“Evaluation of the Effect of Ultraviolet Disinfection on Dimensional Stability of the Polyvinyl Silioxane Impressions.” an in-Vitro Study

Surekha R Godbole1, Trupti M Dahane2, Nikita A Patidar3, Sharayu V Nimonkar4

1 HOD and Professor, Department of Prosthodontics, Sharad Pawar Dental College, Sawangi, Wardha, Maharashtra, India.

2 Reader, Department of Prosthodontics, Sharad Pawar Dental College, Sawangi, Wardha, Maharashtra, India.

3 Post Graduate Student, Department of Prosthodontics, Sharad Pawar Dental College, Sawangi, Wardha, Maharashtra, India.

4 Post Graduate Student, Department of Prosthodontics, Sharad Pawar Dental College, Sawangi, Wardha, Maharashtra, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Nikita A. Patidar, Post Graduate Student, Department of Prosthodontics, Sharad Pawar Dental College, Sawangi, Wardha, Maharashtra, India. Phone : 9766339814, 9158900453, E-mail : nikitapatidar88@gmail.com

Introduction: Infection control is an important concept in the present day practice of dentistry. The prosthodontists are at an added risk of transmission because of the infection spreading through the contaminated lab equipments while working in the lab. The purpose of this study is to evaluate the effect of UV light disinfection on dimensional stability of polyvinyl siloxane impressions.

Materials and Methods : Impressions were made in perforated custom tray. After polymerization of impression, half the samples were disinfected in UV light and remaining samples were not subjected to disinfection and poured in die stone which served as control group. Linear dimensions were measured on the cast with travelling microscope of 0.001accuracy.

Result : The result showed that UV light disinfectant showed no significant dimensional changes on impressions.

Conclusion: Hence, it can be safely used to disinfect impressions in clinical prosthodontic procedures.

Disinfection, Impression materials, UV disinfectant unit

Introduction

Dentistry through centuries has always aimed at providing relief from pain, treating loss of function and correcting unaesthetic appearance. Sometimes in the smooth execution of a treatment plan, an unforessen complication can arise due to infectious status of the patient. This was not an issue of major concern in olden days but with the increased awareness of diseases like hepatitis B and AIDS, it has been accentuated. Hence, “Dental safety is a key area of concern and needs to be addressed on top priority. The impression is the first milestone in the sequence of procedures performed for the fabrication of any prosthesis [1]. It is the blueprint for successful foundation of restorations built on it at the same time the impression material can act as a vehicle for the transfer of many micro-organisms and a link for infection between patient to other personnel [2].

Addition silicon impression material have been reported to be the most accurate and dimensionally stable. They have become one of the most widely used impression material in restorative dentistry for indirect restorations such as crowns, fixed partial dentures, veneers, inlays, for implant supported restorations and removable partial and complete dentures. The material is available in different viscocity to accommodate different impression techniques. Accuracy of impression after disinfection is of significance and matter of interest.

The American Dental Association first recommended disinfection of impression in 1985. It is therefore imperative that the recommendations for disinfecting dental impressions presented by center of disease control and ADA are to be followed for all the patients. When considering the methods for disinfection two factors are important [3].

Efficacy of disinfection process.

Effect of disinfection procedure on properties of impression materials.

Certain chemical solutions routinely used to disinfect impressions may cause significant dimensional changes [4]. Dimensional accuracy of the impression is an important attribute which determines the success or failure of the restoration or prosthesis made from it and hence ultraviolet radiation has emerged as an effective approach for inactivation of micro organisms in the last few decades as compared to other methods of disinfection like spraying and immersion method [5].

Therefore, this in vitro study has undertaken to evaluate “effect of ultraviolet disinfection on dimensional stability of the polyvinyl silioxane impression.”

Materials and Methods

Materials used

Materials

Addition polyvinyl silioxane impression material

Putty - Reprosil soft putty/ regular set

Light body - Reprosil ultra LV cartilage

Die material (kalabhai, Mumbai, India).

Polyethylene vinyl acetate sheet 1.5 mm thick.

Baseplate wax link modelling wax No-2,MDM Corp, Delhi.

Heat cure acrylic resins (Dentsply).

Tray adhesive universal VPS ahesive(GC) America Inc.

Equipments

Ultraviolet disinfection chamber.

Vibrator (Unident, Unident India).

Mean value articulator (jabbar product, India).

