Dental impression is a negative imprint of orofacial structures. Accuracy of impression is dependent on dimensional stability of impression material [1], and influenced by a number of factors such as impression technique, impression tray and properties of the impression materials [2]. An accurate impression is an important step in processing and final fitting of dental prosthesis [3].

A significant limitation of VPS impression material is their hydrophobicity. There are two different aspects of the hydrophobic nature of VPS impression materials. The first aspect was related to surface free energy and the high contact angle of the solid polymerized VPS that had formed when polymerized VPS impression materials contact with the wet dental gypsum. The surface free energy of the unpolymerized, liquid phase of the impression material that lacks the ability to wet the oral tissues while impression making, forms the second aspect. Hence, certain intrinsic factors such as nonylphenoxypolyethanol homologues had been added by manufacturers to overcome the limitation of VPS hydrophobicity [7].

Impression techniques can be classified into monophase and dual phase. Monophase impression technique was completed in single step procedure by using medium viscosity impression materials; whereas putty and light body wash impression was used to complete the dual phase (1-step and 2-step putty/light body) impression technique [8].

In the present study dimensional accuracy of hydrophobic VPS and hydrophilic VPS compared using monophase, single mix and double mix impression techniques. The aims and objectives of this invitro study was

Materials and Methods

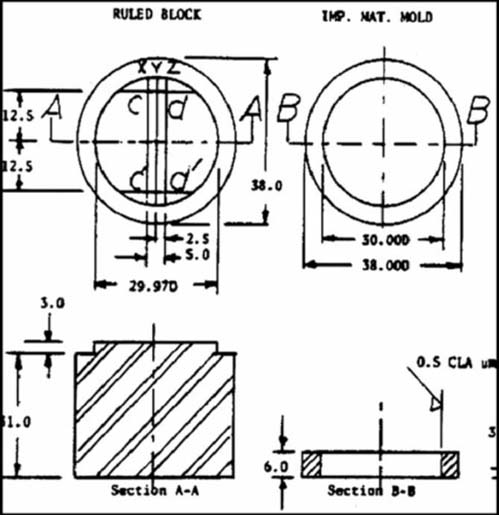

This invitro study was conducted in Department of Prosthodontics and Implantology, Government Dental College and Hospital, Hyderabad from the period 2012 to 2015. A stainless steel die was made according to ADA specification no 19. Die had a Ruled block and Mould [Table/Fig-1]. Ruled block had a height of 31 mm with diameter of inner ring and outer ring was 29.970 mm and 38 mm respectively. Mould had 30 mm inner ring and 38 mm outer ring with a height of 6mm.

Schematic scheme of Stainless steel die according to ADA specification No.19.

Three vertical lines of width 0.016mm were made on the ruled block, which were labeled as X, Y, Z. The distance between two consecutive vertical lines was being 2.5 mm. Two horizontal lines were scored intersecting the vertical lines on either side with a distance of 25 mm between them. The intersection of vertical and horizontal line Y was marked as x and x1 and served as the start and end points of measurements for dimensional accuracy.

Impression Procedure

30 impression samples each of hydrophilic VPS (aquasil) as Group 1 and hydrophobic VPS (variotime) as Group 2 were made using monophase, 1-step and 2-step impression technique. These two groups were again divided in to three subgroups such as group A, B, C for monophase, 1-step and 2-step putty wash impression technique. Each subgroup contained 10 impression samples. The impression materials used in this study were Aquasil (Dentsply/caulk, 78467, Kontanz, Germany) hydrophilic VPS of type 1 Monophase (Lot No 130814, Dentsply/Caulk), type 1 Light body (Lot No 130430, Dentsply/Caulk), Putty soft (Lot No 1201001103, Dentsply/Caulk) consistencies and hydrophobic VPS type 1 monophase (Lot No 380148, Heraeus Kulzar), type 3 Light body (Lot No 390460, Heraeus Kulzar), easy putty (Lot No 400352, Heraeus Kulzar) [Table/Fig-2].

