Introduction

Recent phase in restorative dentistry is mainly demanding aesthetics. In fixed Prosthodontics, highly aesthetic restorations are all ceramic restorations but this restoration has certain limitation such as fragile nature, low tensile strength, technique sensitive laboratory procedures & cost etc.

Metal ceramic restorations are one of the most widely used fixed restorations. This has resulted in part from technologic improvements in the fabrication of restorations by the dental laboratories and in part from the growing amount of demands for aesthetic with durable restoration [1]. The metal ceramic restorations combines the physical properties of metal i.e. rigidity and impact strength, with aesthetic qualities, abrasion and strain resistance of dental porcelain [2]. The metal ceramic restoration was known as ‘Ceramco Crown,’ ‘Porcelain veneer crown’, ‘as well as ‘Porcelain fused to metal (PFM)’ [3].

The success of metal ceramic restorations depends on preparation design, design of the coping, and proper ceramic thickness. The recommended metal coping design to receive the porcelain includes forming of a thin labial cervical collar made of metal. The metal collar serves as a truss that strengthens the casting and overlying ceramic material and enables it to resist deformation during the ceramic firing cycles. Unfortunately, the metal collar often becomes an aesthetic liability by producing a dark line or shadow beneath the gingival tissues that becomes visible if gingival recession occurs [4].

Another alternative is available to eliminate the unsightly metal collar i.e. collarless metal ceramic restoration with porcelain labial margin. The aesthetic appearance of this restoration is better due to elimination of the labial metal collar and increased thickness of the gingival porcelain at the margin. Plaque retention may be minimized by having only highly glazed porcelain at the margins. Periodontal health is further promoted by minimal extension of metal into gingival sulcus [5]. Inspite of these advantages little information 2is available regarding the effect of reduction in the metal support of metal coping in the labial margin area on fracture resistance of these restorations with shoulder porcelain labial margin.

Therefore, the present in vitro study was undertaken to compare the fracture resistance of porcelain with different coping designs like metal coping extension on labial surface uptogingivoaxial line angle, metal coping extension 1mm short of the gingivoaxial line angle and metal coping with 0.4mm wide labial metal collar, in metal ceramic crowns.

Aim and Objectives

The aim of the present study was to compare effect of different metal coping designs on fracture resistance of porcelain in metal ceramic restorations with following objectives-

1. To evaluate the fracture resistance of porcelain in metal ceramic restoration with metal coping extending upto gingivoaxial line angle of finish line.

2. To evaluate the fracture resistance of porcelain in metal ceramic restoration with metal coping extending 1mm short of gingivoaxial line angle of finish line.

3. To evaluate the fracture resistance of porcelain in metal ceramic restoration with metal coping having 0.4mm wide labial metal collar.

4. To compare the fracture resistance of porcelain in metal ceramic restoration with metal coping extending uptogingivoaxial line angle of finish line, metal coping extending 1mm short of the gingivoaxial line angle and metal coping having 0.4mm wide labial metal collar.

This in vitro study to compare the fracture resistance of porcelain in metal ceramic restoration with different metal coping designs, was carried out in the Department of Prosthodontics, Sharad Pawar Dental College, Sawangi (Meghe), Wardha, Maharashtra, India

Materials and Methods

A solid rectangular brass metal block (57mm x 39mm x 16mm) with a mounting platform in its center for the mounting of ivorine maxillary central incisor was fabricated. A provision for securing the ivorine tooth to the platform with a screw (10mm length x 2mm diameter) coming from the downside of the rectangular metal block was made. Over this rectangular metal block a brass metal custom tray with central hollow dome shaped space (29.5mm outer diameter x 19.5mm inner diameter x 15.5mm length) was prepared. The dome was having perforations of 2mm in diameter all along its circumference to allow excess material to come out.

An ivorine maxillary central incisor was screwed in vertical position in the center of the rectangular block [Table/Fig-1]. After mounting putty index (Index no. 1) of this tooth was made. It was sectioned in labial and lingual halves, which were later used for contouring the ceramic build up of the metal ceramic crown.

