According to the Glossary of Prosthodontic terms “Complete denture is defined as a removable dental prosthesis that replaces the entire dentition and associated structures of maxilla and mandible [1].”

Some of the requirements of a clinically acceptable denture base material are biocompatibility, strength, durability, satisfactory thermal properties, chemical stability, colour stability, ease of fabrication, repair and moderate cost [2]. An additional requirement that would benefit both the clinician and the patient is a denture base material that has a soft tissue fitting surface and a hard occlusal surface so that tissue health is maintained along with an uncompromised masticatory efficiency.

Acrylic resins were introduced in 1936 as denture base materials. Amongst their characteristics, are easy handling, good thermal conductivity, low permeability to oral fluids and colour stability [3]. Dimensional stability being a critical factor for the retention and stability of prostheses, polymerisation shrinkage is the greatest disadvantage of this material. Factors like water sorption by the acrylic resin, resilience of the gingival mucosa and the action of saliva may compensate this effect. Hypersensitivity and mucosal irritation caused by the release of methylmethacrylate are not unknown. Another problem encountered while providing acrylic prosthesis is the limitation of strength and design in meeting the functional demands of the oral cavity [4]

Flexible resins were initially developed for the construction of provisional prosthesis such as immediate RPD’s. They are indicated for the construction of RPD’s, mainly for anterior retention where esthetics is required. This is because of its translucency and a natural appearance without laboratorial characterization. Furthermore, the flexibility of these materials prevents prosthesis from getting fractured. It also adds to patient comfort as it is light by weight [5].

Although the related literature shows the properties of these materials in terms of deformation and retention, there is a lack of information about sorption, solubility & microhardness [3]. Therefore, the purpose of the present in-vitro study is to evaluate and compare the sorption, solubility and microhardness of flexible (thermoplastic polyamide nylon) and heat cure polymethyl methacrylate denture base resin.

Materials and Methods

Flexible (thermoplastic polyamide nylon) and heat cure PMMA denture base resin were included in this investigation. Manufacturers’ recommendations were used in fabrication and recovery of all the specimens. Established testing protocols were employed when available, and are identified in the following sections. All instruments and devices used in this investigation were calibrated and monitored in accordance with manufacturers’ recommendations.

Sorption and Solubility

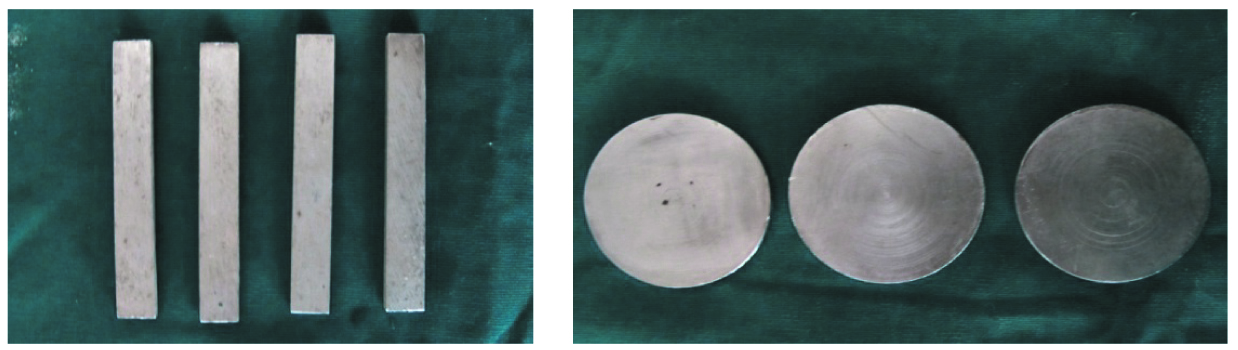

In compliance with ADA Specification No. 12, two specimens of each denture base material were fabricated for sorption, solubility, and microhardness testing. Individual specimens were 50 mm x 0.5 mm in thickness for sorption and solubility & 65 mm x 10 mm x 2.5 mm for microhardness [Table/Fig-1,2,3and4]. Standard tests of sorption, solubility, and microhardness were performed in accordance with ADA Specification No. 12.

