The mechanical properties of an archwire are an important consideration in the fabrication of an orthodontic appliance. Even the most advanced bracket systems will not perform adequately when paired with archwires of insufficient desirable properties.

There are numbers of arch wire options available from which an orthodontist can choose depending upon the clinical requirement. Stainless steel alloy, introduced in 1929, slowly found its way into orthodontic field and became an ideal wire with good mechanical properties and extreme affordability. From 1940’s, it still remains to be the wire of choice for most clinical situations. With the introduction of the Beta titanium wire in 1980’s which possess unique balance of high spring back and formability with low stiffness [1–4] it has become one of the material of choice but its high friction is a major disadvantage when it was used in sliding mechanics. Hence there were several attempts made to reduce the friction of Beta titanium archwires by surface treating the wire with ion implantation. Burstone and Farzin-Nia F showed that ion implantation increases archwire hardness, reduces flexibility, and improves surface finish [5].

Ion-implantation is a technique in which the metallic substrate is hardened by the implantation of high energy ions in a very thin surface layer. This process of ion-implantation is supposed to reduce the surface roughness and friction of the archwires [5].

Hence the purpose of this study was to evaluate and compare the frictional characteristics, surface characteristics and load deflection rate of coloured (Ion implanted) TMA wires with uncoated TMA wires.

Materials and Methods

This study was conducted at Central Institute of Plastic Engineering and Technology (CIPET), Chennai, India.

In this study 3 different types of archwires were evaluated for friction, surface characteristics and load deflection rate which have been grouped as shown in [Table/Fig-1].

Archwire alloys used in the study

| Arch wire | Alloy | Size | Sample size | Manufacturer |

|---|

| Group I | Uncoated TMA | 0.019”×0.025” | 5 | Ormco |

| Group II | Purple TMA | 0.019”×0.025” | 5 | Ormco |

| Group III | Honey dew TMA | 0.019”×0.025” | 5 | Ormco |

Frictional Characteristics

Four lower incisors brackets were bonded as half arch fixed appliance setup with archwire ligated in position. The wires tested were of 0.019"x0.025" dimension and evaluation of the friction was done using Instron Universal testing machine (Instron Corporation Canton, Massachusetts, USA) [6–8].

In order to negate the effects of the in-built torque in the brackets, a section of stainless wire having dimensions of 0.021"x0.025" was placed in the bracket slots to align the lower anterior brackets [9]. The distance between the anterior brackets were kept at 3 mm simulating the clinical situation. The inter bracket distance was standardized for all the jigs with the help of plastic sleeves. Before testing, the brackets and the straight length wire were degreased with ethanol to remove any residue or debris. Then, the 6cm long 0.019"x0.025" wire was ligated to the brackets with an un-stretched elastomeric ligature [10], for the purpose of standardization. A total of 15 samples were tested. The Instron Universal Testing Machine (UTM) was used to achieve a steady state displacement of the archwire relative to the bracket allowing evaluation of the static frictional resistance. The crosshead speed was adjusted at 5mm per minute [9]. The load cell generates the maximum load (N) which was recorded graphically in the computer connected to the Instron testing machine and results were tabulated. Each specimen in 3 groups was tested repeatedly for 5 times and the results were recorded.

Load Deflection Rate

The load deflection characteristics of uncoated and coloured ion implanted (Purple and Honey dew) TMA wires from each group was evaluated with Instron universal testing machine. About 38mm of total wire length was taken, out of which 6mm constituted the anterior portion whereas the posterior portion was 22mm. In order to secure the specimen in the Instron Universal testing machine, about 5mm length on each side was spared in each specimen. Five straight length archwire specimens from each group were made in reverse U loop design [11] and evaluated. They were formed as canine retraction loops with the dimensions matching one side of the dental arch consisting of maxillary canine, first and second premolar, and first molar which are shown in [Table/Fig-2]. A total of 15 specimens (5 samples for each group) were used for evaluation with the Instron universal testing machine, the load cells of which extended at 1 mm/min [11]. The load at the extension of 1.5 mm was recorded and statistically calculated.

