Artificial teeth forms an integral part of denture prosthesis. Although various materials like acrylic resin, composite resin, porcelain, teeth with metal inserts have been used with varying degrees of success, the principal advantage of acrylic teeth is their ability to bond to the acrylic denture base material [1]. The bonding of acrylic teeth to the denture base is necessary to improve the durability of the prosthesis.

The debonding of acrylic resin teeth from denture base resins remains a major problem in everyday clinical practice [2–6]. Studies have revealed teeth debonding to be the most frequent repair in removable prosthodontic practice and adhesive bond failure between acrylic resin teeth and denture base resin as the most common type of bond failure [7–10].

In the literature several methods have been suggested by various authors to improve the bond strength between acrylic resin teeth and denture base resins. These include placement of retentive grooves on the ridge lap surface of the teeth, application of chemical agent on the ridge lap areas and sandblasting the ridge lap area. All these methods have been individually tested and compared keeping untreated teeth as a control group. In all these studies a definite increase in bond strength has been reported by employing one of these methods of enhancing retention [11,12].

These methods of improving the bond strength between acrylic resin teeth and denture base resin have been separately studied but very few studies have evaluated and compared all these methods together along with an untreated surface.

In view of the above considerations, the aim of the present invitro study was to evaluate the shear bond strength between denture base resin and acrylic resin teeth using different surface modifications namely placement of retentive grooves, chemical treatment and sandblasting on the ridge lap area and to compare these results with that of the unmodified surface on the ridge lap area of acrylic teeth. The null hypothesis adopted was that different surface modifications of the ridge lap area have no effect on the shear bond strength between denture base resin and acrylic resin teeth.

Materials and Methods

The present study was conducted in 2013 in the Department of Prosthodontics, Ragas Dental College & Hospital, Chennai, India.

The following methodology was adopted for this study:

1. Fabrication of Acrylic Prototype Model.

2. Duplication of Acrylic Prototype model.

3. Fabrication of Test Specimen.

4. Testing of Bond Strength.

1. Fabrication of Acrylic Prototype Model:

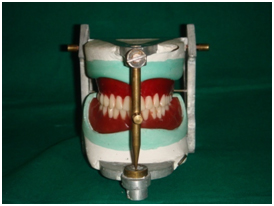

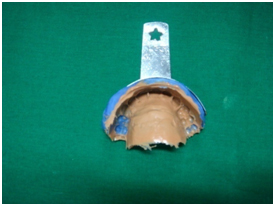

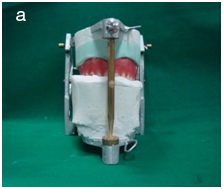

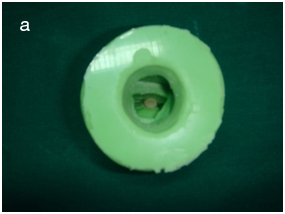

To ensure standardised test specimens, an acrylic prototype model was fabricated first. Teeth arrangement was done following principles of teeth arrangement on maxillary and mandibular edentulous cast mounted on a mean value articulator in Class I ridge relation [Table/Fig-1]. An impression of the maxillary anterior region from the canine to canine was obtained by two step polyvinyl siloxane putty wash impression technique in a stock tray [Table/Fig-2]. Molten modelling wax was gently poured in to the impression and allowed to harden. The wax model was retrieved from the impression [Table/Fig-3].

Sectional Impression of Maxillary Teeth

Wax Model Obtained From Maxillary Sectional Impression

Following this, a plaster index of the maxillary teeth arrangement was obtained. The mandibular cast with the teeth arrangement was removed from the articulator. A glass plate was placed on the mandibular member of the articulator. Petroleum jelly was applied to the labial surface and incisal third aspects of the maxillary anterior teeth on the articulator and the glass plate, as these surfaces were the designated surfaces contacting the indexing plaster. A mix of dental plaster was placed on the glass plate and the upper member was closed over and in to the plaster mix up to one third of the labial surface of the teeth, to obtain a plaster index of the labial and incisal aspects of the maxillary anterior teeth [Table/Fig-4a]. This was to facilitate the placement of the test tooth in the same position and inclination for all the teeth as in the master model.

The set plaster index was removed from the assembly and placed on the model platform of the dental surveyor at a 0 degree tilt [Table/Fig-4b]. The wax model, previously obtained was placed in the indentations of the plaster index.

