One of the primary goals in orthodontics is to provide the most efficient tooth movement possible. Friction in orthodontic treatment does exist and is thought to reduce the efficiency of orthodontic appliances during sliding mechanics. During sliding mechanics, a friction force is produced at the bracket archwire-ligature unit which tends to counteract the applied force and in turn resists the desired movement [1]. In fixed orthodontic treatment, due to friction, about 12% to 60% of applied force is lost. The friction at bracket-archwire-ligature interface is determined by the combination of mechanical and chemical factors [2]. Thus whenever there is treatment planning of orthodontic tooth movement, the frictional forces should be eliminated or minimized.

Friction force has two components, static and dynamic friction. The static friction is initial friction between archwire and bracket, when force is applied. It must be overwhelmed to initiate tooth movement. As tooth moves, the dynamic friction comes into action. The archwire moves in the direction of applied force as it is directed through the molar and premolar bracket slot [3]. There are many factors that affect friction, such as wire alloy composition [1,4–7], wire dimensions [8–11], bracket material [4,12,13] and the test variables including bracket archwire angulations [11], dry and wet conditions [5,8,14] and ligation method and material [8,15–18].

Various methods have been used to reduce the friction of ligation, such as stainless steel ligature, self ligating brackets. Stainless steel ligature create variable ligation forces and are very time overwhelming to place. Some self ligating bracket system can lead to reduced treatment time and low frictional resistance as measured in laboratory, but are more costly [2]. In 1960s, elastomeric modules were introduced in orthodontics, and they have replaced the stainless steel ligature. These elastomeric modules have several advantages like quick application and removal, enhanced patient comfort and convenience in various colors for better patient acceptance [19]. The polyurethane ligatures adhere with high contact to metal archwires but some ligatures have been fabricated with the goal of decreasing the coefficient of friction to allow easier movement of the archwire along the brackets.

A single module produces a ligation force of 50-150 grams. Modules covalently coated with metafasix (super slick) have been claimed to reduce the friction of ligation by 60% compared with uncoated module with similar elastic properties would be of clinical benefit only if the coating remained functional in oral cavity [2].

Similarly synergy modules are silicone injected and produce less amount friction compared to the conventional modules. The Octavia ties and slide ligature module having different physical shape like figure of 8, because of this it cannot actively bind the wire in mesial and distal end of brackets and help in reducing the friction.

The aim of the present invitro study was to determine the friction between archwire of different sizes, cross-section, alloy and brackets ligated with different brands of low friction elastic ligatures.

Materials and Methods

The present invitro study was carried out to compare the frictional resistance produced by non conventional elastomeric ligature of four different companies, during sliding mechanics using seven archwires of different sizes, cross section, and alloy.

Inclusion Criteria: Brackets of 0.022″ slots with MBT prescription of 3M company, Low friction elastic ligature of four different types, Arch wire without dent of different sizes cross section and alloy were used. Artificial saliva was used to simulate wet oral condition. Exclusion criteria was the placement of bracket was not in arch form.

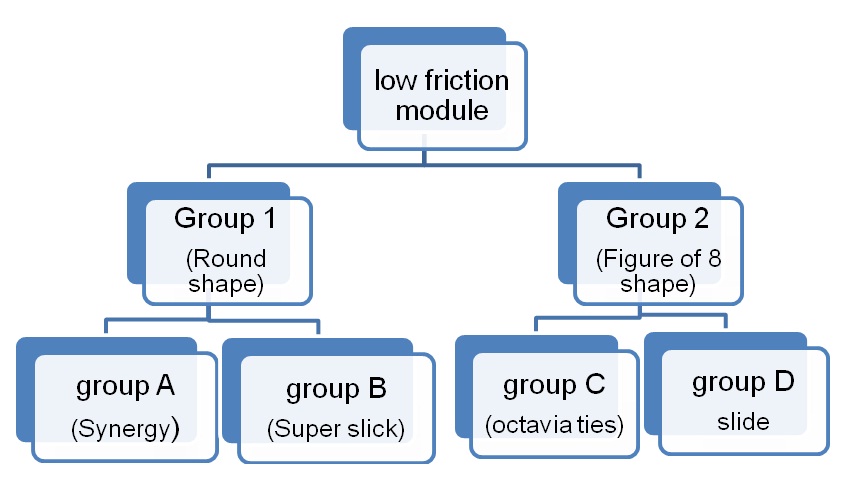

The following materials were used as shown in [Table/Fig-1]. Low friction module was divided in following groups as shown in [Table/Fig-2].