The ivorine central incisor was then prepared with airotor handpiece mounted on the surveyor to receive metal ceramic crown with shoulder facial margin according to standard norms recommended by Shillinburg et al., [3]. The tooth was initially prepared with a 900, 1.5mm shoulder on the facial surface that was carried to the midproximal region both mesially and distally and blended to a 0.8mm chamfer finish line on the lingual surface

To fabricate duplicate dies of the prepared ivorine tooth an impression of the tooth was made with polyvinyl siloxane impression material by putty wash technique in the prepared custom metal tray [Table/Fig-2]. After final set of the material, the impression was checked for any voids under magnifying lens. To prepare duplicate dies of the prepared tooth autopolymerising polymethyl methacrylate polymer and monomer was added in the obtained elastomeric impression and after complete polymerization it was removed. Thus a duplicate autopolymerising polymethyl methacrylate resin die of the prepared ivorine tooth was obtained. In the similar fashion 30 resin dies were prepared (15 each for group A and B specimens).

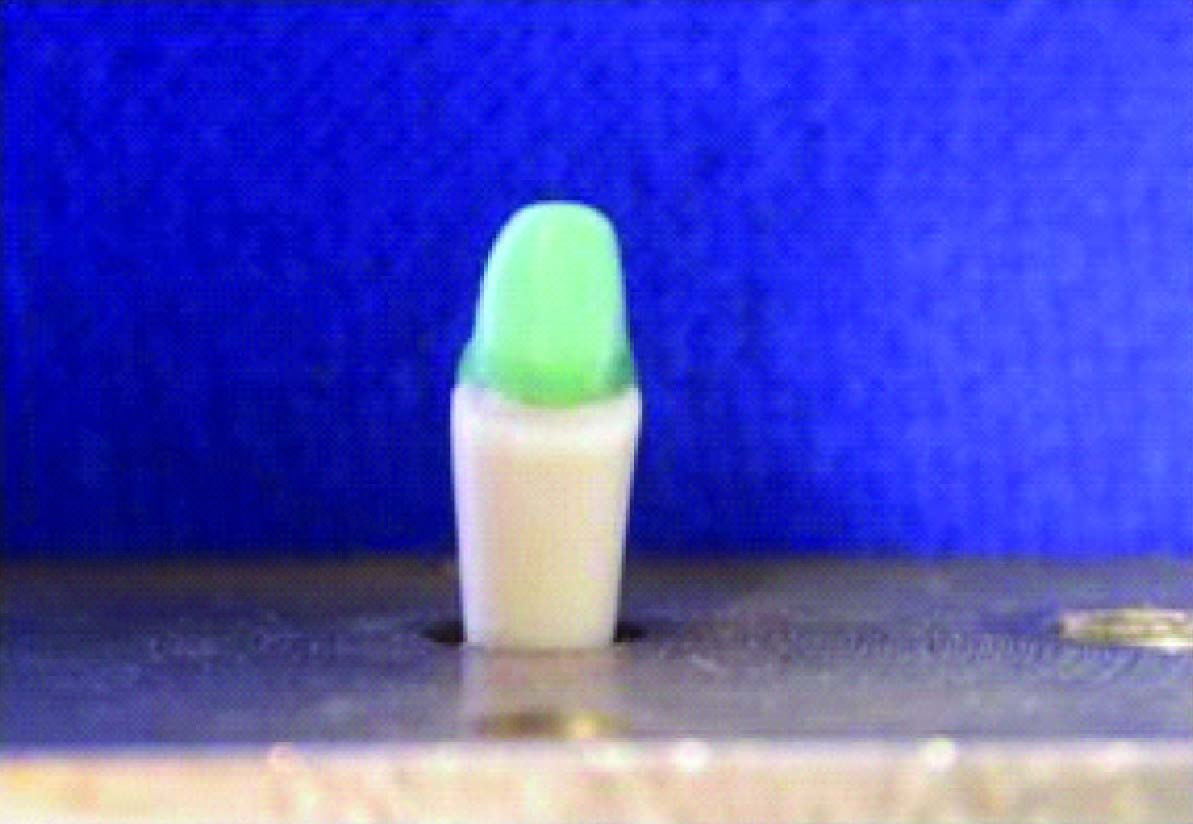

Two coats of die spacer were applied to mounted prepared ivorine tooth surface excluding 1mm area around the finish line. On this ivorine tooth wax pattern with labial margin upto gingivoaxial line angle of the finish line (Group A) was prepared with green dip wax [Table/Fig-3] . The lingual surface porcelain metal junction was created approximately 5mm coronal to the midlingual margin. Thickness of veneering surface was maintained to 0.4mm. Green inlay wax was used to establish lingual surface contours and final marginal adaptation.

