Accurate fit and retention of the crown or bridge are of prime concerns for both the patient as well as the dentist. Displacement of crowns or bridges is best prevented by proper tooth preparation, by closely adapted internal surface, surface finish of the preparation and of the fitting surface of the casting, cementation variables such as type of cement, physical properties of the luting agent, placement techniques, seating force and environmental conditions [1].

In the past, researchers believed that better retention would be achieved with a frictional fit between the coping and the tooth surface [2]. This inferred that during cementation process a perfect fit could not be obtained because of the lack of space for the luting agent [3,4].

Die spacing is a commonly used technique to provide space for the luting agent between the prepared tooth and the casting [5]. This space provides room for the luting agent which binds the crown and tooth together and allows complete seating of the restoration during cementation [6].

Provisional crowns and bridges are vital and integral part of Fixed Prosthodontic therapy. The fabrication techniques are named based on the method used for adapting the restoration to the teeth i.e., Direct, Indirect and Indirect –Direct techniques [7]. Inspite of the fact that the use of provisional crowns and bridges is often well thought out to be for an interim period of use, there are situations where long term use would be obligatory.

No matter what may be the intended period, the provisional restorations should be made to provide pleasing aesthetics, adequate support and good protection for teeth while maintaining periodontal health. An accurate fit, retention and margination of provisional restoration are essential to ensure and maintain good pulpal health of the prepared tooth.

The provision of space for luting agent, the spacer thickness, its effect on retention and seating of crown was mostly discussed over past but then again only in relation to cast, crowns and bridges. The present study is done to evaluate the space provided for the temporary luting cement, after the application of various die spacers during the fabrication of provisional crowns and bridges. The objectives of this study was to determine and compare the available luting space after application of various die spacers i.e.

Materials and Methods

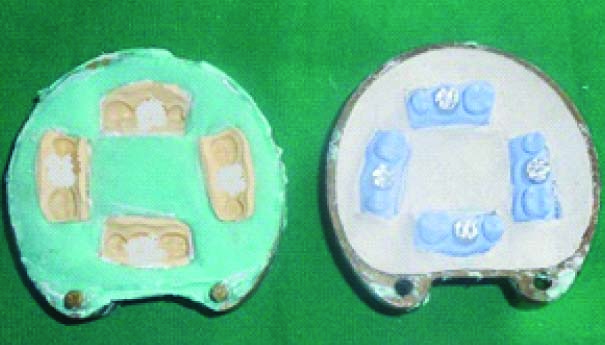

The present study was carried out in Department of Prosthodontics and crown & bridge, Sibar Institute of Dental Sciences, Guntur, (A.P), India. An intact mandibular typhodont model with full complement of teeth was used for this study. Five sectional custom trays with ideal wax spacer thickness were fabricated on the fourth quadrant using tray acrylic material [Table/Fig-1]. A total of 50 silicone putty indexes with the ESF’s of 45, 46, 47 teeth using putty elastomeric impression material were obtained to be served as the matrix for fabrication of provisional restorations. Then, tooth preparation for a metal ceramic restoration is carried out on 46 teeth, following the ideal principles. A multiple mix impression technique using regular and light bodied elastomeric impression material was made in all the five sectional customs trays. In these impressions a type IV gypsum product was poured carefully. Thus five master models which included the prepared tooth and the teeth immediately adjacent to it [Table/Fig-2] are obtained which were further used to duplicate in a silicone mould.

A Type III gypsum product was poured in the silicone mould [Table/Fig-3] for preparation of the specimens. A total of 50 specimens were prepared.

Pouring of dental stone into silicone mould

All the prepared 50 specimens were divided in 5 groups i.e.

10 control group specimens that are to be coated with separating medium and coded as CG.

10 specimens for Silver die spacer application of single coat and coded as SD1.

10 specimens for Silver die spacer applicationof double coat and coded as SD2.

10 specimens for Gold die spacer of application of single coat and coded as GD1.

10 specimens for Gold die spacer application of double coat and coded as GD2.

