Permanent soft denture liners have been a valuable asset for dentists. These Soft denture liners because of their viscoelastic properties [1], help in providing an even distribution of functional loads on the denture-bearing area, thus avoiding local stress concentrations and also improving the retention of the dentures by engaging undercuts [2]. These laboratory-processed materials are used for management of sore or atrophied mucosa, traumatic ulceration, and for obturators after maxillofacial surgery.

Denture liners have several problems associated with their use such as the loss of softness, colonization by Candida albicans, porosity, poor tear strength, and various degrees of softness. One of the more serious problems with soft denture liners is the failure of adhesion between the soft denture liner and the denture base [3]. Bond failure also creates a potential surface for bacterial growth, plaque, and calculus formation. Thus it becomes imperative that the strength of the lining material denture-base bond be optimized by different mechanical and chemical surface treatments [4].

Hence, this study was carried out to evaluate and compare the shear bond strength between two commercially available liners and polymethylmethacrylate denture base with and without different surface treatments. Four different surface treatments were tested: 1) Untreated polymethylmethacrylate (PMMA), 2) Sandblasted PMMA, 3) Monomer treated PMMA, 4) Pre-polymerized PMMA.

Materials and Methods

This in-vitro study was conducted in 2013 at Terna Dental College & Hospital, Navi Mumbai and ethical clearance was taken. For the study two commercially available soft denture liners were chosen on the basis of different chemical compositions [Table/Fig-1]. The bond strength was determined, in tension, after processing with Heat cured PMMA (Trevalon denture base resin).

Soft denture Liners used in the study

| Designation | Type | Trade Name | Form | Manufacturer |

|---|

| Material A | Silicone Elastomer | Luci-Sof | Sheets | Dentsply, International Inc.,Usa |

| Material B | Plasticized Acrylic Resin | Super-Soft | Powder and Liquid | Gc America Inc., Illinois,Usa |

A total of 80 samples were made, 40 each for each of the two materials under investigation. The 40 samples were further divided into four groups, containing 10 samples each. They were as follows:

Group I: Consisted of an untreated surface of polymethyl methacrylate which acted as the control.

Group II: The surface of polymethyl methacrylate surface was sandblasted.

Group III: The polymethyl methacrylate surface was treated with monomer.

Group IV: The lining material was processed with acrylic resin dough.

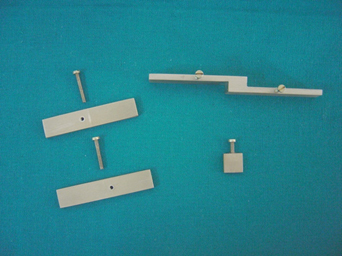

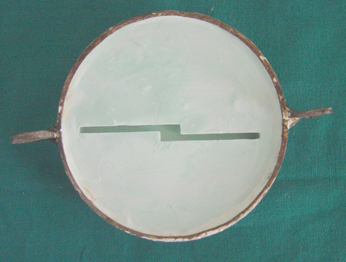

Fabrication of acrylic resin plates: Brass metal dies measuring 50 x 10 x 3mm [Table/Fig-2] were used to make a mould in a mixture of 50% dental plaster and 50% dental stone [Table/Fig-3]. Mould was packed with denture base material and cured as per manufacturer’s instructions.

Brass dies used in the study

Moulds prepared for acrylic resin strips

Surface Treatment of acrylic resin surfaces to be bonded: An area of 10 x 10mm of the acrylic surface was treated for bonding with soft liners. Four groups were considered for both material A and B in this study:

Group I: 20 samples, surface of which was left untreated, used as control.

Group II: In the second group 20 samples were treated by sandblasting with a sandblaster system (Minisab2T, TISSI Dental). The nozzle measuring about 1.0mm diameter was held in light contact with each specimen. Aluminium oxide particles measuring about 250μm were used as the sandblasting medium at a pressure of 0.62 Mpa.

Group III: The third group of 20 samples was swabbed with the monomer (methylmethacrylate heat cured) of the denture base resin for 180 sec.

Group IV: For 20 samples, pre-polymerized denture base resin dough was packed with heat cured silicone and acrylic based liner.

Design of the model for the application of the soft liner: The acrylic samples used in this study were based on the test adapted from the American Society for Testing Materials (ASTM) test version D -2295-72 [5]. Using a brass die [Table/Fig-2] a mould was created [Table/Fig-4] for application of the soft liner.

