Wispy Prosthesis: A Novel Method in Denture Weight Reduction

Gopinadh Anne1, Sreedevi Budeti2, Sampath Kumar Anche3, Srujana Zakkula4, Jyothi Atla5, Ravi Rakesh Dev Jyothula6, Krishna Chaitanya Appana7, Vijaya Kumar Peddinti8

1 Professor and Head of Department, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

2 Professor, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

3 Reader, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

4 Senior Lecturer, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

5 Senior Lecturer, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

6 Senior Lecturer, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

7 Post Graduate Student, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

8 Post Graduate Student, Department of Prosthodontics, Sibar Institute of Dental Sciences, Guntur, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Krishna Chaitanya Appana, C/O Sai Appana’s Dental Home, Y N College Street, Narsapur-534275, W.G.DT, India.

E-mail: chaitanya.bmw@gmail.com

Introduction

Stability and retention of the denture becomes at stake with the increase in weight of the denture prosthesis. As a consequence, different materials and methods have been introduced to overcome these issues but denture weight reduction still remains to be a cumbersome and strenuous procedure.

Aim

To introduce a novel technique for the fabrication of denture prosthesis where in the weight of the denture will not affect the retention and stability of the denture.

Materials and Methods

Four groups with a sample size of 10 each, were included where in one group was control and other three were study groups. The control group samples were made completely solid and the study group samples were packed with materials like bean balls, cellulose balls and polyacrylic fibers. The weight of all the samples of each study group was measured and compared with the control group. The observations were analyzed statistically by paired t-test.

