Introduction

An increased awareness of aesthetics in dentistry has resulted in the need for removable partial dentures that reveal little or no metal supporting structures or retentive elements. Partial dentures frequently rely on clasps for direct retention, yet their appearance has long been recognized as an obstacle to patient appearance.

Several types of metal alloys and polymers have been used in removable partial denture constructor. Frequently, removable partial denture clasps are made from the same alloys as the metal framework. The most common alloys used for clasps are cobalt chromium alloy, gold and titanium alloys [1]. The attractiveness of chromium containing base metal casting alloys for removable partial dentures stems from their corrosion resistance, high strength and modulus of elasticity, low density, and low cost, however these attributes also contribute to some disadvantages, including fatigue under repeated load and unaesthetic appearance.

The alternatives to visible buccal or labial clasp arms are numerous. Lammie and Osborme [2] described the mesiodistal clasp that engages the mesial and distal surface of the tooth. The Equipoise clasp [3] similarly engages the proximal tooth surface. King et al., suggested the use of lingual retentive clasps and Highton et al., proposed the use of palatal I bars [4,5]. King also approached the problems of unaesthetic clasping by use of a dual path or rotational path of insertion [6]. Others have attempted to camouflage the visible clasps by covering them with tooth coloured veneers [7,8] while removable partial dentures with precision attachments are aesthetically satisfying, but they are expensive and more difficult to fabricate [9].

Unfortunately, many client situations are not suitable for using these concepts, and conventional retainers in the anterior region of the mouth are often necessary. Direct retainers fabricated in tooth coloured materials, such as acetal resin (Thermoplastic technopolymer) may be more aesthetic [10].

Thermoplastic processing implies using completely polymerized or prepolymerized resins [11]. These materials are presented as low molecular weighed (about 150,000) grains having low plasticizing temperature and higher rigidity [12].

Polyoxymethylene (POM) also known as acetal resin, is an alternative denture base and denture clasp material used since 1986, it was primarily fabricated to deliver superior aesthetics [13]. Acetal resins have been used as an alternative denture base and clasp material [14]. Acetal resins are formed by the polymerization of formaldehyde and are been considered as the alternative material for removable denture framework fabrication for patients with allergic reactions to cobalt–chromium alloys [13]. It is reported to have a sufficiently high resilience and modulus of elasticity, high impact strength and resistance to organic solvents, oils, and hot and cold water [15,16] to allow its use in the manufacture of retentive clasps, connectors, and support elements for removable partial dentures [13,14].

The functions of a removable partial denture are affected by the physical properties of its direct retainers [10].

Investigators have considered the long term effectiveness of the clasps and the effects that the clasp might have on the abutment teeth [17,18]. A clasp arm design producing less stress is important for predictable long term use of a removable partial denture. Removable partial denture retentive clasp arms must be capable of flexing and returning to original form and should satisfactorily retain the prostheses [19]. In addition clasps should not unduly stress abutment teeth or be permanently distorted during service. On the other hand, if clasps are too flexible they may not provide adequate partial denture retention when placed in shallow undercut. However, the mechanical properties of clasp materials are generally determined by the alloy used.

Metals and metal alloys undergo permanent deformation and fatigue when exposed to repeated stress. The loss of a material’s mechanical properties after repeated loading is an important consideration in metal selection for removable partial denture fabrication [20]. Vallittu and Kokkonen, using a constant deflection test, concluded that clasp fatigue affected the retentive properties of removable partial denture and loss of retention may be caused by the permanent deformation of clasps [1]. However, since clasp fatigue is based on the recurring deflection of clasp during removable partial denture insertion and removable, a repeated placement and removal test would be a more appropriate fatigue test.

To know the various properties of materials used for removable partial denture clasps, extensive research has been undertaken but very few applications of acetal resins have been found [17,18,21].

Therefore, this invitro study was done to compare the retentive force and deformation of acetal resin and cobalt – chromium claps after subjecting them to a simulated clinical use, with the following aims:

To determine the tensile load required to dislodge acetal resin and the cobalt –chromium clasps from two different depths of undercuts after repeated cycles of placement and removable simulating clinical use.

To compare the retentive ability of circumferential clasps for removable partial denture made of cobalt chromium alloy and acetal resin.

To determine the permanent deformation of both the clasps after simulated clinical use.