Mould prepared for making shear bond strength samples

The soft liner with dimension 10 x 10 x 2.5 mm was bonded to two plates of acrylic resin (Trevalon) and processed following manufacturers’ instructions for each material. All the samples prepared were thermocycled for 500 cycles with temperatures from 5° ± 1°C to 55° ± 1°C and a 60 sec dwell time.

Measurement of shear bond strength: After storage period of 24 h [6], the soft liners bonded to the acrylic plates were subjected to the shear stress on a Zwick universal testing machine (Materiaprufüng 1445). The specimens were deformed using a cross head speed of 20 mm per min. The load cell was calibrated and set to zero before each specimen was tested. The load at which failure occurred was recorded together with the type of failure.

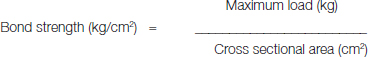

Shear bond strength was calculated using the following formula:

The samples were evaluated under Scanning Electron Microscope (SEM) to study the bond interface. The type of failure was observed under stereomicroscope and was recorded as follows:

Adhesive (A): If the failure occurred at the denture base-soft liner interface.

Cohesive (C): Soft liner material ruptured within itself.

Mixed (M): If part of the failure occurred at the denture base–soft liner interface while remaining part of the failure occurred within the soft liner itself.

Statistical Analyses

Data was analyzed using independent samples t-test, analysis of variance (ANOVA) and Post-Hoc Analysis. A significance level of α = 0.05 was used for statistical analyses.

Results

Mean values, standard deviations and type of failure are shown in [Table/Fig-5].

Mean bond strength values and type of failure

| Variables | Material A | Material B |

|---|

| Mean ± SD | Failure | Mean ± SD | Failure |

|---|

| Group I - Control (Kg/cm2) | 18.27 ± 0.57 | Adhesive | 18.82 ± 0.57 | Mixed |

| Group II - Sandblasted (Kg/cm2) | 18.76 ± 0.82 | Adhesive | 27.42 ± 1.41 | Mixed |

| Group III - Monomer (kg/cm2) | 23.82 ± 1.38 | Mixed | 32.74 ± 2.47 | Cohesive |

| Group IV - Prepolymerized (Kg/cm2) | 15.12 ± 0.88 | Adhesive | 34.80 ± 1.94 | Cohesive |

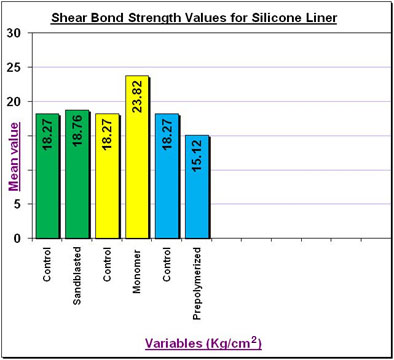

For Material A (Silicone Liner) statistical analysis with One-way ANOVA and post –hoc analysis showed a statistically significant difference between Bond strength values of Group III and IV with Group I (Control) (p < 0.05). Highest Bond strength values were seen with group III (Monomer treated) and least Bond strength was seen with Group IV (Pre-polymerized) [Table/Fig-6].

Shear Bond strength values for Silicone Liner (Material A)

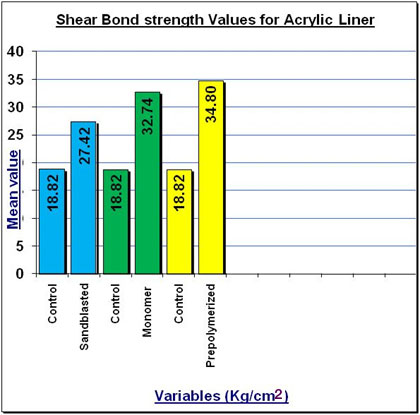

For Material B (Acrylic Liner) statistical Analysis with One–way ANOVA and post–hoc analysis showed a statistically significant difference between Bond strength values of Group II, III and IV with Group I (Control) (p < 0.05). Highest Bond strength values were seen with Group IV (Pre-polymerized) and least Bond strength was seen with Group I (Control) [Table/Fig-7].