Travelling microscope (INCO, Ambala, India).

Vaccume moulding machine (ASHVAC,Jaypee Gen.Agencies).

Method

This study was done in the Department of Prosthodontics, Sharad Pawar Dental College, Sawangi, Wardha , Maharashtra,India.

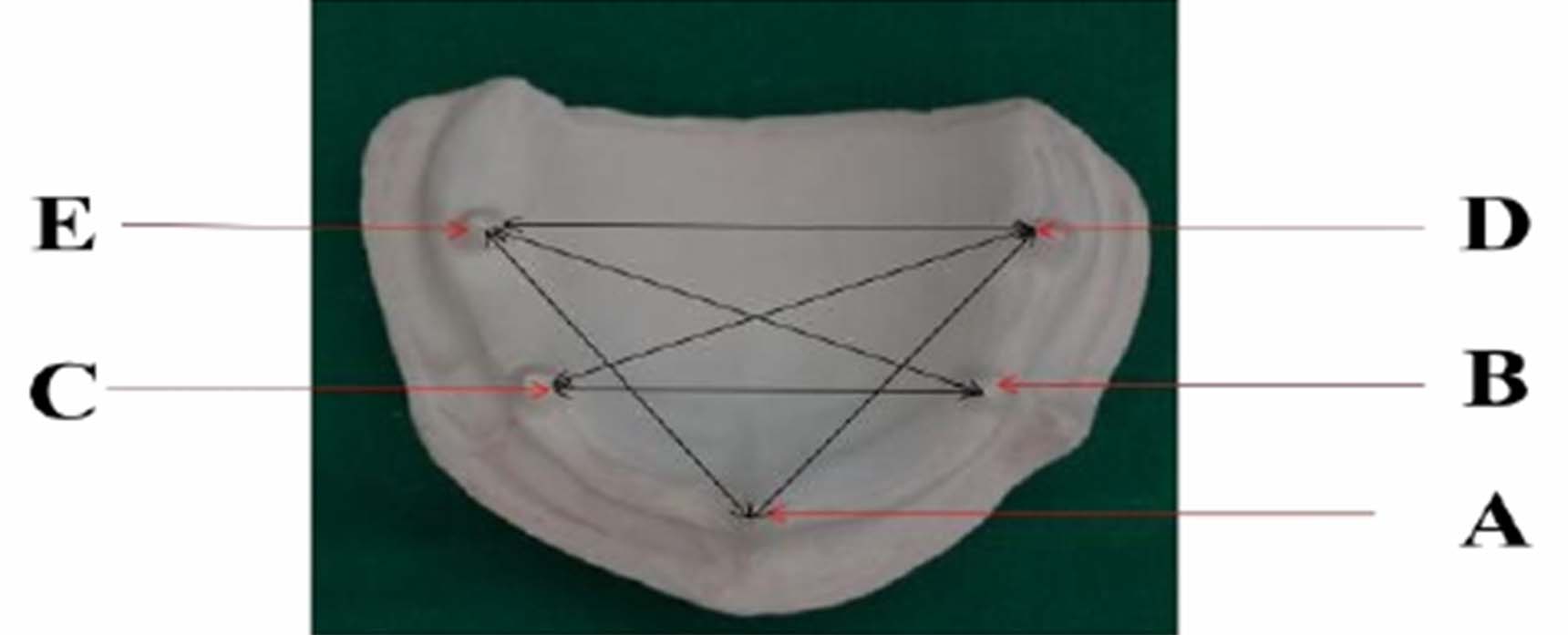

Preparation of master model - A brass model simulating maxillary arch with five conical tapered abutments with pointed tips was fabricated. One abutment located in the central incisor, two in the premolar region and two in the molar regions was used as the reference points [Table/Fig-1].

Adapatation of polyethylene spacer - A polyethylene acetate sheet of 1.5 mm thickness was vaccume adapted over the maxillary model using vaccum moulding machine to provide the space for the controlled thickness of the wash material [Table/Fig-2].