Results

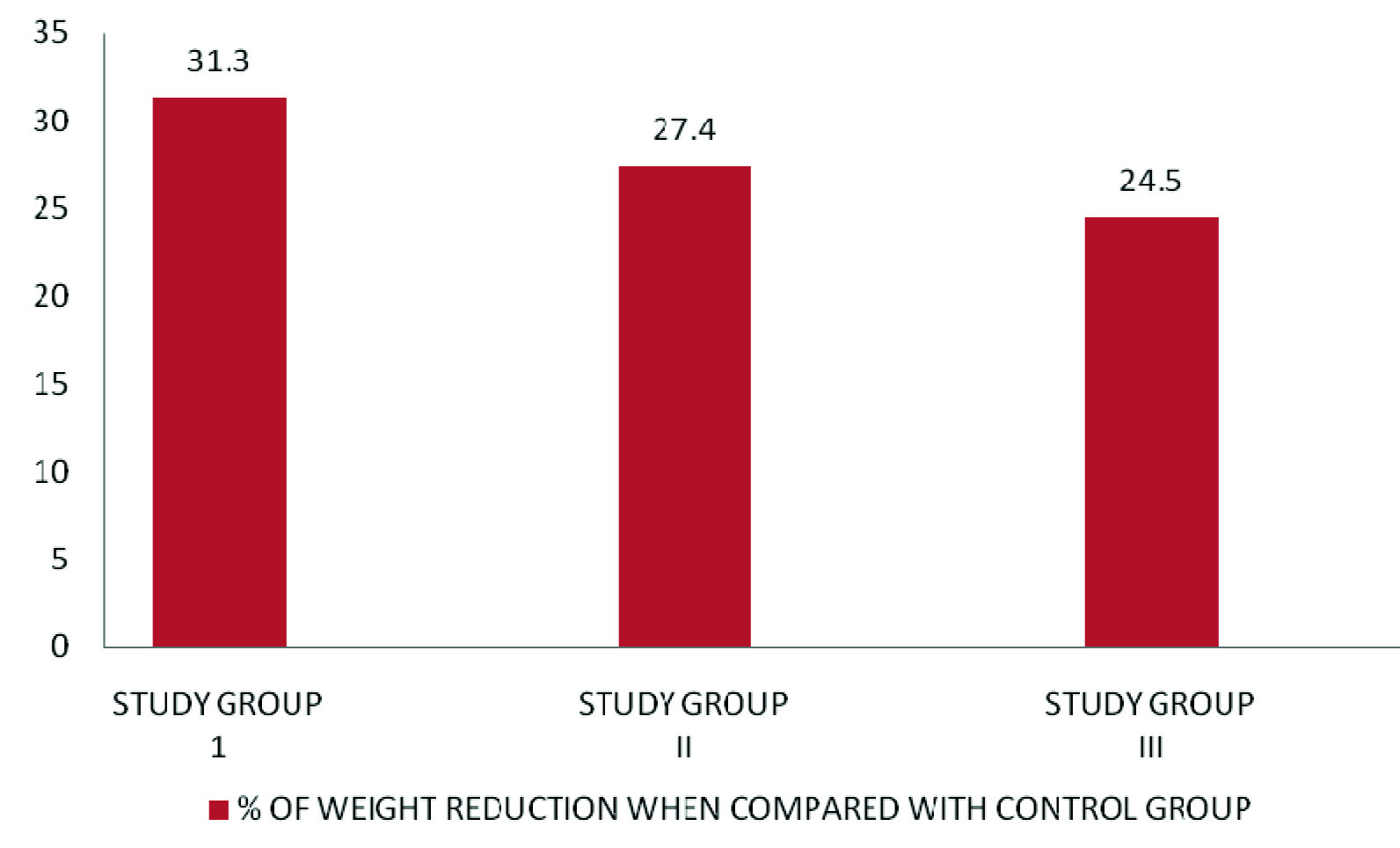

It was observed that the bean balls group produced a weight reduction of 31.3%, cellulose balls group 27.4% and polyacrylic fibers group 24.5% when compared to that of the control group.

Conclusion

This novel technique will eliminate the problems that were associated in creating hollowness and at the same time will reduce the weight of the prosthesis and among all the study groups, bean balls group were found to reduce maximum weight of the prosthesis.

Bean balls, Cellulose balls, Hollow, Obturator

Introduction

The management of congenital and acquired palatal defects has always been challenging as the increase in maxillary rim length results in increase in the bulk of the denture, compromising the stability and retention of the prosthesis. To overcome this, it has been recommended to make the denture hollow which in turn reduces the weight of the prosthesis [1]. To achieve hollowness inside the denture different accessory materials which don’t bind with the acrylic have been used such as a solid three dimensional spacer including dental stone [2], cellophane wrapped asbestos [3], silicone putty [4], acrylic shim [5], polyurethane foam [6], sugar [7,8], ice [9], visible light-polymerized resin [10,11] and modeling clay [12]. These materials were incorporated during laboratory processing to exclude denture base material from the planned hollow cavity of the prosthesis. Once the denture polymerization was completed, then the packed accessory material inside the denture would be removed. However, the retrieval of the packed material was laborious and cumbersome. Further, it resulted in alteration of the tissue surfaces which were recorded with utmost care. Several authors have proposed different techniques for creating hollowness. Some of them have been described here. Holt processed a shim of indexed acrylic resin over the residual ridge and used a spacer which was then removed and the two halves were luted with auto polymerized acrylic resin [4].

Fattore et al., introduced a double flask technique for fabrication of obturator where heat polymerized acrylic resin was added over the definitive cast in one drag and the processing of minimal thickness of acrylic resin around the teeth was done in different drag [13]. Later, both the portions of resin would be attached using a heat polymerized resin. Worley and Kniejski described a method that allowed for the fabrication of a true closed hollow obturator while controlling the thickness of the hollow portion and eliminating auto polymerized resin seams [14]. O’Sullivan et al., described a modified method for fabricating a hollow maxillary denture in which a trial denture base was made of clear matrix and then the trial denture base was invested in the conventional manner until wax elimination [1]. Later, a 2mm heat polymerized acrylic shim was made on the master cast by another flask and silicone putty was placed over the shim. The thickness of the putty was estimated by the clear template. The flask where the teeth were invested was placed over the putty attached flask and the processing was done. After the completion of processing the putty was removed from the distal ends of denture and the openings were closed by auto polymerizing resin. This technique has its own pros of estimating the spacer thickness and cons of difficulty in removal of putty and making the distal openings as large as possible for removal of putty.

So, to eliminate the problems that were associated with hollow dentures a novel technique was specified wherein there is no such necessity of retrieving the accessory materials. These accessory materials can be left undisturbed to occupy high volume and at the same time must have lesser weight than that of acrylic. Several materials were tested on this aspect and three materials were finalized. But, to confirm the best among the selected materials a short study was conducted. So, the aim of the article was to find out which material among the study groups would better aid in reducing the acrylic denture weight.