Materials and Methods

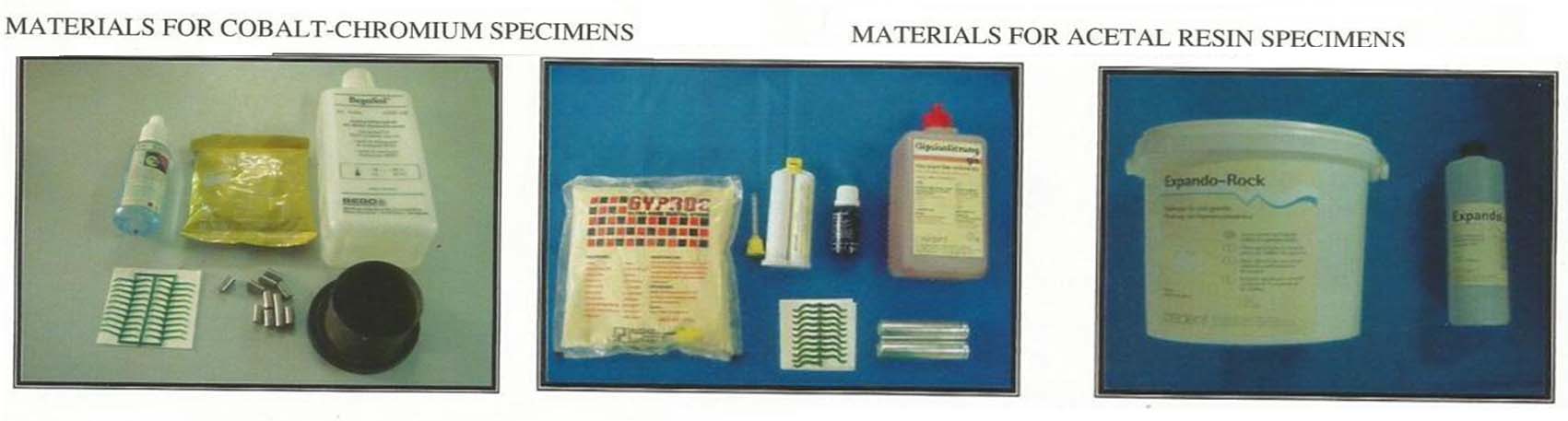

This study was done at Department of Prosthodontics, T.N.G.D.C&H, Chennai, Tamilnadu in the year 2008. Materials used for this study were commercially available Cobalt-Chromium alloy namely Wironit, Bego, Germany and Acetal resin namely Biodentaplast, Bredent, Germany. These two materials were used with two different depths of undercut for this study. Information on the materials used is given in [Table/Fig-1,2].

Materials used in this study.

| S. No. | Commercial Name of the Material | Form of the Material | Composition | Manufacturer Details |

|---|

| 1 | Wiront | Pellets | Co-64%, Cr-28.65%, Si, Mn, Ctrace | Bego, GmbH & Co. KG, Germany |

| 2 | Biodentaplast | Cartridges | Acetal resin (Poly-Oxymethylene) | Bredent, GmbH & Co. KG, Germany |

| 3 | Circumferential Wax Paterns (For Co-Cr clasps). | Preformed half-round paterns | Paraffin, Ceresin, Bees wax, Resins & other waxes. | Bego, Wachsschablonen, GmbH & Co.KG Germany |

| 4 | Circumferential Wax Paterns (For Resin clasps). | Preformed half-round paterns | Paraffin, Ceresin, Bees wax, Resins & Other eaxes. | Protek Wachskleber, Bredeent, GmbH & Co. KG Germany |

| 5 | Wirovest | Powder & Liquid | Phosphate bonded investment & Colloidal silica | Bego, GmbH & Co. KG, Germany |

| 6 | Expandorock | Powder & Liquid | Type III Dental stone | Bredent, GmbH & Co. KG, Germany |

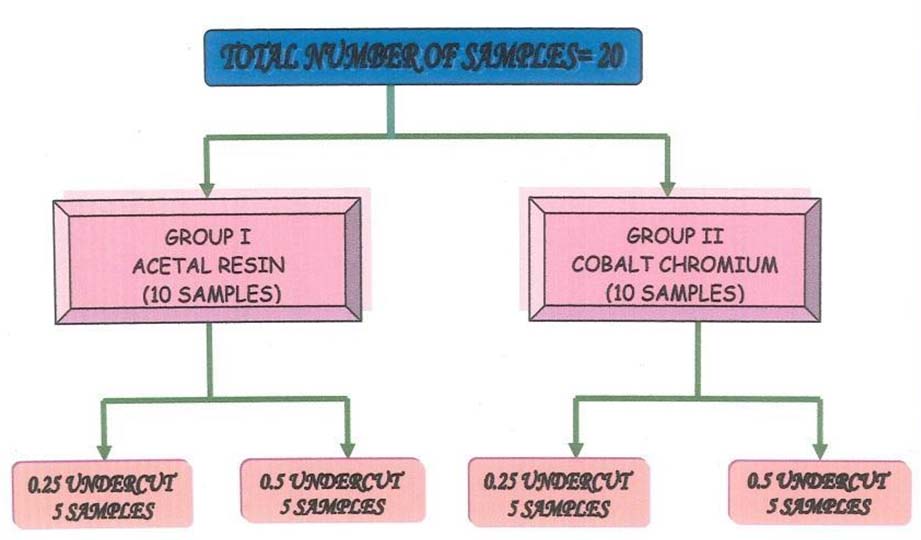

Grouping of samples

The test samples were divided into two major groups based on the type of materials used in the study. Each major group is further subdivided into two sub groups based on the retentive undercut depths used to engage the clasps. So a total of 20 specimens were prepared, comprising of 5 specimens in each sub group [Table/Fig-3]. Then the specimens were tested for retention force and deformation.