A putty index (Index no. 2) of this wax coping was made and sectioned in two halves i.e. labial and lingual. By using this sectional putty index 15 wax patterns for the copings of group A specimens were prepared using inlay wax on the prepared ivorine tooth. Margins of all 15 wax patterns were readapted with green inlay wax.

One of the wax patterns with labial margin at gingivoaxial line angle was made 1mm short from the gingivoaxial line angle to prepare the wax coping for group B specimens [Table/Fig-4]. A putty index (Index no. 3) of this wax coping was made and sectioned in two halves i.e. labial and lingual. By using this sectional putty index 15 wax patterns for the coping of group B were prepared on the ivorine tooth. Margins of all 15 wax patterns were readapted with green inlay wax.

After through scrutiny of duplicate autopolymerising polymethyl methacrylate resin dies and wax patterns for group A and group B, they were casted in Ni- Cr alloy according standard casting protocol. After casting, individual metal model and copings of group A and B were critically analysed for casting defects. All the casted tooth metal models and metal copings were inspected with a light microscope and the casting irregularities were removed with small rotary instrument and air abrading with 50-μm aluminum oxide.The veneering surfaces of the copings were finished with abrasive wheel to obtain a uniform thickness of 0.4 mm and castings were cleaned with a 50-μm aluminum oxide air abrasive.The finished copings of group A and B were checked for their proper fit on the respective metal models of group A and B.

Thirty metal copings for group A and group B which were having proper fit on the metal dies of respective groups were selected for ceramic built up. The putty index number one was used as a guide for developing the final contours of the crowns. The porcelain build up for both groups were carried out on the mounted ivorine tooth.

All the copings were cleaned in an ultrasonic cleaner to remove any investment material particles or impurities.

Preheating: The metal copings of group A and B were preheated at manufactures set temperature (9750C) for preheating .

Opaque Application: Ceramco 3 opaque was available as base opaque and paste opaque. The base opaque was applied with brush technique by applying an even stroke of brush allowed to dry for prescribed time. The copings were then fired in ceramic furnace. After firing of base opaque, paste opaque was applied in the same manner by applying even strokes of brush, allowed to dry and then fired in furnace.

Shoulder porcelain application: Shoulder porcelain was applied to group A and B copings by direct lift technique. Die release was applied to the shoulder margin of the prepared ivorine tooth and coping was then seated on the ivorine tooth. Shoulder porcelain was brushed to the gingival margin of the coping and was carved with a concavity to eliminate over contouring the final restoration. This layer was dried and fired. A second corrective layer of shoulder porcelain was applied, dried and fired.

Dentin and Enamel ceramic application: Dentinal porcelain was applied on the opaque and shoulder porcelain and contoured with the help of sectional putty index no. 1. This application was cut back in the standard fashion and enamel porcelain was added. The overall build up was overbuilt maintaining the developed contour to compensate for firing shrinkage. This built up was allowed to dry and then fired.

The crowns were then contoured with abrasive wheels. Measurements were made to ensure that the total thickness of the facial margin is a uniform of 1.5 mm. The crowns were then glazed. The porcelain application and condensation was standardized as much as possible within the confines of usual laboratory procedures for fabricating metal ceramic crowns.

After fabrication of metal dies & porcelain fused to metal crows of group A & group B; the labial shoulder of the mounted prepared ivorine tooth was modified to shoulder with 450 bevel to receive a metal ceramic crown with a 0.4mm wide metal collar.

To duplicate the prepared ivorine tooth with beveled labial shoulder margin, an impression of the tooth was made with polyvinyl siloxane impression material by putty wash technique in the similar fashion as for 900 shoulder. The impression was checked for any voids under magnifying lens.Similar to the previous dies for group A and group B again fifteen autopolymerizing polymethyl methacrylate resin dies were fabricated for group C by using the polyvinyl siloxane impression in the metal tray.

