Aim: Aim of the study is to evaluate the distribution of forces on the instrument in the apical 3rd of curved canal with three Nickel Titanium rotary systems.

Methodology: Three brands of instruments (ProTaper Universal; DENTSPLY Maillefer, RevoS; MicroMega and Hyflex; Coltene-Whaledent, Allstetten, Switzerland) were scanned with the Laser assisted computerized scanner to produce a real-size, 3-dimensional (3-D) model for each. The stresses on the instrument during simulated shaping of a root canal were analyzed numerically by using a 3-D finite element package, taking into account the nonlinear mechanical behavior of the nickel-titanium material.

Results: RevoS shows lowest values for force generation in the apical 3rd of canal as compared to Protaper which shows highest values, while Hyflex shows intermediate values for forces.

Conclusion: With FE simulation of root canal shaping by 3 files, it was observed that different instrument designs would experience unequal degree of force generation in canal, as well as reaction torque from the root canal wall.

Finite element analysis, NiTi rotary files, Residual stresses, Screwing, Stress distribution

Introduction

The objective of the root canal preparation is to clean and shape the root canal space without creating any iatrogenic aberrant forms such as ledge, canal transportation, or perforation [1]. Nickel-titanium engine-driven rotary instruments are used increasingly in endodontic practice [2]. Due to their flexibility, coupled with the design of the blades, it is feasible to use nickel titanium instruments with a handpiece in a rotary motion to prepare root canals [3]. Flexibility is conferred by the pseudo-elastic behavior of the SMA (Shape Memory Alloys, to which the Ni-Ti alloy belongs [4]. The superelasticity of the material allows the NiTi rotary instruments to be used in continuous rotation, even in curved root canals, to produce a desirable, tapered root canal form, with a low risk of transporting the original canal lumen [5,6]. With the increased use of Nickel-Titanium (NiTi) rotary instruments for root canal therapy in endodontics, instrument fracture has become more and more prevalent.

Endodontic instrument fracture is an undesirable occurrence in clinical practice and one of the major concerns when rotary instruments are used [7]. Rotary endodontic instruments may fracture because of flexural fatigue, torsional load [3,8] or a combination of both. In clinical applications, rotary endodontic instruments are frequently subjected to composite flexural and torsional stresses [9]. Residual stresses might be induced in a part after mechanical loading, which stresses could jeopardize the durability of the part if it is to be loaded repeatedly.

Various brands of NiTi rotary system have been introduced to the market, each having a slightly different design for its cross-sectional shape, helical angle, and “radial lands” [10]. Most of them come with a regularly tapered shaft, whereas some (ProTaper Universal) have a varying taper along the length of the instrument. The design of the instrument has been suggested to affect its mechanical behavior, hence the tendency to fracture [11].

The ProTaper system has a cross-sectional design of a triangle with convex sides. The original ProTaper instrument has been said to transport canals slightly more than other NiTi systems in extracted human teeth [12]. The ProTaper Universal was launched recently as an improvement to the original design. It incorporates a shallow U-shaped groove at each of its convex triangular sides in cross section, supposedly to improve the flexibility of the larger instruments [11].

Recently, the new Revo-S NiTi instrument system (Micro-Mega, Besancon, France) has been introduced, which includes three shaping instruments; SC1, SC2 and SU (Universal). SC1 and SU files are having asymmetrical cross section that provides less stress on the instrument and enables better root canal penetration [13].

Hyflex is a new NiTi rotary file for root canal preparation that has been commercialized since 2011 & has been produced by an innovative methodology that uses a unique process that controls the material’s memory. According to many authors, such compositional deviations between 54 and 57 Ni %wt, probably attributed to raw material variations during manufacturing, did not seem to affect the mechanical properties of NiTi instruments [14,15]. This system has double fluted cross section same as Hedstrom file with uniform taper of 4%, 6% and 8%.

The purpose of this study was to estimate the forces generated on three different NiTi instruments in apical 3rd of simulated curved canal during shaping and to compare residual stresses by using a 3-D Finite-Element (FE) analysis.