Consistency, Batch No and Manufacturers of the impression materials evaluated.

| Product Name | Consistency | Batch No | Manufacturing company |

|---|

| Aquasil (Group 1) | MonophaseLight bodyPutty | Lot 130814Lot 130430Lot 1201001103 | Dentsply/Caulk |

| Variotime (Group 2) | MonophaseLight bodyPutty | Lot 380148Lot 390460Lot 400352 | Heraeus Kulzar |

Prior to impression making, the die was cleaned ultrasonically so as to remove any residue. The die was air dried and care had been taken to avoid contamination of the die surface. Gloves have not used in this study as they inhibits polymerization process of elastomeric impression materials and also to avoid contamination of the die surface. By using auto mixing impression gun (Dentsply/Caulk), which was loaded with prepacked cartridges of impression material, the impressions were made. Fine mist of water (32oC±2oC) was sprayed on to the surface of the die from a spray bottle before impression material was syringed onto the die surface. The mould was kept on the beveled area of the stainless steel die to ensure 3mm thickness of the impression.

For making impressions using monophase technique, monophase impression material was applied to the lined area of the die and was covered with polyethylene sheet. A glass plate was placed over it with a weight of 500gm on it and allowed to polymerize on stainless steel die for 12 minutes. The polymerization time was doubled, as recommended by the manufacturer, to compensate for impressions being made at room temperature (20oC) instead of at mouth temperature. No tray adhesive was used. The excess material was removed with a bard parker No.15 blade and impression was stored at room temperature. 10 impression samples each of hydrophilic VPS (Aquasil) and hydrophobic VPS (Variotime) were made using monophase technique.

For making impressions using single mix technique light body was applied to the lined area of the die. Simultaneously, soft putty was mixed with finger tips for 30 seconds until the colour was uniform and was placed on the light body. Then the same procedure mentioned for monophase impression was repeated. 10 impression samples each of hydrophilic VPS (Aquasil) and hydrophobic VPS (Variotime) were made using 1 step putty wash technique.

For making impressions using double mix impression technique (two-step putty wash technique), polyethylene spacer was placed on the die prior to putty impression to create space for light body material. Preliminary impression was first made using soft putty and was allowed to polymerize for 12 minutes. In second step the polyethylene spacer and putty impression were removed and light body impression material was syringed onto lined area of the die and on to the putty impression. A fine mist of water was sprayed from a standard distance of 15mm using spray bottle. Preliminary putty impression was reinserted along with light body and evaluated for fit on the die until mould made a firm contact with beveled area of the die. Ten impression samples each of hydrophilic VPS (Aquasil) and hydrophobic VPS (Variotime) were made using two-step putty wash technique.