Wax pattern for coping of group C was prepared similar to wax pattern for group A & B except that this wax pattern was maintained with a 0.4mm wide facial collar [Table/Fig-5]. A putty index (Index no. 4) of this wax coping was made and sectioned in two halves i.e. labial and lingual. By using this sectional putty index fifteen wax patterns for the copings of group C specimens were prepared on the mounted ivorine tooth. Margins of all fifteen-wax patterns were readapted with green inlay wax.

After through scrutiny of autopolymerising polymethyl methacrylate resin dies and wax patterns for group C, they were casted in Ni-Cr alloy in similar fashion as for group A and B and were individually analysed for casting defects.The finished copings of group C were checked for their proper fit on the respective metal dies of group C. The fifteen metal copings for group C, which were having proper fit on the metal dies for group C, were selected for ceramic built up. The porcelain build up was carried out on the mounted ivorine tooth as done for group A & B samples.

All the 45 metal dies of group A, B, C were embedded in acrylic resin block in vertical position. The resin block was finished to ensure that it would be secured in correct alignment when compressive forces were applied. The internal surface of the castings and the metal dies were air abraded with 50-μm aluminium oxides. Finished crowns of all three groups were cemented to the respective metal dies with glass ionomer luting cement under 15 kg of static load and was allowed to set for 24 h.