Plaster Index Placed on Surveying Table

A wax block of size 2.5cm X 2.5cm was attached to the surveying arm of the surveyor and lowered till it contacted the wax model [Table/Fig-4c]. The block was fused with the superior aspect of the wax model to become a single unit. The wax prototype model obtained in the above manner was acrylised using heat cure acrylic resin (DPI Heat cure, Mumbai, India). The acrylised model was trimmed and polished. A knob of autopolymerising acrylic resin (DPI Cold cure, Mumbai, India) was attached to the base of the acrylised model to facilitate easy removal of the model after future duplication procedures. The model thus obtained was designated as the acrylic prototype model.

Orientation of Wax Model to Plaster Index

2. Duplication of Acrylic Prototype model:

The prototype model was stabilised on a glass slab with the help of modelling wax. A duplicating ring (Bego, Germany) of adequate size was selected and seated around the prototype model on the glass slab. Duplicating silicone (KalSil, Kalabhai, Mumbai, India) was mixed and poured as per manufacturer’s instructions over the prototype model. After the silicone had set the acrylic prototype model was removed from the mould.

3. Fabrication of test specimens

a. Selection and preparation of acrylic teeth for the test samples

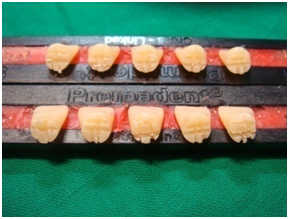

Forty, maxillary left central incisors of the same shade and size were selected (M1-24) (Premadent, Super Dental Products, New Delhi, India). The selected teeth were randomly divided into four groups of ten samples each, according to the type of surface modification of the ridge lap area, described as follows:

Group-I; (Control Group) The ridge lap areas of this group of ten test sample teeth were left unmodified [Table/Fig-5].

Unmodified Ridge Lap Area

Group-II; (Sandblasted Group) [13,14]: The ridge lap areas of this group of ten test sample teeth were sand blasted with 250μm of aluminium oxide (Aluminox -250, Delta, Chennai, India) for 30 seconds at 4 p.s.i pressure [Table/Fig-6]. This surface modification was carried out just before obtaining the wax model with the test tooth.

Sandblasting of Ridge Lap Area

Group-III; (Chemical Treatment Group) [15,16]: The ridge lap areas of this group of ten test sample teeth were treated with 1:1 ratio of methylmethacrylate monomer (DPI Heat cure monomer, Mumbai, India) and dichloromethane solution (Lab Chemicals, Chennai, India). This modification was done after the dewaxing procedure prior to the packing the mould with acrylic dough [Table/Fig-7].

Chemical Treatment of Ridge Lap Area

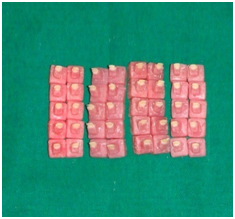

Group-IV; (Retentive Grooves Group) [17,18]: The ridge lap areas of this group of ten test sample teeth were prepared by placing 2mm deep grooves using straight fissure diamond abrasive. Two vertical and two horizontal grooves were placed [Table/Fig-8]. This surface modification was carried out just before obtaining the wax model with the test tooth.

Vertical and Horizontal Retentive Grooves Placed on Ridge Lap Area

b. Preparation of wax model with test teeth

The test teeth as per above mentioned test group requirements were placed in the duplicated silicone mould [Table/Fig-9a] and molten wax was carefully flowed into the mould. After the wax hardened, the sample was retrieved from the silicone mould. The wax replicating the adjacent anterior teeth on either side of the test teeth and the knob at the base were sectioned and removed such that the wax model had only a wax base and the tooth meant for testing. The wax models were appropriately finished [Table/Fig-9b].

Tooth positioned into the mould

Forty wax models were obtained and designated as Groups I, II, III and IV as per the designated surface modifications. The finished wax models along with their respective test tooth were processed in heat cure acrylic by following conventional flasking, dewaxing, packing & curing procedures.

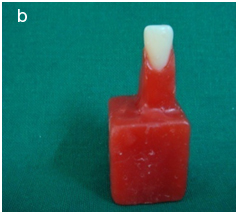

Acrylization of the Test Sample: The acrylized samples were finished and polished. The finished test samples were subjected to shear bond strength testing [Table/Fig-10].

