Effect of Application Time of Two Different Disinfectants on the Surface Roughness of an Elastomeric Impression Material

Tahir Karaman1, Faruk Oztekin2, Samet Tekin3

1 Assistant Professor, Department of Prosthodontics, Firat University, Elazig, Turkey.

2 Assistant Professor, Department of Endodontics, Firat University, Elazig, Turkey.

3 Assistant Professor, Department of Prosthodontics, Firat University, Elazig, Turkey.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Tahir Karaman, Assistant Professor, Department of Prosthodontics, Fırat University, Elazig, Turkey.

E-mail: tkaraman@firat.edu.tr

Introduction

Pathogens, such as cytomegalovirus, hepatitis B virus, hepatitis C virus, herpes simplex virus types 1 and 2, and human immunodeficiency virus are transmitted, threatening the health of dental laboratory workers, especially as a result of saliva and blood contact of patients. To prevent cross-infection, impression materials should be disinfected at the end of the impression process in the mouth.

Aim

To study the effect of application time of sodium hypochlorite and quaternary ammonium-based disinfectant solution on the surface roughness of an elastomeric impression material.

Materials and Methods

In this in-vitro study done during March 2020, 10 disc-shaped samples were used in each group, with a total of 110 samples obtained from a light body elastomeric impression material with dimensions of 15×3 mm. The samples were kept in a sodium hypochlorite solution (Wizard; Rehber Kimya, Istanbul, Turkey) at concentrations of 1% and 5% for 1, 5, 10, and 30 minutes and in a quaternary ammonium-based disinfectant (Zeta 7 Solution, Zhermack SpA, Italy) for 10 and 30 minutes. Surface roughness measurements were taken with a profilometer device. The data obtained were statistically analysed by Kolmogorov-Smirnov test and Wilcoxon signed rank test for dependent/paired groups for the continuous data. The significance level was set to α=0.05.

Results

A statistically significant difference was found between the control group and the 1% sodium hypochlorite (30 min p-value 0.037), and 5% sodium hypochlorite (30 min p-value 0.017). The statistical evaluation of the surface roughness of the samples with different concentrations of sodium hypochlorite and the same times was done and found statistically significant at 30 mins, p-value 0.021.

Conclusion

The prolonged application of the sodium hypochlorite disinfectant at 1% and 5% concentrations caused a significant increase in the light body elastomeric impression material’s surface roughness.

Ammonium-based disinfectant, Chemical disinfection, Cross-infection, Disinfection times, Sodium hypochlorite

Introduction

Dental impression, which is necessary in the laboratory construction stages of restorations, can play a role in the transmission of infectious diseases between patients and dental staff. Pathogens, such as cytomegalovirus, hepatitis B virus, hepatitis C virus, herpes simplex virus types 1 and 2, and human immunodeficiency virus are transmitted, threatening the health of dental laboratory workers, especially as a result of saliva and blood contact of patients [1,2]. Impressions need to be disinfected to prevent the risk of cross-infection among the patient, the staff assistant and the dental laboratory workers [2-4]. Before the disinfection process, the impressions should be rinsed under tap water to remove saliva, blood and other residues [5]. The impression disinfectant materials were applied at different concentrations and application times and their effects on the dimensional stability of impressions were evaluated [6-9].

Different substances, such as glutaraldehyde, formaldehyde, alcohol, iodine solution, synthetic phenol, sodium hypochlorite and other chlorine-releasing solutions are used for the chemical disinfection of materials used in dentistry [6]. Changes can be observed in the surface chemistry and dimensional stability of the impression materials depending on the disinfectant materials used [7,8]. Two different chemical disinfection applications, such as spray disinfection and immersion disinfection are carried out on impression materials. The immersion method has been considered to be more effective and reliable [10].

To achieve successful restorations in dental practice, teeth and the surrounding tissue must be clearly recorded and transferred to the model [4,11,12]. Silicone-based impression materials are used to measure the size of fixed dentures. Polyvinyl siloxane (silicone) elastomeric impression materials have excellent dimensional stability. It’s mechanical physical, and biological properties are superior [4]. After taking the impression, the plaster model can be cast even for a long time and then the model can be obtained. To not negatively affect the dimensional accuracy and the accuracy of the models obtained, infection control procedures should be applied successfully and should not damage the dimensional stability of the measure [13].

Depending on clinical or laboratory workload, the impression can be kept in a disinfectant solution at different times and the application times can be extended [14]. For this reason, in the present study study, it was investigated whether the exposure of light body elastomeric impression materials to two different concentrations, sodium hypochlorite and a quaternary ammonium-based disinfectant solution, for two different application times affects surface roughness.

Materials and Methods

This in-vitro study was performed at the Fırat University Faculty of Dentistry, Department of Prosthetic Dentistry, application and research center laboratory (study period March 2020). When a power analysis using the NCSS PASS 2015 (NCSS, Kaysville, Utah, USA) program at 80% power and a 0.05 significance level for this study’s variables was performed, it was calculated that each group should have at least 9 samples, though 10 is optimal. Also, since this was an in-vitro research and material study, an application to the ethics committee was not filed.