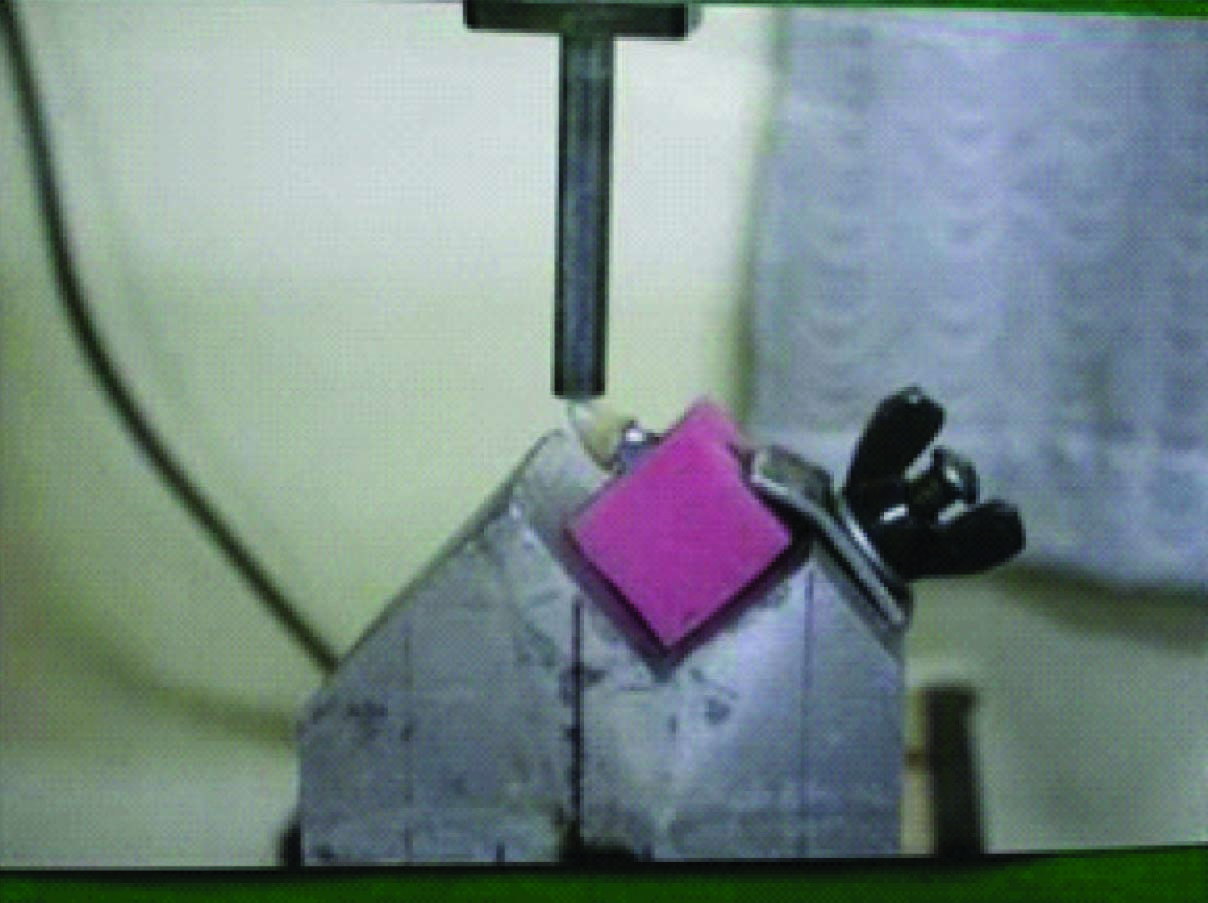

Load was applied at lingual incisal line angle, at 1300 to the long axis of the specimen until catastrophic porcelain fracture occurs. This position was used to represent the occlusal forces directed to a maxillary central incisor in natural dentition. Load was applied by a 6.35mm diameter rod with the center of the rod in contact with porcelain surfaces. A crosshead speed of 2.5mm per minute was used to apply the load. The specimens were tested on an Instron testing machine [Table/Fig-6]. The results were obtained in KiloNewton but to compare the results with the previous studies, values were converted to Newton by using following formula.

1 Newton = 1 KiloNewton x 1000.

The statistical evaluation of the results was done using the student unpaired t- test [6].

Results

A total of 45 samples were prepared which were divided equally amongst the three groups.

[Table/Fig-7] shows the mean fracture load for group A, B, C specimens. In this, the Group C specimens showed the lowest mean fracture load of 480.86 N with a standard deviation of 53.11 N and the range of fracture load was from 383.0 N to 546.0 N.

The group A specimens showed highest mean fracture load of 715.13 N with a standard deviation of 80.96 N and the range of fracture load was 608.0 N to 867.0 N.

The Group B specimens showed mean fracture load of 681.26 N with a standard deviation of 105.29 N and the range of fracture load was 566.0 N to 844.0 N.

[Table/Fig-8] shows t-test comparisons between various groups. Results of group A specimens were first compared with results of group C specimens. For this comparison, the calculated t-value was 4.74 and the tabulated t-value was 2.05. Hence, the calculated t-value was higher than the tabulated t-value at 0.05% level of significance. It means that there is a significant difference in the fracture resistance of group A and group C specimens.

Secondly, the results of group B specimens were compared with results of group C specimens. For this comparison, the calculated t value was 3.98 and the tabulated t-value was 2.05. Hence the calculated t-value was higher than the tabulated t-value at 0.05% level of significance. It means that there is a significant difference in the fracture resistance of group B and group C specimens.

Lastly, the results of group A specimens were compared with group B specimens. For this comparison, the calculated t-value was 1.302 and the tabulated t-value was 2.05. Hence the calculated t-value was lower than the tabulated t-value at 0.05% level of significance. It means that there is no significant difference in the fracture resistance of group A and group B specimens.