To avoid any inaccuracies during provisional crown fabrication a conventional flask method was carried out. The specimens were flasked using a two pour technique with dental stone ensuring the putty indexes in the upper member and the specimens in the lower member of the flasks. Flasking of all the 50 specimens, 5 in each flask were carried out.

All the control group specimens were applied with a single coat of separating media using a sable brush and were allowed to dry for two mins. Now tooth coloured auto polymerizing methyl-methacrylate resin material loaded into the putty indexes in the upper member of the flasks [Table/Fig-4]. Later the lower member of flasks were closed and clamped using a hydraulic bench press with 1000 psi for 20 min to ensure complete polymerization of the acrylic material.

Flasks with provisional restorative material in previously made putty indexes

A similar procedure is followed for SD1, SD2, GD1, GD2 samples. But in case of SD2, GD2 samples as the spacer was applied in double coat, a complete dryness period of 2 min between the applications is followed.

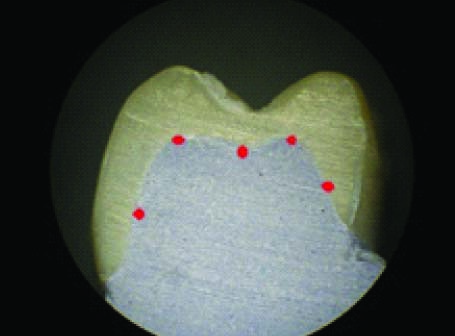

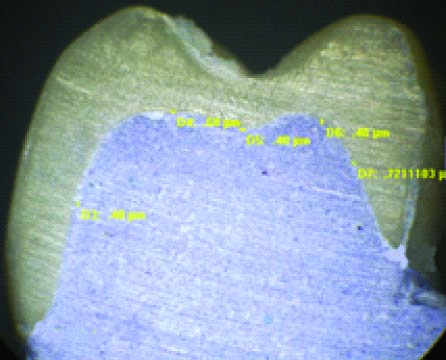

The flasks were opened and the specimens along with the provisional crowns were intactly retrieved from the indexes carefully. Later these dies were sectioned buccolingually along with the provisional crowns. The sectioned specimens were focussed under a stereomicroscope with magnification of 100X. The images were captured with the help of the camera connected to this stereomicroscope. Later these images were recorded with the help of Image Pro 6.0 Express software. The images so obtained were evaluated and recorded for the amount of space formed by the separating media and die spacers between the inner surface of the provisional crowns and the specimens at 5 different locations i.e., mid buccal, buccal cusp tip, mid occlusal, lingual cusp tip, mid lingual [Table/Fig-5]. [Table/Fig-6] show control group; silver colour single coat; silver colour double coats; gold colour single coat; gold colour double coats specimens as viewed under stereomicroscope. The data thus obtained was statistically analysed using one-way ANOVA test and unpaired t-test.

Measuring areas at five different locations

Control group specimen as viewed under Stereomicroscope

Results

When compared at various areas in all the specimen groups, statistical analysis by one-way ANOVA test showed significant differences (p=0.001) in the mid lingual points; a value of (p=0.001) at the lingual cusp tips; a value of (p=0.001) at mid occlusal area and a value of (p=0.001) at buccal cusp tips; a value of (p=0.001) at Mid buccal points in all the specimen groups.

