Modification of Fixture Mount to be Used as an Impression Coping in Closely Placed Implants

Sudhindra Mahoorkar1, Anoop Jain2, Cauvery K3, Pawan Kumar4, Raghavendra Havale5

1 Professor, Department of Prosthodontics, HKE’S SN Institute of Dental Sciences & Research, Karnataka-585105, India.

2 Director, Senior Prosthodontist & Implantologist, Department of Prosthodontics, Dental XPERTS, A3/221, First F loor, Sector 17, Rohini, Delhi-110089, India.

3 Senior Lecturer, Department of Periodontics, PDU Dental College, Kegoan, Solapur, Maharastra- 413225, India.

4 Reader, Department of Prosthodontics, Al-Badar Rural Dental College & Hospital, MSK Mill Road, Gulbarga, Karnataka- 585102, India.

5 Reader, Department of Pedodontics, AME’S Dental College, Raichur, Karnataka-584103, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Anoop Jain, Dental XPERTS, A3/221, First Floor, Sector 17, Rohini, Delhi-110089, India.

Phone: +91-8860700181,

E-mail: dranoopjain@ymail.com

An implant-level impression is often desired for designing and fabricating an implant-supported fixed restoration. This clinical report describes the use of modified press-fit metal implant fixture mount as an impression coping for making an impression of closely placed implants. The fixture mount is easier to manipulate, time saving and more comfortable for both the clinician and patient because the implant fixture mount is connected to the implant by pressing on instead of screwing. As compared to plastic press fit impression coping, metal fixture mount will not distort when modification of fixture mount are required in convergently or closely placed implants. It has the advantage of both the open-tray and closed-tray implant impression techniques.

Dental implants, Dental impression technique, Fixture mount, Impression, Impression coping

Clinical Report

A 52-year-old patient reported with no health problems and taking no medications presented to our dental clinic, for restoration of edentulous area in left mandibular posterior region. Therefore, the patient was evaluated for restorative options and it was decided to restore the edentulous area with two 4.2 × 11.5 mm and 3.5 x 10 mm internal connection implants (Adin dental implants sys. ltd. Israel). After the placement of implants and a healing period of three months, the prosthetic phase of the treatment was initiated. The primary challenge of this situation was to find a mechanism to create an implant-level cast for restorative treatment planning.