Retraction loop tested in Instron Universal testing machine

Surface Characteristics

Two, one cm straight length archwire specimens from each of the archwire alloy materials was taken to evaluate the surface characteristics of 0.019”×0.025” uncoated TMA and coloured (Purple and Honey dew) ion implanted TMA wires with scanning electron microscope before and after friction testing was done. Since the protocol required wires to be tested as received, they were not altered by anodic or physical polishing. Surface characteristics of each of the specimens of wires from each group were studied with the help of a scanning electron microscope (FEI Quanta, FEG 200, Hillsboro, OR, USA) [12]. A one cm long specimen of each alloy wire was mounted on studs, which were later placed in the vacuum chamber of the SEM. The accelerating voltage, angle of fit and the aperture was adjusted to optimize the quality of the micrograph. The scanned surface was viewed at the magnification of 500x and micrographs for each alloy type were obtained [13].

Results

Frictional Characteristics

The coefficient of friction obtained after friction evaluations for all three groups of archwires were tabulated and shown in [Table/Fig-3]. The results were examined using one way analysis of variance (ANOVA) with the data entered into the Sigmastat statistical package (Microsoft) followed by Post-hoc comparison shown in [Table/Fig-4,5] respectively.

Static frictional values for various TMA archwire alloys

| Group | Materials | N | Mean | S.D |

|---|

| 1 | Uncoated TMA wires | 5 | 7.9020 | .42429 |

| 2 | Purple TMA wires | 5 | 6.9780 | .23435 |

| 3 | Honey Dew TMA wires | 5 | 5.8740 | .27364 |

All units are in Newton seconds

One-way ANOVA analysis for Frictional characteristics

| Sum of squares | df | Mean square | F | Sig. |

|---|

| Between GroupsWithin groupsTotal | 10.3091.23911.548 | 21214 | 5.1540.103 | 49.911 | .000 |

Post-Hoc comparison for frictional characteristics

| (I) Group | (J) Group | MeanDifference(I-J) | StdError | Sig. | 95% ConfidenceInterval |

|---|

| LowerBound | UpperBound |

|---|

| Group 1-UncoatedTMAwires | Group 2-PurpleTMA wiresGroup 3-HoneyDew TMA | .92400*2.02800* | .20325.20325 | .002.000 | .38181.4858 | 1.46622.5702 |

| Group 2-Purple TMA wires | Group 1-UncoatedTMA wiresGroup 3-HoneyDew TMA | -.92400*1.10400* | .20325.20325 | .002.000 | -1.4662.5618 | -.38181.6462 |

| Group 3-HoneyDewTMA | Group 1-UncoatedTMA wiresGroup 2-PurpleTMA wires | -2.02800*-1.10400* | .20325.20325 | .000.000 | -2.5702-1.6462 | -1.4858-.5618 |

*. The mean difference is significant at the .05 level

When all the normal forces and repetitions were combined (averaged) it was found that the Honey dew coloured TMA (group III) had the lowest static frictional force values followed by the purple TMA (group II) and Uncoated TMA wires (group I).

Load Deflection Rate

Load deflection rate was evaluated for all three groups of TMA wires and the mean and standard error of the mean were calculated and shown in [Table/Fig-6]. One-way analysis of variance (ANOVA) and Post-Hoc comparison was also done to see the comparison between the groups which were shown in [Table/Fig-7,8] respectively.

Load deflection rate for various TMA wires

| Group | Materials | N | Mean | S.D |

|---|

| 1 | Uncoated TMA wires | 5 | 3.6480 | .28270 |

| 2 | Purple TMA wires | 5 | 2.5820 | .37326 |

| 3 | Honey Dew TMA wires | 5 | 2.3180 | .18130 |

All units are in Newton seconds

One-way ANOVA analysis for Load Deflection rate

| Sum of squares | df | Mean square | F | Sig. |

|---|

| Between GroupsWithin groupsTotal | 4.9581.0085.967 | 21214 | 2.479.084 | 29.501 | .000 |

Load deflection rate

Post-Hoc comparison for load deflection rate

| (I) Group | (J) Group | MeanDifference(I-J) | StdError | Sig. | 95% ConfidenceInterval |

|---|

| LowerBound | UpperBound |

|---|

| Group 1-UncoatedTMAwires | Group 2-PurpleTMA wiresGroup 3-HoneyDew TMA | 1.06600*1.33000* | .18334.18334 | .000.000 | .5769.8409 | 1.55511.8191 |

| Group 2-Purple TMA wires | Group 1-UncoatedTMA wiresGroup 3-HoneyDew TMA | -1.06600*.26400 | .18334.18334 | .000.353 | -1.5551-.2251 | -.5769.7531 |

| Group 3-HoneyDewTMA | Group 1-UncoatedTMA wiresGroup 2-PurpleTMA wires | -1.33000*-26400 | .18334.18334 | .000.353 | -1.8191-.7531 | -.8409.2251 |