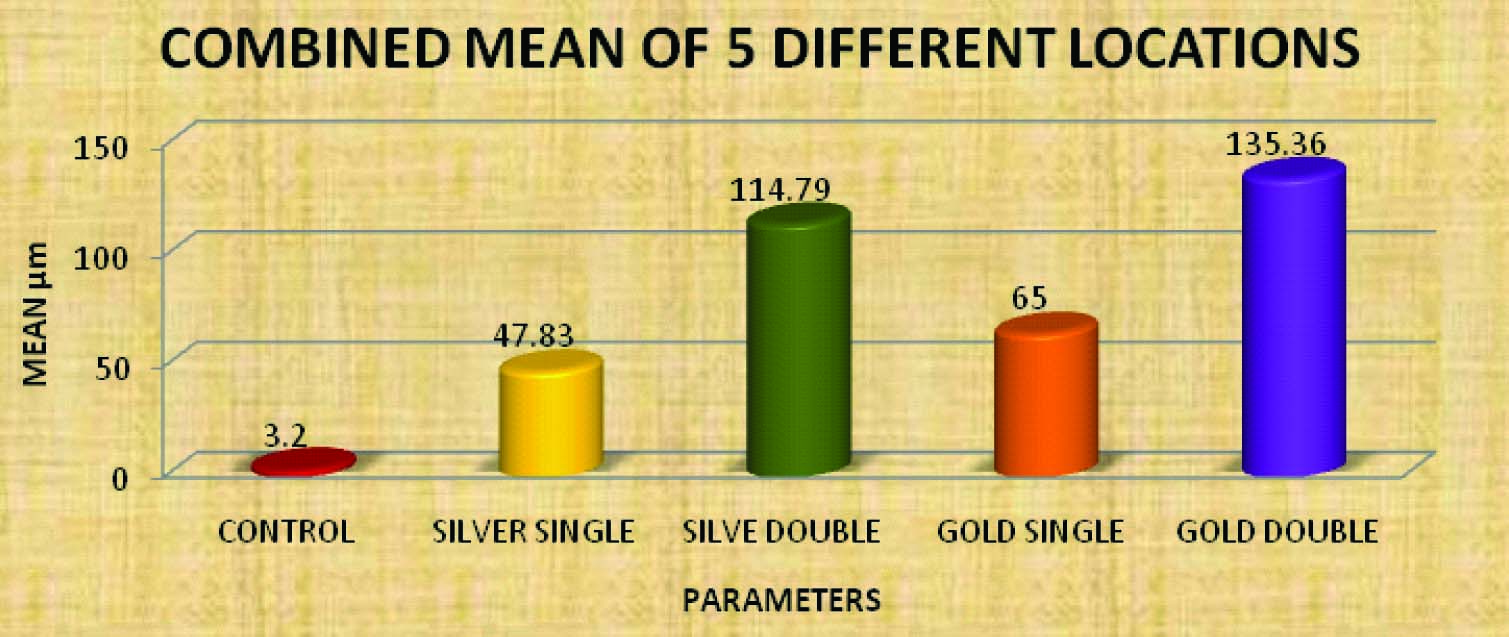

Mean film thickness of all the study groups are depicted in [Table/Fig-7] with a significant statistical difference of (p<0.001).

Bar diagram representation of ANOVA one way test. The obtained sum of all the five locations of different colored die spacer was plotted

Control group specimens showed a mean film thickness of 3.2 μm in comparison with SD1 (p<0.001); in comparison with SD2 (p<=0.001); in comparison with GD1 (p<0.001) and (p=0.001) in comparison with GD2 specimens.

The sum of mean values of all the values i.e., Control group of 3.2 μm, Silver single coat of 47.83 μm, Silver double coats of 114.79 μm, Gold single coat of 65 μm, Gold double coats of 135.36 μm are represented in [Table/Fig-7].