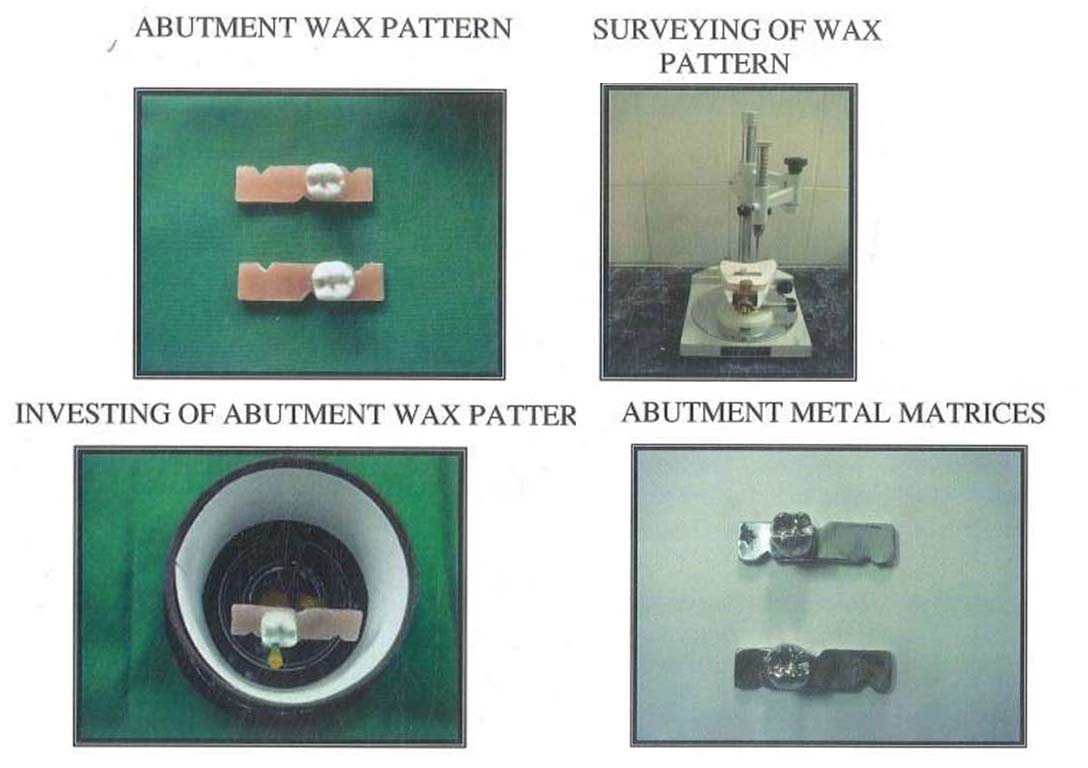

1. Preparation of metal matrices representing a mandibular first molar

Two metal matrices representing a mandibular first molar abutment of varying depths of retentive undercut made of Cobalt-Chromium alloy were used as abutments for the study. The wax molar tooth was removed from the impression and fixed on a wax plate with dimensions of 4cm length, 1cm breadth and 2mm in height. Three V-shaped notches were made on the wax plate, to aid in repositioning the wax plates on plaster blocks, which were prepared for positioning the wax models on the surveying table [22].

On both abutment wax models, the molar tooth was modified with the placement of a 2mm deep mesial occlusal rests that served as a stop for insertion. The waxed crowns were trimmed on a surveyor to provide mesial and lingual guide planes to standardize the path of insertion and removal. The wax models were invested singly in casting rings and cast with Cobalt-Chromium alloy [Table/Fig-4].

Preparation of abutment metal matrices.

2. Fabrication of Die stone models

Impressions of the metal matrices, each with a different retentive undercut, were made in silicone impression material with stock trays. Each impression was poured with Type 4 dental stone.

3. Surveying and Shaped block out of the die stone models

Each cast was surveyed to determine the vertical path of insertion for the clasps and undesirable undercuts were blocked out. Ledges were carved in the blockout material to standardize the position of the clasps [19]. The terminal one fifth (2mm) of the clasp engaged the retentive undercut.

4. Duplication of die stone models for

Investment refractory casts for Cobalt-Chromium alloy, and

Type 3 stone models for Acetal resin specimens.

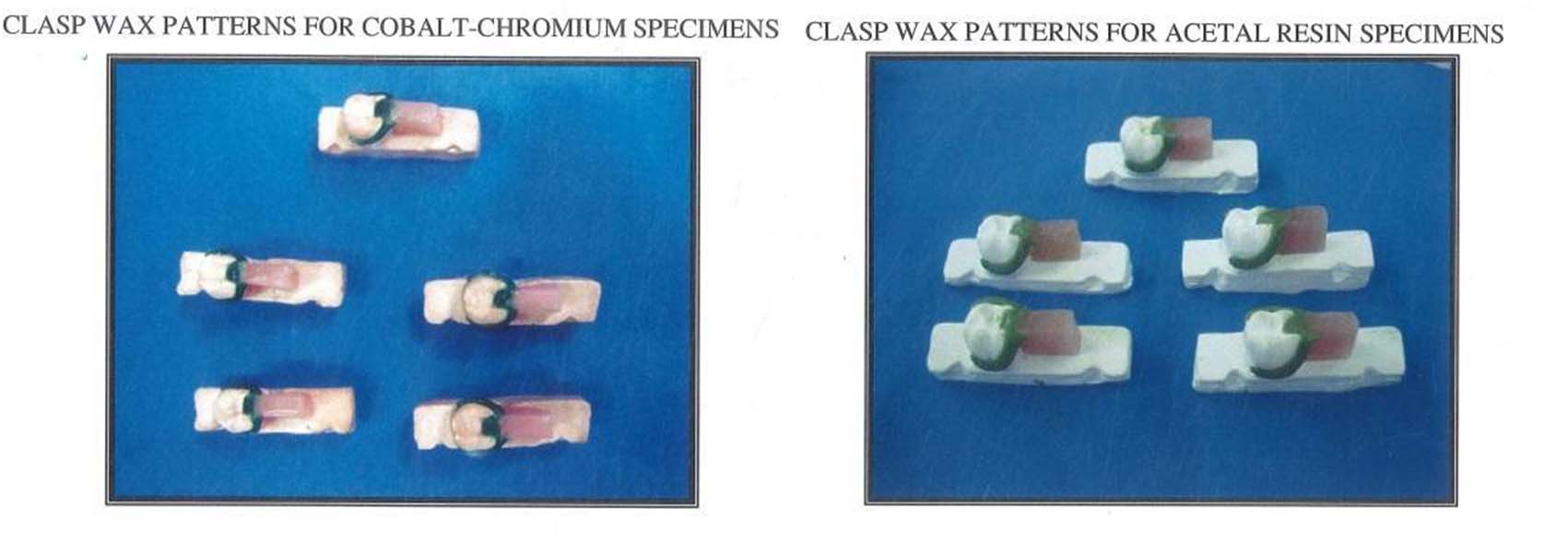

5. Fabrication of clasp wax patterns for Cobalt-Chromium alloy and Acetal resin specimens

Wax circumferential clasps with occlusal rests, and retentive and reciprocal arms were fabricated with preformed half-round standard clasp patterns which were 1.2mm thick and 2mm thick for Co-Cr and Acetal resin specimens respectively [Table/Fig-5].

