Orthodontic treatment involves the application of forces that are continuous in activity on as many areas of the dentition as possible and working in the direction in which the teeth are to move, with maximum comfort to the patient, is a condition that fulfills the requirements of treatment efficiency [1]. The operator should have a thorough knowledge about the force exerted by the auxiliaries, in order to predict the outcome of the treatment. Through the careful usage of this force delivering auxiliaries, the movement of teeth can be controlled and the desired tooth movement can be achieved.

Therefore, Quantification of force delivered by orthodontic mechanics plays a very important role in the outcome of treatment. The force delivered from auxiliaries is commonly calibrated using Dontrix tension gauge [2] and Corex gauge [3] in clinical situations. These equipments are standardized and highly reliable. However, when large samples have to be analyzed, as in experimental studies, where accurate measurement of the force delivered is of paramount importance, it is mandatory that very sensitive and highly specialized equipments machine be used.

Hence, the need to fabricate a device that would be economical, small in size and also yield accurate results for measuring forces delivered from orthodontic springs. Having this in mind, an apparatus was designed that would measure force as accurately as the universal testing machine and still be available in a clinical setup.

An indigenous apparatus is designed to measure the orthodontic force delivered from elastomeric chains and compare this force with values obtained from the Instron universal testing machine.

Material and Methods

Apparatus Design

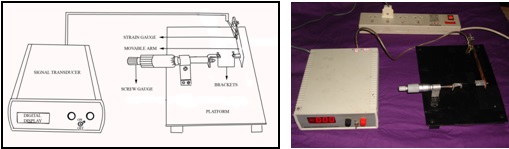

The Indigenous apparatus consists of a rectangular steel platform on which a micrometer and a moving arm fabricated out of 1mm thick mild steel sheet are mounted. Two canine brackets with hooks are attached to the apparatus in such a way that, one is fixed to the movable arm and the other is placed on the end of the screw gauge, which is present opposite to the movable arm. This will ensure that the brackets are in the same central line. Brackets with hook are mounted, instead of simply fixing hooks on the two arms of the apparatus, because it not only facilitates the easy engagement of the nickel titanium closed coil springs and the elastomeric chain, but also, provides slot for the comfortable engagement of the loop springs. On the fixed end of the movable arm, four strain gauges are glued using cyano-acrylate adhesive. An electrical wire circuit connects the strain gauges to the signal conditioner which has a digital display. Force is expressed in grams in the display screen [Table/Fig-2].

Parts of the Indigenous Apparatus

This apparatus is small in size comparatively and is sensitive that it can calibrate force changes for activation distances as low as 0.01mm. This can be explained with reference to the screw gauge. The spring is activated 1mm by two full rotations of the screw gauge. Each rotation covers a circumference of 50mm. Therefore, two rotations will have a circumference of 100mm together. Thus, it shows that for 100mm rotation of the screw gauge, 1mm of activation of the spring is achieved. Then for 1mm rotation the activation will be one in hundredth portion of it, which is 0.01 mm.

A Universal Testing Machine is used to test the tensile and compressive properties of materials and perform tests like compression, bending, tension, etc., to examine the material in all mechanical properties. In the field of dentistry, especially in Orthodontics, it is used in many instances for measuring forces delivered by various force exerting auxiliaries, to calculate friction between different brackets and arch wires, to evaluate bond strength of different resins, etc. The universal testing machine is very sensitive that it can measure force changes as small as 0.001 grams.

This study measured the forces generated from elastomeric chains with two different equipments – an indigenously designed apparatus and a well reputed and standardized Instron testing machine. The elastomeric chain segments with 4 links were mounted on both the equipments and activated. The force values obtained from both the equipments were measured and compared.

Null Hypothesis

There is a significant difference between the force values obtained from the universal testing machine and the indigenous apparatus, in terms of measurement of forces delivered by orthodontic force delivery systems.

Statistical Analysis

The force values obtained from activation of the elastomeric chain segments in the experiment will be tabulated.

The mean and the standard deviation of the force values, at each mm of activation, are calculated and tabulated. In addition, the independent t-test was also performed with p-value predetermined at p< 0.01. The obtained p-values were also included in the [Table/Fig-3].