Multiple comparisons Dependent variable: Load deflection rate Tukey HSD

*. The mean difference is significant at the .05 level

The results showed that coated TMA wires i.e., Purple (group II) and Honey dew (group III) TMA wires had low load deflection rate when compared to uncoated TMA wires (group I). On Post hoc tests, there was no significant difference between Purple and Honey dew TMA wires.

Surface Characteristics

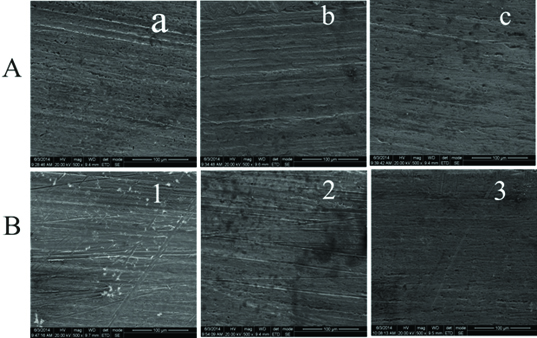

The wire samples when viewed under the scanning electron microscope under a magnification of 500 X revealed the following results, which were shown in [Table/Fig-9].

Scanning electron micrograph of: a) as received archwires at 500x, an-uncoated TMA wire, b) purple TMA wire, c) Honeydew wire and B, Scanning electron micrograph of archwires after sliding at 500x: 1-uncoated TMA wire, 2-purple TMA wire and 3- Honeydew wire

As Received Wires

The results showed that Honey dew (group III) TMA wires had the smooth surface with few irregularities followed by Purple (group II) TMA wires and the Uncoated (group I) TMA wires. Uncoated TMA wires had the roughest surface with multiple small ovoid areas and small craters with fewer elevated regions.

After Sliding

The results showed that Honey dew TMA wires had the least surface alterations after sliding followed by Purple TMA wires and Uncoated TMA wires. Uncoated TMA wires showed large areas of stress, which could be seen as black hazy patches, prominent ridges and drawing lines, thereby a further increase in surface irregularities

Discussion

Optimal range of forces is needed for efficient tooth movement. When sliding mechanics are used, a proportion of the applied force is dissipated to overcome friction and much of the remainder force is transferred to supporting structures of the tooth to mediate tooth movement. This implies that the frictional property can effectively play a significant role in the biomechanics of tooth movement.

Frictional Characteristics

In friction mechanics, wire selection plays an important role for efficient tooth movement. A multifactorial analysis done by Drescher et al., showed that wire material was the decisive factor in affecting frictional involvement when compared to retarding force (biologic resistance), wire size and bracket width [14]. TMA wires with its unique balance of high spring back and formability with low stiffness can be used for either initial tooth alignment or finishing arches. Its high friction [15–19] is a major setback when it comes to sliding mechanics. But a significant breakthrough by Burstone et al., showed that Ion implantation does improve the surface properties and reduce the frictional characteristics [5]. With the introduction of ion implanted coloured TMA wires for the purpose of reducing friction, the question remains whether it can maintain or improve the good properties of TMA wires like formability, ductility and low load deflection rate [5].

Cash et al., had stated that there is a significant difference in thickness of ion implantation between Honey dew and Purple coloured TMA wires, hence this study was done to evaluate and compare these two coloured TMA wires in two different groups with the control group of uncoated TMA wires [20].

In the evaluation of frictional characteristics, the ion implanted varieties of the TMA archwires exhibited significantly lower frictional resistance than the uncoated TMA archwires. Several studies on ion-implanted TMA by Burstone et al., Rosemary Ryan, Husmann et al., and Umal H Doshi et al., showed similar results of reduction in frictional forces for Ion implanted TMA wires [5,21–23]. Burstone had even said that ion implantation radically reduces TMA’s high frictional coefficient to about the same level as that as of the stainless steel. Vinod Krishnan et al., had concluded that ion implantation does reduce the friction of the TMA wires [24]. The reduction in the friction could be attributed to the process of ion-implantation, as it tends to increase hardness and improves the surface finish as ions penetrate the surface regardless of the composition of the material.