Clasp wax patterns for Cobalt-Chromium and Acetal Resin specimens.

6. Processing of test samples

Spruing, investing and casting the wax patterns of Cobalt-Chromium clasp specimens.

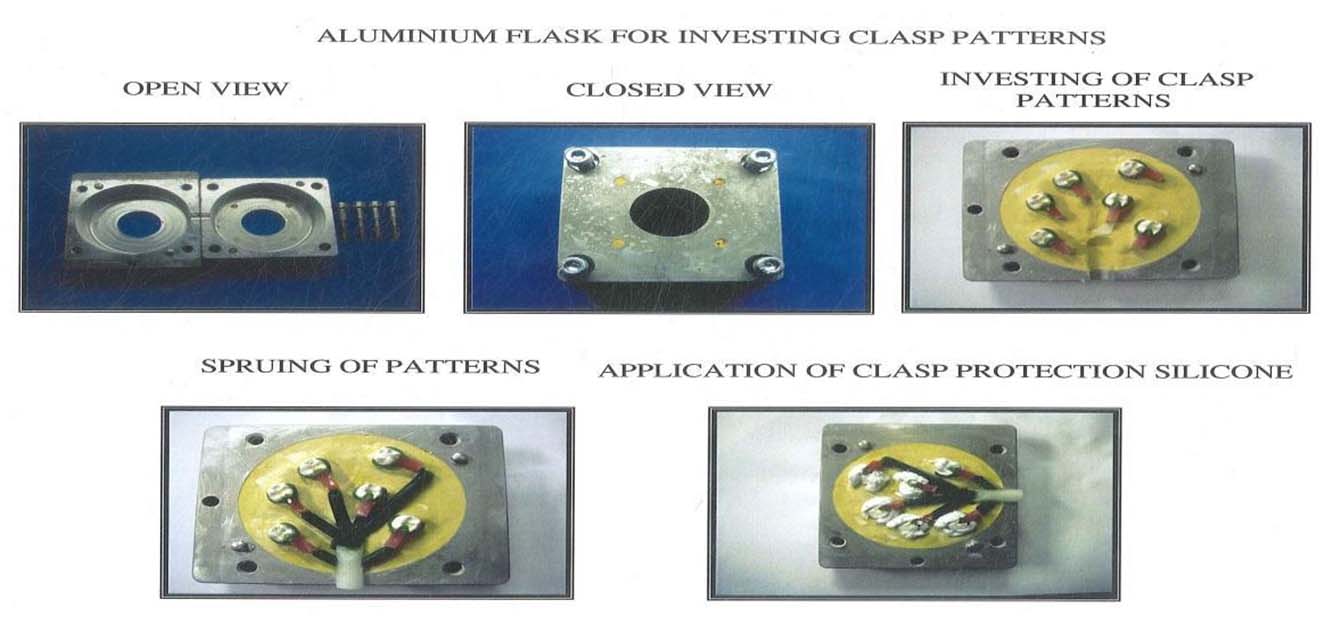

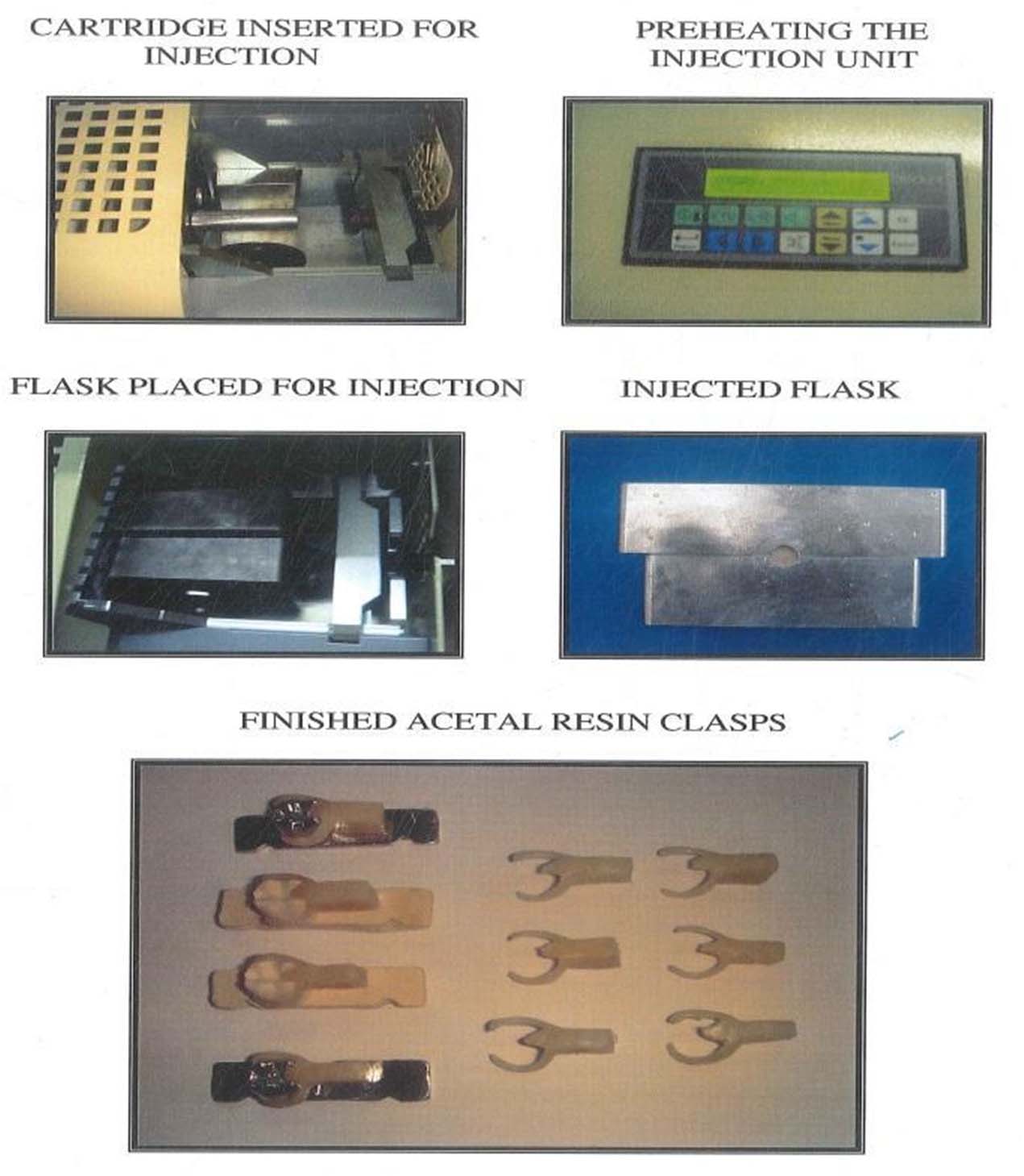

Flasking, dewaxing and injecting Acetal resin clasp specimens [Table/Fig-6].

Investing of Acetal Resin specimens

7. Finishing of test specimens:[Table/Fig-7]

Processing and finishing of Acetal Resin specimens.

8. Testing of specimens

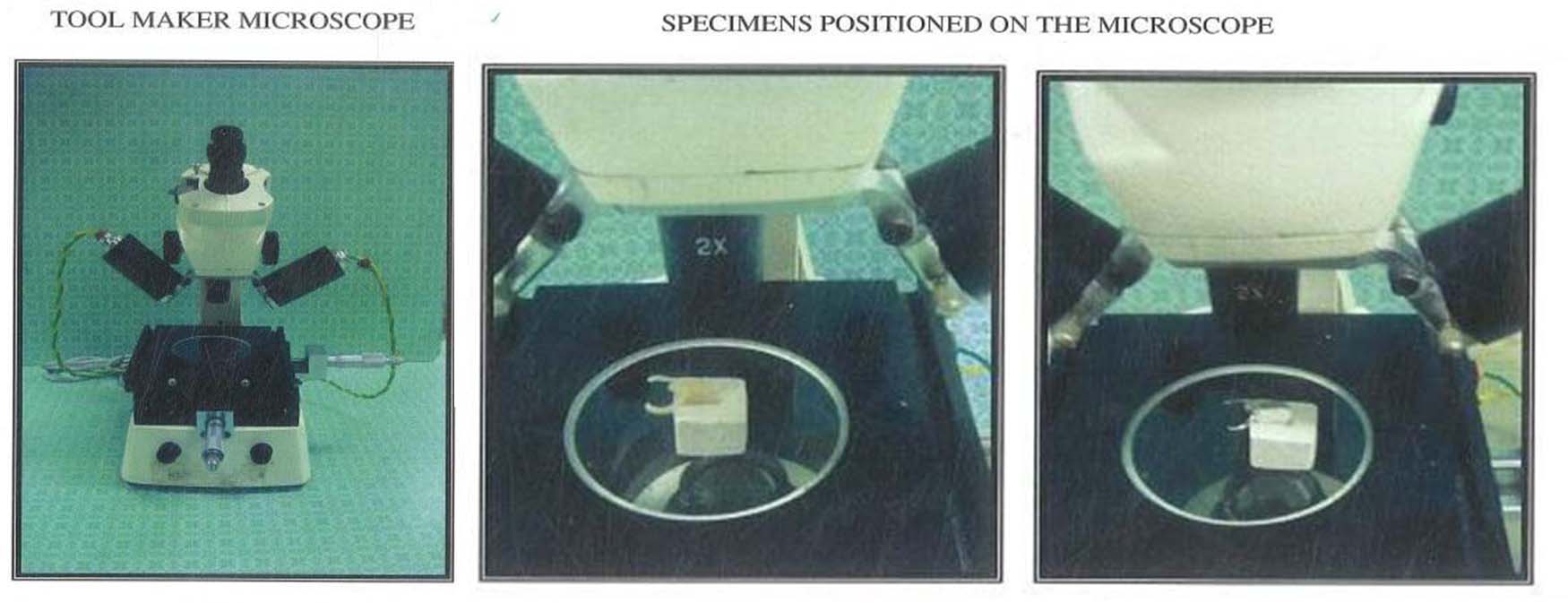

Deformation Testing- Prior to retention testing, the clasps were placed in plaster blocks to standardize the measurements with microscope [Table/Fig-8]. The distance between the inner tips of the retentive and reciprocal arms of the clasps were measured with a Tool maker Microscope to the nearest 0.01.

Deformation Testing of specimens.

After fatigue testing, the distance between the tips of the retentive and reciprocal arms of each clasp, which were placed in the plaster blocks in the same position, were again measured and compared with the data before the tested cycle.

