Clinical Instrument Refurbishment-A Chair side Technique

Rohan Pulgaonkar1, Suma Liz Panicker2, Prasad Chitra3

1 Postgraduate Student, Department of Orthodontics and Dentofacial Orthopaedics, Army College of Dental Sciences, Secunderabad, Telangana, India.

2 Private Practitioner, Chitra Dental Clinic, Secunderabad, Telangana, India.

3 Professor and Head, Department of Orthodontics and Dentofacial Orthopaedics, Army College of Dental Sciences, Secunderabad, Telangana, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Rohan Pulgaonkar, Army College of Dental Sciences, Secunderabad-500087, Telangana, India.

E-mail: dr.rohanpulgaonkar@gmail.com

Damage, Distal end cutters, Orthodontic pliers, Sharpness

A pin and ligature and distal end cutter are some of the most commonly used instruments in orthodontic practice. These instruments are also prone to tip damage on account of heavy usage as well as repeated sterilization. Steam sterilization is most common and the quickest method of sterilization; however, it causes corrosion and rusting of orthodontic pliers and damages the cutting edges [1]. When the tips of these instruments break, a clinician is usually left with no option other than replacing the instruments with new ones at considerable cost or getting the instruments retipped or repaired by sending them back to the manufacturer which again entails expense and time loss. In India, this facility of retipping is at present not provided by most of the manufacturers and this means that the instrument has to be discarded and a new one to be purchased.

A simple method of refurbishment of damaged instrument tips is presented. This procedure can be performed in a clinical setting without the use of any specialised equipment. Airotor burs (coarse and fine which are easily available) were used. The advantages of this procedure are:

Immediate reuse of the instrument is possible without loss of time.

The instruments retain their sharpness and can be used for a long time.

The safety hold feature of distal end cutters is not lost.

Procedure can be used for stainless steel and tungsten carbide tips.

It is cost-effective and the procedure can be carried out multiple times on the same instrument if needed. The shortening of the tip due to the procedure is very slight and causes no loss of cutting efficiency.

Refurbishment Procedure:

Mark the desired contour for the instrument tips as shown [Table/Fig-1].