| Experimental Groups | Mean Score for Smear Layer |

|---|

| Coronal 3rd | Middle 3rd |

|---|

| Upper left central incisor brackets(MBT prescription) | 0.022″ X 0.028″ | 3M Unitek |

| Archwire | Dimension | Description |

| NiTi | 0.014″ | G & H |

| NiTi | 0.016″ | G & H |

| Stainless Steel | 0.016″ X 0.022″ | G & H |

| NiTi | 0.017″ X 0.025″ | G & H |

| Stainless Steel | 0.017″ X 0.025″ | G & H |

| TMA | 0.017″ X 0.025″ | G & H |

| Stainless Steel | 0.019″ X 0.025″ | G & H |

| Ligature module | Specification | Description |

| Slideelastomeric module | Figure of eight type | Leone |

| Octovia ligature module | Figure of eight type | Desire |

| Superslick elastomeric module | Coated with covalently bonded metafasix | TP orthodontics |

| Synergy module | Coated with silicone | RMO orthodontics |

Low friction module divided in following groups as shown in figure.

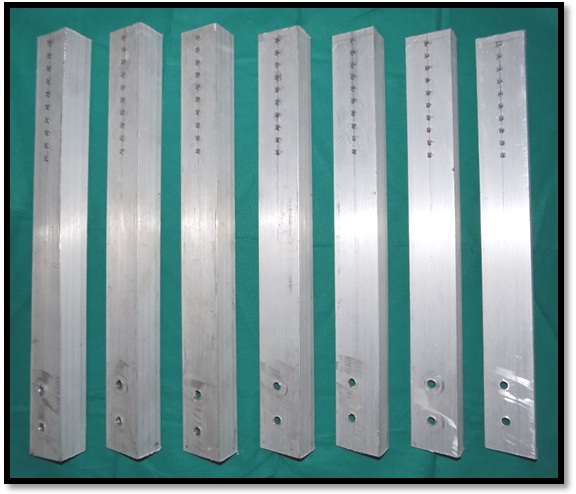

Preparation of test assemblies: The 10 maxillary left central incisor brackets were arranged with the preliminary insertion of a 0.021″x 0.028″ stainless steel archwire through the brackets slots, without ligation, before bonding. This arrangement was done on the specially designed metal plate jig.

After bonding of the brackets on the metal plate with the help of cynoacrylate resin, the 0.021″x0.028″ stainless steel arch wire was accurately removed, and for each group respective wire was placed and ligated with specific module with the help of Mathew module applicator forcep for that group.

Seven types of such jigs were used in this study with different bracket, archwire and module combinations [Table/Fig-3].

For every wire a new jig was used and for every module a new wire was used for testing.

Each metal plate had line parallel to its long axis. This was to benefit in aligning the pull of the wire through the brackets so that friction was not persuaded by hostile tipping or torsion moments.

