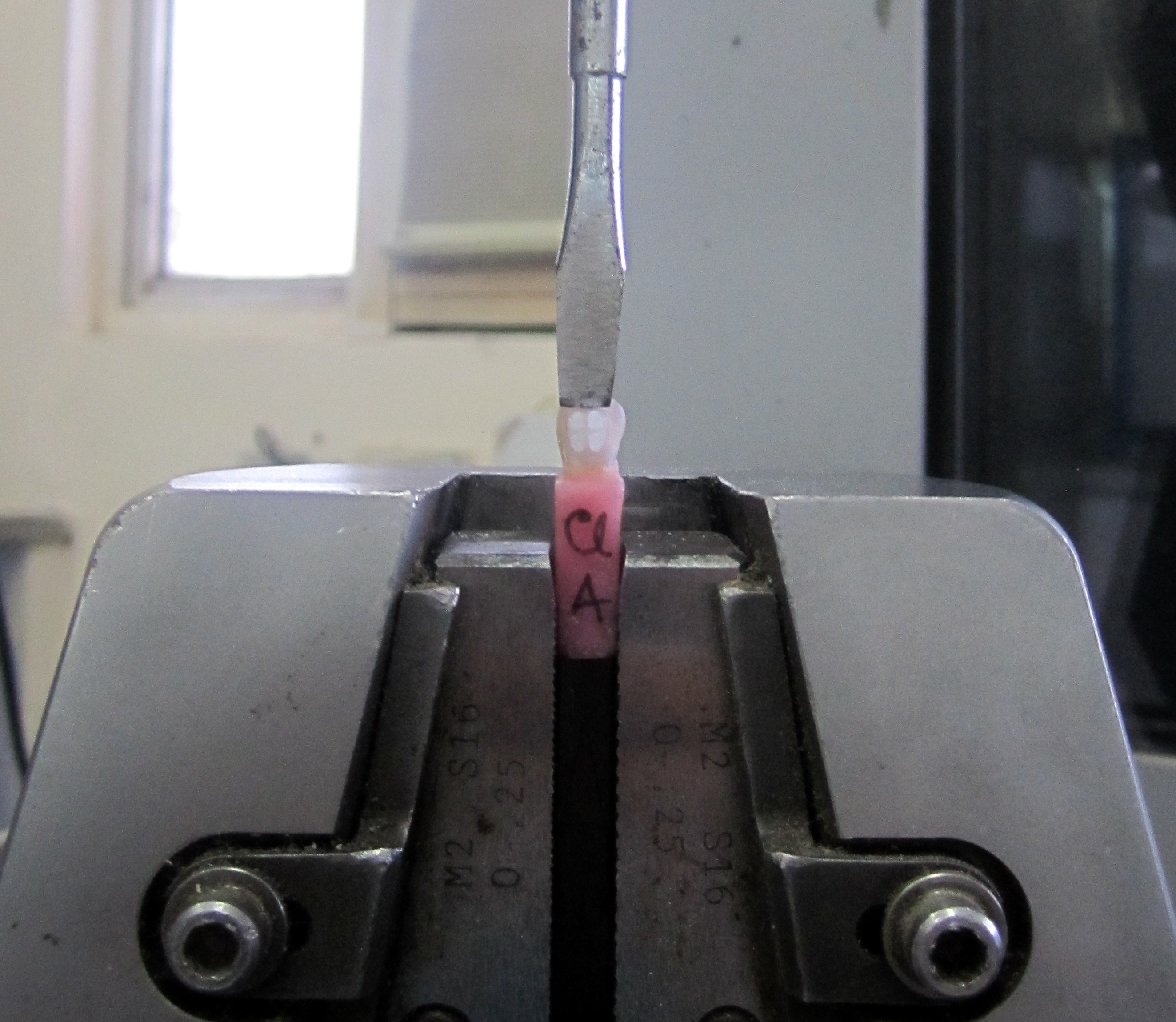

The specimens were secured in the lower jaw of the machine so that the bonded brackets base was parallel to the shear force direction. Force applying chisel was secured in upper jaw and specimens were stressed in an occlusogingival direction at the bracket-tooth interface with the help of chisel [Table/Fig-4].

Stressed specimen at the bracket-tooth interface with the help of chisel.