4. Testing of the samples

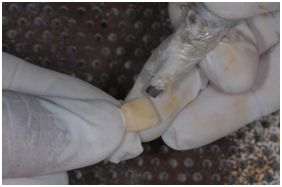

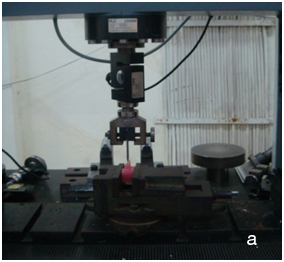

The acrylized test samples were tested for shear bond strength on a universal mechanical testing machine (Lloyd’s universal testing machine, U.K.) [Table/Fig-11a]. A 2mm groove was placed with a straight fissure bur on the palatal aspect of the test teeth so as to facilitate proper seating of the testing chisel and to prevent it from slipping during application of the load [Table/Fig-11b].

Testing of Sample in Universal Testing Machine

Placement of 2mm Groove in Palatal Aspect

Test samples were fixed to the sample fixture at the bench vice of the machine with the monobeveled chisel blade placed flat against the prepared 2mm groove. An incident pressure of 2 kg at a crosshead speed of 2mm/min was applied at this junction until the tooth fractured off the specimen. The computer attached to the testing machine recorded the load at which this fracture occurred. From these load values obtained, shear bond strength in mega Pascal (Mpa) was calculated.

Results

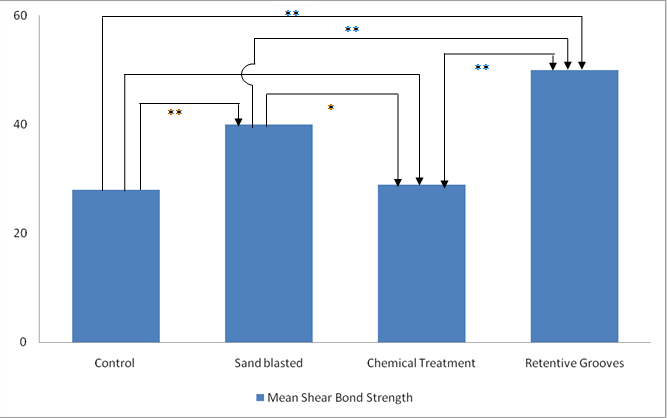

The shear bond strength (Mpa) was calculated from the fracture load values using the formula mentioned below:

Newton (N) = Kg×9.81

The mean shear bond strength values, standard deviation and the minimum and maximum values of shear bond strength of the four test groups are presented in [Table/Fig-12]. Among the four test groups, Group IV (Retentive grooves) exhibited the highest mean shear bond strength value, followed by Group II (sandblasted group), Group III (chemical group) and Group I (control group) respectively. Statistical analysis between test groups was done using One-way ANOVA and Student-Newman-Keul test and the results are presented in [Table/Fig-13]. The mean shear bond strength value of the retentive groove test samples was highly significant when compared to those of the sandblasted, chemically treated and unmodified test samples. The mean shear bond strength of the sandblasted test samples was highly significant compared to that of the unmodified test samples and significant compared to that of the chemically treated test samples. The mean shear bond strength of chemically treated test was not significant compared to that of the unmodified test samples.

Mean, Standard Deviation, Minimum and Maximum Shear Bond Strength Between Four Test Groups

| N | Mean±Standard Deviation | Minimum | Maximum |

|---|

| Control | 10 | 27.460±4.4677 | 19.8 | 34.5 |

| Sand Blasted | 10 | 33.900±3.8239 | 26.2 | 38.7 |

| Chemical Treatment | 10 | 30.740±2.5448 | 26.4 | 35.4 |

| Retentive Grooves | 10 | 42.010±4.5121 | 34.1 | 48.5 |

Comparison of mean shear bond strength values

* - Significant **- Highly significant

Discussion

The study evaluated that the shear bond strength between denture base resin and acrylic teeth with surface modifications of the ridge lap area was evaluated and compared with that of unmodified teeth. Based on the data the null hypothesis that the different surface modifications of the ridge lap area had no effect on the shear bond strength between denture base resin and acrylic resin teeth was rejected. The results of the study shows a significant difference in mean bond strength when the ridge lap area of the acrylic teeth were submitted to different modifications, when compared with the control group.