Shear bond strength values for Acrylic Liner (Material B)

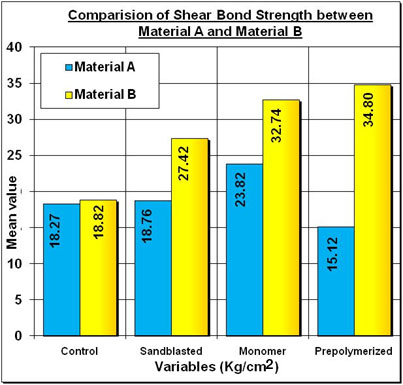

Independent t–test indicated a statistically significant difference between the shear bond strength values of Material A and Material B (p < 0.05) [Table/Fig-8]. For all the groups the shear bond strength of Material B was higher as compared to the shear bond strength of Material A.

Comparison of shear bond strength values between Material A and Material B

Discussion

Soft liners when used together with hard denture base resin provided the advantage of cushioning effect without decreasing the masticatory efficiency. However failure of the bond between polymethyl methacrylate (PMMA) and denture soft liners has been a significant reason for the limited use of the soft lined dentures [7].

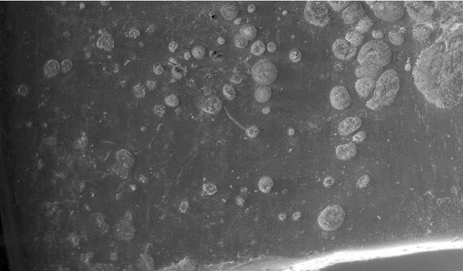

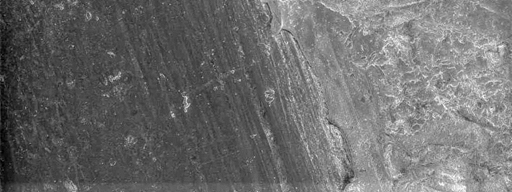

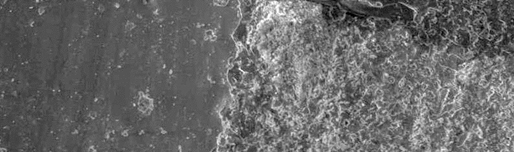

Material A (Silicone Liner) showed lesser mean bond strength compared to Material B (Acrylic Liner). Acrylic Liner had a composition similar to the PMMA denture base acylic resin. The intimate nature of the bond can be co-related with SEM observations where interface of the bond between the acrylic based liner and denture base resin is not distinct [Table/Fig-9]. Comparatively SEM analysis of the control sample [Table/Fig-10] of silicone liner bonded to the denture base shows the distinct interface between the silicone liner and the denture base. No chemical bond would occur between them. To further enhance the bond strength surface treatments were done on the denture base for both the materials.

Scanning electron microscope analysis: Interface of the bond between the acrylic based liner and denture base resin is not distinct

SEM analysis of the control sample of silicone Liner bonded to the denture base shows a distinct interface

Sandblasting units have been used to alter the surface of the PMMA with the intention of providing increased surface area and mechanical locks. Sandblasting increased the bond strength for the two materials under investigation. The increase was statistically significant (p<0.05) for Material B (Acrylic Liner) when Group I and II were compared. This can be attributed due to the increased surface area in sandblasted samples and similar chemistry between the Acrylic Liner and the denture base resin. However, for material A (Silicone Liner) the increase in mean bond strength was statistically insignificant. This increase seen by surface roughening was due to the frictional force that was generated when two contacting surfaces moved relative to each other [8].

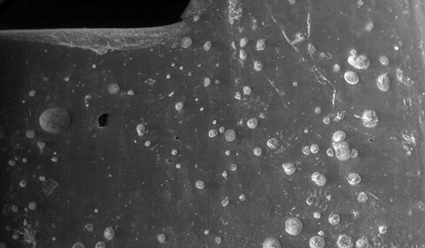

The above readings could be co-related with the findings of the SEM in which Material A (Silicone Liner) shows a distinct interface for sandblasted samples [Table/Fig-11] whereas an indistinct interface can be seen in Material B (Acrylic Liner) [Table/Fig-12].

SEM Analysis: Silicone Liner shows a distinct interface with sandblasted samples of denture base resin

SEM Analysis: Acylic Liner shows an indistinct interface with sandblasted samples of denture base resin

In the present study the surface treatment of the denture base by its monomer resulted in a statistically significant (p<0.05) increase in the bond strength of both the materials under investigation. Denture base monomers are polymerizable. Hence the penetration of these monomers into the denture base improved the bonding with acrylic liner by their participation in the polymerization reaction [9].