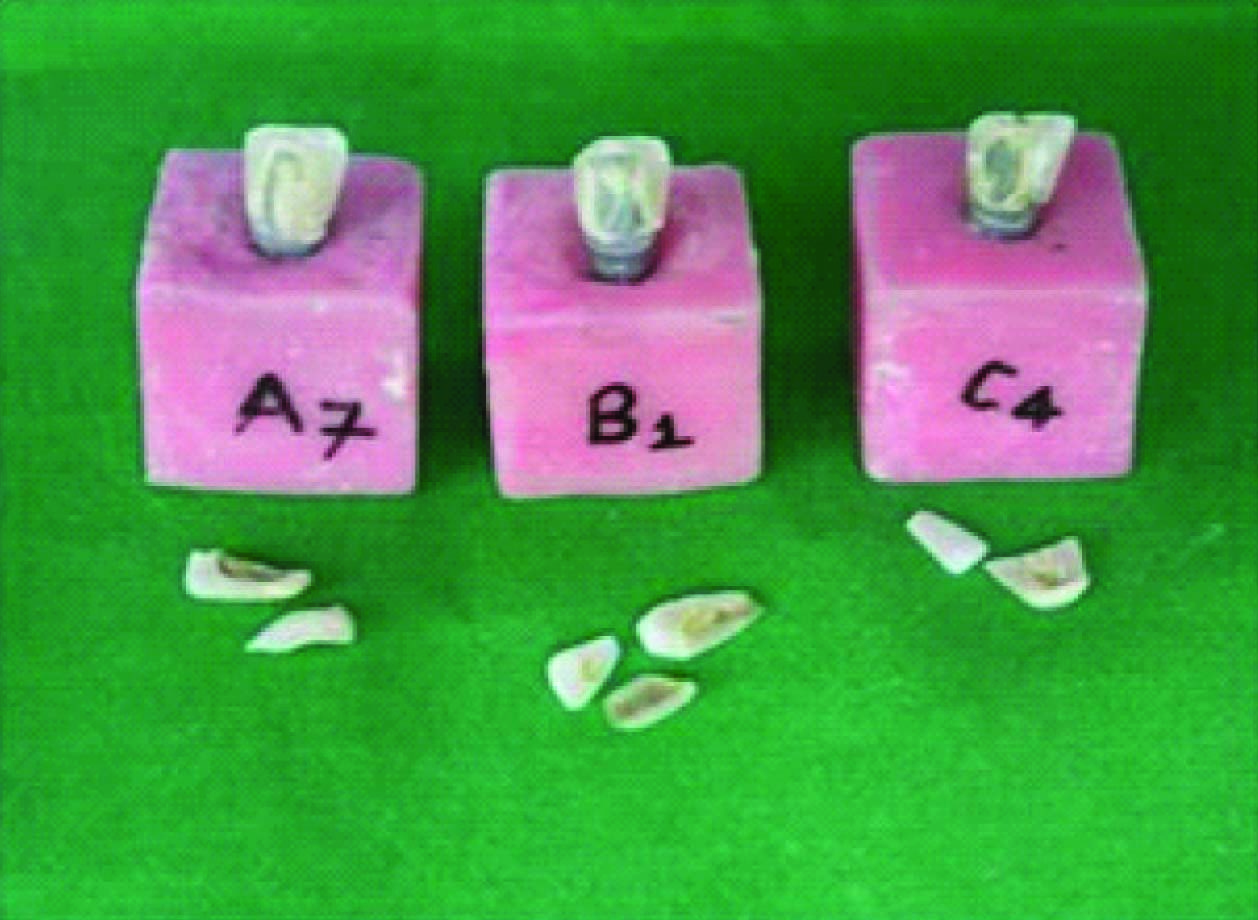

Visual examination of the fractured specimens of group A, B and C showed remarkably similar failure modes with nearly all specimens failing through a shear fracture of porcelain from load point to facial margin of the crown [Table/Fig-9].

Discussion

The metal ceramic restoration has one disadvantage from aesthetic point of view i.e. the cervical metal collar that may be noticed in the facial aspect [7]. This metal collar beneath thin, friable gingival tissues gives a blue gray, cyanotic appearance to the gingival tissues [8]. Another alternative is available to build porcelain fused to metal restoration i.e. metal ceramic restoration without cervical metal collar, popularly known as collarless metal ceramic restorations [4,7]. This restoration with shoulder porcelain facial margin reinforces almost the entire crown with metal yet maintains the aesthetics quality of jacket crown and physiologic contour in the facial gingival margin area.

Availability of shoulder porcelain made it possible to reduce the metal substructure from the facial margin but one concern with the collarless metal ceramic restoration with different metal coping design in the facial margin area has been its ability to withstand load at the facial porcelain margin [9]. A study by Gardner [10] stated that loads required to fracture porcelain from crowns with porcelain margins was statistically significantly greater than crowns with metal collar margins. There was no statistically increase in light transmission with framework reduction greater than 1mm from the gingivoaxial line angle of the finish line and no statistically significant decrease in the fracture resistance in crowns with up to 2mm of framework reduction was suggested by O’ Boyle [11].