Material and Methods

Constructing a 3-D model

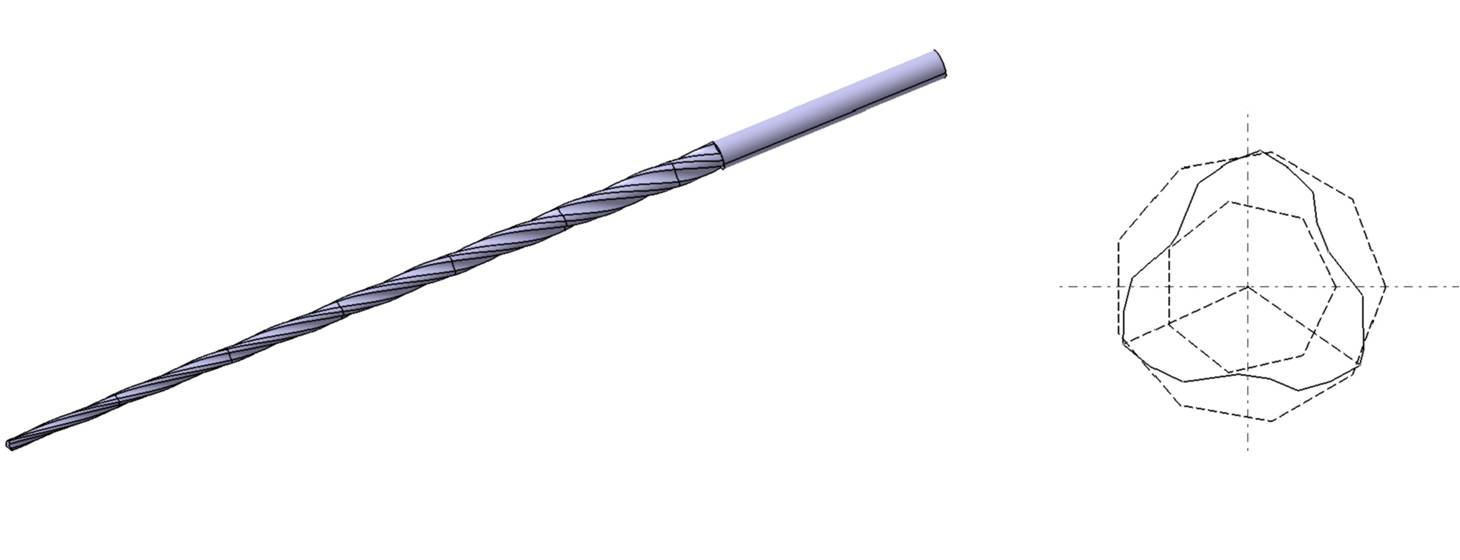

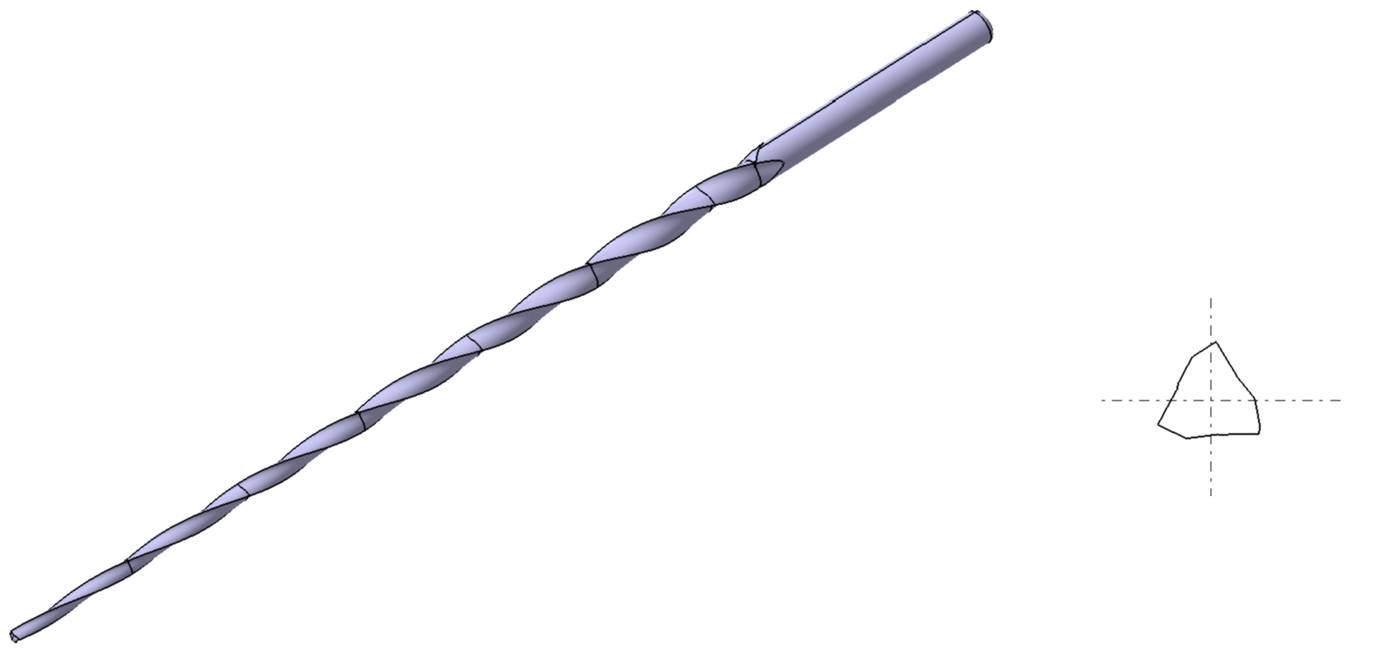

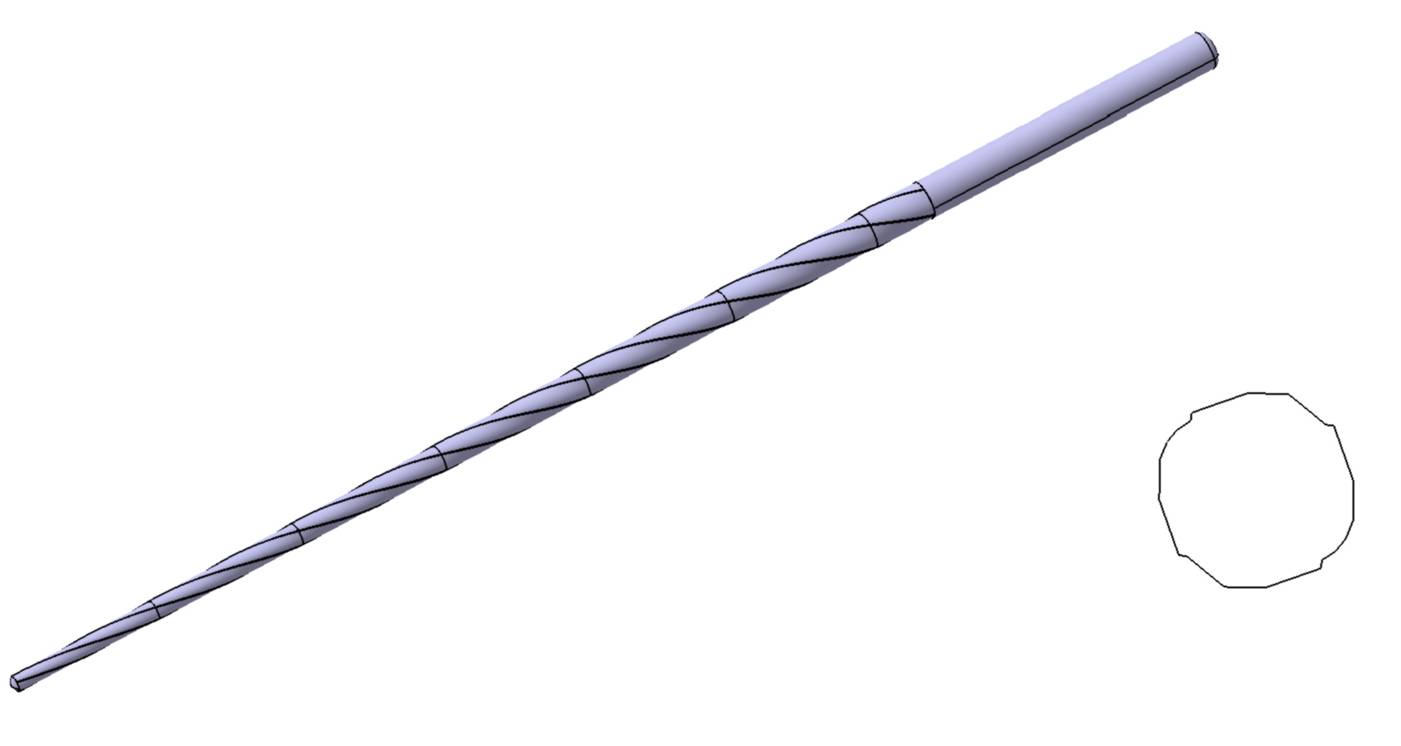

Three brands of rotary NiTi instrument Protaper (DENTSPLY Maillefer, Ballaigues, Switzerland), RevoS (Micro-Mega, Besançon, France) and Hyflex CM (Coltene-Whaledent, Allstetten, Switzerland) that were used. The three NiTi root canal files studied represent three very different cross-sectional designs with large Variations in the depth of the flute, the area of the inner core, and the radial land. In each systems, the first files used in the apical preparation were the ones with constant tip diameter 0.25 mm i.e., Protaper F2 (0.25 mm diameter and 8% taper), RevoS SC2 (0.25 diameter and 4% uniform taper) and Third file of Hyflex CM (0.25 diameter and 4% taper) were scanned at 2 mm interval in a Laser assisted computed scanner machine. Images of the files were collected; these 2-dimensional (2-D) data were saved in a computer and were reconstructed to give the 3-D model. 3-D models were put together to give rough models. After proper modification, models were completed with a smooth surface to obtain a real-size, geometric configuration of the instruments in 3-D. The noise in the stack of data was suppressed digitally, and a 3-D model of each instrument was reproduced in software (CATIA SOFTWARE) [Table/Fig-1,2&3] respectively.

Schematic drawings of the cross-sectional (Right column) and longitudinal shapes (Left column) of the Protaper F2 file

Schematic drawings of the cross-sectional (Right column) and longitudinal shapes (Left column) of the RevoS SC2 file

Schematic drawings of the cross-sectional (Right column) and longitudinal shapes (Left column) of the Hyflex file