Materials and Methods

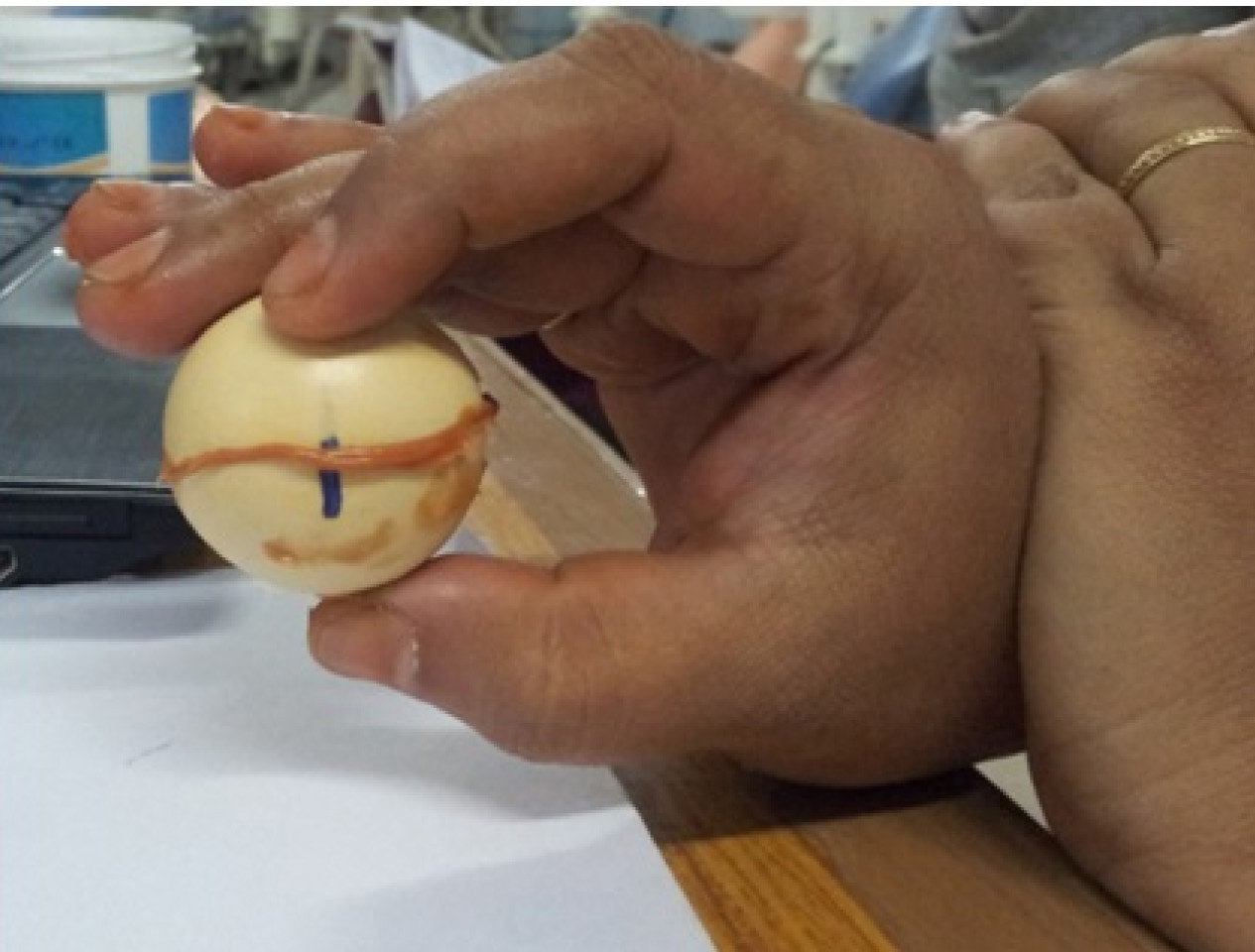

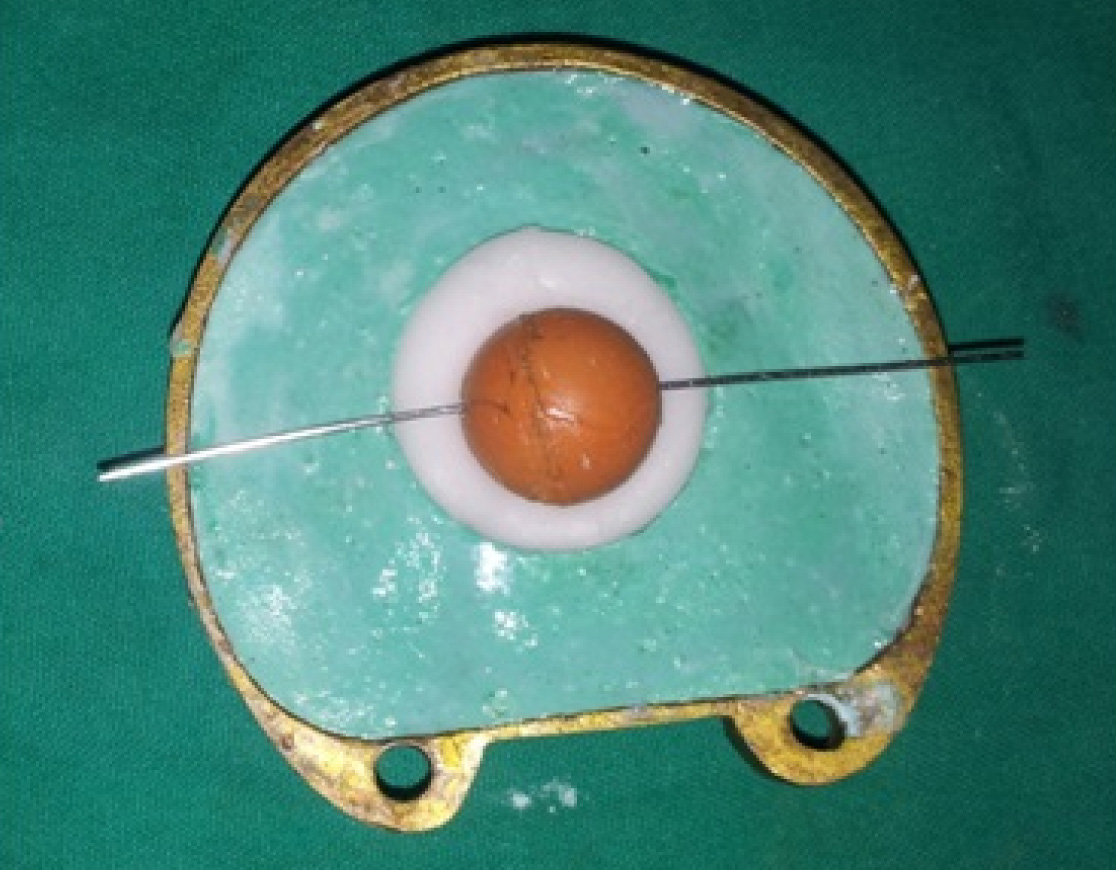

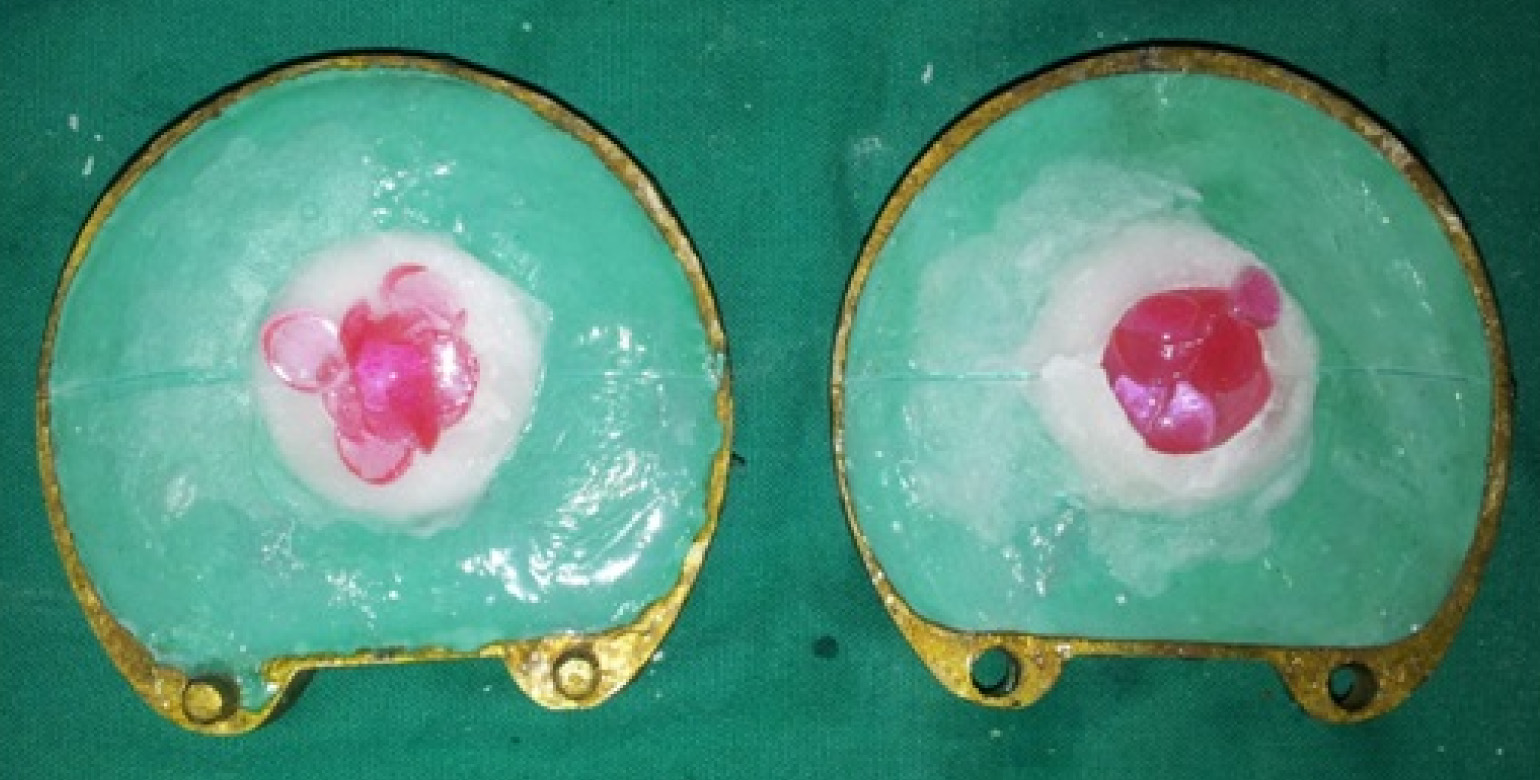

The current study was conducted in the Department of Prosthodontics, SIBAR Institute of Dental Sciences, Guntur, Andhra Pradesh. The aim of the study was to evaluate the weight reduction of acrylic resin in the denture prosthesis via different materials. There were four groups, one control and three study groups and the sample size in each group was 10. To compare between the study and control groups it was necessary