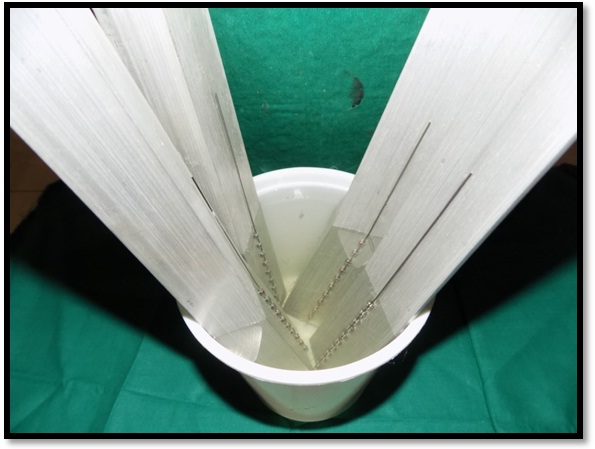

Standardization Protocol Following During Testing: Each arch wire /bracket slot was cleaned with spirit; respective modules were placed on bracket /archwire assemblies and dipped into the artificial saliva, one hour before each test [Table/Fig-4].

Metal jigs with wire and module dipped in artificial saliva.

The bracket/archwire/module assembly was vertically mounted on the base on the Universal testing machine (computerized, software based) Company: Star Testing System, India. Model No. STS 248, Accuracy of the machine: ±1% [Table/Fig-5,6].

Universal testing machine.

Testing jig mounted on universal testing machine.

The archwire extended from the bracket was carefully secured, so that wire was parallel to the line notched on metal plate and to the long axis of the machine.

This device allows the wire to move along the brackets as an axial tensile force was applied by the machine with a speed of 5mm/min for 5mm distance.

The force exerted by different types of module is received and retrieved samples were recorded in the form of static and dynamic friction force resistance.

The static resistance to sliding was determined by the peak force that was needed to initiate movement. The kinetic resistance to sliding was taken as the force at 5 mm of wire/bracket sliding. Ten unique tests were run for each of the four ligature groups with seven different wires. Care was taken not to twist the test wire.

Four different low frictional modules were tested. All measurements were performed at room temperature of 27 ± 2°C. In this study two frictional resistance were measured i.e. static friction and dynamic friction by comparing four different types of ligature on seven different types of wire.

Statistical Analysis

Descriptive statistical data, including mean and standard deviation values were calculated for each bracket-archwire combinations for static and dynamic force. The differences of forces observed between the four groups of ligatures for each archwire was compared using ANOVA (one-way analysis of variance) test. The difference of forces in between each pair of groups for each archwire was calculated by Post-Hoc LSD (Least significant difference) test. The level of significance of 5% was considered so that the mean difference of p<0.05 was taken significant. The Data was analysed using statistical software (Statistical Package for the Social Sciences for Windows, version 19 (SPSS).

Results

Mean static friction force (gm) in four groups at difference archwires and mean dynamic friction force (gm) in four groups at difference archwires are shown [Table/Fig-7,8] respectively.

Mean static friction force (gm) in four groups at difference archwires.

| Wire | Static Force-gm (Mean±S.D) |

|---|

| Group A | Group B | Group C | Group D |

|---|

| 0.014″NiTi | 955.0 | 963 | 92 | 38 |

| 0.016″NiTi | 1104 | 977 | 219 | 39.0 |

| 0.017″x0.025″NiTi | 1952 | 1710 | 403 | 53.0 |

| 0.016″x0.022″stainless steel | 1521 | 1450 | 293 | 39 |

| 0.017″x0.025″stainless steel | 1917 | 1519 | 381 | 41 |

| 0.019″x0.025″stainless steel | 1924 | 1678 | 403 | 49 |

| 0.017″x0.025″ TMA | 2213. | 1841 | 433 | 204 |

Mean dynamic friction force (gm) in four groups at difference archwires.