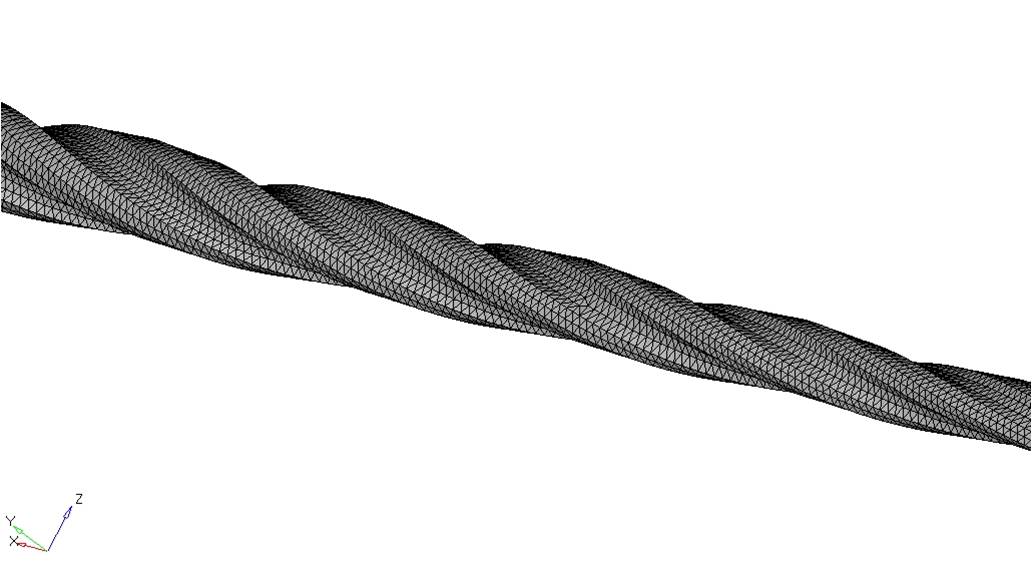

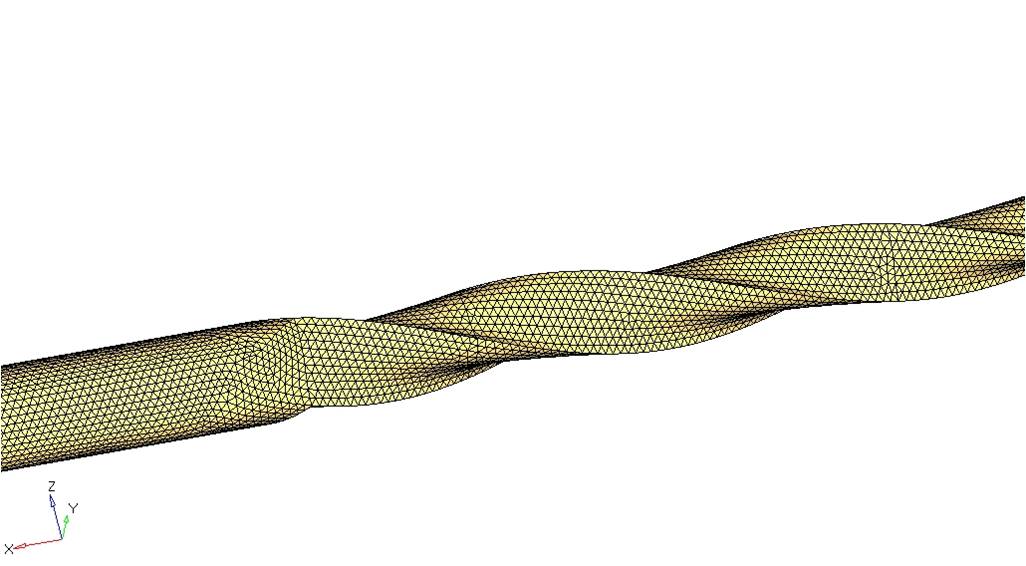

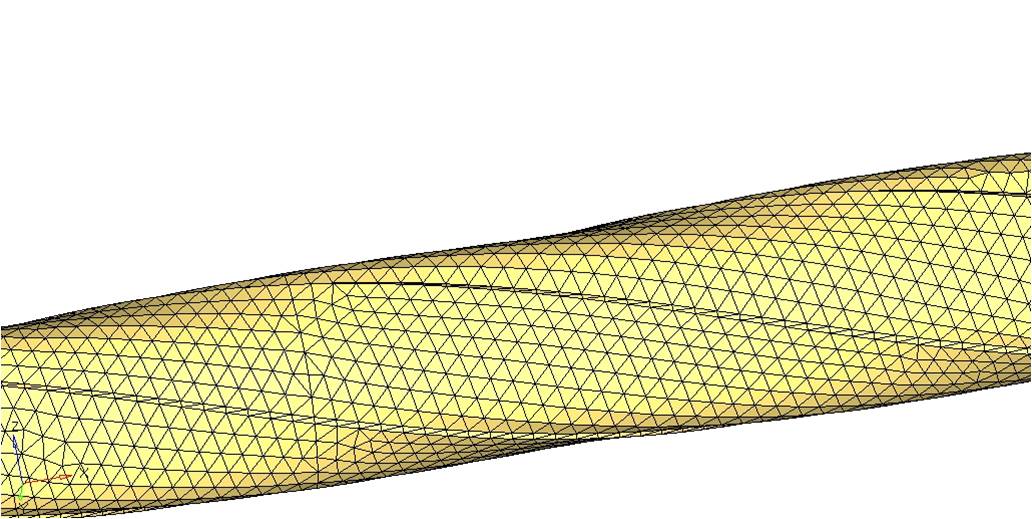

A Finite Element Analysis was carried out on the files. The finite element meshing was carried out using medium size mesh feature with 3-D elements like brick elements and tetrahedron element. A mesh of linear, 4-noded, tetrahedral elements was laid over the instrument in software to produce a 3D model for entry into FE analysis. The final model for ProTaper consisted of 81385 elements with 20573 nodes, for RevoS 78579 elements with 19690 nodes and for Hyflex CM 104912 elements with 25491 nodes [Table/Fig-4,5&6]. The z-axis was chosen to be normal to the cross section, i.e., along the length of the instrument.

Element Type: 4 noded tetrahedral structure of Protaper file

Element Type: 4 noded tetrahedral structure of RevoS file

Element Type: 4 noded tetrahedral structure of Hyflex file

Mechanical Properties of NiTi

The non-linear mechanical behavior of NiTi material, similar to the one reported by others [16], was taken into account in this study. Briefly, the model stress-strain behavior of NiTi alloy comprises a linear elastic deformation of the parent phase (austenite), a pseudoelastic plateau during which stress-induced phase transformation from austenite to martensite occurs, followed by elastic and then plastic deformation of the martensitic phase. The elastic strains (of both the austenite and martensite) and the transformation strain are mostly reversible, but the plastic strain is not [16,17]. The general mechanical properties entered for the NiTi material in the analysis were Young’s modulus_36 Gigapascals (GPA) and the Poisson’s ratio_0.3. The critical stress at the beginning of the forward phase transformation was taken as 504 Megapascals (MPa) and at the end point of recoverable strain was 755 MPa [17].

Mathematical Simulation of Root Canal

Another 3D-FE model was constructed for a root canal 13 mm long with a curvature of 45-degree angle and 6 mm radius. The model of the canal had an apical foramen of 0.50 mm diameter and about 5% apical taper. The behavior of the 3 brands of NiTi file was analyzed numerically in an FE package (ABAQUS V6.5-1; SIMULIA, Providence, RI) to simulate the bending and torsional conditions during root canal shaping. The file was inserted to the full length of the simulated root canal and the stress distribution on the surface and within the instrument was evaluated.