to standardize the samples. The accessory materials selected for study groups were bean balls, cellulose balls and polyacrylic fibers. Evaluation of the weight reduction using a denture is a cumbersome procedure. So, to get a uniform mold space for all the samples, table tennis balls were selected and flasked individually [Table/Fig-1]. After the flasking procedure the flask parts were separated and the table tennis balls were retrieved [Table/Fig-2].

Flasking of table tennis ball.

Mold space that was created after dewaxing.

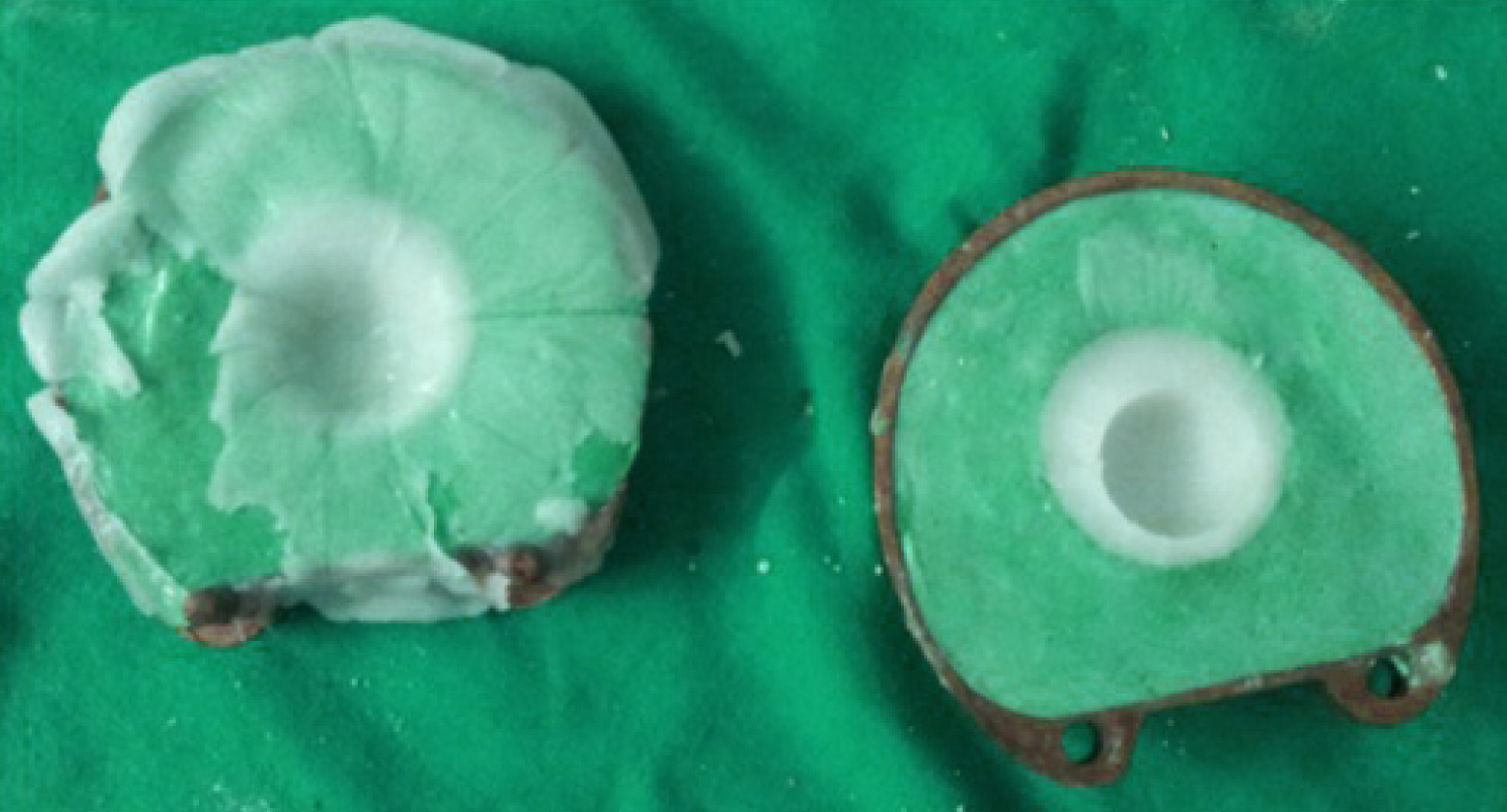

Now, a uniform outer space was created and the next important task was to create a uniform inner mold space too. For that reason a glass marble of diameter smaller than that of table tennis ball was selected and duplicated by putty. In order to the created mold space by the glass marble, regular body poly vinyl siloxane material was injected and allowed to set [Table/Fig-3]. Later for the purpose of suspending the elastomeric ball and to create a uniform space equally, a 20 gauge wire was inserted through and through the elastomeric ball [Table/Fig-4,5].