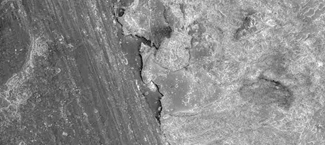

In case of Silicone Liners, using monomer and adhesive together may effectively increase the dissolution of the PMMA surface prior to the resilient liner application [10]. Another reason which can be suggested for higher bond strength value is monomer most probably reaches deep in to the polymer chains and facilitates the penetration of adhesive primer. Presence of significant bond strength values are a sign of absence or less micro leakage, the high bond strength values resulting from chemical surface pre treatments in the present study are similar to the results of micro leakage study by Sarac et al., [11]. The above could be co-related with the findings of SEM analysis. The shear bond sample of silicone liner bonded with monomer treated denture base clearly depicts the dissolved portion of the denture base into which silicone based liner has flown which helps in better mechanical retention than the control sample which has fewer undercuts for retention [Table/Fig-13]. In case of monomer treated samples of Acrylic Liner the increased surface area provided due to dissolved denture base resin and similar chemistry of the liner helping in a chemical bond could be the reason for better bonding than in case of sandblasted and control samples [Table/Fig-14].

SEM analysis of interface between silicone liner and monomer treated denture base resin

SEM analysis of interface between acrylic liner and monomer treated denture base resin

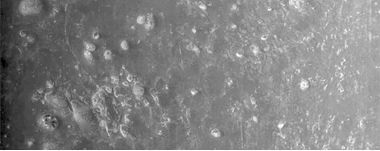

Pre-polymerized samples of the two materials under study have shown highest and lowest bond strengths. Material A ( Silicone Liner) pre-polymerized samples showed lowest mean bond strength among all the groups under study whereas, Material B (Acrylic Liner) pre-polymerized samples have showed the highest bond strength among all the groups in the study. Different chemical nature of the silicone liner when packed against the dough stage may not provide the mechanical retention advantage as seen with the monomer treated sample, resulting in less intimate bond. This can be appreciated in SEM analyzed samples [Table/Fig-15]. Material B being an acrylic based liner has a very intimate bond with the denture base resin at dough stage. SEM analyzed bond interface of the pre-polymerized samples in acrylic Liner show a highly intimate bond where the junction of the bond is very indistinct [Table/Fig-16]. This could be the reason for the pre-polymerized Material B samples to achieve highest bond strength, of all the groups.

SEM Analysis of samples prepared by packing silicone liner with pre-polymerized denture base resin

SEM Analysis of samples prepared by packing Acrylic liner with pre-polymerized denture base resin

It has been reported that denture liners with 10 pounds per inch (0.44 Mpa) or 4.5 kg/cm2 bond strength are acceptable for clinical use. Considering this criterion both the materials had satisfactory bond strength to denture base resin [12].

Another aspect of the study was to characterize the debonding characteristics between PMMA denture base and the soft liners. They were classified as per the criteria given by Al-Athel MS et al., [13]. Silicone Liner samples showed adhesive failures [Table/Fig-17] for all the groups except monomer treated (Group III) which showed a mixed type of failure. Cohesive failures were mainly exhibited by Acrylic Liner in monomer treated and pre-polymerized samples [Table/Fig-18]. A cohesive failure indicated that the tensile strength of the soft liner was weaker than the bond strength to PMMA. The other groups of Acrylic Liner (Control and Sandblasted) however showed mixed type of failure [Table/Fig-19]. A mixed failure indicates that the bond strength of the liner was almost equal to the tensile strength of the liner. Adhesive failures indicated that tensile strength of the liner was greater than the bond strength with the denture base. A significant increase in the bond strength in monomer treated samples could be co-related with the mixed type of failure achieved with them, indicating it almost reached the tensile strength of the liner.

Evaluation of adhesive failure under stereomicroscope

Evaluation of cohesive failure under stereomicroscope

Evaluation of mixed failure under stereomicroscope

Conclusion

Within the parameters of the materials used and the study design, it was concluded that for Silicone Liner highest increase in the bond strength values was seen with monomer treated samples followed by sandblasted samples. However, pre-polymerized samples showed a decrease in bond strength values. For Acrylic Liners there was significant increase in the bond strength for all the surface treatments as compared to the control group. Both acrylic and silicone liner had clinically acceptable bond strength to PMMA denture base resin. Silicone liner showed predominantly adhesive failure whereas acrylic liner showed both cohesive and mixed failures.

Changes in the oral environment, may lead to significant differences in the bond strength between the two materials. A further study, especially a clinical trial can however conclusively prove the real utility of different resilient liners and surface treatments.