Upper jaw was moved at a crosshead speed of 1mm/minute [33], the maximum load necessary to debond or initiate bracket-tooth interface fracture was recorded in Newtons and then converted into Megapascals as a ratio of Newtons to surface area of the bracket [34] (SBS in MPa).

Bond strength in MPa = Force (in Newton)/Surface area of bracket (in mm2). After shear mode testing, enamel surfaces of teeth were inspected independently by one evaluator. An optical microscope (Stereomicroscope) at 10X magnification was used to determine the Adhesive Remnant Index (ARI) score at the site of bond failure. This scale ranges from 0 to 3 [35].

Score 0 = no adhesive remaining on the tooth in the bonding area

Score 1 = less than half the bonded area covered by the adhesive

Score 2 = more than half the bonded area covered by the adhesive

Score 3 = All adhesive remaining on the entire bonded area.

SBS data were summarized as Mean±SD and compared by one way analysis of variance (ANOVA) and the significance of mean difference between the groups was done by Tukey’s post-hoc test. The ARI scores were summarized in number and percentage and compared by chi-square (χ2) test. A two-tailed p-value less than 0.05 (p<0.05) was considered statistically significant. All analyses were performed on SPSS software (windows version 17.0).

Results

The present study determines and compares the shear bond strength of ceramic brackets with different base designs. The range mean (± SD) and median of SBS (MPa) of five groups are summarized in [Table/Fig-5].

Shear bond strength of five groups.

| Groups | N | Min | Max | Mean | SD | COV(%) | Median | Fvalue | pvalue |

|---|

| Group 1 | 10 | 13.20 | 29.13 | 20.13 | 5.20 | 25.80 | 20.65 | 13.28 | <0.001 |

| Group 2 | 10 | 23.25 | 28.89 | 27.26 | 1.73 | 6.34 | 28.04 |

| Group 3 | 10 | 13.67 | 20.69 | 17.54 | 1.91 | 10.91 | 17.85 |

| Group 4 | 10 | 14.34 | 31.78 | 23.45 | 5.09 | 21.72 | 23.82 |

| Group 5 | 10 | 13.76 | 22.24 | 17.50 | 2.41 | 13.68 | 17.26 |

Min: Minimum, Max: Maximum, SD: Standard deviation, COV: Coefficient of variation, F: ANOVA F value

The mean SBS of Clarity Advanced was the highest followed by Inspire Ice, Clarity Advanced (APC Flash-free), Gemini Metal and InVu the least (InVu < Gemini Metal < Clarity Advanced (APC Flash-free) < Inspire Ice < Clarity Advanced). Further, coefficient of variation (%) showed that SBS of Clarity Advanced to be least variable (6.34%) followed by InVu (10.91%), Gemini Metal (13.68%), Inspire Ice (21.72%) and Clarity Advanced (APC Flash-free) (25.80%) the highest [Table/Fig-5].

Evaluating the effect of groups on SBS, ANOVA revealed significant effect of groups on SBS (F=13.28, p<0.001) [Table/Fig-5].

Further, comparison of the mean SBS among different groups using Tukey’s test showed the following results [Table/Fig-6].

Comparison of mean shear bond strength (MPa) between groups by Tukey’s test.

| Comparisons | Mean Diff. | Q | p-value | 95% CI ofdiff. |

|---|

| GROUP 1 vs. GROUP 2 | -7.13 | 6.23 | p < 0.001*** | -11.73 to -2.526 |

| GROUP 1 vs. GROUP 3 | 2.60 | 2.27 | p > 0.05 | -2.003 to 7.197 |

| GROUP 1 vs. GROUP 4 | -3.32 | 2.90 | p> 0.05 | -7.915 to 1.285 |

| GROUP 1 vs. GROUP 5 | 2.55 | 2.23 | p > 0.05 | -2.046 to 7.154 |

| GROUP 2 vs. GROUP 3 | 9.72 | 8.50 | p < 0.001*** | 5.123 to 14.32 |

| GROUP 2 vs. GROUP 4 | 3.81 | 3.33 | p > 0.05 | -0.7891 to 8.411 |

| GROUP 2 vs. GROUP 5 | 9.68 | 8.47 | p < 0.001*** | 5.080 to 14.28 |

| GROUP 3 vs. GROUP 4 | -5.91 | 5.17 | p < 0.01** | -10.51 to -1.312 |

| GROUP 3 vs. GROUP 5 | -0.04 | 0.04 | p > 0.05 | -4.643 to 4.557 |

| GROUP 4 vs. GROUP 5 | 5.87 | 5.13 | p< 0.01** | 1.269 to 10.47 |

CI: confidence interval, p>0.05 (not significant), **p<0.01 (moderate significant), ***p<0.001 (highly significant)