Preparation of custom tray- For making custom tray, wax pattern of 4 mm thickness was made on the master model for impression material. It was duplicated by using alginate to make a stone cast. Again a 3 mm thick wax pattern was made on the stone cast. The wax pattern was invested in dental stone and then dewaxed. Heat cure acrylic resin was used to pack the mold and curing was done. The tray was retrieved after processing and polishing. Perforations were made on the custom tray. Handle was attached to the tray [Table/Fig-3&4]

Making stand for Master Mold - A mean value articulator was modified for making stand. Metal spring was removed from the condylar housing so that only opening and closing movements was allowed. The incisal guide pin contacting the incisal guide table maintains the vertical distance between the model and the custom acrylic tray. A remount jig was customized and attached to the lower member of the articulator at the height of 4.8 cm using screws. The height of the master model was adjusted by keeping 4 mm clearance for the impression material between inner wall of the tray and the reference points on the model and then position of the master model over jig was fixed. The contact relationship between the incisal guide pin with incisal guide table acted like a vertical stop. Thus the thickness of the impression material was standardized (4 mm ) each time while making impressions [Table/Fig-5].

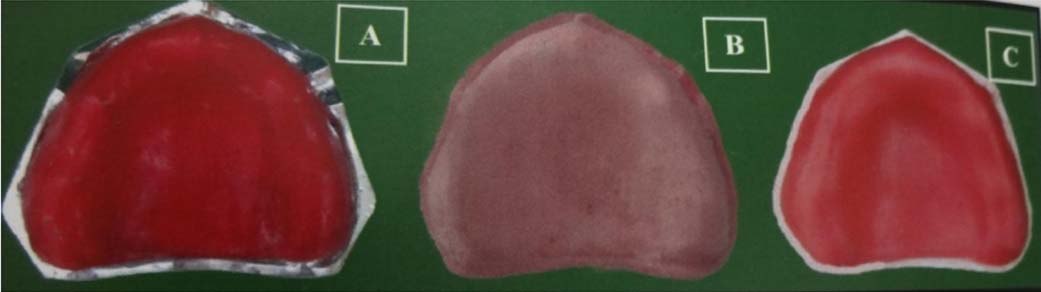

Fabrication of sample:- The tray adhesive was applied to the custom tray and allowed to dry for 10 min. The polyethylene spacer was placed on the model. Putty (Reprosil) was mixed as per the manufacturers direction. Equal amount of base and catalyst was hand kneaded and then loaded on the tray and impression was made. Then spacer was removed and the light body (Reprosil) was loaded and again impression was made [Table/Fig-6,7,8]. All the samples of both the groups were fabricated with the same material and same technique.

Grouping of the samples –Total 40 sample size was used. Samples were divided into 2 groups 20 samples per group. Control group twenty samples - not subjected to any disinfectant. Disinfected group twenty samples- subjected to ultraviolet light

Disinfection of the samples - After the fabrication of the samples 20 samples were disinfected in the UV chamber for 10 min. And 20 samples were not disinfected which served as a control group Shoebox shaped UV disinfection unit [Table/Fig-9] was used which consist of outer body and inner body. Outer box is made up of galvanized tin sheets of dimensions 455 mm x 200 mm x160mm. Inner box is made up of copper and then silver plated and is meant for keeping impressions for disinfection of dimensions 125mm x 325mm x 125 mm. Two UV germicidal lamps (Sankyo Denki Co Ltd,Japan) of 8 watt,254 nm wavelength are fitted. U.V. output is 2.5 watt, rated life -6000hrs , length of tube is 1 feet , indicator on top centre of lid indicates lamp is glowing. This unit is designed to reflect the UV light emitted so that the impression within the unit is exposed to UV radiations from many directions. It consists of mains to control the supply of electricity to whole system, timer to start the apparatus after setting of time. Time was set by rotating the knob between 1-60 min. Voltmeter indicates the volt. Distance between impression tray and tube was 10 cms. UV light act by the formation of thymine centaminary photo products in the DNA of the cells, which causes the cells to die. And thus, gives a powerful bactericidal effect.

Pouring of impression- The impressions were poured in die stone after 30 min of impression making for control group and for disinfectant group after 20 min they were placed in UV chamber and disinfected for 10 min in disinfectant and poured immediately and allowed to set [Table/Fig-10].

Testing of the samples- The cast were retrived and the distance between the 5 reference points BC , DE, DC, BE, AD, & AE on the cast were measured under travelling microscope [Table/Fig-11] of 0.001mm accuracy.

Spacer adapted on the master mold

Steps in fabrication of custom tray. a:- 4mm thick wax pattern on the master model for uniform thickness of impression material. b:- Duplicated stone cast with alginate. c:-3 mm thick wax patern for the thickness of custom tray

Heat cure acrylic resin custom tray

Modified articulator with master mold

Putty impression with spacer

Spacer removed from impression for the light body wash impression

Time taken to complete the study was 30 day.

