Dental composites are defined as polymeric materials which are highly cross-linked, reinforced by a dispersion of glass, crystalline or resin filler particles and/or short fibers attached to the matrix by silane coupling agent [1]. Studies have shown that the clinical performance of resin composites depends on the type of matrix, filler loading, placement technique, type of LCU, duration, distance etc. Two types of filler particles exist as microfil and macrofil while combinations of these two are termed “hybrids” [2]. Micro-hybrid-composites have the mean particle size of 0.7-2.0 μm. Nanohybird composite resin is made up of micro-sized (diameter of 0.3-1 μm) and nano-sized (diameter 0.02-0.05 μm) fillers [3]. Microhybrids most closely simulate the dentin of natural structure of tooth. Microhybrids are fit to support the microfill enamel layer on account of greater opacity and higher strength. These composites are less polishable, tougher to marginate and wear sooner than microfill resins. Nanohybrid composites were recently introduced in order to provide a material which had high initial polishing and superior polish and gloss retention. Nanohybrids use the method of uniting nanomeric and conventional fillers [4].

Surface hardness is a significant property of the dental restorative materials and it indicates degree of polymerisation in composite resins. Surface hardness is pertinent in view of the clinical technique of incremental packing and curing. When the light passes through resin composite, there is a significant reduction in its intensity on account of absorption of light as well as scattering by the restorative material. This results in attenuation of the curing potential of light. This is found to be consistent with the gradual and significant reduction in hardness observed for depths more than 3 to 5 mm [5,6]. Although the literature has revealed varying results in the depth of cure of composite resins, the clinician has no means of monitoring the cure of resin composite not directly exposed to curing in clinical conditions [7,8].

For optimal polymerisation of light cured composites, different curing systems have been developed. QTH LCU are the most commonly used light-activation units in dentistry. The demerits of using QTH LCU for polymerisation of resin composite include: a) limited effective lifetime i.e., 40- 100 hours approximately; b) degradation of reflector and filter with time; and c) large quantity of heat generated [9]. To rectify the demerits of QTH curing light units, blue LEDs came into picture for the purpose of polymerising light-activated resin composite. The LED curing units have a bandwidth of approximately 20 nm and extremely narrow spectral ranges (around 470 nm) [9]. The LED LCUs make use of lower light intensity as compared to traditional LCUs. Yet, they can cure resin materials owing to light emission in particular wavelength for activating camphorquinone (450-480 nm) [10,11]. More recently, increased filler loading and small particle size composite resin along with the use of high intensity LCU have been advocated to achieve adequate strength and wear resistance, a feature that has been designed in this study period. Also in the present study, a 2 mm depth was maintained in all the specimens to mimic ideal cavity depth in clinical situations [12,13].

This study was based on hypothesis that there is no significant difference in the surface hardness of composite resins cured by LCU. Therefore, the present invitro study was undertaken to evaluate and compare the surface hardness of two composite resins (Nanohybrid & Microhybrid) polymerised by two different curing units (QTH & LED LCU.

Materials and Methods

This invitro experimental study was carried out in the Department of Conservative Dentistry and Endodontics, Bharati Vidyapeeth Deemed to be University, Dental College and Hospital, Sangli and Department of Mechanical Engineering, MTE’s Walchand College of Engineering, Sangli, Maharashtra, India. The duration of study was about 10 months- February to November in the calendar year 2019, approved by the institutional Ethical Committee on December 7th 2017 (Letter number -BVDUMC&H/IEC/ Dissertation 2017-18/249).

Sample Size Estimation

Sample size was calculated based on the data from using the formula

{2 (Zα +Zβ)2 σ2}/δ2where, Zα 1.96 (as Type I error α 5%), Zβ 0.842 (as Power 80%), Standard deviation (σ) 1.7 and Difference in means (δ) 1.22. The calculated sample size was 30.4, rounded off to 30.