Evaluation of Dimensional Accuracy

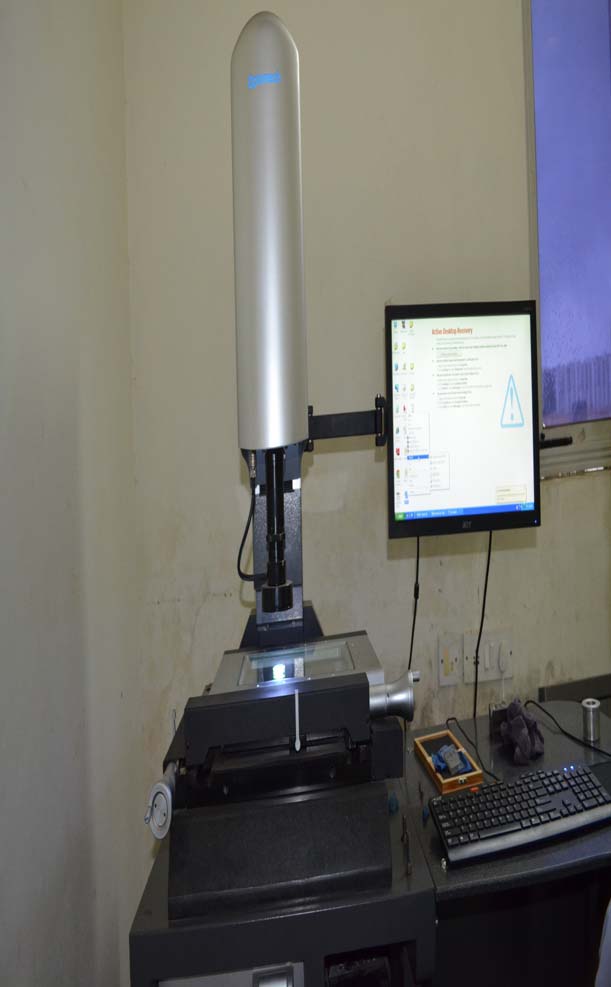

In this study dimensional accuracy was determined by measuring the dimensional change of line Y between points x and x1 three times using the vertical profile projector [Table/Fig-3]. The three measured values were averaged and compared with the original length of line Y of the stainless steel die. The measurements were made after 24 hours of impression making. The percentage of dimensional change was measured using the formula: % dimensional change = A-B/B×100. (A- Length of measured line Y of this specimen in mm, B- length of line Y on stainless steel die.

Vertical Profile Projector.

Statistical Analysis

This study used one-way analysis of variance (ANOVA) to compare means within the groups. A post-hoc test for multiple mean comparisons was done using Tukey HSD test. Comparison between the groups was done using Unpaired t- test.

Results

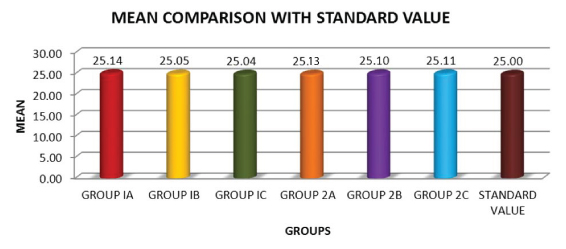

The mean values of hydrophilic VPS (Aquasil) for 10 measurements with each impression technique and the corresponding SD and % dimensional change were calculated. The percent errors were low, ranging from 0.56% to 0.16% [Table/Fig-4]. The mean values, SD and % dimensional change of hydrophobic VPS (Heraeus Kulzar) for 10 measurements according to impression technique were calculated. All impression dimensions were greater than that of stainless steel die [Table/Fig-5].

Means, S.D & % dimensional changes of hydrophilic VPS (Aquasil, Densply/Caulk) for the three impression techniques.

| Monophase | 1-step | 2-step |

|---|

| Mean | 25.14 | 25.05 | 25.04 |

| S.D | 0.87 | 0.03 | 0.04 |

| % dimensional change | 0.56 | 0.20 | 0.16 |

Means, S.D % dimensional changes of hydrophobic VPS (Variotime, Heraeus Kulzar) for three impression techniques.

| Monophase | 1-step | 2-step |

|---|

| Mean | 25.13 | 25.10 | 25.11 |

| S.D | 0.17 | 0.07 | 0.05 |

| % dimensional change | 0.50 | 0.40 | 0.44 |

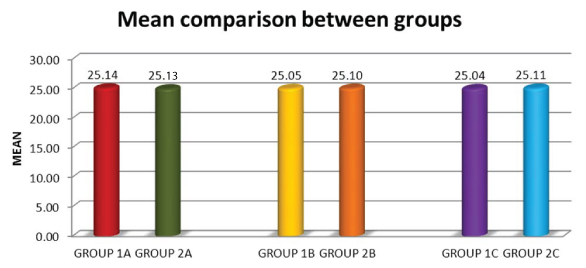

The one-way ANOVA for the samples of hydrophilic VPS [Table/Fig-6] revealed that all the dimensions were not significantly different among the impression techniques. Significant difference was noted among the impression techniques among the hydrophobic VPS group using one-way ANOVA test [Table/Fig-7]. In general greater percentage deviation was observed for monophase impression technique in both the groups. Unpaired t-test revealed statistically significant (p<0.05) difference between one-step and two- step techniques among the groups.

Mean comparison among subgroups in group I using one-way ANOVA test.

| Anova Test |

|---|

| Source of Variation | Sum of Squares | Df | Mean Square | F-value | p-value |

|---|

| Between Subgroups | 0.20 | 2 | 0.102 | 0.400 | 0.671Not significant |

| Within Subgroups | 22.23 | 87 | 0.256 |

| Total | 22.44 | 89 | |

Statistical Analysis: ANOVA test. Statistically significant if P<0.05, Df = degree of freedom

Mean comparison among sub groups in group 2 using one-way ANOVA test.

| Anova Test |

|---|

| Source of Variation | Sum of Squares | Df | Mean Square | F value | p-value |

|---|

| Between Subgroups | 0.195 | 2 | 0.097 | 6.865 | 0.002Significant |

| Within Subgroups | 1.234 | 87 | 0.014 |

| Total | 1.429 | 89 | |

Statistical Analysis: ANOVA test. Statistically significant if P<0.05, Df = degree of freedom

Comparison of mean values between group I and group II using Monophase, 1-step, 2-step putty wash impression techniques.