Results

[Table/Fig-12,13]. The statistical analysis of this in vitro study revealed that the impression without disinfection has arithmetic mean for measurement BC 36.79, DE 47.68, DC 45.86, BE 45.70, AD 38.72, AE 37.74. And impressions disinfected with UV light has mean for measurement BC 36.72, DE 47.68, DC 45.64, BE 45.67, AD 38.60, AE 37.64.

(Student’s paired t test) Descriptive Statistics

| Distance (in mm) | | Mean | N | Std. Deviation | Std. Error Mean |

|---|

| BC | Before U.V. Light disinfection | 36.79 | 20 | 0.15 | 0.03 |

| After U.V. Light disinfection | 36.72 | 20 | 0.10 | 0.02 |

| DE | Before U.V. Light disinfection | 47.68 | 20 | 0.41 | 0.09 |

| After U.V. Light disinfection | 47.68 | 20 | 0.26 | 0.05 |

| DC | Before U.V. Light disinfection | 45.86 | 20 | 0.50 | 0.11 |

| After U.V. Light disinfection | 45.64 | 20 | 0.27 | 0.06 |

| BE | Before U.V. Light disinfection | 45.70 | 20 | 0.13 | 0.03 |

| After U.V. Light disinfection | 45.67 | 20 | 0.20 | 0.04 |

| AD | Before U.V. Light disinfection | 38.72 | 20 | 0.29 | 0.06 |

| After U.V. Light disinfection | 38.60 | 20 | 0.09 | 0.02 |

| AE | Before U.V. Light disinfection | 37.74 | 20 | 0.11 | 0.02 |

| After U.V. Light disinfection | 37.64 | 20 | 0.19 | 0.04 |

| Paired Differences | T | Df | p-value |

|---|

| Mean | Std. Deviation | Std. Error Mean | 95% Confidence Interval of the Difference |

|---|

| Lower | Upper |

|---|

| BC | 0.06 | 0.18 | 0.04 | -0.02 | 0.14 | 1.499 | 19 | 0.150 NS,p>0.05 |

| DE | 0.001 | 0.49 | 0.11 | -0.22 | 0.23 | 0.009 | 19 | 0.993 NS,p>0.05 |

| DC | 0.21 | 0.53 | 0.12 | 0.03 | 0.46 | 1.789 | 19 | 0.090 NS,p>0.05 |

| BE | 0.03 | 0.24 | 0.05 | -0.08 | 0.14 | 0.591 | 19 | 0.561 NS,p>0.05 |

| AD | 0.12 | 0.28 | 0.06 | -0.009 | 0.26 | 1.953 | 19 | 0.066 NS,p>0.05 |

| AE | 0.10 | 0.25 | 0.05 | -0.01 | 0.22 | 1.772 | 19 | 0.092 NS,p>0.05 |

Result of this study was not significant. There was no difference in dimensional stability of impression before and after disinfection with UV light.

Discussion

Infection control has become a cardinal issue in clinical practice. The risk of contamination and cross infection through dental impressions has been a topic of interest for many years. As the growing body of research suggests, it is essential to develop an effective means of disinfecting materials including impression before their transfer to dental laboratory personnel [6]. Autoclaving impressions may distort the impressions due to high temperature. And hence, this study was performed to evaluate the dimensional accuracy of the impressions disinfected with the UV light. According to Pleasure MA, Durr EL et al., [7] has reported that impression material used are thermoplastic and would be destroyed and distorted by usual sterilizing methods. Hence, use of disinfectants on impression materials is recommended and hence chemical disinfectants were used. There are many previous studies concerning the disinfection of impressions, yet, nearly all of them study the chemical disinfectants. Lepe X et al., [8] evaluated the accuracy of polyether and addition silicone impression materials after long term disinfection in full strength 2% acid gluteraldehyde solution. It was found that accuracy of both the impression were adversely affected which directly affected the fit of the fix partial prosthesis. Such studies show that these chemicals have undesirable effects an impression materials and need for alternative technique is evident. Therefore, it was decided to conduct an in vitro study to compare the effect of UV light disinfection on the dimensional stability of polyvinyl siloxane impressions. Research data on UV light disinfection is scarce but Singh S et al., and Wakefield CW [9] has reported the clinical relevance of disinfection by UV rays by revealing the application of “germicidal” UV rays for disinfecting drinking water, culture media, titanium implants , impression materials, dental hand pieces etc. Boylan RJ [5] evaluated the disinfectant properties of the buffalo ultraviolet disinfection unit (BDU). An instrument that emitted UV rays in an enclosed area, on some dental materials that might be adversely affected by exposure to chemical disinfectant . UV light kills the microorganisms within seconds. Result showed that BDU reduced the number of microorganism remaining on the surface of impression even after they were thoroughly rinsed with running tap water. Bharathi et al., [3] has reported a similar study but the dimensional changes are found to greater as compared to present study. They compared disinfection with gluteraldehyde and found that UV light disinfection gives lesser dimensional change. However, description for the equipment used is not sufficient. Although it is not possible to directly correlate the results of this study with others because of the difference in methods and materials it appears that for polyvinyl siloxane impression material the dimensional changes are statistically insignificant with UV disinfection and also less than with gluteraldehyde.