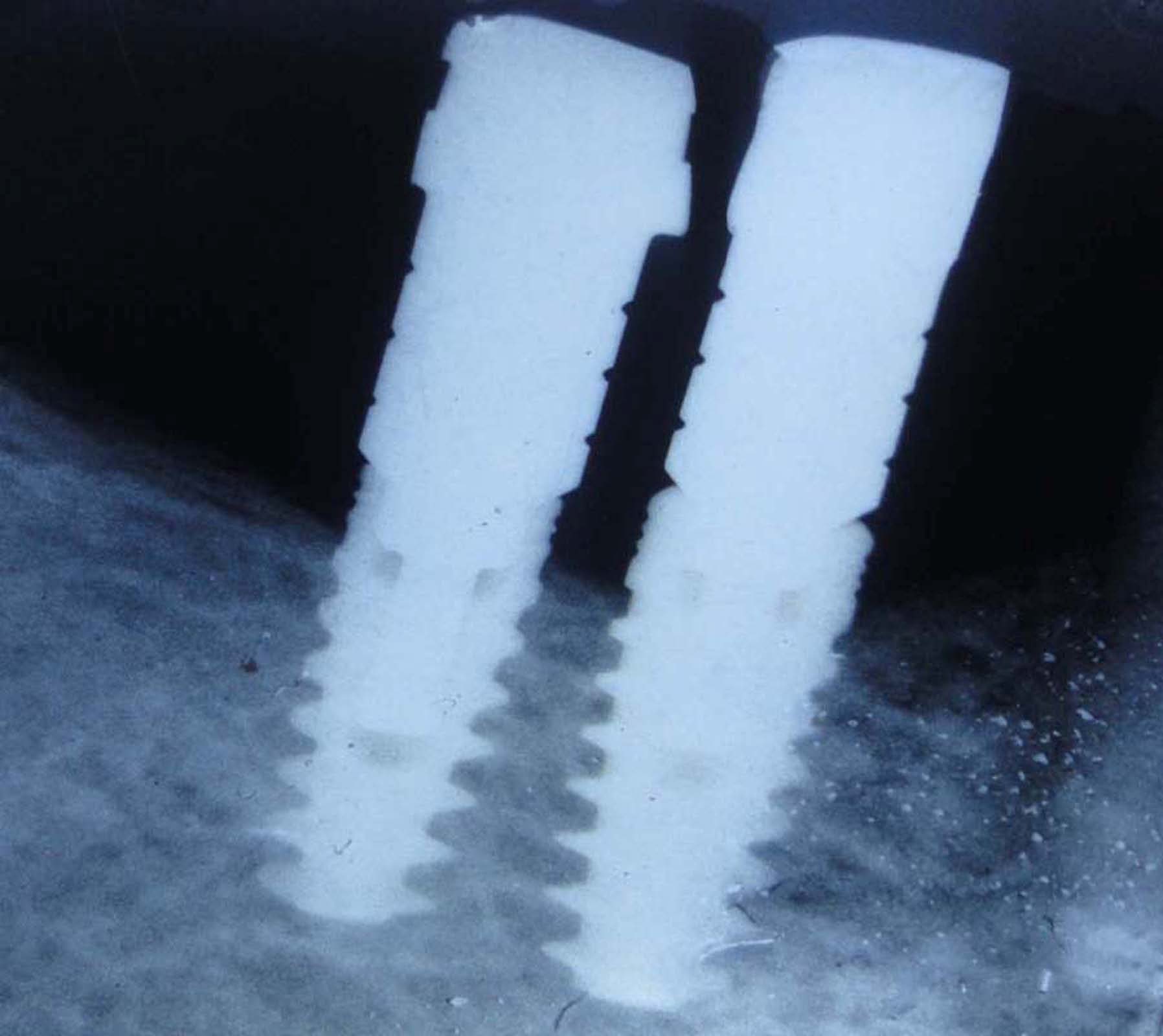

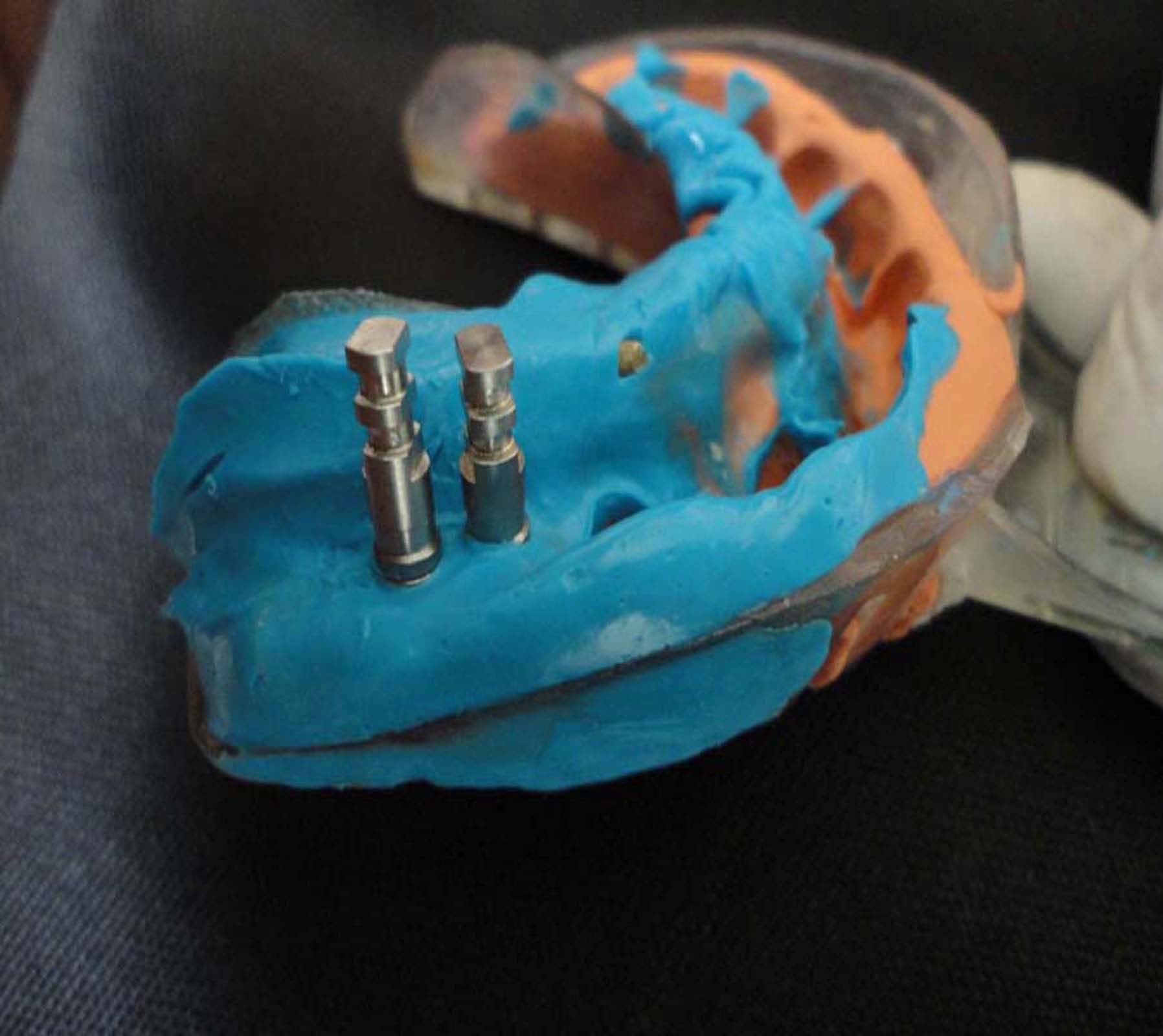

The press-fit metal implant fixture mounts (Adin dental implants sys. ltd. Israel) were used for making of impression as an alternative to impression coping, which were provided with implants [Table/Fig-1]. The implant fixture mounts were conservatively modified until it could be placed on implants without obstruction. The implant fixture mount connected to the implant by pressing on, instead of screwing [Table/Fig-2]. The fit of the implant fixture mount was verified radio graphically [Table/Fig-3]. The definitive impression was made with putty and light body consistency of additional silicone impression material (3M ESPE ExpressTM STD, seefeld, Germany) with a closed tray. Impression tray was removed along with the implant fixture mount [Table/Fig-4]. The implant analogs (Adin dental implants sys. ltd. Israel) were placed on the implant fixture mount within the impression, and the definitive cast was poured in type IV die stone (Kalrock kalabhai dental products, Mumbai, India) [Table/Fig-5]. Then the cast was evaluated for prosthetic design. Abutments (Adin dental implants sys. ltd. Israel ) for a cementable, fixed partial denture restoration were selected and modified for the fabrication of a 2-unit,high noble metal substructure (Eclipse; Dentsply Ceramco, Burlington, NJ).

Implant fixture mount, which was used as an impression coping

Implant fixture mount connected to the implant by pressing on method

Radiographic verification of implant fixture mount fit on implant

Fixture mount picked up in the impression

Implant analogs attached to fixture mount

Prior to the application of porcelain (Ceramco 3; Dentsply Intl), the metal substructure was returned for intraoral verification of fit. Clinical and radiographic examination revealed closed margins.

Discussion

An implant carrier is an implant component originally designed to transport the implant from the sterilized package to the implant site [1,2]. It enables the surgeon to connect the implant to the hand piece, ratchet, or manual driver, and it prevents direct contact with the sterilized implant [3]. Usually the surgeon disposes of the implant carrier after implant placement.

An implant-level impression is often desired for designing and fabricating an implant-supported fixed restoration, especially when two or more implants have been placed [4]. Precision fit of the fixed implant-supported restoration is dependent on the accuracy of the location of the implant analogs within the definitive cast [5]. Metal, screw-retained, open- or closed-tray impression copings are used to position these analogs when making implant impressions [6]. Conventional impression coping requires more time to confirm the complete seating of it, which is more time consumable and more uncomfortable procedure.

A fixture mount has been readily attached to the implant before packaging or before implant placement, therefore, can greatly reduce the chair time and guarantee the precision of the interface. In addition, there is no need to purchase a separate impression coping so the cost of restorations can be reduced, which also benefits the patients. Therefore, we can modify the implant fixture mount so that it can be used as an impression coping [7].