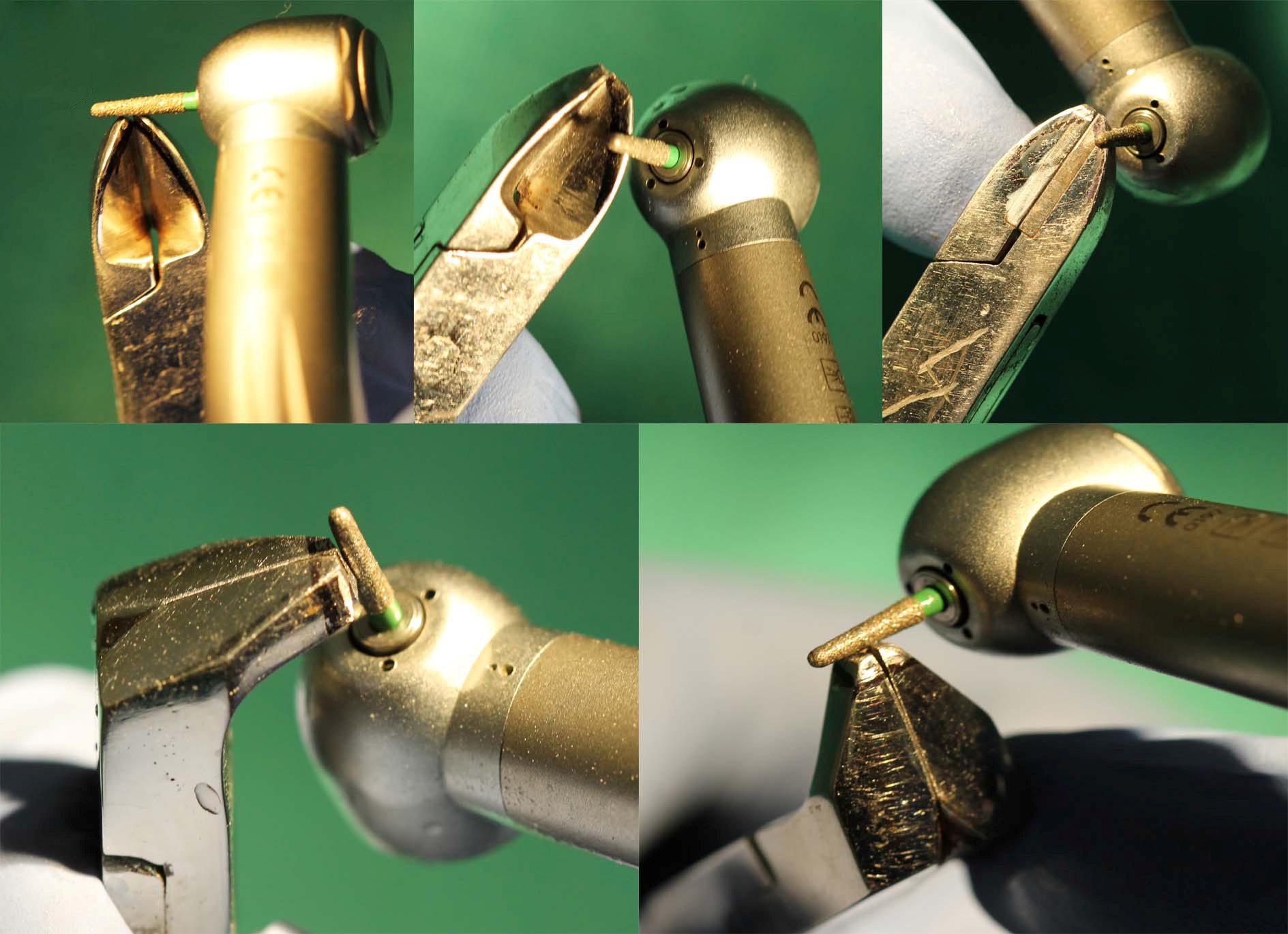

Use coarse airotor burs (Mani™TR – 13 C and/or TR – 26) on both edges of the broken metal tip to gently recontour the sides in the shape of the marking. The removal of metal from both edges of the broken area gives a uniform cutting surface. Ensure that metal is not further removed in the already fractured zone [Table/Fig-2].

The reduced metal surfaces are now smoothened with a fine airotor (Mani™ TR – 13 EF) prior to final finishing.