The virtual rate of rotation was 250 for Protaper and RevoS while 400 for Hyflex CM. The forces generated on the NiTi instruments in apical 3rd of simulated curved canals during shaping were evaluated and residual stresses on the instruments were compared.

Results

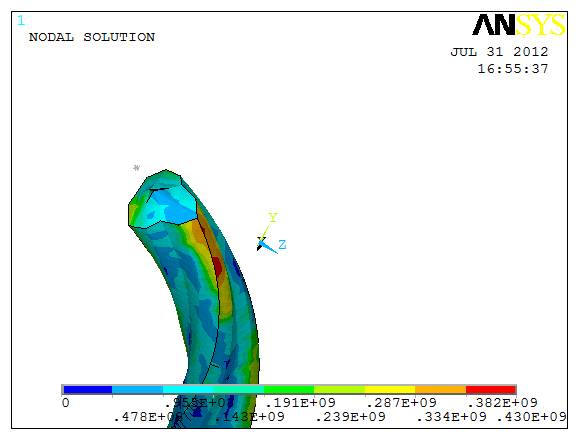

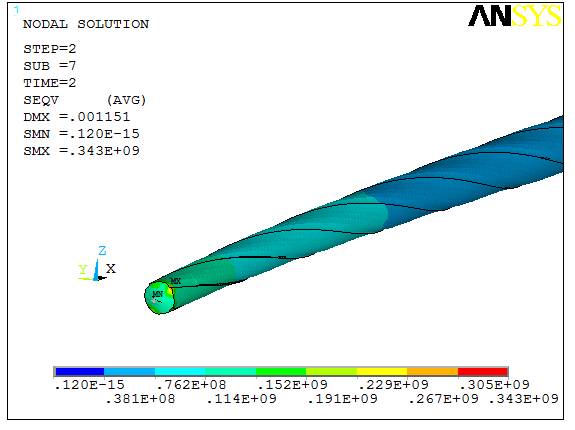

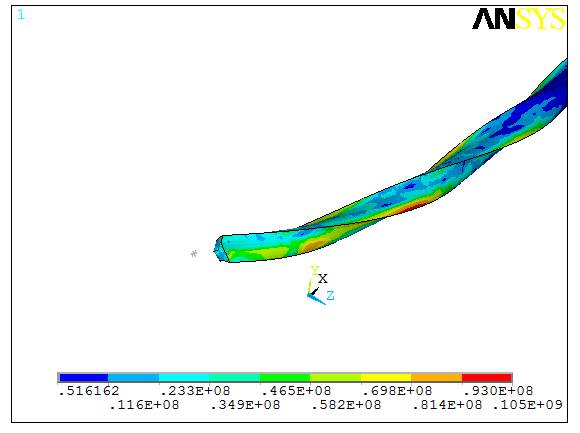

The surface of Pro-Taper instrument showed the highest value of force generated in apical 3rd of root canal, whereas RevoS showed the lowest and Hyflex showed intermediate value. Forces seen on surface of Protaper were 430 Mpa, on RevoS were 105 MPa and on Hyflex file were 343 Mpa [Table/Fig-7,8&9]. During insertion into the canal, all files experienced a force, but to varying degrees, along the direction of its longitudinal axis, pulling it apically as well as a reaction torque from root canal wall. The value of the force become more or less constant (with slight fluctuations) once the full length of the canal was reached.

Distribution of forces on external surface of Protaper file while rotating in simulated canal

Distribution of forces on external surface of RevoS file while rotating in simulated canal

Distribution of forces on external surface of Hyflex file while rotating in simulated canal

After the instrument was withdrawn from the canal and assuming complete recovery of the elastic strains, residual stress could be noticed along the length of all instruments, with the location of such maximum stress corresponding well with that of maximum curve of the canal. Residual stresses seen on Protaper were highest and RevoS shows lowest stresses among them.

Discussion

During the last decade, NiTi rotary instruments have been gaining popularity among general dentists and endodontic specialists. Meanwhile, there is an increasing concern about the instrument fracture during the use, as evidenced by the amount of reports on this problem [10,11]. By examining fracture instruments under electron microscope basically two types of fracture mechanisms were identified: (I) fatigue failure, characterized by numerous patches of linear fatigue-striation marks and (II) torsional failure, characterized by circular abrasion marks on the fracture surface [18,19].