In the present study, the shear bond strength between denture base resin and acrylic teeth with surface modifications of the ridge lap area was evaluated and compared with that of unmodified teeth. Surface modifications such as, placement of vertical and horizontal retentive grooves, treating the ridge lap area with a combination of methyl methacrylate monomer and dichloromethane, sandblasting of the ridge lap area with 250μ aluminium oxide have been employed in this study to know their effect on the bond strength between acrylic resin teeth and denture base resin. The sample size in each test group was limited to ten samples based on that followed in similar studies [2,5,7,18]

The results of the present study revealed that acrylic resin teeth treated with retentive grooves (Group IV) recorded the highest mean shear bond strength value (42.01Mpa), whereas the control group samples which were left untreated recorded the least mean shear bond strength value (27.46 Mpa). Sandblasted samples (Group II) and chemically treated samples (Group III) recorded mean shear bond strength of 33.9Mpa and 30.9Mpa respectively [Table/Fig-12].

It was evident from the results that mean shear bond strength between acrylic resin teeth and denture base resin was enhanced significantly by either placement of retentive grooves or sandblasting as compared to that of the unmodified surface. However, the mean shear bond strength between acrylic resin teeth and denture base resin was not enhanced significantly by chemical treatment of the ridge lap area as compared to unmodified surface indicating that chemical treatment did not greatly enhance the penetration of monomer into the resin surface. Although the most likely mechanism for the increase in bond strength of acrylic tooth to denture base is the result of tooth surface treatment, the effects of the inherent strengths of acrylic tooth and denture base material cannot be eliminated.

The bond strength values obtained for the samples with retentive grooves (Group IV) in the present study werein line with the study done by Cardash et al., who evaluated the bond strength of acrylic resin teeth with and without retentive grooves processed onto standard and high impact denture base resin [17,18]. The retentive grooves were oriented either vertically or horizontally on the ridge lap area in that study. The author attributed the improvement in bond strength to the increased area available for physical and chemical bonding between acrylic resin teeth and the denture base.

Studies have revealed a significant increase in bond strength following sandblasting with 250μ of alumina, suggesting that the improvement in the bonding is due to better micromechanical retention [13,14]. In the present study, similar improvement in the shear bond strength have been obtained by sandblasting with 250μ of alumina (Group II) which can be attributed to increase in surface area available for bonding.

Studies have revealed that painting the ridge lap area with 1:1 ratio of monomer and dichloromethane considerably increased the bond strength between the acrylic resin teeth and denture base resin [15,16,19]. This combination was selected as the second type of surface modification (Group III) in the present study. The result obtained in the present study for this type of surface treatment was not significantly different from that obtained for the untreated samples. Others have studied the effect of different chemical treatments with/without mechanical treatment and have reported improvement in bond strength [7,19–21]. This could be due to differences in sample preparation and study environment. This as well as the possible effects of these chemicals on other properties of denture base resin and acrylic resin teeth merits further investigation.

Some of the published literature between denture base resin and acrylic resin teeth are presented in [Table/Fig-14] [2–7,13,15,18,19]. However, the surface treatments and the study design followed in some of the studies [4,5,7] were different to that followed in this study and hence correlations with those results cannot be drawn.

Studies on shear bond strength between acrylic resin teeth and denture base resin at a glance

| Journal | Author & year | No of Samples | Materials Used | Testing Groups | Testing Methodology | Results |

|---|

| Journal of Prosthodontics(JOP) | Marra J [2]2009 | 20 specimens for Denture base+acrylic Teeth(n=10) | Three acrylic teeth(Biotone,Trilux, Ivoclar)Four Denture Base ResinsMicrowave(Acron)Heat cure(Lucitone&Qc)Light Polymerised(Versyo) | 1. Without Thermocycling2. With Thermocycling | Thermo-cyclingShear bond strength test | Highest Shear bond strength was observed withLucitone/Biotone(control)Lowest with Qc/Trilux in the Thermocycled GroupThermocycling reduced bond strength. |

| Journal of Prosthodontics(JOP) | Feltcher-Stark ML [3]2011 | 160 central Incisors(n=40) | Denture Base ResinsLucitone(PMMA)Eclipse (UDMA) | 1. Ground surface (control)2. Ground surface+Diatoric3.Groundsurface+Bonding agent.4. Ground surface+Bonding agent+ Diatoric | Thermo-cyclingCyclic loadingShear bond strength test | UDMA shows greater shear bond strength.Group 4 showed greatest shear bond strength. |

| Indian Journal of Dental Research | Baskaran S [4]2012 | 80 CentralIncisors(n=40) | Acrylic Resin TeethDenture Base Resin | 1. Unmodified surface (Control)2. Ridge lap area treated with Tin foil substitute. | Shear Bond Strength | Unmodified surface showed highest bond strength.Tin foil substitute contamination of ridge lap area greatly reduced the bond strength |

