The aim of FPD is to restore function and esthetic of lost intra-oral structures without hampering the oral and general health of the patients [1]. Ill fitting restoration potentially affect abutment teeth and supporting periodontium as it provides access and host for oral bacteria adherence which can cause secondary caries and traumatic periodontal irritation [2,3]. Precise well fitting cast metal restorations have some discrepancies between the margins of the restoration and the preparation of abutment tooth [4]. Luting cement fills space between a fixed prosthesis and the prepared tooth [5].

One problem recognized during cementation of the crowns is that the cementing medium may prevent the seating of the crown, positioning it in hyperocclusion and causing inadequately sealed margins. Open margins cause the abutment teeth to become sensitive for prolonged period after final cementation. Inadequately sealed margins along with occlusal discrepancies cause the crowns to loosen prematurely [6].

The escape path of the cement at the margins decrease as the crown is seated on a prepared tooth. Different finish lines have different effect on the escape of cement during the cementation process. Hence, this study was undertaken to compare the marginal sealing ability of the various configurations of the finish lines and its effect on the occlusal seat of the full crowns after cementation.

Materials and Methods

The study was conducted during the period of February 2006 to February 2007 at the Department of Prosthodontics of Government Dental College and Hospital Mumbai, Maharashtra, India. This study was proposed at the ethical committee of the Government Dental College and Hospital Mumbai, Maharashtra with all the details regarding the study, and the approval was obtained.

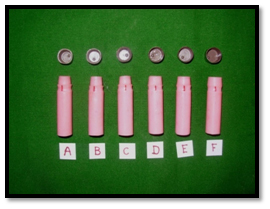

Six stainless steel metal dies were machined to simulate molar crown preparations. The diameter was 10 mm and height was 6mm. A taper of 5 degrees was given to the dies. The occlusal surface was kept flat and a small circular dimple was machined for reorientation of the wax pattern and metal copings, margins of various designs were machined accurately [Table/Fig-1].

Metal Dies of various finish line

Group A- Ninety degree shoulder, Group B-Rounded shoulderGroup, C-45 degree sloped shoulder, Group D-Chamfer, Group E-Long chamfer, Group F-Feather edge

The margins prepared were-

Group A- Ninety degree shoulder

Group B- Rounded shoulder

Group C- 45 degree sloped shoulder

Group D- Chamfer

Group E- Long chamfer

Group F- Feather edge

Full cast metal crowns of base metal alloy were fabricated over the metal dies [Table/Fig-2]. The intaglio surface of the crowns was lubricated with a drop of silicon oil. A measured volume of methyl methacrylate resin was vibrated into the castings to make direct dies. They were then indexed to aid proper repositioning at cementation. The acrylic resin dies were then retrieved from the crowns. These dies were the exact replica of the intaglio surface of the crowns and the finish lines.

Acrylic Resin Dies with Metal Crowns

Group A- Ninety degree shoulder, Group B- Rounded shoulder Group, C-45 degree sloped shoulder, Group D-Chamfer, Group E- Long chamfer, Group F-Feather edge

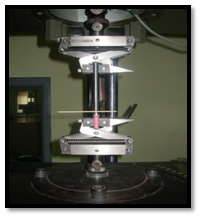

Zinc phosphate luting cement was used for the cementation. A device was designed to load the specimens vertically and placed in a machine to apply 5 kg of constant load. To simulate clinical procedure of dynamic loading, an orangewood stick was placed in between the crown and the compression head of the Zwick testing machine [Table/Fig-3]. The stick was rocked back and forth, horizontally and vertically through arcs of 10-15 degrees for 30 seconds. The load was maintained for five minutes for each cementation while the cement was setting.

Cementation of crowns using Zwick machine

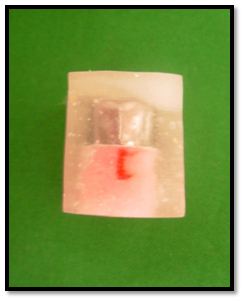

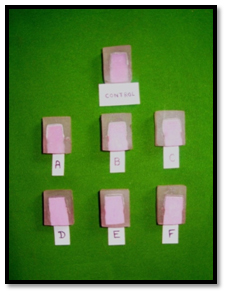

After twenty four hours, the cemented crown and die assembly were embedded in clear acrylic resin so as to hold the assembly together while sectioning. Twenty four hours later, all the samples were sectioned sagitally [Table/Fig-4].

Cemented crown and die assembly embedded in clear acrylic resin

The sectioned halves were focused under a stereomicroscope and the cement spaces were measured to the nearest micron. The cement thickness was measured at two points on the occlusal surface and one at each margin [Table/Fig-5].

Sectioned samples

(Group A-Ninety degree shoulder, Group B- Rounded shoulder Group, C-45 degree sloped shoulder, Group D- Chamfer, Group E- Long chamfer, Group F-Feather edge)

Observation

The cement thickness at the occlusal surface gave information regarding the occlusal seat and the cement at the marginal area represented the marginal sealing ability afforded by that particular finish line design [Table/Fig-6].