Fractographic examination (at high magnification), in conjunction with longitudinal examination, is necessary to reveal features that might indicate the crack origin and the mode of material failure [18]. However, the distribution of stresses along the instrument and any residual stresses that might contribute to instrument breakage would not be revealed in such post mortem examination of broken fragments. It would equally be impossible to measure the stress on the instrument during actual clinical use. Thus, a mathematical simulation was used here to estimate the stress distribution and residual stresses on the instrument.

In medical and dental research, to analyze the stress of structural objects with complex morphology, strain gauge technique, photoelastic test, and finite element method are commonly used. FEA has been practically and broadly applied to the field of structural- mechanical analysis. In Finite Element (FE) analysis, a large structure is divided into a number of small simple shaped elements, for which individual deformation (strain and stress) can be more easily calculated than for the whole undivided large structure. By solving the deformation of all the small elements simultaneously, the deformation of the structure as a whole can be assessed [20]. Hence, FE analysis was used in this study.

The forces experienced by the files are correlated with the contact areas, that is, the friction between the instrument and the root canal wall and the load required to cut dentin [21]. If the instrument is stalled in the canal, torsional (shear) stress builds up in the instrument, which, when the elastic limit of the material is exceeded, would lead to plastic deformation and, ultimately, to failure by shear. In this analysis, the ProTaper instrument experienced the greatest reaction torque (430 Mpa) from the root canal wall, suggesting the likelihood of extensive phase transformation from austenite to martensite when it is used to prepare the curved root canal. RevoS instrument shows less reaction torque (105 Mpa) while Hyflex instrument shows intermediate values of reaction torque (343 Mpa). Larger taper of Protaper file, i.e., 8% of F2 responsible for excessive forces in apical 3rd of curved canal compare to RevoS and Hyflex files. Similar asymmetric triangular cross section of RevoS files responsible for less contact with canal wall compare to double fluted cross section of Hyflex files responsible for experiencing less stresses on RevoS files compare to Hyflex files [18].

During the manufacture of NiTi instruments, small machining scratches and grooves are invariably left on the surface. These surface scratches can serve as notches that would concentrate the stress, limiting the instrument’s fatigue life. The highly concentrated stresses at the cutting edge of ProTaper instrument might cause these machining defects to “open” and become microcracks. Crack-like features at the cutting edges have been a frequent observation in clinically used Pro- Taper instruments.

Residual stresses seen on Protaper were maximum while on RevoS were least and Hyflex shows intermediate value. The presence of internal residual stresses indicated that a certain amount of cold work has taken place, which could render the material apparently less flexible or more brittle [22]. Repeated load cycles will lead to further distortion of the crystal lattice [23], which might manifest as microscopic defects. It seems important that NiTi engine-files are used within the limits of stress-induced phase transformation to avoid lattice distortion, a condition that should help to enhance the fatigue life of the instrument. Despite all precautions, the NiTi instrument might still be prone to fatigue fracture especially in a corrosive environment such as sodium hypochlorite, which is a routine root canal irrigant during treatment [24].

Breakage of NiTi rotary files, regardless of the manufacturing defects, is probably related to the dentist failing to follow the directions for use and operator-related factors [2]. A number of recommendations for preventing instrument fracture in the clinical situation, which are based on clinical observations and findings in laboratory investigations, have been proposed [25]. One should realize that there is no any instrument system that can be suitable for all clinical situations, and it is important to understand how the structural characteristics could influence the magnitude of stress on the instrument to prevent its fracture in use.

Conclusion

Within the confinment of this study, it can be seen that lot of stress was generated on surface of Protaper files compared to RevoS, which showed the least stress while the Hyflex showed intermediary stress. The same results were seen with residual forces, i.e., Protaper had highest residual stresses, RevoS had least and Hyflex had intermediate stresses. It can be concluded that each instrument design would experience unequal degree of screw-in tendency, as well as reaction torque from the root canal wall. There is a difference in the location for the maximum stress concentration (in cross section) and in the value and distribution of the residual stresses for various instrument designs. Hence the operator needs to analyze cross sectional design and taper of files for their use.