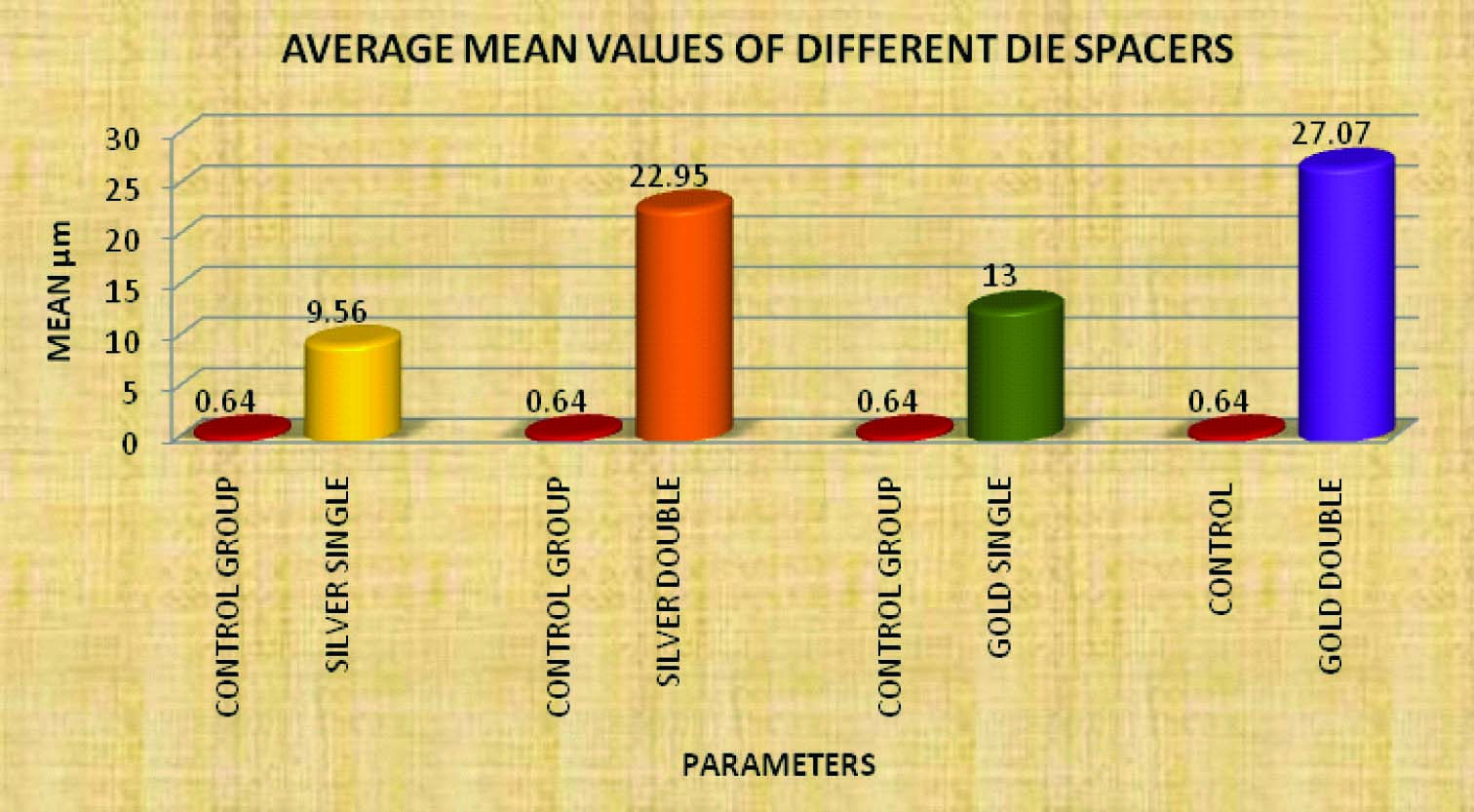

The Statistical mean values of separating media i.e., Control group 0.64μm, and different die spacer coats application i.e., Silver single of 9.56 μm, Silver double of 22.95 μm, Gold single of 13 μm, Gold double of 27.07μm are shown in [Table/Fig-8].

Bar diagram representation of ANOVA one way test. The obtained average values of different Colored die spacer are plotted against control group

Discussion

The success of any crown or bridge depends on the proper fit and cementation of these onto the prepared tooth.

Two techniques, venting and internal relief were developed to improve the seating of castings and to relieve hydraulic pressure within the crown. The impracticality of repairing the perforation after cementation in venting procedure has prevented its wide acceptance.

Internal relief methods like mechanical grinding inside the crowns or carving of the wax pattern are crude, inconsistent and incapable of achieving a uniform space for cement. Aqua regia etching of ceramo metal crowns is time-consuming and requires a highly corrosive product which is not generally recommended. Electrochemical milling method of internal relief with potassium cyanide milling agent is hazardous and not suggested [8].