Measurement of cement thickness at occlusal seat and marginal seal of various finish lines

| A - Ninety Degree Shoulder |

|---|

| Occlusal seat | Marginal seal |

|---|

| Sr no | Left | Right | Mean | Left | Right | Mean |

|---|

| 1 | 133 | 131 | 132 | 122 | 126 | 124 |

| 2 | 119 | 123 | 121 | 116 | 120 | 118 |

| 3 | 137 | 141 | 139 | 132 | 136 | 134 |

| 4 | 127 | 123 | 125 | 124 | 120 | 122 |

| 5 | 128 | 132 | 130 | 120 | 123 | 121 |

| Mean | | | 129 | | | 124 |

| B - Rounded Shoulder |

|---|

| Occlusal seat | Marginal seal |

|---|

| Sr no | Left | Right | Mean | Left | Right | Mean |

|---|

| 1 | 111 | 119 | 110 | 101 | 103 | 102 |

| 2 | 98 | 102 | 100 | 99 | 97 | 98 |

| 3 | 110 | 106 | 108 | 104 | 102 | 103 |

| 4 | 117 | 121 | 119 | 111 | 109 | 110 |

| 5 | 111 | 113 | 112 | 108 | 110 | 109 |

| Mean | | | 110 | | | 104 |

| C - 45 Degree Shoulder |

|---|

| Occlusal seat | Marginal seal |

|---|

| Sr no | Left | Right | Mean | Left | Right | Mean |

|---|

| 1 | 169 | 171 | 170 | 145 | 147 | 146 |

| 2 | 178 | 174 | 176 | 153 | 151 | 152 |

| 3 | 162 | 166 | 164 | 156 | 158 | 157 |

| 4 | 170 | 168 | 169 | 155 | 151 | 153 |

| 5 | 177 | 173 | 175 | 161 | 163 | 162 |

| Mean | | | 171 | | | 154 |

| D - Chamfer |

|---|

| Occlusal seat | Marginal seal |

|---|

| Sr no | Left | Right | Mean | Left | Right | Mean |

|---|

| 1 | 221 | 217 | 219 | 148 | 150 | 149 |

| 2 | 227 | 225 | 226 | 146 | 144 | 145 |

| 3 | 218 | 216 | 217 | 152 | 150 | 151 |

| 4 | 227 | 223 | 225 | 144 | 145 | 145 |

| 5 | 228 | 230 | 229 | 138 | 142 | 139 |

| Mean | | | 223 | | | 146 |

| E - Long Chamfer |

|---|

| Occlusal seat | Marginal seal |

|---|

| Sr no | Left | Right | Mean | Left | Right | Mean |

|---|

| 1 | 281 | 279 | 280 | 52 | 50 | 51 |

| 2 | 285 | 289 | 287 | 56 | 52 | 54 |

| 3 | 273 | 275 | 274 | 52 | 55 | 53 |

| 4 | 277 | 281 | 279 | 46 | 49 | 47 |

| 5 | 288 | 284 | 286 | 58 | 55 | 56 |

| Mean | | | 281 | | | 52 |

| F - Feather- Edged Margin |

|---|

| Occlusal seat | Marginal seal |

|---|

| Sr no | Left | Right | Mean | Left | Right | Mean |

|---|

| 1 | 302 | 298 | 300 | 37 | 35 | 36 |

| 2 | 291 | 295 | 293 | 34 | 30 | 32 |

| 3 | 307 | 311 | 309 | 29 | 31 | 30 |

| 4 | 301 | 297 | 299 | 38 | 34 | 36 |

| 5 | 305 | 301 | 303 | 35 | 33 | 34 |

| Mean | | | 301 | | | 34 |

Results

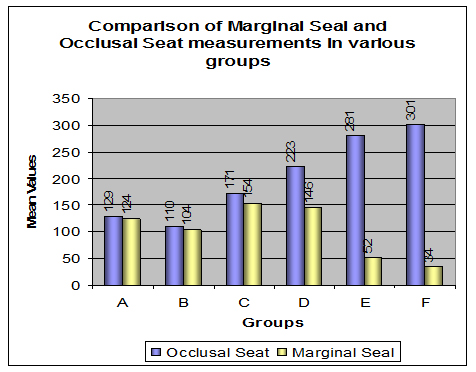

Significant differences were observed in the occlusal seat and marginal seal of all the finish line configurations [Table/Fig-7].

Comparison of Marginal Seal and Occlusal Seat Measurements in various groups

Group A-Ninety degree shoulder, Group B- Rounded shoulder Group, C- 45 degree sloped shoulder, Group D- Chamfer, Group E-Long chamfer, Group F- Feather edge

The rounded shoulder had the best occlusal seat, followed by ninety degree shoulder. The occlusal seat and marginal seal afforded by the shoulder finish lines were similar whereas there was a vast difference in the seating and sealing of long chamfer and feather edged preparations. They showed the worst occlusal seat.

The marginal seal of the feather edged preparations was the best followed by long chamfer designs. The seal of chamfer was better than that of the shoulder preparations. The 45 degree shoulder showed the worst seal.