Aluminium denture flasks meant for injection moulding procedure

Samples weighed before testing for sorption & solubility

Sorption testing was accomplished by creating ten disks using each material. Disks were 50 ± 1 mm in diameter and 0.8 ± 0.1 mm thick. Subsequently, the thickness of each disk was reduced to 0.5 ± 0.05 mm using abrasive papers in successive grits of 120, 240, 400, and 600. Grinding was performed to ensure that the surfaces of these disks were flat and parallel. Abrasive papers were flooded with water throughout the grinding procedures.

Upon completion of grinding procedures, disks were dried in a desiccator containing anhydrous calcium sulfate at 37 ± 2oC for 24h [Table/Fig-5]. Individual disks were then placed in a similar desiccator at room temperature for 1h, and subsequently weighed with a precision of 0.2mg. This cycle was repeated until the weight loss of each disk was not more than 0.5mg in any 24h period [Table/Fig-6]. Disks were immersed in distilled water at 37 ± 10C for 7 days [Table/Fig-7]. At the end of this period, individual disks were removed from the water with forceps, wiped with a clean dry towel, permitted to air dry for 15s, and weighed [Table/Fig-8]. Water sorption for each disk was calculated using the formula:

Samples kept in dry anhydrous calcium sulfate

Samples weighed again to check till weight loss did not differ more than 0.5 mg

Samples kept in distilled water

Samples weighed again to check water sorption by the material

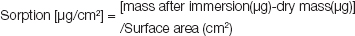

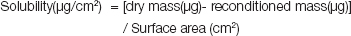

The average value for each material was recorded to the nearest 0.01 mg/cm2. In turn, these disks were used to determine solubility values. The disks were reconditioned to constant weight using the desiccation techniques previously described. Solubility for each disk was determined using the formula:

Microhardness

Using vickers indenter an indentation (rhomboidal in shape) was made on the block samples using 50g load for 10s.

F: Load in kg

d: Arithmetic mean of the two diagonals, d1 & d2 in mm

HV: Vickers hardness, By using formula, vickers number will be converted to knoop hardness number

KHN = F/A = P/CL2

F: applied load in kg

A: the unrecovered projected area of the indentation in mm2

L: measured length of long diagonal of indentation in mm

C = 0.07028 = constant of indenter relating projected area of the indentation to the square of the length of the diagonal

Knoop v/s Vickers:

Vickers indenter penetrates about twice as deep as knoop indenter

Vickers indentation diagonal about 1/3 of the length of knoop major diagonal

Results

On comparison of sorption [Table/Fig-9], solubility [Table/Fig-10] and microhardness [Table/Fig-11] between PMMA and flexible (thermoplastic polyamide nylon) resin by using unpaired-t test, statistically significant values were observed. Heat cure PMMA samples showed more sorption, solubility and microhardness values than flexible (thermoplastic polyamide nylon) resin.

Comparison of sorption between PMMA & flexible (thermoplastic polyamide nylon) resin

| Material | Number of samples | Mean | Std. Deviation | p-value |

|---|

| PMMA | 10 | 20.963820 | 3.1559640 | < 0.0001 |

| Flexible resin | 10 | 14.255960 | 1.4506029 |

Comparison of solubility between PMMA & flexible (thermoplastic polyamide nylon) resin

| Material | Number of samples | Mean | Std. Deviation | p-value |

|---|

| PMMA | 10 | 0.244630 | 0.0391754 | < 0.0001 |

| Flexible resin | 10 | 0.026030 | 0.0036990 |

Comparison of microhardness between PMMA & flexible (thermoplastic polyamide nylon) resin.

| Material | Number of samples | Mean | Std. Deviation | p-value |

|---|

| PMMA | 10 | 12.0810 | 1.43437 | 0.001 |

| Flexible resin | 10 | 10.2070 | 0.43622 |

Discussion

Water sorption depends on the degree of hydrophobicity and porosity of the material. In clinical use, resin denture base materials are vulnerable to water sorption and solubility when immersed in an aqueous medium such as saliva, nasal secretion, and water or cleansing agents. When immersed in such solutions, plasticizers and other soluble components may leach out over extended periods while water or saliva is being absorbed. The loss of plasticizer may cause a decreased percentage of elongation and increased hardness values. Absorbed water has a detrimental effect on the physical and mechanical properties of the resin denture base [6].