A customised split Teflon mould measuring 6 mm in diameter and 2 mm in height was placed on a transparent Mylar strip over a glass slide. The dimensions was measured using digital Vernier caliper (Precision Measuring, 150 mm, 6”) and this specified dimension ensured uniform and maximum polymerisation keeping in view of the diameter of LCU. The Teflon mould was approximated using a jig (cylindrical rubber). Nanohybrid composite resin (FiltekTM Z250 XT, 3M ESPE, Saint Paul, MN, USA) and Microhybrid composite resin (Charisma classic, Heraus Kulzer, Hanau, Germany) materials were placed into the Teflon mould in a bulk increment to obtain resin mould of 2 mm in height. Mylar strip (Samit products, New Delhi) was placed to cover the top of the mould. A cover slip was placed on this Mylar strip and gently pressed to extrude excess material [14]. A total of 60 Split Teflon moulds were prepared and divided into two main groups A and B (n=30 each).

Group A: Cured with LED system (Ivoclar Vivadent, Bluephase N) light intensity of 385-515 mW/cm2.

Group B: Cured with QTH system (Bonart, Unicorn) 300 and 500 mW/cm2. Both the groups were again divided into two sub-groups i.e., A1, A2 and B1, B2 (n=15 each) [Table/Fig-1].

| Light curing unit | Type of composite |

|---|

| Nanohybrid (1) | Microhybrid (2) |

|---|

| LED (A) | A1 | A2 |

| QTH (B) | B1 | B2 |

A1 and B1 were filled with Nanohybrid composite (FiltekTM Z250 XT, 3M ESPE, Saint Paul, MN, USA). This composite resin consists of surface modified zirconia (ZrO2) or silica (SiO2) with median particle size of 3μ or less, as well as non-agglomerated or non-aggregated 20 nm surface modified silica particles. The filler loading is about 82% by wet and 68% by volume; as per 3 M instruction manual.

A2 and B2 were filled with Microhybrid composite (mean particle size 0.7-2.0 μm) (Charisma classic Heraus Kulzer, Hanau Germany). This composite resin is a micro glass II filler technology, consisting of Barium Aluminium Fluoride as filler with improved colour adaptation. The filler loading is 61% by volume; as per Kulzer instruction manual [Table/Fig-2].

Manufacturer instructions for composites.

| Material | Manufacturer instructions |

|---|

| Nanohybrid composite (Filtek Z250 XT) | Lot number- NA43880Visible light-activated - store in dark place Composition-Surface-modified silica/ zirconia with a median approximate particle size-3 microns or less Silica particles-Non-agglomerated/non-aggregated 20 nanometer surface-modified The filler loading is 82% by weight (68% by volume)Used for anterior and posterior restorationsGood handling properties -viscosity, stickiness, flow and ability to hold shape(Filtek™ Z350 XT Universal Restorative Technical Product Profile, 3M ESPE) |

| Microhybrid composite (Charisma classic) | Lot number - K010724Visible light-activated - store in dark place Composition- 61% filler by volume with Barium Aluminium Fluoride (Ba3Al2F12) glass.Microglass II filler technology-improved colour adaption Used for anterior and posterior restorations |

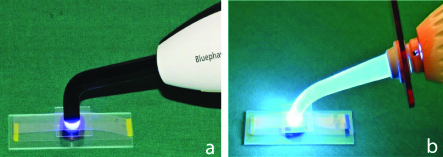

The specimens were then cured from top through the glass cover slip and Mylar strip. Sub-groups A1 and A2 were cured with LED LCU and sub-groups B1 and B2 were cured with QTH light curing system [Table/Fig-3]. The light curing systems were used in standard mode for polymerisation of resin based composite. A Cure Rite digital radiometer (Caulk Dentsply EFOS, USA 2001) was used to measure the intensity of the curing light. Three different readings were taken for both LCUs at 15 minutes interval and mean was calculated. The light intensity for LED LCU and QTH was 510 mW/cm2 and 450 mW/cm2, respectively.

a) Curing with LED LCU; b) Curing with QTH LCU.

For LED LCU, uninterrupted curing time has to be less than 20 seconds, since this is the maximum time duration tolerated in vivo (Bluephase manual instructions). However, an exposure for 20 seconds even with high intensity LEDs can lead to composite restorations with inferior curing depth and increased monomer leaching. It is therefore recommended to use two cycles of 20 seconds so as to ensure adequate curing and minimise the risk of monomer leaching. Similarly, with the QTH LCU, two cycles of 20 seconds were used for nanohybrid composites to keep parity with LED. But for microhybrid composite curing time of 20 seconds was used for both LED LCU and QTH LCU, as advised by manufacturer of Charisma classic, Heraus Kulzer, Hanau, Germany [Table/Fig-3a,b] [15,16].