Thus it was found that though the feather edged and long chamfered margins had the best marginal seal, their occlusal seating was unsatisfactory.

Discussion

The dies used were machined to produce a crown preparation similar to the volumetric size of an average molar. The machined dies controlled the variables of preparation dimensions, degree of axial wall taper and the finish line dimensions. By using standardized dies of volumetric size similar to that of teeth, castings of duplicate size and shape were produced, thus decreasing the variation between each group of finish line preparations.

Gavelis JR et al., stated that the most significant source of variation between the results of previous studies stems from casting variables [6]. Teteruck WR and Mumford G also found that all investigations in which patterns were waxed and cast and the castings returned to their original dies were affected by casting variables [7].

Hence, a method intended to eliminate all casting error and measure only the marginal opening due to the marginal configuration during the cementing process was devised. The source of casting error was controlled by forming acrylic resin dies directly within the castings. The castings were boxed and methyl methacrylate acrylic resin was poured into the castings to make direct dies to minimize the variable causing casting and die discrepancy. It is accepted that methyl methacrylate resin shrinks on polymerization but this factor did not affect the present study. Shrinkage did occur, but it was limited to the open end of the boxed castings, thus causing meniscus formation. This technique was used by Gavelis JR et al.,[6].

Internal relief was not given for two reasons

To eliminate the influence of cement space on the seating of the crown.

To avoid the computation of the variable as a result of inability to standardize the dimension of the acquired relief space.

Elimination of any internal relief also kept the occlusal cement thickness approximately equal to the vertical discrepancy of the marginal adaptation. This vertical discrepancy would have been considerably reduced if internal relief was provided to accommodate the cementing medium. The advantages of assessing the vertical discrepancy without use of internal relief were given by Tjan AHL et al., [8].

Zinc phosphate luting cement was used for the cementation. A load of 5 kg was used to for the cementation of the crowns over the acrylic resin dies Jorgensen KD reported that the relationship between the degree of lack of cementing of cast crowns and the cementing loads was in the form of a hyperbolic curve, and that increase in load beyond 5 kg had little effect on the result [9].

A great bulk of dental cement is at the occlusal surface during the initial phase of crown seating. As the crown is directed to a full marginal seat, the cement must escape through a space at the marginal collar. Cement resist full seating of crown as cement have small space to get away when crown approaches to its ideal resting place. Further, the cement at the occlusal surface must travel the greatest distance and to overcome the frictional resistance to escape cervically [10].

The passage between crown and prepared tooth is reduced in size that large cement particle lodged at the entrance due to excess flow of cement, uneven distribution of cement powder particle in the phosphate matrix as result of cement liquid filtration occurs at margin [11].

The crown and dies were then embedded in clear acrylic resin and sectioned through their long axis. The cement thickness was measured under a stereomicroscope.

The cross-sectional method of measuring marginal fidelity was described by John Sorensen [12]. This technique was advocated for measuring marginal discrepancies of cemented crowns, to permit comparison of different margin designs and to evaluate the fit of restorations. Though this technique is time consuming, requires additional steps and sacrifices the crowns, the additional steps and effort provide more information and greater precision of measurement. The cross-sectional evaluation of the margins allows greater precision in the determination of measuring points and permits determination of the degree of horizontal discrepancy that is not possible with the direct viewing technique.

The lowest cement thickness values at the occlusal surface were obtained with the rounded shoulder finish line configuration, followed by the ninety degree shoulder. The seat was better than the 45 degree shoulder, chamfer, long chamfer and feather edged margins. Cho LR et al., explained that the better seat of rounded shoulder finish line preparation was because it allowed the cement to escape more easily [13].

The occlusal cement thickness was maximum with the feather edged preparation, followed by the long chamfer and chamfer marginal design. These margins did not allow the castings to completely seat. This is because, these margins seal earlier and start the filtration process sooner. They substantially decrease the closing angle between the tooth preparation and the restoration and do not allow the cement to escape easily [8].

Long chamfers and feather edge marginal designs magnify the difference between seating and sealing gaps. The degree of lack of seating of crowns influence the widths of the exposed cement lines. The seating and sealing discrepancies are equal in horizontal designs such as shoulders.Hence, the width of the exposed cement line of a crown cemented on a preparation with a cervical shoulder is as great as the magnitude of lack of seating of the crown. This was in support of the views given by Grajower R and LewinsteinI [14].

Limitations of The Study

The present study compared the marginal sealing ability of the various configurations of the finish lines and its effect on the occlusal seat of the full crowns after cementation. The limitations of this study were that the assessments of marginal seal and occlusal seat were not performed intraoraly and that the errors in fabrication and handling of dies and casting are assumed to be minimal. Further invivo studies are required for clinical application of present data.

Conclusion

Within the limitations of the current study, it was found that the degree of marginal seal and occlusal seat of the crowns was significantly affected by the different finish line designs. The seating and sealing discrepancies are equal in horizontal designs like shoulders, whereas vertical designs magnify the difference between seating and sealing gaps. Shoulder margins provide good seat but a comparatively wider marginal seal. Chamfer, long chamfer and feather edge margin provide superior sealing of the margins despite poor seat.