Adhesive Remnant Index Score: The ARI score of five groups is summarized in [Table/Fig-7]. The frequency (%) of 0 was highest for InVu (30%) and Gemini Metal (30%), 1 was highest for InVu (60%), 2 was highest for Clarity Advanced (APC Flash-free) (30%) and 3 was highest for Clarity Advanced (80%) [Table/Fig-7].

Comparison of frequency (%) of ARI scores among five groups.

| ARI Score | Group 1(n=10) (%) | Group 2(n=10) (%) | Group 3(n=10) (%) | Group 4(n=10) (%) | Group 5(n=10) (%) | χ2value | p-value |

|---|

| 0 | 0 (0) | 0 (0) | 3 (30) | 0 (0) | 3 (30) | 34.07 | <0.001*** |

| 1 | 2 (20) | 0 (0) | 6 (60) | 1 (10) | 5 (50) |

| 2 | 3 (30) | 2 (20) | 1 (10) | 2 (20) | 2 (20) |

| 3 | 5 (50) | 8 (80) | 0 (0) | 7 (70) | 0 (0) |

***p<0.001(highly significant)

Chi-square (χ2) test was used to compare the frequency (%) of ARI score among the groups. It showed significantly different ARI scores among the groups (χ2=34.07, p<0.001).

Discussion

Ceramic brackets are available in many forms. The expensive ceramic brackets include monocrystalline brackets which have excellent aesthetics while the less expensive ceramic brackets are the polycrystalline brackets which have comparatively poorer aesthetics. One of the important and challenging requirements of these ceramic brackets is to be able to provide adequate bond strength during the orthodontic treatment alongwith easy debonding procedure resulting in minimal damage to the enamel surface. Since, majority of ceramic brackets depend on the mechanical retention to form an acceptable bond, the base designs play an important role in the SBS values. The advantage of the ceramic bracket over metal bracket is affinity of the ceramic brackets to incident light which allows more transmission of light onto the bracket base resulting in high polymerization of the adhesive and thus, providing a high SBS [2].

Several factors such as method of enamel conditioning, com-position of adhesive, bracket retention mechanism as well as method of debonding influence the forces applied for debonding the brackets. In the present study, similar debonding conditions were kept in all the five groups to minimize the variables influencing the debonding characteristics. The results indicated that different base designs have different effects on SBS. Base design charac-teristics were the reason for these results. These results were in accordance with studies conducted by Kang DY et al., and Sharma-Sayal SK et al., [16,36].

In the present study, when comparing the mean SBS of different bracket systems, it was observed that the mean SBS of microcrystalline base (Clarity Advanced) was the highest followed by bead ball base (Inspire ice), Adhesive precoated brackets (Clarity Advanced APC Flash-free), polymer mesh base (InVu), while the bracket system with the least mean SBS was of mechanical mesh base (Gemini Metal). The Clarity Advanced ceramic bracket with microcrystalline base is composed of small glass particles fused to a polycrystalline alumina, which increases the surface area available for adequate bonding and thus, the bond strength. These results were in accordance with studies conducted by Park MG and Kang DY et al., [2,16].

Result showed that the mean SBS of Clarity Advanced (APC Flash-free) was lower than that of Clarity Advanced ceramic brackets showing a significant statistical difference [Table/Fig-6]. These results were in accordance with Bearn et al., Oliver BM et al., Wong M and Power S and Cal Neto JP et al., who reported that the mean SBS of ceramic brackets which were manually coated and bonded with Transbond XT was significantly higher than the adhesive precoated brackets and also the rate of bond failure was higher with adhesive precoated brackets as compared to the conventional brackets [37–40]. Although in contrast to this study Lee M and Kanavakis G observed that the SBS of APC Flash–free group was significantly greater than the manually pasted Clarity Advanced ceramic bracket [26].