So the present in vitro study was designed to compare the fracture resistance of porcelain in metal ceramic restoration with different design of metal coping.

On the basis of previous studies we decided to carryout the present study; in which the shoulder porcelain facial margin crowns were constructed using two designs of the coping, one with facial margin of the coping uptogingivoaxial line angle of the finish line (Group A) and other with facial margin of the coping 1mm short of the gingivoaxial line angle of the finish line (Group B). The group with porcelain fused to metal with collar margin, represents Group C.

To simulate the clinical condition an ivorine tooth with similar in size and shape of a human tooth was chosen to carry out the study. An ivorine maxillary central incisor was initially prepared to receive a metal ceramic crown with a 1.5mm shoulder on the facial surface. The total thickness of the crowns was maintained to a uniform thickness of 1.5mm at the facial gingival margin area.

A beveled shoulder margin is recommended for the facial surface of a metal ceramic restoration where a metal collar is used. The beveling removes unsupported enamel; it also allows finishing of the metal.For fabrication of the metal ceramic crowns with metal collar facial margin (Group C), the labial shoulder finish line of the prepared ivorine central incisor of group A was modified to shoulder with 450 bevel by considering its advantages as mentioned by the previous studies. While preparing the bevel we have not hampered the integrity of the original shoulder prepared. Fifteen duplicate autopolymerising polymethyl methacrylate resin dies were prepared. On the modified ivorine tooth wax copings were prepared with facial gingival collar (Group C). These autopolymerising polymethyl methacrylate resin dies and wax copings for group C were casted to obtain metal dies and metal copings. On these metal copings metal ceramic crowns with facial metal collar were fabricated. The total thickness of the crowns was maintained to a uniform of 1.5mm at the facial gingival margin area.

Metal ceramic crowns of group A, B and C were cemented under 15 Kg static loads to the respective metal dies with glass ionomer cement. Load was applied at lingual incisal line angle of the crowns, at 1300 to the long axis of the specimen until catastrophic porcelain fracture occurs. This position was selected to reproduce the occlusal forces directed to a maxillary central incisor during function [12]. The specimens were tested on an Universal Instron testing machine. Peak fracture loads of all specimens are listed in [Table/Fig-7] .

The Group A specimens with shoulder porcelain facial margins with labial termination of the metal coping at gingivoaxial line angle of the finish line had showed mean fracture strength of 715.13 N with a standard deviation of 80.96 N. The Group B specimens with shoulder porcelain facial margin with labial termination of the metal coping 1mm short of the gingivoaxial line angle of the finish line had showed mean fracture strength of 681.26 N with a standard deviation of 105.29 N. The Group C specimens with metal collar margin with 0.4mm wide metal collar had showed mean fracture strength of 480.86 N with a standard deviation of 53.11 N.

Visual examination of the fractured specimens showed remarkably similar failure modes between the three groups, with nearly all specimens failing through a shear fracture of porcelain from load point to facial margin of the crown [Table/Fig-9]. Some specimens fractured through the ceramic and some showed the fracture at the porcelain metal junction, as there occurred the exposure of the metal. With naked eye the failures were appeared to have the features of both adhesive and cohesive failure.

Stastical analysis of the results of this study suggests that fracture resistance of shoulder porcelain margin (Group A and B) was significantly higher than that of porcelain fused to metal collar margin (Group C). The comparison of fracture resistance between group A and B i.e. crowns with shoulder porcelain margins is statistically not significant. According to the results of this study the fracture strength of shoulder porcelain margins was higher than porcelain fused to metal collar margin.

The metal ceramic restoration with shoulder porcelain facial margin has the support of the underlying metal coping covering almost the entire crown except only in the facial gingival margin area [7]. Also the 900 internal line angle of the finish line is believed to provide internal buttressing of the shoulder porcelain and it remains under compression. According Sozio [9] the major force distribution upon the labial margin of collarless metal ceramic restoration is compressive in nature and not tensile. Under compressive load the dental porcelain is highly resistance to rupture almost ten times than under tensile load.According to Anusavice and Hojjatie [13] the labial extension of the metal coping does not significantly affect the stress distribution in the crown. The principle stresses within the gingival region are compressive in nature and their magnitudes are well below the compressive strengths of porcelain (340mpa).