Making of elastomeric ball by regular body for creating uniform inner mold space

Suspension of elastomeric ball by 20 gauge wire.

Uniform inner mold space created by suspended elastomeric ball.

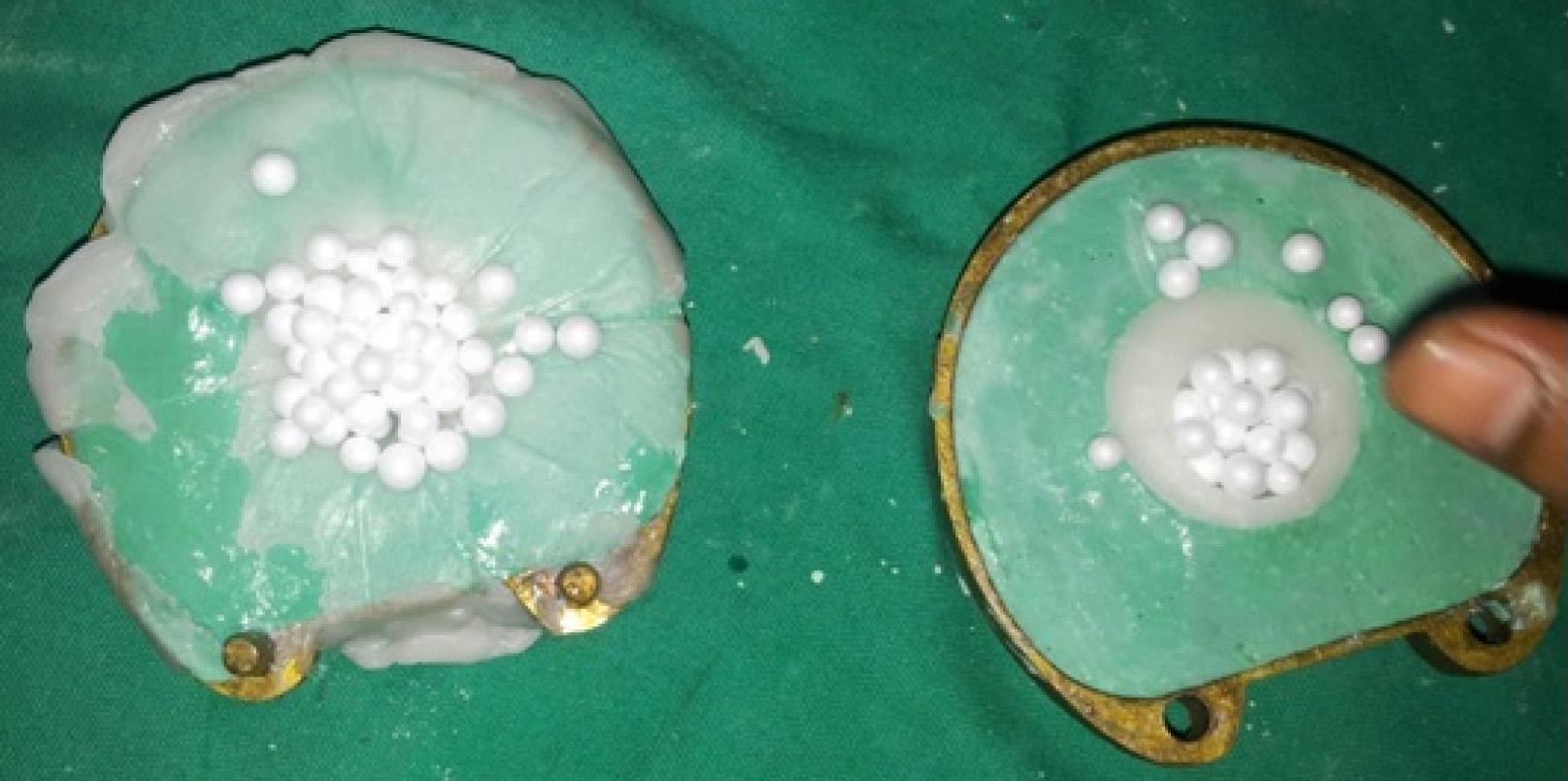

In control group all the samples were completely solid and in study group all the samples were packed with the obtained mold space by elastomeric ball during trial closure with the three different study groups i.e. bean balls [Table/Fig-6], polyacrylic fibers [Table/Fig-7] and cellulose balls [Table/Fig-8]. After bench curing, the normal polymerization procedure was carried out. The processed balls were retrieved, finished and polished. Finally the weights of all the processed 40 acrylic balls were measured electronically [Table/Fig-9].