Honey dew coloured TMA wire showed reduced friction when compared to Purple TMA wire. This result was in concurrence with the results of Cash et al., and Premanand et al., [20,25]. Cash et al., found reduction in frictional resistance only in Honey dew coloured TMA wires but whereas in other coloured TMA wires like aqua, purple and violet, they could not find any significant difference when compared to the uncoated regular TMA wires [20]. As suggested by Cash et al., as the thickness of the ion implantation increases, surface irregularities and surface reactivity of the material decreases, whereas, hardness increases, thereby reducing the frictional resistance [20]. This explains the reason that Honey dew coloured TMA wire with increased thickness of the ion implantation has less friction than Purple coloured TMA wire.

Load Deflection Rate

TMA wire’s unique advantage is its formability and low load deflection rate [4,26–28]. Hence the ion implanted coloured TMA should maintain these properties. In this study the load deflection rate was done using closed looped design as it incorporated more length of the wire and reduction of force level was possible. The two coloured TMA wires were consistently showing lower load deflection characteristics than its uncoated forms, which was statistically significant. Vinod Krishnan et al., had concluded in his study that ion implanted TMA had low load deflection rate in comparison to its uncoated forms [24]. The low load deflection properties of the coloured TMA wires might be due to the etching and heating process, while coating is performed over archwire blanks. Orthodontic loop making involves complex bending processes with high chances of archwire fracture. However, both coated archwires withstood the bending process and the load deflection rates exhibited were also similar to each other.

SEM Study

Scanning electron micrographs of as received wires showed that ion implanted TMA wires had reduced surface roughness compared to uncoated regular TMA wires which was in concurrence with the results of Burstone and Farzin Nia, Vinod Krishnan et al., Vincenzo D’Anto et al., and Manu Krishnan et al., [5,13,24,29]. In contrary to this studies by Robert P Kusy et al., have concluded that the surface roughness cannot be drastically reduced by the ion implantation, moreover the ions may not evenly get implanted into all bearing surfaces [30]. In this study Honey dew coloured TMA wire showed the least surface roughness and found to be having better surface finish than purple coloured TMA wires. Similar results were obtained by Manu Krishnan et al., Cash et al., and Premanand et al., [13,20,25]. Cash et al., has also found that the thickness of the ion implantation was more in Honey dew coloured TMA wire when compared to Purple coloured TMA wires [20]. This finding gives us an idea that the increased thickness of the ion implantation might be responsible for the improved surface finish by covering up most of the surface irregularities.

Evaluation of the surface roughness of the wires after sliding showed that the untreated TMA wires exhibited the maximum alteration of the surface morphology after sliding, followed by the Purple coloured TMA and the Honey dew coloured TMA archwire. These differences in surface alterations after sliding may be because of differences in frictional resistance exhibited by the materials. Since Honey dew coloured TMA wire showed improved surface finish, thereby decreased surface reactivity and least frictional properties, the surface alteration was also least after sliding as it might not have bonded to the bracket as much as the other two wires.

Limitation

As with any in-vitro study limitation, this investigation does not replicate the exact clinical intra oral environment during tooth movement. One must be careful about relating this information to clinical situations and hence in-vivo studies have to be conducted in the future to test these wires under different clinical scenario to truly establish their efficiency in orthodontic biomechanics.

Conclusion

The load values obtained for frictional characteristics showed that uncoated TMA wires generated higher frictional force compared to coloured ion implanted (Purple and Honey dew) TMA wires. Honey dew coloured ion implanted TMA wires generated the least frictional force followed by Purple coloured ion implanted TMA wires making it an ideal wire for sliding mechanics. The values obtained for load deflection rate indicates that both coloured ion implanted (Purple and Honey dew) TMA wires had significantly low load deflection rate when compared to uncoated TMA wires. Hence coloured ion implanted TMA wires can be clinically used in situations like periodontally compromised patients who require very low consistent forces for tooth movement. SEM evaluation of surface characteristics of as received Honey dew coloured TMA wires showed smoother surface than Purple coloured TMA wires whereas uncoated TMA wires showed the roughest surface. After sliding, Honey dew coloured wires had least surface alterations followed by Purple coloured TMA wires whereas uncoated TMA wires showed the maximum surface alteration after sliding.