| Wire | Dynamic Force -gm (Mean±S.D) |

|---|

| Group A | Group B | Group C | Group D |

|---|

| 0.014″NiTi | 900.4 | 893.6 | 78 | 28.8 |

| 0.016″NiTi | 1014.2 | 899.2 | 191 | 28.8 |

| 0.017″x0.025″NiTi | 1899.8 | 1606.8 | 378.2 | 43.4 |

| 0.016″x0.022″stainless steel | 1469.6 | 1415.8 | 272.6 | 32 |

| 0.017″x0.025″stainless steel | 1867.8 | 1465.2 | 276.8 | 33 |

| 0.019″x0.025″stainless steel | 1888 | 1591.8 | 346.6 | 42.8 |

| 0.017″x0.025″ TMA | 2175.6 | 1794.4 | 409.6 | 191.4 |

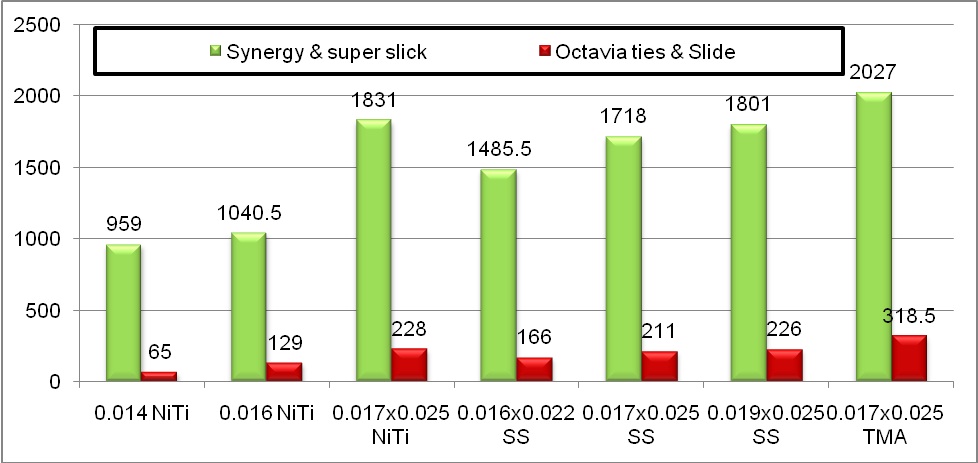

The mean static friction force for all seven types of wires was lower in Group 2(C, D) combined compared to Group 1 (A, B) and the difference was statistically very highly significant (p<0.001) as shown in [Table/Fig-9].

Mean static friction force (gm) in two groups group 1 and group 2 Unpaired t-test.

| Wire | Group1 (A & B) | Group 2 (C & D) | Mean differ-ence | t | p-value |

|---|

| 0.014″NiTi | 959.00±120.91 | 65.00±30.69 | 894.00 | 32.049 | <0.001 |

| 0.016″NiTi | 1040.50±121.24 | 129.00±102.44 | 911.50 | 25.682 | <0.001 |

| 0.017″x0.025″NiTi | 1831.00±195.90 | 228.00±185.15 | 1603.00 | 26.595 | <0.001 |

| 0.016″x0.022″stainless steel | 1485.50±123.95 | 166.00±132.92 | 1319.50 | 32.469 | <0.001 |

| 0.017″x0.025″stainless steel | 1718.00±280.56 | 211.00±175.50 | 1507.00 | 20.366 | <0.001 |

| 0.019″x0.025″stainless steel | 1801.00±168.36 | 226.00±186.93 | 1575.00 | 27.999 | <0.001 |

| 0.017″x0.025″ TMA | 2027.00±214.23 | 318.50±125.42 | 1708.50 | 30.779 | <0.001 |