Packing of bean balls into the inner mold space.

Packing of polyacrylic fibers into the inner mold space.

Packing of cellulose balls into the inner mold space.

Measuring each sample weight by electronic weighing machine.

All the observations were tabulated [Table/Fig-10] and subjected to statistical analysis for their mean and standard deviation [Table/Fig-11] by paired t-test. The obtained means by the study groups were compared with the control group for amount of weight reduction in percentage by a formula given by Kobayashi K, Shimoda S, Nakagawa Y, Yamamoto A [15].

Electronically weighed measurements of all the 10 samples in each group.

| Sample | Control(Solid) | Study Group I(Bean Balls) | Study Group II(Cellulose Balls) | Study Group III(Polyacrylic Fibers) |

|---|

| 1 | 35.60 | 24.25 | 25.75 | 26.90 |

| 2 | 35.10 | 24.75 | 25.50 | 27.30 |

| 3 | 36.00 | 23.75 | 26.00 | 26.30 |

| 4 | 35.30 | 24.10 | 25.25 | 26.10 |

| 5 | 35.70 | 23.90 | 25.80 | 26.50 |

| 6 | 34.80 | 24.60 | 25.50 | 25.80 |

| 7 | 35.20 | 24.85 | 25.65 | 26.60 |

| 8 | 35.60 | 24.40 | 25.50 | 27.20 |

| 9 | 35.25 | 24.25 | 26.35 | 27.10 |

| 10 | 34.90 | 23.95 | 25.15 | 26.80 |

Mean and Standard deviation of all the four groups.

| Group | No. of Samples | Mean ± StandardDeviation |

|---|

| Control | 10 | 35.35 ±0.38 |

| Study Group I(Bean Balls) | 10 | 24.28 ± 0.37 |

| Study Group II(Cellulose Balls) | 10 | 25.65 ± 0.35 |

| Study Group III(Polyacrylic Fibers) | 10 | 26.66 ± 0.49 |

Here, Error denotes weight reduction; A denotes mean in study group; B denotes mean in control group.

Results

The results of all the four groups that were elicited in [Table/Fig-10,11] were obtained by paired t-test and the values were found to be statistically significant (p-value was 0.0001). The means of all the groups were substituted accordingly in the above mentioned formula given by Kobayashi K, Shimoda S, Nakagawa Y, Yamamoto A [15]. From that formula %weight reduction of the study groups was calculated. Study group I i.e., bean balls group produced 31.3% weight reduction, whereas cellulose balls group produced 27.4% and polyacrylic fibers group produced 24.5%. Tabular and graphical representations of % weight reduction were elicited in [Table/Fig-12,13]. The reason for bean balls group to produce highest weight reduction among all the study groups was they occupy more volume and at the same time produce less weight to the prosthesis.

Percentage of weight reduction of the study groups in comparison with control groups.

| Group | % of Weight Reduction |

|---|

| Control Vs Study Group 1(Bean Balls) | 31.3 |

| Control Vs Study Group II(Cellulose Balls) | 27.4 |

| Control Vs Study Group III(Polyacrylic Fibers) | 24.5 |

Graphical representation of the weight reduction (%) of study groups in comparison with control group.

Discussion

Due to the developmental or acquired defects of the maxilla and in cases of increased ridge resorption, the maxillary rim length is increased, that in turn increases the weight of the maxillary denture. If conventional maxillary denture is constructed in such a situation then it would result in increased weight of the maxillary denture that may result into resorption of maxillary edentulous foundation at a higher rate. As said by O’Sullivan et al., heavy maxillary denture may further compound the poor denture-bearing ability of the tissues and lead to decreased retention and resistance [1]. However, reducing the weight of the maxillary prosthesis by making the maxillary denture hollow has been shown to be beneficial [16].

Hollowing the denture in denture weight reduction is not a recent concept. However, the problems associated in creating the hollowness remains the same till date. Kalavathy et al., stated that to increase the retention and stability of heavy prosthesis, many methods have been tried like utilizing the undercuts, modifying the impression technique, use of magnets and use of implants, etc., [17]. There were several materials that were tried to create hollowness as mentioned previously. However, each material has its own pros and cons, and at the end these materials have to be retrieved either by placing holes near the packed region or by altering the tissue surface of the denture, which was an unacceptable as well as a cumbersome procedure. Several methods were also proposed by different people like Fattore et al., [13] double flask technique, Holt [4] technique, Worley & Kniejski [14] technique, O’Sullivan et al., [1] clear matrix method. But, these procedures are a bit difficult and were technique sensitive.