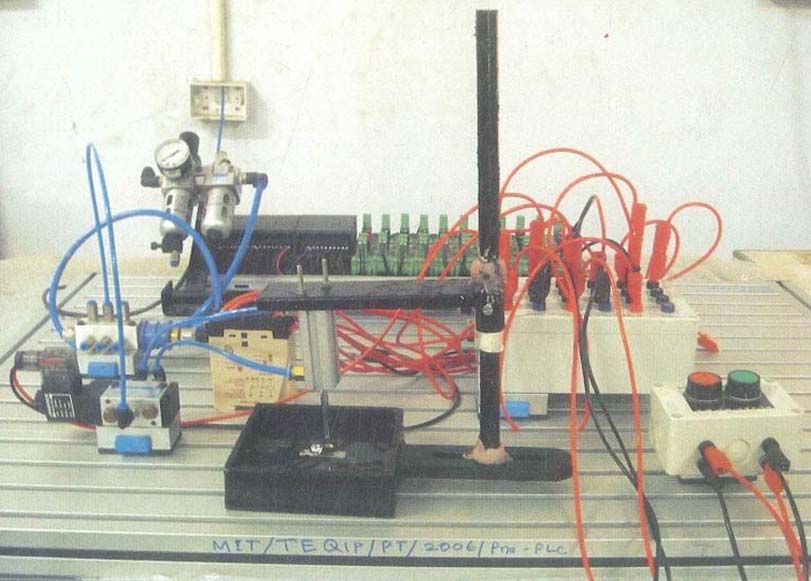

Retention Testing- To perform the retention test of the clasp, a specially designed insertion removal apparatus designed at Madras Institute of Technology, Chennai was used [Table/Fig-9]. The apparatus allowed the placement of the clasp to its predetermined terminal position and its subsequent removal from the metal matrix, thus simulating the placement and removal of the apparatus. The retentive force of the clasp was also measured during removal.

Testing Machine-Insertion Removal Apparatus.

Description of the Equipment

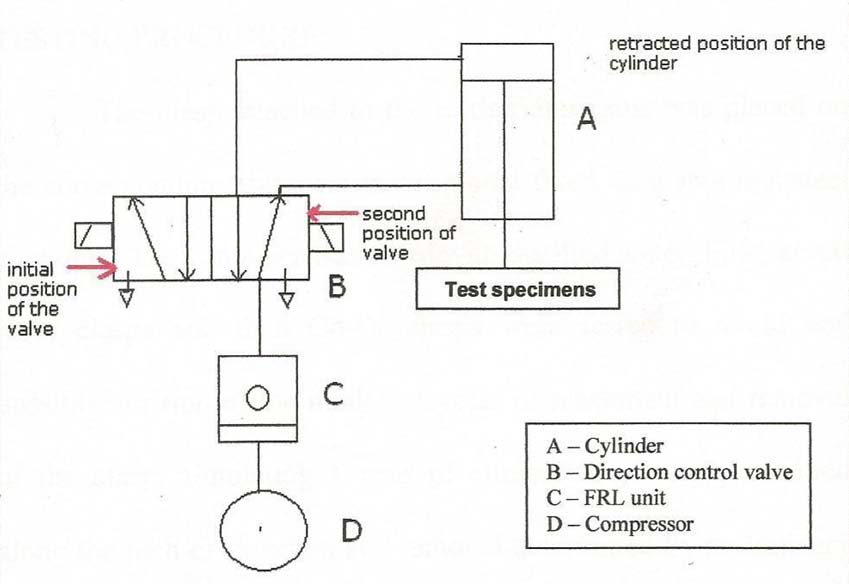

The apparatus consisted of a sliding pneumatic cylinder placed parallel to a square cross-sectional cylinder, working on the principle of Electropneumatics [Table/Fig-10].

Working Principle of Testing Apparatus.

The up and down motion is provided by the compressed air, so that the specimen is placed properly in the tooth during the downward motion and is removed from the tooth in the upward motion.

Testing Procedure

The clasp attached to the testing apparatus was placed on the corresponding abutment metal model fixed on a stainless steel container. The container was filled with distilled water [22]. First, acetal resin clasps and then Co-Cr clasps were tested to avoid any possible attrition of the models. Cycles of placement and removal of the clasp, simulating 1year of clinical use, were performed along the path of insertion and removal determined by preliminary surveying procedures of the metal abutment model.

The force needed to remove the fitted clasp was measured in Newton. After the measurement of the retentive force of the fitted clasps, the clasps were cycled on and off the dies at 3 different periods of 0,730,1460 cycles, representing the simulated insertion and removal over 1year. The test was performed with 41cycles/minute at a constant speed of 35.7mm/second [22]. After this simulated clinical use, the force of removal was re-measured to determine the reduction in the amount of retentiveness remaining.

Statistical Analysis

Comparison between mean forces (N) required to dislodge clasps using 3-way ANOVA [Table/Fig-11].

Comparison between mean forces (N) required to dislodge clasps using 3-way-ANOVA.

| Source Of Variation | Sum of Squares | df | Mean Square | F | P Value |

|---|

| Material | 263.342 | 1 | 263.342 | 633.703 | .000** |

| Undercut | 9.409 | 1 | 9.409 | 22.642 | .000** |

| Period | 3.979 | 2 | 1.989 | 4.787 | .013* |

| Material x Undercut | 0.195 | 1 | 0.195 | 0.469 | .497 |

| Material x Period | 3.979 | 2 | 1.989 | 4.787 | .013* |

| Undercut x Period | 0.128 | 2 | 0.064 | 0.154 | .858 |

| Material x Undercut x Period | 0.128 | 2 | 0.064 | 0.154 | .858 |

| Error | 19.947 | 48 | 0.416 | | |

| Total | 301.105 | 59 | 5.103 | | |

Note 1:**denotes significance at 1% level.

Note 2:*denotes significance at 5% level.

Material: Cobalt-Chromium clasp or Acetal resin clasp

Undercut: 0.25mm or 0.50mm

Period: 0month, 6 months or 12months.

Results

This invitro study was performed to compare the retentive force and deformation of acetal resin and cobalt-chromium clasps after subjecting them to a simulated clinical use. The force needed to remove the clasp was measured at the initial test period and then the clasps were cycled on and off the dies at 3 different periods of 0,730,1460cycles, representing the simulated insertion and removal over 1 year. After cycling, the retention force was measured to determine residual retentiveness. The distance between the clasp tips was also measured before and after the testing cycles.