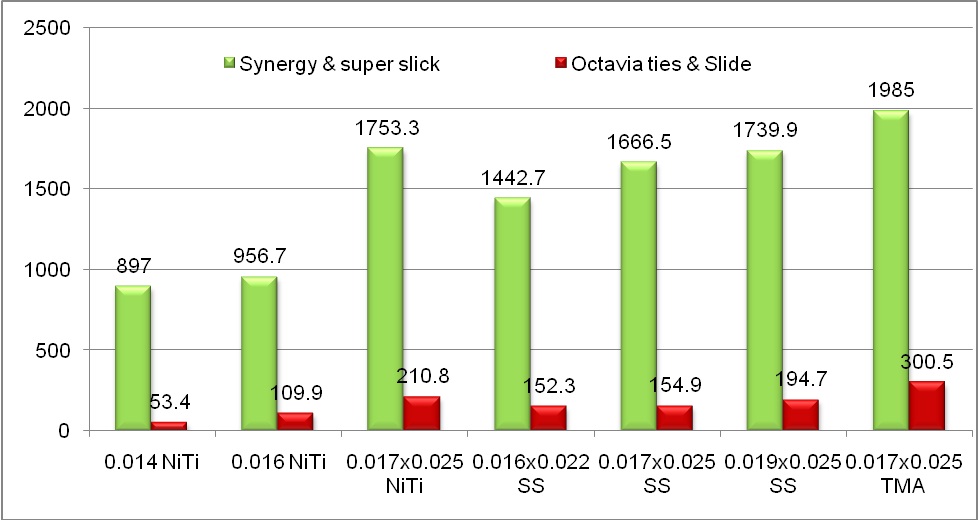

The mean dynamic friction force for all seven types of wires was lower in Group 2 (C, D) combined compared to Group 1 (A, B). And the difference was statistically very highly significant (p<0.001) as shown in [Table/Fig-10].

Mean dynamic friction force (gm) in two groups group 1 and group 2 Unpaired t-test.

| Wire | Group1 (A & B) | Group 2 (C & D) | Mean differ-ence | t | p-value |

|---|

| 0.014″NiTi | 897.00±102.13 | 53.40±27.58 | 843.60 | 35.662 | <0.001 |

| 0.016″NiTi | 956.70±130.63 | 109.90±90.92 | 846.80 | 23.794 | <0.001 |

| 0.017″x0.025″NiTi | 1753.30±203.52 | 210.80±175.87 | 1542.50 | 25.646 | <0.001 |

| 0.016″x0.022″stainless steel | 1442.70±152.54 | 152.30±125.94 | 1290.40 | 29.173 | <0.001 |

| 0.017″x0.025″stainless steel | 1666.50±303.70 | 154.90±126.76 | 1511.60 | 20.542 | <0.001 |

| 0.019″x0.025″stainless steel | 1739.90±197.27 | 194.70±156.43 | 1545.20 | 27.447 | <0.001 |

| 0.017″x0.025″ TMA | 1985.00±222.83 | 300.50±118.43 | 1684.50 | 29.853 | <0.001 |

