Retrieval of a Cold Welded and Damaged Gingival Former: A Clinical Tip

Unmesh Wani1, Rajashree Jadhav2, Paresh Gandhi3, Bhushan Pol4

1 Postgraduate Student, Department of Prosthodontics, Bharati Vidyapeeth (Deemed to be University) Dental College and Hospital, Pune, Maharashtra, India.

2 Professor and Postgraduate Guide, Department of Prosthodontics, Bharati Vidyapeeth (Deemed to be University) Dental College and Hospital, Pune, Maharashtra, India.

3 Professor and Postgraduate Guide, Department of Prosthodontics, Bharati Vidyapeeth (Deemed to be University) Dental College and Hospital, Pune, Maharashtra, India.

4 Postgraduate Student, Department of Prosthodontics, Bharati Vidyapeeth (Deemed to be University) Dental College and Hospital, Pune, Maharashtra, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Unmesh Wani, 1103, Block H, Amit Bloomfield, Ambegaon, Pune-411046, Maharashtra, India.

E-mail: unmesh1996wani@gmail.com

Cold weld, Gingival former retrieval, Implants, Prosthesis, Screw driver

A 62-year-old male patient was referred to the Department of Prosthodontics at Bharati Vidyapeeth (Deemed to be University) Dental College and Hospital, Pune, Maharashtra, India, for the retrieval of a gingival former in the lower anterior region. An implant from COWELL® Implant Solution was placed in the regions of 33 and 43 at a private clinic approximately 11 months ago. The second stage surgery was performed seven months ago. Two gingival formers with a collar height of 2 mm were placed in the regions of 33 and 43. For the commencement of the prosthetic phase, the gingival formers needed to be removed.

Initially, a hex driver was used for the retrieval of the gingival former. During the removal process, it was noticed that the threads in the access hole of the gingival former in the region of 33 were irreversibly damaged due to excessive torque applied by the previous dentist, which led to cold welding and failure to engage the hex driver. Various methods, such as reverse torquing and ultrasonic retrieval techniques, were attempted but proved ineffective [1].

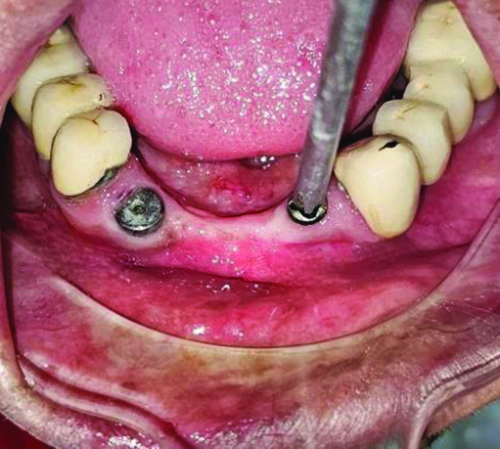

Using a high-speed handpiece and a carbide bur, a plus-shaped groove approximately 2 mm in depth was created from the center by extending the access hole of the former under copious irrigation until the screwdriver fitted snugly [Table/Fig-1] [2]. A high vacuum suction was employed to prevent any particles of the former from being swallowed by the patient. The screwdriver from the Typodont jaw set was autoclaved before use in the patient’s mouth [Table/Fig-2].

Plus-shaped groove made on the gingival former using a carbide bur [2].

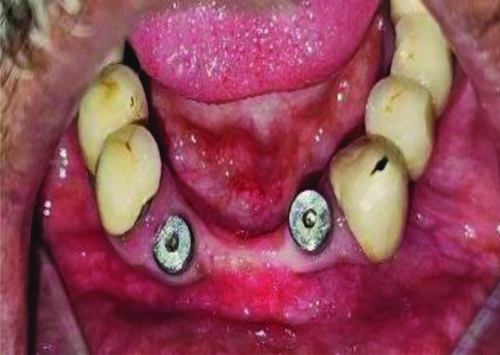

Screw driver used for the retrieval of former.