[1]. Ruddle CJ, Cleaning and shaping root canal systems. Cohen S, Burns RC, edsPathways of the pulp 2002 8th edSt LouisCV Mosby:231-91. [Google Scholar]

[2]. Parashos P, Messer HH, Rotary NiTi instrument fracture and its consequencesJ Endod 2006 32:1031-43. [Google Scholar]

[3]. Sattapan B, Palamara JE, Messer HH, Torque during canal instrumentation using rotary nickel-titanium filesJ Endod 2000 26:156-60. [Google Scholar]

[4]. Necchi S, Taschieri S, Petrini L, Migliavacca F, Mechanical behavior of nickel-titanium rotary endodontic instruments in simulated clinical conditions: a computational studyInt Endod J 2008 41:939-949. [Google Scholar]

[5]. Schäfer E, Schulz-Bongert U, Tulus G, Comparison of hand stainless steel and nickel titanium rotary instrumentation: a clinical studyJ Endod 2004 30:432-5. [Google Scholar]

[6]. Garip Y, Gunday M, The use of computed tomography when comparing nickeltitanium and stainless steel files during preparation of simulated curved canalsInt Endod J 2001 34:452-7. [Google Scholar]

[7]. Yared G, Bou Dagher F, Machtou P, Influence of rotational speed, torque and operator’s proficiency of Nitinol root canal filesInt Endod J 2002 35:7-12. [Google Scholar]

[8]. Berutti E, Chiandussi G, Gaviglio I, Comparative analysis of torsional and bending stresses in two mathematical models of nickel-titanium rotary instruments: proTaper versus ProFileJ Endod 2003 29:91-5. [Google Scholar]

[9]. Ullmann CJ, Peters OA, Effect of cyclic fatigue on static fracture loads in ProTaper nickel titanium rotary instrumentsJ Endod 2005 31:183-6. [Google Scholar]

[10]. Ankrum MT, Hartwell GR, Truitt JE, K3 Endo, ProTaper, and ProFile systems: breakage and distortion in severely curved root of molarsJ Endod2004(30):234-7. [Google Scholar]

[11]. Bergmans L, Van Cleynenbreugel J, Beullens M, Wevers M, Van Meerbeek B, Lambrechts P, Progressive versus constant tapered shaft design using NiTi rotary instrumentsInt Endod J 2003 36:288-95. [Google Scholar]

[12]. Peters OA, Peters CI, Schönenberger K, Barbakow F, ProTaper rotary root canal preparation: effects of canal anatomy on final shape analysed by micro CTInt Endod J 2003 36:86-92. [Google Scholar]

[13]. Bettina B, Torsional profiles of new and used revo-s rotary instruments: An in vitro studyJ Endod 2011 37:989-992. [Google Scholar]

[14]. Liu Y, VanHumbeeck J, Stalmans R, Delaey L, Some aspects of the properties of NiTi shape memory alloyJournal of Alloys and Compounds 1997 247:115-21. [Google Scholar]

[15]. Frick CP, Ortega AM, Tyber J, Thermal processing of polycrystalline NiTi shape memory alloysMaterials Science and Engineering 2005 405:34-49. [Google Scholar]

[16]. Xu X, Eng M, Zheng Y, Eng D, Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sectionsJ Endod 2006 32:372-5. [Google Scholar]

[17]. Wang GZ, A finite element analysis of evolution of stress-strain and martensite transformation in front of a notch in shape memory alloy NiTiMaterials Science and Engineering 2007 1:383-91. [Google Scholar]

[18]. Cheung GSP, Peng B, Bian Z, Shen Y, Darvell BW, Defects in ProTaper S1 instruments after clinical use: fractographic examinationInt Endod J 2005 38:802-9. [Google Scholar]

[19]. Wei X, Ling J, Jiang J, Huang X, Liu L, Modes of failure of ProTaper nickel-titanium rotary instruments after clinical useJ Endod 2007 33:276-9. [Google Scholar]

[20]. Srirekha A, Bashetty K, Infinite to finite: An overview of finite element analysisIndian J Dent Res 2010 21:425-32. [Google Scholar]

[21]. Schrader C, Peters OA, Analysis of torque and force with differently tapered rotary endodontic instruments in vitroJ Endod 2005 31:120-3. [Google Scholar]

[22]. Abujudom DN, Thoma PE, Fariabi S, The effect of cold work and heat treatment on the phase transformations of rear equiatomic NiTi shape memory alloyMaterial Science Forum 1990 56-58:565-70. [Google Scholar]

[23]. Kuhn G, Tavernier B, Jordan L, Influence of structure on nickel-titanium endodontic instruments failureJ Endod 2001 27:516-20. [Google Scholar]

[24]. Cheung GSP, Shen Y, Darvell BW, Effect of environment on low-cycle fatigue of a nickel-titanium instrumentJ Endod 2007 33:1433-7. [Google Scholar]

[25]. Di Fiore PM, A dozen ways to prevent nickel-titanium rotary instrument fractureJ Am Dent Assoc 2007 138:196-201. [Google Scholar]