Mean, SD and Significance of force values of elastomeric chain segments

| Main Group | n | Mean | SD | Significance |

|---|

| 1mm | Universal testing machine | 10 | 131.650 | 11.5850 | 0.556 |

| Indigenous apparatus | 10 | 128.700 | 10.3928 |

| 2mm | Universal testing machine | 10 | 202.200 | 18.5895 | 0.200 |

| Indigenous apparatus | 10 | 192.100 | 15.2129 |

| 3mm | Universal testing machine | 10 | 248.010 | 7.2537 | 0.009 |

| Indigenous apparatus | 10 | 231.600 | 16.3041 |

| 4mm | Universal testing machine | 10 | 301.380 | 13.9084 | 0.233 |

| Indigenous apparatus | 10 | 293.600 | 14.2922 |

| 5mm | Universal testing machine | 10 | 343.350 | 16.0747 | 0.252 |

| Indigenous apparatus | 10 | 334.800 | 16.2056 |

| 6mm | Universal testing machine | 10 | 373.090 | 21.8546 | 0.273 |

| Indigenous apparatus | 10 | 362.500 | 19.9736 |

| 7mm | Universal testing machine | 10 | 393.410 | 24.2512 | 0.899 |

| Indigenous apparatus | 10 | 392.000 | 24.7072 |

| 8mm | Universal testing machine | 10 | 410.990 | 21.3166 | 0.985 |

| Indigenous apparatus | 10 | 410.800 | 24.3621 |

| 9mm | Universal testing machine | 10 | 427.890 | 19.4936 | 0.975 |

| Indigenous apparatus | 10 | 427.600 | 21.0143 |

| 10mm | Universal testing machine | 10 | 450.160 | 45.1655 | 0.516 |

| Indigenous apparatus | 10 | 445.900 | 19.0581 |

Results

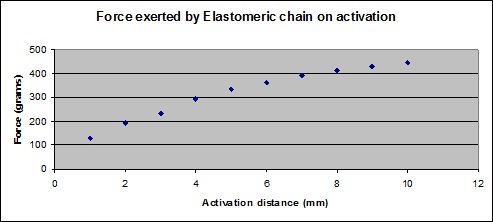

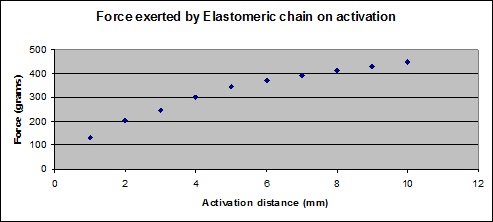

The force values obtained from activation of elastomeric chain segments in the Instron universal testing machine and the indigenous apparatus, were in the range of 100 to 150 grams, initially at 1mm activation, then took a steep rise to 300 to 350 grams at 5mm activation and then, had a gradual increase for the remaining 5mm activation, reaching 400 to 450 grams [Table/Fig-4 and 5].

Scatter diagram showing the distribution of mean force, recorded by the Instron universal testing machine, at each mm of activation for elastomeric chain segments

Scatter diagram showing the distribution of mean force, recorded by the Indigenous apparatus, at each mm of activation for elastomeric chains segments

The force measurements from both machines were in the same range for the same amount of activation of the springs.

The mean and standard deviation of the force values, measured from the Instron universal testing machine and the indigenous apparatus, at each mm of activation of elastomeric chain segments are given in [Table/Fig-3]. The independent t-test was performed with these values and the significance or the p-value was calculated for the springs at each mm of activation.

This disproved the null hypothesis which stated that the force values obtained from the indigenous apparatus are not similar to the force values obtained from the Instron universal testing machine. Therefore it can be said that the force values measured from the indigenous apparatus are as comparable as the force values measured from the Instron universal testing machine.

Discussion

Orthodontic treatment is based on the principle that if prolonged pressure is applied to a tooth, tooth movement will occur as the bone around the tooth remodels.

It is known that optimum orthodontic tooth movement is produced by light, continuous force. It is, particularly, important that the light forces do not decrease rapidly, decaying away either because the material itself loses its elasticity or because a small amount of tooth movement causes a larger change in the amount of force delivered. Both the behavior of elastic materials and mechanical factors in the response of the teeth, must be considered in the design of an orthodontic appliance system through which mechano-therapy is delivered [4].

The elastic behavior of any material is defined in terms of its stress-strain response to an external load. Initially, rubber bands were used in orthodontics to transmit force from the upper arch to the lower. Rubber has the particularly valuable quality of a great elastic range, so that the extreme stretching produced when a patient opens the mouth while wearing rubber bands can be tolerated without destroying the appliance. Rubber bands are also easier for a patient to remove and replace than, for instance, a heavy coil spring would be. Rubber and plastic elastomers are also being used to close spaces within the arches [5].