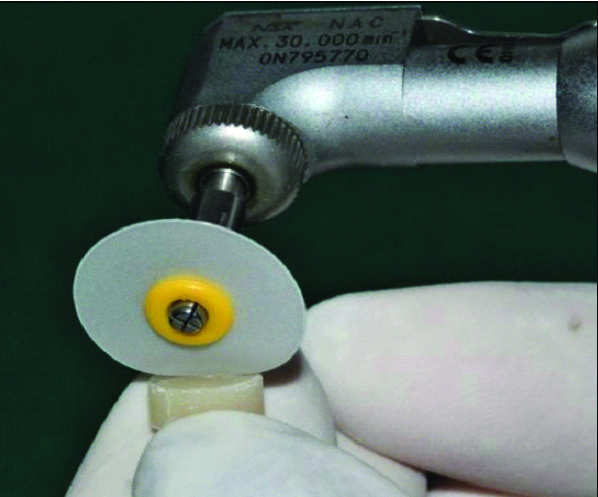

Immediately after light curing, the cover slip was removed from the mould and the top and bottom surface of each specimen were polished [Table/Fig-4] with Soflex disc (Composed of Abrasive Material- Aluminum Oxide, Ceramic, Precision Shaped Ceramic, Silicon Carbide) (3M Oral Care 2510 Conway Avenue St. Paul, MN 55144-1000 USA). The lower surface was marked with pen and removed from the mould. Maximum hardness was achieved in all composites after 24 hours. In this study, the samples were kept for storage after curing in dark light-proof container to prevent subsequent curing due to light exposure after the stipulated curing cycle. The container was placed in distilled water at 37°C for 24 hours in incubator [14]. This gave four sets of light cured resin composite samples.

Polishing of the samples with sof-Lex disc.

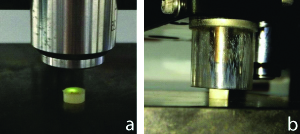

Surface Hardness Measurement: Vickers Hardness Test

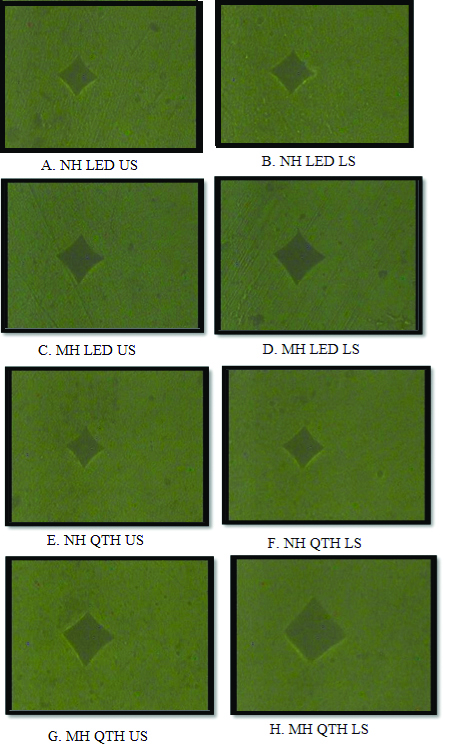

Specimens were subjected to Vickers Microhardness (VMH) testing and were fixed in a holder with the test (upper) surface perpendicular to the diamond indenter tip of a VMH tester (Omni Tech, Model-S.Auto, Pune). Force applied by teeth in healthy conditions during movement in horizontal plane is 500 gram. Hence, surface microhardness was determined by the application of a 500 gram force loaded for 15 seconds [Table/Fig-5a,b] [17]. The same machine was used to view and measure the indentation at 10X objective lens magnification. Utilising the built-in scale and the manufacturer’s conversion table, Vickers values were obtained in micrometer. Three measurements were taken on each surface. Mean values for three indentations were calculated for all tested samples. Similar process was repeated for lower surface [Table/Fig-6a-h] [14]. Images were obtained using image analyser tool, Quantimet, which was interfaced with the machine (Omni Tech, Model-S. Auto Pune).

a) Focusing the area for indentation; b) Diamond indenter applying load of 500 gm on sample.