The mean values and Standard deviation of the retentive force magnitudes were recorded for the 3 test periods (initial, 6 and 12 months) for dislodgement of each clasp. Similarly, the Mean and SD of the distances between the clasp tips measured before and after the insertion-removal test were calculated. The basic data of the results obtained in this study are shown in Appendix.

Discussion

Material of choice for removable partial denture should have enough flexibility for clasp and rigidity for other components of partial denture [19]. Retentive clasp arms must be capable of flexing and returning to their original form and should retain a denture in situ satisfactorily, and yet not stress the tooth unduly or be distorted permanently during service and should provide good aesthetic results [22].

Acetal resin has a high proportional limit with little viscous flow. This property enables them to cover a large area in clasp fabrication [14]. Fitton et al., in their invitro study stated that, resin clasps may be resilient enough to engage undercuts for the retention of removable partial dentures but the low flexural modulus requires coverage of greater cross sectional area than metal alloys in order to gain useful retention [14].

Turner et al., found that if all other variables were equal, 15mm long and 1mm diameter cast cobalt chromium clasp would exhibit the same stiffness as an acetal resin clasp, 5mm in length and 1.4mm in diameter [13]. For this reason, thicker acetal resin clasps were used for comparison in this study.

The present study was designed to compare clasps in function in 2 different amounts of undercuts. The 0.25mm undercut was selected because it represents the undercut commonly used for Cobalt-Chromium clasps. With the increased demands of aesthetics, more patients are requesting that dentists conceal partial denture clasps by placing them closer to the gingival margin, where undercuts tend to be larger. The stiffness of Cobalt-Chromium clasps makes them unsuitable for placement in larger undercuts, because such clasps may induce more stress on the abutment teeth or result in permanent deformation of the clasps [17].

Ahmad et al., found that maximum retention for Cobalt-Chromium clasps was greater for an undercut of 0.50mm (10.21N) than for an undercut of 0.25mm (6.51N) [23]. The results of the present study showed that acetal resin clasps had significantly lower retention force 2.71N for 0.25mm undercut and 3.39N for 0.50mm undercut whereas the Cobalt-Chromium clasps required 7.24N for 0.25mm undercut and 8.37N for 0.50mm undercut.

The results of this study indicate that acetal resin clasps are resistant to deformation and may offer a clinical advantage over the conventional metal clasps. The retentive force of acetal resin clasps did not decrease over the cycling periods. This would be attributed to the resilient nature of acetal resin. Under the conditions of the present study cobalt chromium clasps lost retentive force within 730 cycles of placement and removal and continued to lose retentive force during the remaining test period. Past studies have indicated that there was a loss of retention because of permanent deformation of the cobalt chromium clasps [24] the attrition of the inner surface of the cobalt chromium clasps of the reduction of the retention. This possibility could not be completely eliminated because there was no quantitative evaluation of the specimen surface characteristics. However, no attrition on this surface was observed visually.

Bates showed that a 10mm long cobalt chromium would display a tip deflection of 0.15 mm at the proportional limit [24]. Morris et al., suggested that permanent deformation of a clasp tip by more than 0.025 mm may be significant [25]. Fahed Tannous et al., evaluated the retentive force of clasps made from three thermoplastic resins and cobalt–chromium (CoCr) alloy by the insertion/removal test simulating 10 years use [26].

The results of this present study showed that the mean initial retentive force ranged from 1.2 to 3.1 N for the 1.0 mm thick resin clasps and from 4.9 to 9.1 N for the 1.5 mm thick resin claps. For CoCr clasps it ranged from 11.3 to 16.3 N. The highest initial retentive force (16.3 N) was recorded in the CoCr clasps with 0.50 mm undercut, and the lowest retentive force (1.2 N) was measured in the 1.0 mm POM clasps with 0.25 mm undercut. The retentive force required for removal of the 1.5 mm thick resin clasps was significantly lower (p ≤ 0.001) than that required for removal of the CoCr clasps with 0.25 mm and 0.50 mm undercuts.

All the clasps exhibited an increase in retentive forces during the first period of cycling followed by continuous decrease till the end of the cycling but it was still significantly not different compared to the initial retentive force (p = 0.970). Nevertheless, undercut showed a significant effect on clasps retention with the 0.50 mm undercut provided the higher retention. Samar S. Alwan, showed that acetal resin can be used with limitation as an alternative to co-cr alloy clasps in removable partial dentures [27]. Cr-Co alloy clasp had higher retentive force values in comparison with Acetal thermoplastic clasp. Co-Cr group, results showed that retentive force mean were 13.05N and 17.61N for premolar teeth with 0.25mm and 0.5mm respectively. While for molar teeth it was 16.96N and 24.79N for 0.25mm and 0.5 mm undercut respectively. The premolar group showed that 0.25mm undercut premolar had the lowest value of (13.05N) of the retentive force.

In Acetal group specimen molar with 0.5 mm undercut showed the higher retentive force while premolar with 0.25mm undercut showed the least one. it also demonstrated highly significant difference in the retentive force of Acetal clasp between 0.25mm and 0.5mm under cut depth for both premolar and molar groups.

The results of the present study showed that though there was an increase in the distance between the tips of the cobalt chromium clasps, there was no significant deformation of these clasps at the 12 months test period. However, the acetal resin clasps also showed no significant deformation after 12 months simulated clinical use.

Suggesting that acetal resin is a better material because it assists in overcoming the poor aesthetics of cobalt chromium clasps in case of anterior clasping and demonstrates greater flexibility resulting in reduced stress on the abutment teeth. Further, longitudinal study on the clinical efficacy of the acetal resin clasps is needed to determine whether these materials are suitable alternative for cobalt chromium clasps.