Among all the above mentioned internal relief methods, the application of paint-on die spacer to dies prior to the fabrication of the wax pattern to improve seating of castings is popular because of its simplicity and convenience during usage along with being cost effective.

Wang CJ have evaluated the effects of luting cements placed in crowns fabricated on dies with and without die spacer applications. They observed a better crown seating in crowns fabricated with die spacer application [9].

The presence of the spacer provides space for the luting agent. The optimal film thickness of provisional luting cements is generally in the range of ‘25- 35’μm [10].

Provisional crown and bridges in fixed prosthodontic rehabilitation have same importance as that of permanent fixed partial dentures, particularly if these are expected to function for extended periods of time or when additional therapy is required before completion of rehabilitation [11].

The proper fit and cementation of provisional restorations onto prepared teeth are crucial to both short and long term functions. Incomplete seating may result in occlusal interferences, discrepancy of marginal fit etc [12]

Numerous articles which have touched upon are related to die spacing in cast restorations but die spacer application and its significance during provisional crowns and bridges fabrication were not studied exhaustively.

Hence, in the present study the same die spacers that are commonly used during the fabrication of cast crowns and bridges are employed during the fabrication of provisional restorations and were evaluated for the availability of the luting space for the provisional luting cement.

A total number of 50 dies were made out of typhodont tooth preparation for a metal ceramic crown and were divided into five groups, each group with 10 specimens i.e., CG (separating media application), SD1 (single coat application of silver die spacer), SD2 (double coat application of silver die spacer), GD1 (single coat application of gold die spacer), GD2 (double coat application of gold die spacer). Later tooth colored autopolymerizing acrylic resin material was used to fabricate provisional crowns on all these specimens using an indirect flask technique. Now these specimens along with the provisional crowns were sectioned buccolingually and were observed using a stereomicroscope under 100X magnification. The images thus obtained were evaluated and noted for the amount of space between the inner surface of the provisional crown and the specimens at five different locations using Image Pro 6.0 Express software.

Results showed that by the application of Gold die spacer in double coat (GD2) gave the highest luting space of 27.07μm in this study. Application of Silver die spacer in double coat (SD2) showed an increased luting space of 22.95μm. Gold die spacer application in single coat (GD1) in 13μm and Silver die spacer application in single coat (SD1) showed 9.56μm of luting space. Control group i.e., application of a coat of separating media showed the least luting space of 0.64μm respectively.

Olivera AB et al., have carried out a study to evaluate the effect of application of die spacer on fit and retention of complete cast crowns by using optical microscope and scanning electron microscope on different areas of stone dies i.e., Occlusal and 1/3 of axial surfaces , occlusal and 2/3 of axial surfaces & entire preparation down to 0.5mm short of the margin and concluded that fit of the cast restorations can be improved by increasing the surface area of application of the die spacer on the entire preparation down to 0.5mm short of the margin [13].

Campagni et al., applied die spacers on stone dies and measured the actual thickness of the spacing material. A luting space of ‘26.55’μm with 2 coats, ‘58.85’μm with 4 coats and ‘77.70’ μm with 6 coats was observed in their study. The double coat application of Gold die spacer in the present study showed 27.07μm which was similar with the authors study. The minor variation probably was caused by the varying compositions of the die spacers used by the authors in their study in composition with the present study [14].

To achieve the needed ideal provisional luting space (25 to 35 μm)[15] during provisional crown and bridge fabrication, the application of Gold die spacer in double coat which resulted in 27.02μm could be highly advantageous and thus could be helpful in attaining short and long term functions of the provisional crowns and bridges.

Conclusion

Within the limitations of this study, it can be concluded that the application of Gold die spacer in two coats on to the dies can significantly increase the temporary luting space than by the application of the conventional separating media before fabricating the provisional crowns and bridges.