Measurement of surface indentation under 10X magnification.

Statistical Analysis

Mean and Standard deviation for surface hardness was calculated using descriptive statistics. The data was analysed with help of Statistical Package for the Social Sciences (SPSS) software version 20. Level of significance was kept at 5%. Independent t-test was used to analyse the intergroup comparison between nanohybrid and microhybrid composites for upper and lower surfaces as well as the intergroup comparison between LED LCU and QTH LCU for nanohybrid and microhybrid composites.

Results

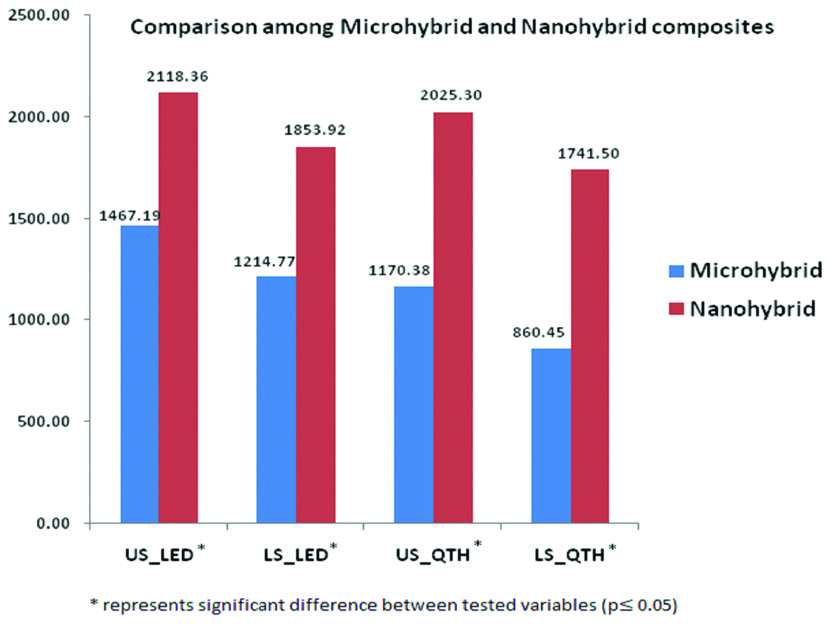

When curing was done by LED LCU, the surface hardness for microhybrid composite was 1467.19 μm and the surface hardness for nanohybrid composite was 2118.36 μm for upper surface. The difference between these two was found to be 651.17 μm (t-value=-18.095). For the same sample, the surface hardness for micro-hybrid composite was 1214.77 μm and the surface hardness for nanohybrid composite was 1853.92 μm for lower surface. The difference between these two was found to be 639.16 μm (t-value=-14.866). The difference was statistically significant (p-value-0.001) [Table/Fig-7,8].

Comparison between Microhybrid and Nanohybrid composites.

| Groups | Composites | N | Mean (μm) | Std. deviation | Mean difference | t-value | p-value |

|---|

| US_LED | Microhybrid | 15 | 1467.194689 | 71.8507363 | -651.17 | -18.095 | 0.001* |

| Nanohybrid | 15 | 2118.360133 | 119.4255175 |

| LS_LED | Microhybrid | 15 | 1214.767160 | 143.9245735 | -639.16 | -14.866 | 0.001* |

| Nanohybrid | 15 | 1853.921556 | 83.7467172 |

| US_QTH | Microhybrid | 15 | 1170.381422 | 87.0542221 | -854.91 | -31.588 | 0.001* |

| Nanohybrid | 15 | 2025.295156 | 58.3862473 |

| LS_QTH | Microhybrid | 15 | 860.449036 | 53.1881083 | -881.05 | -35.305 | 0.001* |

| Nanohybrid | 15 | 1741.500622 | 80.7013809 |

Independent t-test; *indicates significant difference at p≤0.05; N; Sample size; US: Upper surface; LS: Lower surface; LED: Light emitting diode; QTH: Quartz tungsten halogen

Comparison between Micro-hybrid and Nano-hybrid Composites.