Conclusion

This invitro study hence concludes that the cobalt chromium clasp used in fabrication of removable denture prosthesis has superior retentive forces than the acetyl resin due to significantly low retentive force required for removal. The retentive clasp arm of the clasp fabricated using acetyl resin aids in engaging deeper undercuts on the abutments than the cobalt chromium due to the flexibility and the lack of stiffness. The superior flexibility and the long term resiliency that the acetyl resin clasp shows hereby concludes that it can be used in areas where there is an aesthetic demand or periodontal health is a primary concern.

Note 1:**denotes significance at 1% level.

Note 2:*denotes significance at 5% level.

[1]. Vallittu PK, Kokkonen M, Deflection fatigue of cobalt-chromium, titanium, and gold alloy cast denture claspJ Prosthet Dent 1995 74(4):412-19. [Google Scholar]

[2]. Lammie GA, Osborne J, Partialdentures 1974 OxfordBlackwell Scientific [Google Scholar]

[3]. Goodmann JJ, The equipoise removable restorationTrends Tech Contemp Dental Lab 1991 8:45-8.:50-52. [Google Scholar]

[4]. King GE, Barco MT, Olson RJ, Inconspicuous retention for removable partial denturesJ Prosthet Dent 1978 39(5):505-07. [Google Scholar]

[5]. Highton R, Caputo A, Malyas J, Force transmission and retentive capabilities utilizing labial and palatal I-bar partial denturesJ Oral Rehabil 1987 14:489-99. [Google Scholar]

[6]. King GE, Dual path design for removable partial denturesJ Prosthet Dent 1978 39:392-95. [Google Scholar]

[7]. Moreno de Delgado MM, Garcia LT, Rudd KD, Camouflaging partial denture claspsJ Prosthet Dent 1986 55:656-60. [Google Scholar]

[8]. Ozcan M, The use of chairside silica coating for different dental applications:A clinical reportJ Prosthet Dent 2002 May 87(5):469-72. [Google Scholar]

[9]. Hansen CA, Iverson G, Anaesthetic removable partial denture retainer for the maxillary canineJ Prosthet Dent 1986 56:199-203. [Google Scholar]

[10]. Wu JC, Latta GH, Wicks RA, Swords RL, Invitro deformation of acetyl resin and metal alloy removable partial denture direct retainersJ Prosthet Dent 2003 90(6):586-90. [Google Scholar]

[11]. Wirz KG, Prothesenaus Thermoplast-spritzgu bverfahrenim kartuschen systemDent Labor 1983 31:1103-07. [Google Scholar]

[12]. Negrutiu M, Bratu D, Rominu M, Polymers used in technology of removable denturesRevista Nationala de Stomatologie 2001 4(1):30-41. [Google Scholar]

[13]. Turner JW, Radford DR, Sherriff M, Flexural properties and surface finishing of acetal resin denture claspsJ Prosthodont 1999 8(3):188-95. [Google Scholar]

[14]. Fitton JS, Davies EH, Howlett JA, Pearson GJ, The physical properties of a polyacetal denture resinClin Mater 1994 17(3):125-29. [Google Scholar]

[15]. Forschirm A, Mc Andrew FB, Acetalresins, in J.C. Salamone (ed)The Polymeric Materials Encyclopedia 1996 vol 1LondonEngland CRC Press:6-12. [Google Scholar]

[16]. Masamoto J, Acetal Resins (homopolymers, copolymers and block polymers) in J.C. Salamone(ed)The Polymeric Materials Encyclopedia 1996 vol 1London, EnglandCRC. Press:12-20. [Google Scholar]

[17]. Bridgeman JT, Marker VA, Hummel SK, Benson BW, Pace LL, Comparison of titanium and cobalt-chromium removable partial denture claspsJ Prosthet Dent 1997 78(2):187-93. [Google Scholar]

[18]. Rodrigues RC, Ribeiro RF, deMattos Mda G, Bezzon OL, Comparative study of cobalt-chromium removable partial denturesJ Prosthet Dent 2002 88(3):290-96. [Google Scholar]

[19]. Carr AB, McGivney GP, Brown DT, Mc Cracken’s. Removable partial denture prosthodontics 2004 11th edSt. LouisElsevier:79-117. [Google Scholar]

[20]. Phillips RW, Skinner’s science of dental materials 1991 9th edPhiladelphiaWB Saunders:40 [Google Scholar]

[21]. VandenBrink JP, Wolfaardt JF, Faulkner MG, A various removable partial denture clasp materials and fabrication procedure for placing clasps on canine and premolar teethJ Prosthet Dent 1993 70(2):180-88. [Google Scholar]

[22]. Arda T, Arikan A, An invitro comparison of retentive force and deformation of acetal resin and cobalt-chromium claspsJ Prosthet Dent 2005 94(3):267-74. [Google Scholar]

[23]. Ahmad I, Sherriff M, Waters NE, The effect of reducing the number of clasps on removable partial denture retentionJ Prosthet Dent 1992 68(6):928-33. [Google Scholar]

[24]. Bates JF, The mechanical properties of the cobalt-chromium alloys and their relation to partial denture designBr Dent J 1965 119:389-96. [Google Scholar]

[25]. Morris H, Farah JW, Craig RG, Hood JA, Stress distribution within circumferential clasp armsJ Oral Rehabilitation 1976 3(4):387-94. [Google Scholar]

[26]. Tannous F, Steiner M, Shahin R, Kern M, Retentive forces and fatigue resistance of thermoplastic resin claspsDental materials 2012 28:273-78. [Google Scholar]

[27]. Alwan SS, Ismail IJ, Retentive forces, tensile strength and deflection fatigue of Acetal thermoplastic clasp material in comparison with cobalt-chromium alloyJournal of Baghdad college of dentistry 2014 26(1) [Google Scholar]