| ActaOdontol. Latinoam | Melato B [5].2013 | 40 acrylic teeth(n=10) | Biolux,Trilux, Biotone IPN & VipidentplusAcrylic resin teethDenture base material | 1. Untreated surface (Control)2. Monomer application (MA)3. Airabrasion (AA) or Diatoric cavity(DC) | Shear Bond Strength | Biolux Teeth showed highest bond strength values compared to other branded teeth in all the groups. |

| Journal of Prosthodontics(JOP) | Akin H [6]2014 | 60 Molar Teeth(n=15) | Heatcure(PMMA), (Meliodent)Light cure(UDMA), (Eclipse)Denture Base Resins | 1. Acrylic untreated(AC)2. Eclipse untreated (EC)3. Treated with eclipse bonding agent.(EB)4. Er:YAG Laser irradiated eclipse (EL) | Shear bond strength test | Highest bond strength in EB.Lowest bond strength in EC. |

| Journal of International Oral Health | Krishna VP [7] 2014 | 180 wax specimens (n=10) | Heat cure, High impact & Flexible Denture base resin.Acrylic teeth | 1. Untreated2. Monomer3. Acetone 99%4. Chloroform 99%5. Adhesive cynoacrylate6. Ethyl acetate 99% | Shear Bond Strength | High Impact denture base resin andethyl acetate group showed Highest bond strength. |

| Journal of Oral Rehab | Chung KH [13]2008 | 80(n=20) | Three different brands of acrylic teethHeat cure acrylic resinMicrowave Polymerised acrylic resin | 1. Untreated (control)2. Grinding3. Grinding+sandblasting | Shear Bond Strength | Acrylic teeth treated with grinding and sandblasting showed greatest bond strength.Processing with Heat cure acrylic resin showed highest bond strength. |

| Int J Prosthodont | Takahashi Y [15]2000 | 60(N=20) | Conventional denture teeth,Crosslinked denture teethHeat cure denture base resin, Microwave | 1. Untreated (control)2. Prepared with diatorics or treated with dichloromethane3. Treated with solvent. | Shear bond strength | Heat cure showed highest bond StrengthApplicationof dichloromethaneshowed increased bond strength compared to diatorics. |

| J.Prosthet Dent | Cardash [18]1990 | 60 Maxillary lateral incisors,60 Maxillary canine(n=10) | Acrylic Resin teeth (Luxor)Standard Denture Base Resin (De Treys)High impact heat cure acrylic resin | 1. No mechanical prepration .2. A mesiodistal groove of 2mm deep and wide was prepared in ridge lap area.3A vertical groove of the same dimensions was cut into centre of ridge lap area. | Shear Bond Strength | Vertical grooves showed higher bond strength comparedHorizontal groovesHigh impact resin showed highest bond strength values |

| Journal of Clinical and Diagnostic Research | Jain G [19] 2014 | Maxillary central incisors (n=60) | Acrylic Resin TeethDenture Base Resin | 1. Untreated surface (Control)2. Monomethyl methacrylate application3. Dichloromethane application | Shear Bond Strength | Dichloromethane on ridge lap area shows increased bond strength compared to methylmethacrylate and control surface. |

| Journal of Clinical and Diagnostic Research | Mahadevan V,et al.,(Current Study) | 40 Maxillary central incisors(n=10) | Acrylic Resin TeethDenture Base Resin | 1. Untreated Surface (control)2. Sandblasting3. Treating ridge lap area with 1:1 Dichloromethane and Monomer4. Placement of Vertical and Horizontal grooves | Shear Bond Strength | Placement of retentive grooves showed highest bond strength followed by sandblasting ridge lap area. Chemical treatment with monomer and dichloromethane showed least bond strength. |

Limitations of The Study

It is well-accepted that in vivo performance does differ from an invitro setting. This invitro study design did not consider the effects of aging, thermocycling and cyclic loading of the test specimens. Future experiments designed and performed to investigate the effects of the internal strengths of both the acrylic tooth and denture base material on the mechanism of debonding with or without surface modifications, simulating in vivo conditions are recommended to enhance the results obtained in the present study.

Conclusion

The present study concluded that mechanical surface modification of the ridge lap area of acrylic resin teeth, by placement of retentive grooves or by sandblasting significantly improved the shear bond strength between the denture base resin and acrylic resin teeth. Hence, mechanical modifications of the ridge lap area of artificial teeth are of significance in ensuring adequate bond between denture teeth and denture base resin.