When curing was done by QTH LCU, the surface hardness for microhybrid composite was 1170.38 μm and the surface hardness for nanohybrid composite was 2025.30 μm for upper surface. The difference between these two was found to be 854.91 μm for upper surface (t-value=-31.588). For the same sample, the surface hardness for microhybrid composite was 860.45 μm and the surface hardness for nanohybrid composite was 1741.50 μm for lower surface. The difference between these two was found to be 881.05 μm (t-value=-35.305). The difference was statistically significant (p-value -0.001) [Table/Fig-7,8].

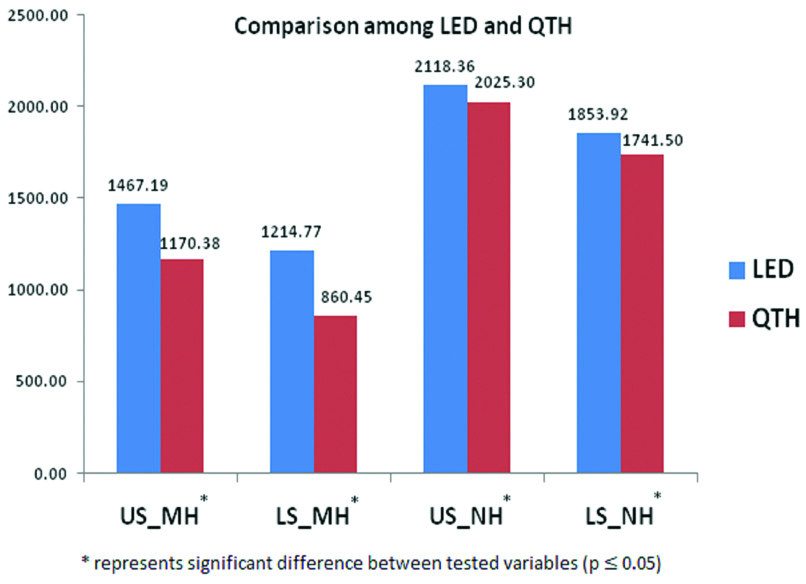

For upper surface of microhybrid composite, the surface hardness using LED LCU was found to be 1467.19 μm whereas the surface hardness using QTH LCU was found to be 1170.38 μm. The difference between these two was observed to be 296.81 μm (t-value=10.184). For lower surface of microhybrid composite, the surface hardness using LED LCU was found to be 1214.77 μm whereas the surface hardness using QTH LCU was found to be 860.45 μm. The difference between these two was observed to be 354.31 μm (t-value=8.943). The difference was statistically significant (p-value - 0.001) [Table/Fig-9,10].

Comparison between LED and QTH LCU.

| Groups | N | Mean (μm) | Std. deviation | Mean difference | t-value | p-value |

|---|

| US_MH | LED | 15 | 1467.194689 | 71.8507363 | 296.81 | 10.184 | 0.001* |

| QTH | 15 | 1170.381422 | 87.0542221 |

| LS_MH | LED | 15 | 1214.767160 | 143.9245735 | 354.31 | 8.943 | 0.001* |

| QTH | 15 | 860.449036 | 53.1881083 |

| US_NH | LED | 15 | 2118.360133 | 119.4255175 | 93.06 | 2.711 | 0.013* |

| QTH | 15 | 2025.295156 | 58.3862473 |

| LS_NH | LED | 15 | 1853.921556 | 83.7467172 | 112.42 | 3.744 | 0.001* |

| QTH | 15 | 1741.500622 | 80.7013809 |

Independent t-test; *indicates significant difference at p≤0.05; N: Sample size; US: Upper surface; LS: Lower surface; LED: Light emitting diode; QTH: Quartz tungsten halogen; MH: Microhybrid; NH: Nanohybrid

Comparison between LED and QTH.