From a materials point of view, the greatest problem with all types of rubber is that they absorb water and deteriorate under intra oral conditions. Gum rubber, which is used in households and offices, begins to deteriorate in the mouth within a couple of hours, and much of its elasticity is lost in 12 to 24 hours. Although orthodontic elastics once were made from this material, they have been largely superseded by latex elastics, which have a useful performance life which is 4 to 6 times more long. In contemporary orthodontics, only latex rubber elastics should be used [5].

Like rubber, however, these elastomers tend to deteriorate in elastic performance after a relatively short period in the mouth. This feature does not prevent them from performing quite well in holding archwires in place, nor does it contraindicate their use to close small spaces. It simply must be kept in mind that when elastomers are used, the forces decay rapidly, and so can be characterized better as interrupted rather than continuous [6].

Although, larger spaces within the dental arch can be closed by sliding teeth with rubber bands or elastomeric chains, same tooth movement can be done much more efficiently with NiTi closed coil springs that provide a nearly constant force over quite a large range [7–9].

Several retraction mechanisms employing nickel titanium closed coil springs, elastomeric chains and various loop designs have been used to effect optimal tooth movement. These springs have been studied thoroughly for their force-delivering ability. The variation in force magnitude has been assessed in several studies, considering that the alteration in wire cross section and material, loop design and elastic size can affect the force exerted by the force delivering systems. Most of these studies used the universal testing machine to assess the force exerted by these force delivering auxiliaries.

A Universal Testing Machine, otherwise, known as a materials testing machine or test frame is used to test the tensile and compressive properties of materials. It has been widely used for measuring various parameters in different fields. In the field of dentistry, especially in Orthodontics, it is used in many instances, for measuring forces delivered by various force exerting auxiliaries, to calculate friction between different brackets and archwires, to evaluate bond strength of different resins, etc. The universal testing machine is very sensitive that it measures force changes of even 0.001 grams. This machine has been tested extensively and is universally accepted as a standard machine for measuring parameters as mentioned above.

The Instron universal testing machine is a sophisticated instrument and is huge and space occupying and is fit for extensive laboratory set up. The charges for testing the specimens in these institutes are also quite high.

Other instruments commonly employed for measuring force generated from retraction springs, chairside are the Dontrix gauge and Corex gauge. These instruments are small in size, economical and easily portable. The Dontrix gauge measures force in ounce and not in grams [1] (ounce is equal to 28.34 grams). Hence force values measured with Dontrix gauge cannot be very specific. In other words, the Dontrix gauge is less sensitive, but it can be used easily in the clinical chairside situation.

However, for large samples, as in experimental in-vitro studies where accurate measurement of force delivered is of paramount importance, it is mandatory that very sensitive equipments be used. In view of these demands, an apparatus that could measure force, in a simple manner and still remain sensitive is designed.

The indigenous apparatus is small in size, inexpensive and does not need expertise to handle it. The apparatus is also very sensitive that it can measure force changes for even 0.01mm activation of retraction springs. It has brackets with hook arrangement on it that could be used to mount springs, elastics and loop wires very conveniently. By adjusting the screw gauge the auxiliaries are activated and the force values can be simply read from the display on the signal conditioner.

Therefore, to evaluate the accuracy of this indigenous apparatus an experiment was conducted. In the present study, a set of elastomeric chain were tested for their tensile force using the Instron universal testing machine. Similar, set of elastomeric chains were tested in the indigenous apparatus for the same parameter. These two sets of values were then compared to evaluate the indigenous apparatus.

The mean and standard deviation of the force values were measured for the elastomeric chain segments and it was found that the force values measured from the indigenous apparatus are as comparable as the force values measured from the Instron universal testing machine.

Clinical Implications

Therapeutic extraction space closure mechanics, in orthodontics, involves placement of appropriate forces for retraction of teeth. This can be achieved by means of elastomeric chain and several springs e.g., T-loop, PG spring, etc.

These elastomeric chains and springs when activated to give forces beyond physiologic limit, will produce undesired tooth movements and even trauma to teeth. Hence, extreme caution has to be exercised and correct magnitude of force should be applied to prevent unwanted side-effects.

The aim of this study is to design an apparatus that will measure the magnitude of force generated for given activation of a standard elastomeric chain used primarily for therapeutic extraction space closure.

Conclusion

From the force values obtained from the indigenous apparatus on activation of elastomeric chain and comparing these values with that obtained from the Instron universal testing machine, we concluded that the Indigenous apparatus can be considered efficient in measuring tensile force generated in orthodontic force delivery systems.