In addition the shoulder porcelain has higher content of crystalline alumina. Because of the crystalline nature it has better packability, which reduces the firing shrinkage and pyroplastic flow of the shoulder porcelain. The alumina has high modulus of elasticity and is the toughest oxide [14]. The crack cannot pass through alumina particles as easily as it can pass through glass matrix. The glazed porcelain is effective in reducing crack propagation within the outer surface because the surface flaws may be bridged by glazed porcelain and maintains the surface under a state of compression [15].

The higher fracture strength of the crowns with shoulder porcelain labial margins may be because of the higher crystalline alumina content of shoulder porcelain, compressive nature of the forces acting on the labial margin area, sufficient bulk of shoulder porcelain at the labial margin area along with metal support covering almost the entire tooth except in the labial margin area.

The present in vitro study compared the fracture resistance of porcelain in anterior metal ceramic restoration with different coping design under simulated clinical conditions. Every effort was made to maintain clinically relevant, standard and uniform samples. Further studies are required to check the application of this design in posterior restorations.

This study was completed in 12 month at Sharad Pawar Dental College and Hospital, Sawangi, Wardha, Maharashtra.

Rectangular metal block with mounted ivorine maxillary central incisor and metallic custom tray

Prepared ivorine tooth with 900 labial shoulder For group A and B & its Polyvinyl siloxane impression

Wax pattern with extension of labial margin uptogingivoaxial line angle of finish line (Group A)

Wax pattern with extension of labial margin 1mm short of gingivoaxial line angle of finish line (Group B)

Wax pattern with 0.4mm wide facial collar margin (Group C)

Load application on one of the specimen

Peak Fracture Load (In Newton)

| Groups | Peak Fracture Load (Newton) | Mean (Newton) | Standard Deviation (Newton) |

| Group A | 867.0 864.0 747.0 619.0 608.0 811.0 726.0 672.0 660.0 736.0 744.0 653.0 664.0 685.0 671.0 | 715.13 | 80.96 |

| Group B | 751.0 815.0 604.0 755.0 606.0 578.0 750.0 566.0 591.0 844.0 827.0 759.0 580.0 606.0 587.0 | 681.26 | 105.29 |

| Group C | 383.0 546.0 537.0 459.0 478.0 430.0 519.0 534.0 490.0 459.0 387.0 482.0 522.0 537.0 450.0 | 480.86 | 53.11 |

Student t test comparison of different groups

| Sr. no | Comparison Between Groups | Degree of freedom | Tabulated t Value | Calculated t Value | Inference |

| 1. | Group A with Group C | 28 | 2.05 | 4.74 | Significant p<0.05 |

| 2. | Group B with Group C | 28 | 2.05 | 3.98 | Significant p<0.05 |

| 3. | Group A with Group B | 28 | 2.05 | 1.302 | Not Significant p>0.05 |

Fractured specimens (Group A,B,C), A7 refers to sample no. 7 out of 15 of group A; B1 refers to sample no. 1 out of 15 of group B; C4 refers to sample no. 4 out of 15 of group C

Conclusion

The present in vitro study was carried out to compare the fracture resistance of porcelain in metal ceramic restoration with different designs of metal coping i.e. metal coping extending uptogingivoaxial line angle of labial finish line, metal coping 1mm short of the gingivoaxial line angle and metal coping with 0.4mm wide labial metal collar. Within the limitations of the present study following conclusions were drawn.

1. The mean facture strength of the samples with shoulder porcelain labial margins having metal coping design extending upto gingivoaxial line angle of the finish line (Group A) was highest.

2. The mean facture strength of the samples with shoulder porcelain labial margins having metal coping design 1mm short of gingivoaxial line angle (Group B) showed significantly higher values in comparison to group C but in comparison to group A, fracture strength values were not statistically significant.

3. The mean fracture strength of samples having porcelain fused to metal coping design with 0.4mm wide metal collar (Group C) was lowest.

4. The mode of porcelain failure was similar for both types of margins with nearly all specimens failing through a shear fracture of porcelain starting from the load point to facial margin of the crown.