For upper surface of nanohybrid composite, the surface hardness using LED LCU was found to be 2118.36 μm whereas the surface hardness using QTH LCU was found to be 2025.30 μm. The difference between these two was observed to be 93.06 μm (t-value=2.711). For lower surface of nanohybrid composite, the surface hardness using LED LCU was found to be 1853.92 μm whereas the surface hardness using QTH LCU was found to be 1741.50 μm. The difference between these two was observed to be 112.42 μm (t-value=3.744). The difference was statistically significant (p-value -0.001) [Table/Fig-9,10].

Hence, it can be inferred that the LED LCU for nanohybrid composite showed greater surface hardness on both upper and lower surfaces as compared to microhybrid composite. The QTH LCU for nanohybrid composite showed greater surface hardness on both upper and lower surfaces as compared to microhybrid composite.

Discussion

The clinical performance of composite resins depends on the degree of monomer conversion after photopolymerisation. There are multiple parameters that influence the degree of polymerisation of composite resins viz., composition, shade, translucency, characteristics of the LCU used, positioning of light-curing tip and restoration surface, time duration of light induced polymerisation and temperature of composite [18]. These parameters and their influence have been studied by various authors [Table/Fig-11] [5,9,18-20].

Summary of other similar studies [5,9,18-20].

| Sr no. | Authors | Composite | Light curing systems | Conclusion |

|---|

| 1. | Ceballos L et al., (2009) [5] | Filtek Z 250 and Spectrum TPH (both are Hybrid composites) | QTH and LED LCU 20/40 seconds | Filtek Z 250 exhibited higher Vickers microhardness values than spectrum TPH with both QTH and LED LCU |

| 2. | Tanthanuch S and Kukiattrakoon B (2019) [9] | Premise (Kerr, USA) | QTH and LED LCU | LED groups have significantly more hardness ratio values than QTH groups. |

| 3. | Dionysopoulos D et al., (2015) [18] | Filtek Z 250 (3MESPE) and Grandio (VOCO Germany) (both pre-heated before use) | QTH LCU for three different time 10, 20, 40 seconds | Temperature of composites affects their surface microhardness. Also, light curing time influence microhardness value |

| 4. | Segal P et al., (2015) [19] | Filtek Ultimate Universal (3M, St. Paul, MN, USA). Empress Direct (Ivoclar Vivadent, Schaan, Liechtenstein) | QTH and LED LCU | Correlation exists between the light intensity and hardness of the top and bottom of composite resin. LED LCU has a higher light intensity. Degree of hardness varies with composition of material |

| 5. | Shafadilla VA et al., (2017) [20] | Nanofill composite | LED LCU | Decreased distance from the tip of the LED LCU and increased curing time increases surface hardness of composites |

| 6. | Current Study | Nanohybrid: Filtek Z 250 XT, 3M ESPE (St. Paul, MN, USA) Microhybrid: Charisma Classic (Heraus Kulzer, Hanau Germany) | QTH and LED LCU | Nanohybrid composite resins and LED system were found to be more effective in terms of surface hardness as compared to their counterparts. |

The present study evaluated and compared the surface hardness of two types of newer generations of composite resin used in aesthetic dentistry. Also, the present study compared surface hardness at both the upper and lower surfaces cured by two most commonly used LCUs in clinical practice. Secondly, the intensity was also measured for both the LCUs to enable optimum wavelength to achieve effective curing. Higher force load was employed in the present study as compared to other studies to assess surface hardness. As forces of mastication vary in individuals, the results obtained from this study can also be an indication to be used in specific clinical cases, especially in patients with higher masticatory load.

Measuring the surface hardness of composite resins can be a good indicator to indirectly assess the degree of photopolymerisation. As per ISO 4049:2000 [18], composite resins have to satisfy the minimum requirement of 80% microhardness at 2 mm depth for achieving the acceptable degree of polymerisation [18]. Polymerisation process for resin composites is dependent on the light-curing distance. There is an inverse relationship between the light-curing distance and the microhardness on top and bottom of the resin composite. With an increase in the light-curing distance, the hardness decreases, so the standard distance of 1 mm is maintained in the study with the help of glass cover slip [19]. For all LCUs in the present study, microhardness values were higher at the top surface, which can be attributed to the relationship between irradiation distance and effectiveness of polymerisation. The hardness values of the bottom surface should be close to that of the top surface, resulting in a hardness ratio more than 0.8. In the present study, effective hardness ratio (>0.8) was obtained with both the LCU groups, which is in conformity with the previous studies [9,21].