In this case report, we have used implant fixture mount with retentive groves for making the implant impression. The implant fixture mounts were conservatively modified until it could be placed on closely placed implants without obstruction. This modification is not possible with plastic press fit impression coping.

An impression is required to fabricate an implant supported fixed prosthesis after implant placement. Traditionally, impression copings need to be placed onto the implants before taking the impression. The complete seating of each impression coping on top of the implant needs to be confirmed by radiograph before impression taking. All of these cost extra chair time and additional discomfort for the patient.

Because this alternative method combines the advantages of conventional transfer and pick-up impression techniques, it can be easily employed in most cases.

McCarthy et al., reported first fixture mount which was used as an impression coping but it did not provide sufficient retentive features [8]. Early attempts of modification of an implant fixture mount by lathe, provided the convenience and function of a completely seated impression coping however, it did not provide the advantage of an readily seated impression coping. The first unmodified fixture mount which was suitable to be used as an impression coping was reported by Ganddini et al., [9].

Presently, used Implant fixture mounts are using ball impression screws for fixation. The fixture mounts are removed and connected to the implant analogs, and then the fixture mount-analog assemblies are reinserted in the impression before fabricating the definitive cast [7]. Unscrewing the ball impression screw from the implant when the tray is removed or screwing the matching implant analog in the impression may cause minor movement and thus influence cast accuracy.

In this clinical report, Press fit metal implant fixture mounts were used without fixation screws. These fixture mount engaged the implants through friction fit only and were envisioned to be picked up with a closed tray.

Selecman and Wicks used press fit plastic impression copings for making of implant impression [10]. Due to the inherent radiolucency of the plastic material, proper seating of the impression coping cannot be verified with a periapical X-ray. The press-fit plastic closed tray impression copings have to be purchased by the dental practitioners as an additional prosthetic component.

Because fixture mount used in this clinical report was made up of metal so it had the advantage of radiographic confirmation of complete seating. And as the fixture mount has been readily attached to the implant before packaging, there is no need to purchase a separate impression coping so the cost of restorations can be reduced, which also benefits the patients.

Conclusion

Metal implant fixture mount can be used as an implant impression coping because it is easier to manipulate, time saving and more comfortable for both the clinician and patient. It has retentive groves on its surface. It can be modified in contrast to plastic press fit impression coping in closely placed implants.

[1]. Binon PP, Implants and components: entering the new millenniumInt J Oral Maxillofac Implants 2000 15:76-94. [Google Scholar]

[2]. Misch CE, Misch CM, Generic terminology of endosseous implant prosthodonticsJ Prosthet Dent 1992 68:809-12. [Google Scholar]

[3]. Papazian S, Morgano SM, Four uses of a disposable implant mountJ Prosthet Dent 1998 79:222-5. [Google Scholar]

[4]. Kupeyan HK, Lang BR, The role of the implant impression in abutment selection: a technical noteInt J Oral Maxillofac Implants 1995 10:429-33. [Google Scholar]

[5]. Assif D, Marshak B, Schmidt A, Accuracy of implant impression techniquesInt J Oral Maxillofac Implants 1996 11:216-22. [Google Scholar]

[6]. Wenz HJ, Hertrampf K, Accuracy of impressions and casts using different implant impression techniques in a multi-implant system with an internal hex connectionInt J Oral Maxillofac Implants 2008 23:39-47. [Google Scholar]

[7]. Chang GH, Tian C, Hung YS, Redesign of a fixture mount to be used as an impression coping and a provisional abutment as wellContemp Clin Dent 2011 2:194-9. [Google Scholar]

[8]. McCarthy GR, Morgan VL Jr, Useful modifications of an implant fixture mountJ Prosthet Dent 1995 73:104 [Google Scholar]

[9]. Ganddini MR, Schejtman N, Ercoli C, Graser GN, Prosthodontic application for implant carriersJ Prosthet Dent 2004 92:399-402. [Google Scholar]

[10]. Selecman AM, Wicks RA, Making an implant-level impression using solid plastic, press-fit, closed-tray impression copings: a clinical reportJ Prosthet Dent 2009 101:158-9. [Google Scholar]