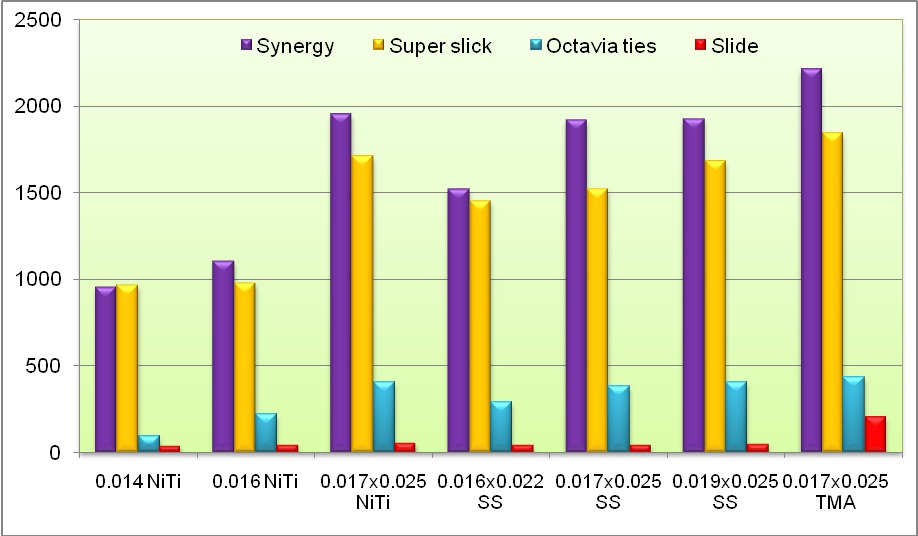

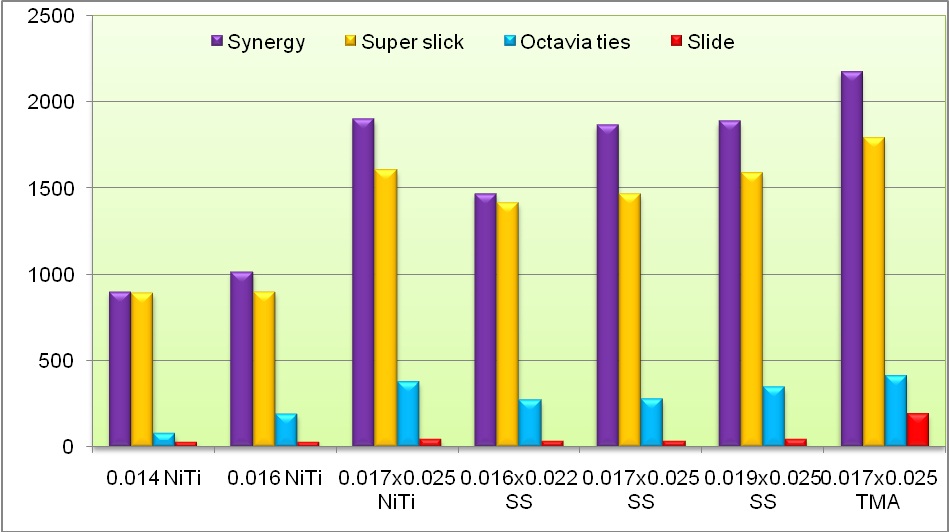

Group 1, low friction round shape module (super slick and synergy) showed higher static and dynamic frictional force than group 2 figure of ‘8’ shape module (slide and Octavia ties) showed much lower static and dynamic frictional force [Table/Fig-11,12].

The mean static friction force (gm) of group 1 and group 2 for different archwires (inches) group A group B.

The mean dynamic friction force (gm) of group 1 and group 2 for different archwires (inches) group A group B.

Amongst the group 1, super slick module (coated with covalently bonded metafasix) showed less frictional force than synergy module (silicone coated) Amongst the group 2, slide module showed less friction than Octavia ties [Table/Fig-13,14].

The mean static friction force (gm) of four groups for different archwires (inches).

The mean dynamic friction force (gm) of four group for different archwires (inches).

Discussion

Franchi et al., determined that the Synergy® bracket with the synergy low-friction ligatures as well as conventional brackets tied with the synergy low-friction ligatures produced forces for tooth movement that were similar to those generated by self-ligating brackets [20]. Only seen at tooth if the displacement for the teeth is more than 3.0 mm, difference between these systems and conventional ligatures was seen. In our study by comparing four low friction modules, which contained synergy low friction module shows that, synergy module produced more friction than other three module by using normal MBT prescription brackets.

As there is greater variation in bracket design, type and method of ligation and testing parameters, comparisons between the present study and the previous studies cannot be made regarding the synergy ligature.

In 2000, there was introduction of a polymeric coated ligature super slick which claimed that it significantly reduced friction compared with conventional ties [2]. It is possible to eliminate the “drag force” while allowing the ligature to rotate teeth. These are manufactured with special polyurethane mixed by injection molded technique. It is claimed that, modules coated with covalently bonded metafasix have been effective in reducing the friction of ligation by 60% compared with uncoated module with similar elastic properties from the same manufacturer [8], although other have reported that coated modules did not produce less friction than uncoated brands [14,21]. Research on the sliding mechanics of super slick with 0.019″ x 0.025″ archwire demonstrated an advantageous reduction in frictional force compared with rectangular cross sectional [14], round cross sectional non coated elastomeric ligature [8,22], and self ligating brackets [8]. However, super slick had also showed higher or similar frictional forces compared with injection molded non coated ligature [14]. In our study super slick module shows less frictional force produced than silicone coated synergy module but more than figure of eight module. These results are difficult to compare because of methodological variables.