Also, there was statistically significant and higher SBS of Inspire Ice than InVu and Gemini Metal [Table/Fig-6]. The bead base surface of Inspire Ice has many round monocrystalline beads as completely distributed over the base surface as possible. These small beads have undercuts for mechanical interlocking of the adhesive resin resulting in the statistically higher SBS than InVu and Gemini Metal brackets. These results were in accordance with studies conducted by Park MG, Kukiattrakoon B and Samruajbenjakul B [2,3,41].

Results also showed that the mean SBS of InVu was lowest among all ceramic brackets [Table/Fig-6]. Since the InVu brackets were the largest (whole bracket base surface area) as compared with the other ceramic brackets, the greater bonding area reduced the bond strength. This is in accordance with a previous study using finite element analysis which stated that bond strength is inversely proportional to the bonding area of the bracket [42]. The larger the bonding area, the higher is the probability that a flaw of critical size is present. Thus, a specific base design which provides a favourable stress distribution should be preferred rather than increasing the bracket dimensions. Irregular surface base of Clarity Advanced and bead ball base of Inspire Ice used in this study may decrease bracket base dimension without affecting SBS. These results were in accordance with studies conducted by Kang DY et al., [16].

Result also showed that the mean SBS of Gemini Metal brackets was lowest among all brackets used in the present study. The lower SBS values of stainless steel brackets are probably due to insufficient light transmission by the shadowing effect of metallic structure as also reported by Park MG and Eslamian L et al., [2,43].

When the bond is tested for failure, there are three main failure sites [44]. These are the bracket base/adhesive interface, the enamel/adhesive interface and cohesive failure.

Highest ARI score 3 was found for Clarity Advanced (80%), Inspire Ice (70%) and Clarity Advanced (APC Flash-free) (50%). This means that debonded brackets had no adhesive remaining on the bracket base and all adhesive remaining on tooth surface resulting in a reduced enamel fracture risk and ultimate bracket bond strength. These results were in accordance with studies conducted by Kukiattrakoon B, Soderquist SA and Samruajbenjakul B et al., [3,32,41].

Lower ARI score 1 was found for InVu and Gemini Metal. This means that debonded brackets had more adhesive remaining on the bracket base and less adhesive remaining on tooth surface resulting in comparatively lower bracket bond strength [Table/Fig-7]. These results were similar with studies conducted by Sibi AS et al., [45].

In the present study, the SBS of all groups exhibited higher values than the minimum orthodontic bracket bond strength as suggested by Reynolds I and therefore, could be considered sufficient for clinical application [46].

Limitation

The present study revealed statistically valid results but a possible limitation of this study was a small sample size. Further studies using a larger sample size and more variety of base designs are recommended.

Conclusion

Bonding of orthodontic brackets to the tooth surface is a necessary procedure in clinical treatment. The bond strength between a bracket and the tooth surface must be highly reliable and is the key to therapeutic success. The present study determined the effect of different bracket base designs on the SBS of orthodontic brackets bonded with Transbond XT. The debonded location of the orthodontic brackets bonded with different base designs were also studied using Stereomicroscope. It was concluded that the mean SBS of Clarity Advanced was significantly higher than Clarity Advanced (APC Flash-free) and InVu. No statistically significant difference was found on comparing Clarity Advanced with Inspire Ice and Clarity Advanced (APC Flash-free) brackets with InVu and Inspire Ice brackets. Between the ceramic brackets and mechanical mesh base metal brackets, it was found that Gemini Metal bracket showed significantly lower SBS than Clarity Advanced and Inspire Ice. However, there were no statistically significant differences when compared with Clarity Advanced (APC Flash-free) and InVu. Comparison of the ARI scores among different groups led to the conclusion that there were significantly (p<0.001) different ARI scores i.e., fracture sites were different among different brackets used.

Min: Minimum, Max: Maximum, SD: Standard deviation, COV: Coefficient of variation, F: ANOVA F value

CI: confidence interval, p>0.05 (not significant), **p<0.01 (moderate significant), ***p<0.001 (highly significant)

***p<0.001(highly significant)