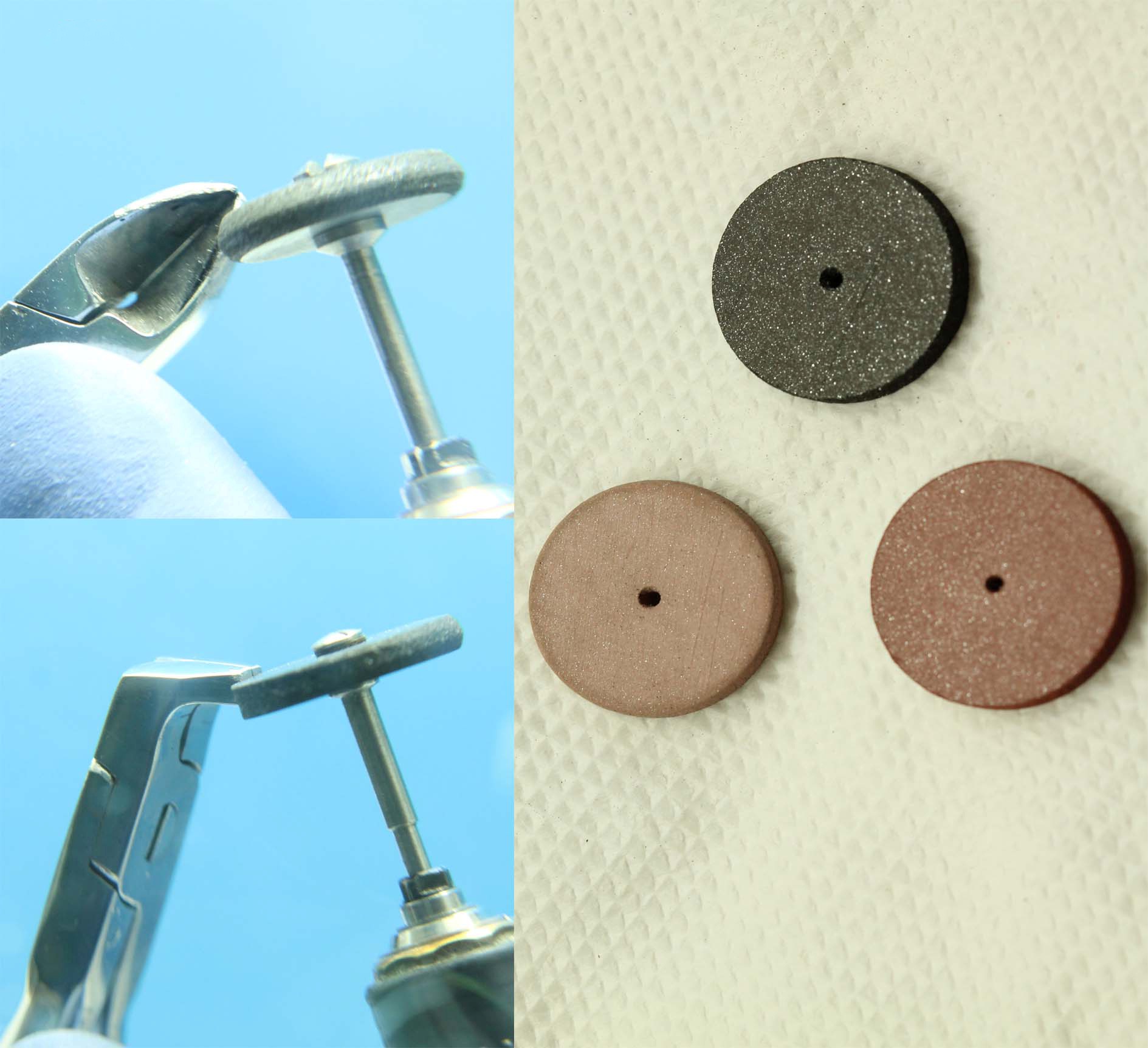

Mounted rubber wheels (metal impregnated for metal polishing) can be used for final polishing to obtain a smooth surface [Table/Fig-3].

The instruments refurbished this way perform well and can undergo repeated use and sterilization procedures with no loss of efficiency [Table/Fig-4].

Marking the contours for adjust.

Recontouring the tips with airotor burs.

Final polishing with mounted rubber wheels.

Refurbished cutting edges.

A video demonstration is available for better understanding at the following link:

https://drive.google.com/folderview?id=0B0qnuimowDYfeURNUUJqa0EzMkE&usp=sharing.

Discussion

A search for published literature on clinical instrument refurbishment in three databases namely Pub Med, Pub Med Central and the Cochrane Library gave no results.

The technique of refurbishment of commonly used cutting instruments in Orthodontics described here works well and helps to significantly increase the working life of an instrument. The main advantage is that the procedure can be carried out by Dentists or Orthodontists themselves without the need for costly equipment. The refurbished instruments are ready for clinical use in a few minutes with new cutting edges of high efficiency. Additionally, multiple instruments can be refurbished and used in a busy practice helping to save sterilization time and costs.

[1]. Yezdani A, Mahalakshmi K, Padmavathy K, Orthodontic instrument sterilization with microwave irradiationJ Pharm Bioallied Sci 2015 7(Suppl 1):S111-15. [Google Scholar]