Mean comparisons of group I and group II with standard value.

Discussion

In the present study, the accuracy of three impression techniques was investigated using hydrophilic VPS and hydrophobic VPS impression materials. In this study no gloves were used to manipulate the elastomeric impression material as well as to avoid contamination of the die surface. For all the groups, significantly larger dimension impression samples were observed compared to stainless steel model. The evidence from this investigation indicated that accuracy of the two impression materials used was not much adversely affected by the presence of moisture.

The results of this invitro investigation should be viewed cautiously because laboratory testing cannot exactly replicate clinical situations. In this investigation, impressions were made of standardized stainless steel dies. Metal dies were non-absorbent to liquids unlike oral tissues. Proteinaceous surfaces of prepared teeth and oral soft tissues had a lesser surface energy than surface free energy of a metal die. Wetting of impression material depended on surface energy of impressed surface. The source of moisture was water, not the saliva, which was again a drawback.

The monophase technique is the easiest to perform, but it has been reported to be the worst in terms of dimensional accuracy and surface defects, as compared to putty light body techniques, because of relatively high viscosity and reduced flow of material used. In one-step technique the putty tends to push the light body wash off the prepared tooth, thus critical areas such as the finish line can be covered by putty that cannot record the details to a satisfactory level. Another difficulty with the one- step technique is that once the light body material is on the preparation, the putty needs to be brought into position and seated. During this critical phase, patients tongue or the elevated floor of the mouth can remove the light body material from the tooth. The two-step technique allows these problems to be overcome by diminishing the volume of polymerizing material at each stage, the final contraction can be reduced, and also the accuracy of the impression improved. Therefore, careful control of the bulk of light body impression material has been advocated because it affects the accuracy of stone casts.

When allowed to polymerize in moist field hydrophobic VPS has a lesser dimensional accuracy in comparison to hydrophilic VPS. ADA specification 19 protocol was used for measurement of dimensional accuracy. In previous studies dimensional changes of impression materials were measured on plaster casts poured of impressions by various devices like traveling microscope, digital vernier calipers, 3 dimensional Zeiss meter and stereomicroscope [9,10]. However, in this study to eliminate possibility of changes in stone casts, measurements were directly performed on the impression using Digital Profile Projector.

However, while the results from three impression techniques revealed two-step impression technique was advantageous in both hydrophilic and hydrophobic VPS with all three impression techniques. Impression accuracy was not technique-dependent as stated by Idris et al., [11]. Hung et al., comparatively studied the accuracy of two VPS impression techniques, the study was performed in 1 step and 2 step with a polyethylene spacer. They concluded that there was no difference between the two techniques [12]. However, Joceph Nisson et al., stated that the technique is a crucial factor that influences the accuracy of the impression [13]. This invitro suggests that the technique can be significant factor in determining dimensional accuracy of impressions.

Limitations

In this study the metal dies were non-absorbent to liquids unlike oral tissues.

Source of moisture was water not the saliva in this study which again a drawback.

Clinical transfer: These results suggest that hydrophilic materials with 2 step impression technique leads to predictable success in the Fixed prosthodontics and Implantology procedures.

Conclusion

Within the limitations of this invitro study, the following conclusions can be drawn:

Hydrophilic VPS yielded more dimensionally accurate impressions than hydrophobic VPS using one step, two step putty wash impression techniques.

In monophase technique, no much difference was found between the hydrophilic and hydrophobic VPS impression materials.

Hydrophilic VPS yielded dimensionally accurate impressions in all the three impression techniques.

Hydrophobic VPS gave better dimensionally accurate impressions in one step, two step putty wash techniques in comparison to monophase impression technique.

Statistical Analysis: ANOVA test. Statistically significant if P<0.05, Df = degree of freedom

Statistical Analysis: ANOVA test. Statistically significant if P<0.05, Df = degree of freedom