This study suggests a simpler and effective method of disinfection for protecting personnel who handle dental impressions and all the hazardous effects of chemical disinfectants can be avoided. It can be a specially helpful for materials which has affinity towards water e.g. Polyether and hydrocolloids. It can also be used for sanitization of dental prosthesis especially made of acrylic resin.

All measurements made in this study were horizontal linear dimensional changes. Three dimensional measurements can be made with the help of software. Also the clinical trial may be helpful to verify the dimensional accuracy of polyvinyl siloxane impression materials in vivo as conditions of oral cavity such as temperature, moisture and undercut may affect its properties. In spite of various investigations, there exists a need for further research to elucidate, the efficacy of the UV light disinfection of the dental impressions without any dimensional changes.

Conclusion

The ultimate responsibility of dental health care providers is to ensure safety from the invisible but deadly world of microbial pathogens which can only be implemented with a thorough understanding of infection control procedures. The increased awareness of the dangers of cross-contamination with hepatitis B virus (HBV) and HIV during dental procedures is having a growing impact on attitudes toward infection control in the dental clinic and laboratory. The principal potential route of transmission from the patient to the dental technician is through contaminated impressions and Prostheses. It has been demonstrated that microorganisms can be recovered from casts recovered from impressions made of dental moulds experimentally inoculated with bacteria. The responsibility to have a thorough knowledge of the patient’s history and to ensure that support staff members are not put at risk of cross-contamination begins with the clinician. It would seem essential therefore, that impressions be disinfected by the clinician or a suitably protected technician prior to the initiation of any laboratory procedures. Further studies using different impression material should be carried out to strengthen the research data.

[1]. Infection control in dentistry. Dental Clinics of North America. 1996;40(2):114–18 [Google Scholar]

[2]. Brandt Robert M, Cofey James P, Infection control in a Prosthodontic residency programJ Prosthodont 1993 2:55-57. [Google Scholar]

[3]. Munagapati Bharathi, Mallikarjun M, Comparsion of efficacy of gluteraldehyde and UV light disinfection and their effect on dimensional stability of polyvinily silioxane impressions an in-virro studyAnnals and Essences of dentistry 2011 3(4):13-15. [Google Scholar]

[4]. Tullner JB, Commette JA, Moon PC, Linear dimensional changes in dental impressions after immersion in disinfectant solutionsJ Prosthet Dent 1988 60:725-28. [Google Scholar]

[5]. Boylan Robert J, Goldstein Gary R, Evaluation of an ultraviolet disinfection unitJ Prosthet Dent 1987 58(5):650-54. [Google Scholar]

[6]. American Dental AssociationInfection Control Recommendations for the dental Office and Dental LaboratoryJ Am Dent Assoc 1992 123(8):1 [Google Scholar]

[7]. Pleasure MA, Durr EL, Eliminating a health hazards in prosthodontic treatments of patients with pulmonary tuberculosisJ Prosthet Dent 1959 9:818-24. [Google Scholar]

[8]. Lepe X, Johnson GH, Berg JC, Surface characteristics of a polyether an addition silicone impression materials after long-term disinfectionJ Prosthet Dent 1995 74:181-86. [Google Scholar]

[9]. Wakefield Charles W, Laboratory contamination of dental prosthesesJ Prosthet Dent 1980 44(2):143-46. [Google Scholar]