A polyurethane elastic ligature ((Slide®, Leone), low-friction material, combined to a conventional bracket forms a tube like structure. Baccetti and Franchi stated that there is significant lower resistance to sliding with the Slide® ligature than with conventional elastic ligatures [23]. They stated that this newly aimed elastic ligature may be used to create a low friction system when conventional brackets were used with the possible advantage of this system was that it could be used selectively in one tooth or in some teeth where lower levels of friction is anticipated.

The shape of Octavia ties (desire orthodontics) is like figure of 8, manufacturer claims that if engaged the module in vertical ‘8’ fashion it reduces the friction, because it cannot bind the archwire actively in mesial and distal end of bracket. If we engage the module in horizontal ‘∞’ fashion it increases the friction because it actively binds the wire in mesial and distal end of brackets [22,23]. In present study Octavia ties shows more friction than slide module but much less than coated super slick and synergy module. No previous study was done regarding the Octavia ties.

In our study basically two groups of elastomeric module are made; Group 1 of conventional round shape module with reduce friction coating i.e. super slick and synergy and Group 2 contained figure of ‘8’ shape module i.e. Octavia ties and Slide ligature. As observed from [Table/Fig-5,6], statistically significant difference existed between the two groups of low friction modules i.e. Group 1 and Group 2 with respect to static and dynamic friction produced with seven different arch wires.

As the anatomical shape of Group 1 module (Super slick and Synergy) is round which is different from figure of ‘8’ shape of Group 2 module (Slide and Octavia ties). The binding force produced by Group 1 module on the wire is more than Group 2 module which is figure of ‘8’ shape. Despite of low friction coating present on Super slick and Synergy module, the arch wire binding technique being different than slide and Octavia ties (Group 2). The Group 2 modules bind arch wire in the middle only. Group 1 module bind the arch wire mesially and distally to the bracket, probably produced more friction. This arch wire binding force of Group 1 module is necessary in initial phases of orthodontic treatment, like alignment and leveling, rotation correction and during torque expression as it requires complete wire engagement in to the bracket slot. There is one more advantage of round low friction module, during individual canine retraction we can use the Group 1 module as it helps in complete sitting of arch wire and minimizes the rotational tendency of canine during retraction also helps to reduce the friction because of lubricious coating present on module, however the force much more than Group 2 module.

But during en mass retraction by using friction mechanics there is large amount of friction created in buccal segment, in brackets of premolar, so care has to be taken to reduce the friction. From the [Table/Fig-9,10] we conclude that Group 2 module creates much less static and dynamic friction than group 1 module, because of shape of these modules are different and it cannot bind the wire mesio-distally to the brackets, it only held the wire passively in to the bracket. In Group 2; Group D (slide, Leone) module shows least amount of static and dynamic friction than Group C; so it is preferable to use Group D (Leone) module in posterior segment during retraction. So, depending upon the treatment, we can use the low friction module, like during en mass retraction by using friction mechanics, we can use the group 1B (Super slick) module in anterior segment to avoid the torque loss by incomplete sitting of arch wire in to the brackets, and we can also used group 2D (Slide; Leone) module in the posterior segment to reduces the static and dynamic friction during sliding of wire.

Limitation

The conclusions of present study were exaggerated by the small sample size. The study was conceded out under controlled laboratory conditions in a passive frictional establishment, and not in an active configuration. The active formation contains some misalignment of brackets, as was explained in previous reports. But no attempt was made to assess the effects of time and oral environment. Effect of lubricating layer on Group 1 modules needs further studies with the use of natural saliva and comparatively prolonged immersion time.

Conclusion

When planning for orthodontic tooth movement, clinician should select the proper combination of bracket and ligation method to reduce the friction and increase the efficiency of the appliance.

Super slick and synergy can be used in the initial and final phase of treatment when full engagement of archwire in the bracket slot is necessary for proper tip and torque expression.

Slide and Octavia ties modules can be used in the premolar brackets during en mass retraction when using friction mechanics.