The main reason behind hollowing the denture is to reduce the denture weight. If the same be achieved without retrieving the accessory material, that would put an end to these problems. That same thought had led us to propose this new technique of weight reduction. But to achieve the same the packed materials must be of lesser weight than the polymer and at the same time should occupy more volume. After a long research, we have finalized these materials i.e. bean balls, cellulose balls and polyacrylic fibers, these materials occupy more volume and also have lesser weight than acrylic polymer.

As we are leaving them in the prosthesis itself and at the same time were not creating any hollowness, we can’t justify the name hollow to this prosthesis. So, we came up with a new word called ‘Wispy’. Wispy is a synonym for feathery. This wispy prosthesis eliminates the above mentioned problems and is much handy for the operator and even more convenient in delivering the prosthesis with reduced weight. This wispy prosthesis is advantageous when compared with the previous ones because the main motto of reducing the prosthesis weight is being solved without creating any hollowness and at the same time has very minimal disadvantages like trial closure is must for packing the accessory materials, that too in speculated time. For that reason the operator should be as quick as possible.

So, we proudly say that this wispy prosthesis brings a revolutionary change in reducing the prosthesis weight as the cumbersome and laborious procedure of removing the packed material as seen in previous methods was not necessary.

Limitations

During the packing procedure trial closure has to be done, for creating hollowness and to pack these accessory materials. The operator must be very quick enough to do the above mentioned steps in the speculated time.

Conclusion

The novel technique described in the article will eliminate the above mentioned problems as the packed material need not be retrieved and at the same time will reduce the weight of the prosthesis. In this short study, every study group has produced a significant reduction in denture weight but among all, the bean balls group produced the most. Using which material in prosthesis weight reduction entirely depends on the operator choice.

[1]. O’Sullivan M, Hansen N, Cronin RJ, Canga DR, The hollow maxillary complete denture:A modified techniqueJ Prosthet Dent 2004 91(6):591-94. [Google Scholar]

[2]. Ackerman AJ, Prosthetic management of oral and facial defects following cancer surgeryJ Prosthet Dent 1955 5(3):413-32. [Google Scholar]

[3]. Worley JL, Kniejski ME, A method for controlling the thickness of hollow obturator prosthesisJ Prosthet Dent 1983 50(2):227-29. [Google Scholar]

[4]. Holt RA, A hollow complete lower dentureJ Prosthet Dent 1981 45(4):452-54. [Google Scholar]

[5]. Chalian VA, Barnett MO, A new technique for constructing a one-piece hollow obturator after partial maxillectomyJ Prosthet Dent 1972 28:448-53. [Google Scholar]

[6]. Tanaka Y, Gold HO, Pruzansky S, A simplified technique for fabricating a lightweight obturatorJ Prosthet Dent 1977 38:638-42. [Google Scholar]

[7]. Matalon V, La Fuente H, A simplified method for making a hollow obturatorJ Prosthet Dent 1976 36:580-82. [Google Scholar]

[8]. Parel SM, LaFuente H, Single-visit hollow obturators for edentulous patientsJ Prosthet Dent 1978 40:426-29. [Google Scholar]

[9]. Schneider A, Method of fabricating a hollow obturatorJ Prosthet Dent 1978 40:351 [Google Scholar]

[10]. Benington IC, Light-cured hollow obturatorsJ Prosthet Dent 1989 62:322-25. [Google Scholar]

[11]. Polyzois GL, Light-cured combination obturator prosthesisJ Prosthet Dent 1992 68:345-47. [Google Scholar]

[12]. DaBreo EL, A light cured interim obturator prosthesis: a clinical reportJ Prosthet Dent 1990 63(4):371-73. [Google Scholar]

[13]. Fattore LD, Fine L, Edmonds DC, The hollow denture: An alternative treatment for atrophic maxillaeJ Prosthet Dent 1988 59:514-16. [Google Scholar]

[14]. Worley JL, Kniejski ME, A method for controlling the thickness of hollow obturator prosthesesJ Prosthet Dent 1983 50:227-29. [Google Scholar]

[15]. Kobayashi K, Shimoda S, Nakagawa Y, Yamamoto A, Accuracy in measurement of distance using limited cone-beam computerized tomographyInt J Oral Maxillofac Implants 2004 19(2):228-31. [Google Scholar]

[16]. Brown KE, Fabrication of hollow-bulb obturatorJ Prosthet Dent 1969 21(1):97-103. [Google Scholar]

[17]. Kalavathy N, Shetty MM, Premnath Pawashe K, Patel RKV, Hollow mandibular complete denture - a case report. SRM UniversityJournal of Dental Sciences 2010 1(3):243-46. [Google Scholar]