A possible reason for higher microhardness values for the upper surface could be related to the light intensities and the duration of curing time used. Camphorquinone in the resin composite material gets excited when subjected to increased light energy intensity for lengthier time duration. The results of the present study revealed that an increase in the duration of irradiation time resulted in significantly more polymerisation than lesser irradiation time for the same thickness, corroborating with the results of previous studies [9,21].

In the present study, it was observed that when curing was done by LED LCU, the surface hardness was more in case of nanohybrid composite as compared to microhybrid composite in both upper and lower surfaces. Also, when curing was done by QTH LCU, the surface hardness was more in case of nanohybrid composite as compared to microhybrid composite in both upper and lower surface. This is because of more compact spatial and molecular arrangement in nanohybrids and fused nanocluster agglomerates resulting in porous structure agglomerated with silane [22,23]. As light is passed through the bulk of a resin composite, its intensity decreases due to the absorption and scattering of light by filler particles and the resin matrix. This reduction in intensity results in a gradation of cure in a way that it reduces from the top surface towards the bottom. This leads to the variation between top surface hardness and bottom surface hardness of all the specimens cured with each light source [9]. As per studies, it has been demonstrated that the light attenuation may reduce irradiance to three-fourth of that reaching the top surface at a depth of 2 mm [18]. This explains the difference in hardness values for upper and lower surface.

Further, it is observed that the surface hardness values are more in case of nanohybrid composite as compared to the micro-hybrid composite. This can be attributed to the fact that in nanohybrid composites, the spatial and molecular arrangement of fillers is more compact. This leads to improved curing and better polymerisation resulting in increased surface hardness of nanohybrid composite resin [4].

The present study also found that for microhybrid composites, the surface hardness was more for LED LCU used as compared to QTH LCU in both upper and lower surface. Similarly, for nanohybrid composite, the surface hardness was found more when LED LCU was used as compared to QTH LCU in both upper and lower surfaces. These results are in accordance with the study by Bala O et al., [14]. However, the results of this study are in contrast to the study by Dunn WJ and Bush AC, who found QTH LCU produced significantly harder top and bottom surfaces than LED LCU [24].

Thus based on the present study it can be observed that the surface hardness and therefore the polymerisation activity was more in case of LED light curing system. The resin composite that is used in this study has camphorquinone as the photoinitiator. This photoinitiator is seen to be best activated at a wavelength range of 450-500 nm. Of the light emitted by a blue LED unit, 78% to 95% is within this wavelength range, in contrast to 56% for a QTH unit. This explains the superiority of LED curing unit in the present study [25].

Limitation(s)

The specimens made for invitro studies are relatively flat, uniform, translucent and untextured as compared to intraoral restorations impacting the results considerably. Secondly, the presence of factors like saliva, transmission of light through enamel, isolation, depth of cavity etc., influence the light curing process, which are not accounted in this invitro study.

Conclusion(s)

Nanohybrid composite resins exhibited greater surface hardness as compared to microhybrid composite resin at both the surfaces irrespective of the curing units used. The samples cured by LED LCU revealed higher surface hardness than those cured by QTH LCU. Upper surface always revealed improved surface hardness than lower surface irrespective of the composite resin used and the curing light employed. Although companies recommend protocol to use the materials/equipments, the dentists need to evaluate and optimise different composite materials, placement techniques and the curing units depending on clinical situations.

The future invitro studies evaluating surface hardness should simulate oral conditions to precisely determine the surface hardness of composite resins cured by LCUs. Other prospective studies must include role of curing techniques as well as interaction of novel light sources with composite resins and their influence on surface hardness.

Independent t-test; *indicates significant difference at p≤0.05; N; Sample size; US: Upper surface; LS: Lower surface; LED: Light emitting diode; QTH: Quartz tungsten halogen

Independent t-test; *indicates significant difference at p≤0.05; N: Sample size; US: Upper surface; LS: Lower surface; LED: Light emitting diode; QTH: Quartz tungsten halogen; MH: Microhybrid; NH: Nanohybrid