The gingival former was modified until the beak of the screwdriver fit snugly into the plus-shaped groove [Table/Fig-3]. Utmost care was taken during the grooving process, as excessive removal of the structure could lead to failure in fitting the screwdriver [Table/Fig-4]. The gingival former was modified until the beak of the screwdriver fit snugly into the plus-shaped groove [Table/Fig-3]. Careful attention was given during the grooving process, as excessive removal could result in failure to fit the screwdriver properly.

Snugly fitted screwdriver with modified gingival former.

Retrieved gingival former.

Once the former was retrieved [Table/Fig-4], an implant-level impression was recorded using putty and light body material and a new gingival former was placed [Table/Fig-5]. The final prosthesis was delivered to the patient in accordance with the principles of implant-protected occlusion [Table/Fig-6].

New gingival former placed after making impression.

Discussion

Cold welding is an unusual and rare mechanical complication that can occur following second-stage implant surgery. Cold welding happens when dried blood and bone fragments remain on the surfaces of implant components. Tension builds up in the screw due to excessive tightening and the first load produced by applying torque is known as preload. This results in the elongation of the screw [3]. An excessive clamping force forms between the implant and the gingival former because of this preload. Large amounts of preload have been shown to result in plastic deformation or a permanent alteration of the material, which is frequently referred to as cold welding, ultimately leading to the screw becoming unretrievable.

If the gingival former is autoclaved multiple times, there is a chance of corrosion occurring in the threads of the access hole of the gingival former, which may become damaged during excessive torquing. Corrosion can also be caused by the intraoral environment. An electrochemical cell can form if the prosthetic parts consist of less noble or base metal alloys. An anode forms from the base metal alloy, while a cathode is created from a higher noble material, such as an implant alloy with a high titanium content, leading to corrosion [4].

Arshad M et al., demonstrated a technique to retrieve a cold-welded abutment using an impression coping and crown removal; however, this method may exert torsional forces on the implant [5]. The merits of this technique include its ease of use, affordability and applicability with any implant system that has been damaged due to the cold welding phenomenon occurring between the gingival former and the abutment.

To prevent cold welding, excessive torquing of the gingival former should be avoided. Ideally, the prosthetic components should be changed after a few patients. This technique should be performed under high vacuum suction or a rubber dam to prevent debris from the gingival former from being swallowed. This technique is easy to use and can be performed on all types of implants.

Author Declaration:

Financial or Other Competing Interests: None

Was informed consent obtained from the subjects involved in the study? Yes

For any images presented appropriate consent has been obtained from the subjects. Yes

Plagiarism Checking Methods: [Jain H et al.]

Plagiarism X-checker: Jul 16, 2024

Manual Googling: Oct 31, 2024

iThenticate Software: Nov 02, 2024 (3%)

[1]. Vaidya S, Gupta S, Kapoor C, Cold-welded healing cap: A unique implant complication and its managementInt J Clin Implant Dent 2015 1(2):72-76.10.5005/jp-journals-10004-1037 [Google Scholar] [CrossRef]

[2]. Thomas M, Joshi A, Bhat PR, Mushannavar LS, A novel technique to retrieve a cold welded gingival former-A technical noteInternational Dental Journal of Students’ Research 2022 10(4):130-33.10.18231/j.idjsr.2022.030 [Google Scholar] [CrossRef]

[3]. Jörnéus L, Jemt T, Carlsson L, Loads and designs of screw joints for single crowns supported by osseointegrated implantsThe International Journal of Oral & Maxillofacial Implants 1992 7(3):353-59. [Google Scholar]

[4]. Branemark PI, Osseointegrated implants in the treatment of the edentulous jaw: Experience from a 10-year periodScad J Plast Reconstr Surg 1977 16:01-32. [Google Scholar]

[5]. Arshad M, Mahgoli HA, Rasouli K, Refoua S, A novel technique to retrieve cold-welded implant abutment: A case seriesClinical Case Reports 2019 7(10):1854-57.10.1002/ccr3.237531624597PMC6787859 [Google Scholar] [CrossRef] [PubMed]