Testing these materials for microhardness, water sorption and solubility can give a better picture about decreased resiliency & increased porosity. In the present study, we evaluated & compared these three properties of PMMA with that of flexible (thermoplastic polyamide nylon) resin.

The sorption value between PMMA & flexible (thermoplastic polyamide nylon) resin was observed to have mean (std. deviation) of 20.96(3.155) and 14.25(1.45) respectively. By using unpaired-t test, the results found were statistically significant & p-value found was <0.05. Heat cure PMMA samples showed more sorption values than flexible (thermoplastic polyamide nylon) resin. The maximum ADA standard values of water sorption for denture base materials are 32μg/mm2.

Acrylic resins absorb water slowly over a period of time, primarily because of the polar properties of the resin molecules. High equilibrium uptake of water can soften an acrylic resin because the absorbed water can act as a plasticizer of acrylates and reduce the strength of the material [7]. The extent and rate of water uptake into polymer networks are predominantly controlled by resin polarity, dictated by the concentration of polar sites available to form hydrogen bonds with water and network topology [8]. Arima et al., suggested that the chemical nature of the polymer versus that of the water molecule directly affects the water sorption of resin [9]. Water is absorbed into polymer by the polarity of the molecules in the polymers by unsaturated bonds of the molecules or unbalanced intermolecular forces in the polymers. According to Dixon et al., the residual monomer could affect water sorption and expansion [10]. Hayashi et al., suggested that, since the contact angle between the flexible resin and water is high with low surface free energy, their water repellency is also high, resulting in lower water sorption values [11]. There is a strong hydrogen bonding between amide groups and a reduction in attachment areas for water molecules; therefore, the amount of water sorption in flexible resin is lower than conventional PMMA. The higher residual monomer contents could also be related to the higher solubility levels of PMMA [8].

Solubility values between PMMA and flexible (thermoplastic polyamide nylon) resin was observed to have mean (std. deviation) of 0.24(0.03) and 0.02(0.003) respectively. By using unpaired-t test, the results found were statistically significant & p-value found was <0.05. Heat cure PMMA samples showed more solubility values than flexible (thermoplastic polyamide nylon) resin. The maximum ADA standard values of water solubility for denture base materials are 1.6 μg/mm2.

The soluble materials present in acrylic resins are initiators, plasticizers and free monomer. It has been suggested that there might be a correlation between residual monomer and the weight loss determined by the solubility test [8]. The largest amount of residual monomer is usually leached from acrylates within the first few days of water storage. Consequently, it might be difficult to estimate the effect of residual monomer released from acrylates with the ADA standardized solubility test [8,12]

The microhardness values between PMMA and flexible resin was observed to have mean (std. deviation) of 12.08(1.43) and 10.2(0.43) respectively. By using, unpaired- t-test the results found were statistically significant & p-value found was <0.05. Heat cure polymethyl methacrylate samples showed more microhardness values than flexible (thermoplastic polyamide nylon) resin.

PMMA demonstrated higher hardness values when compared to flexible resin. This result may be attributed to a high monomer-polymer ratio and attachment of this material and the presence of methyl-methacrylate monomer. Moreover, cross-linking agents may exist in the material. Flexible resin demonstrated lower hardness values and also possessed lower amounts of cross-linking agents, indicating that cross-linking agent may affect surface hardness. This finding shows that polyamide resin is a more flexible material than the heat cure polymethylmethacrylate [6].

Clinical Implications

Flexible denture bases may be indicated in patient’s requiring replacement of teeth in esthetic zone, with restricted mouth opening, severe soft and hard tissue undercuts, allergy to acrylic or metal, as temporary prosthesis or as space maintainers [13]. Less sorption and solubility of the flexible (thermoplastic polyamide nylon) resin would eventually decrease porosity of the denture base and thus promote hygiene maintainence [5].

Inspite of the innumerable advantages and various indications of flexible (thermoplastic polyamide nylon) resin , further long-term studies are recommended to assess the overall usefulness of the material.

Conclusion

Based on the study conducted and the available literature, it may be concluded that:

Heat cure PMMA has more sorption values than flexible (thermoplastic polyamide nylon) resin.

Heat cure PMMA has more solubility values than flexible (thermoplastic polyamide nylon) resin.

Heat cure PMMA has more microhardness values than flexible (thermoplastic polyamide nylon) resin.