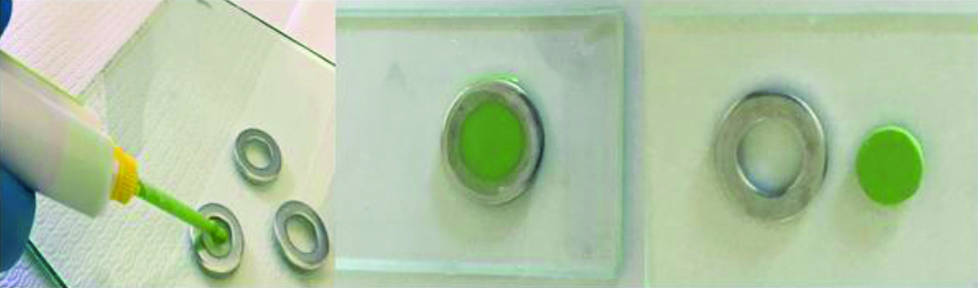

A light-body elastomeric impression material (Elite HD+light body, Zhermack SpA, Badia Polesine, Italy) was used as the impression material in this in-vitro study to investigate the effects of the materials used for disinfection on the surface roughness of the impression material. A light-body elastomeric impression material was applied to the prepared metal ring using a cartridge system. During the impression process, the exposed material of the metal ring surface was placed in the mold cavity in contact with the shiny glass surface and kept for the polymerisation time as specified by the manufacturer [Table/Fig-1]. A total of 110 disc-shaped, 15×3 mm samples were obtained. Samples with macroscopic porosity or deformities were excluded from the study and then reimpressioned. The samples were rinsed for 10 seconds under cold tap water and divided into 11 groups.

The process of obtaining samples from the elastomeric impression material.

The following groups were formed: not disinfected (control group), 1% sodium hypochlorite, 5% sodium hypochlorite (Wizard; Rehber Kimya, Istanbul, Turkey) and quaternary ammonium-based disinfectants (Zeta 7 Solution, Zhermack SpA, Italy). Disinfection was conducted at room temperature. The sodium hypochlorite groups underwent the immersion method for 1, 5, 10 and 30 minutes [6,9,15] and the quaternary ammonium-based disinfectant group underwent holding times of 10 and 30 minutes [16-18]. At the end of the waiting periods, the samples were rinsed under cold tap water for 10 s to remove the disinfection solutions and then air dried to remove excess moisture.

The surface roughness of the samples was measured using the Mitutoyo surface test SJ-410 (Mitutoyo Corp, Japan), which had a probe speed of 0.5 mm/s and measurement length of 2.5 mm/s [19,20]. The device was calibrated according to the manufacturer’s instructions before measurement. The measurements were performed three times on each sample surface, and the obtained surface roughness values (Ra) were averaged. The data obtained were statistically evaluated.

Statistical Analysis

Statistical analysis of the data was conducted using IBM Statistical Package for the Social Sciences (SPSS) v22 statistical software. Data were examined for normal distribution using the Kolmogorov-Smirnov test. Descriptive statistics of the data were specified as the median (min-max) for the variables in continuous data. A Wilcoxon signed rank test was used to compare the dependent/paired groups for the continuous data. The significance level was set to α=0.05.

Results

[Table/Fig-2] presents the surface roughness measurement values of the control, 1% sodium hypochlorite (1, 5, 10 and 30 min), 5% sodium hypochlorite (1, 5, 10 and 30 min) and quaternary ammonium-based disinfectant (10 and 30 min) groups.

Median, minimum, and maximum values of samples surface roughness (Ra).

| Groups according to disinfectants | Disinfection times (minute) | n | Median Ra | Minimum Ra | Maximum Ra |

|---|

| Control | | 10 | 0.79 | 0.54 | 0.94 |

| 1% Sodium hypochlorite | 1 | 10 | 0.77 | 0.56 | 0.91 |

| 5 | 10 | 0.80 | 0.63 | 0.91 |

| 10 | 10 | 0.76 | 0.61 | 0.91 |

| 30 | 10 | 0.90 | 0.76 | 1.01 |

| 5% Sodium hypochlorite | 1 | 10 | 0.78 | 0.59 | 0.92 |

| 5 | 10 | 0.79 | 0.65 | 0.91 |

| 10 | 10 | 0.80 | 0.61 | 0.92 |

| 30 | 10 | 1.02 | 0.80 | 1.08 |

| Quaternary ammonium-based | 10 | 10 | 0.77 | 0.61 | 1.14 |

| 30 | 10 | 0.84 | 0.70 | 0.98 |

As shown in the [Table/Fig-2], the median surface roughness value of the control group was 0.79 Ra. In the 1% and 5% sodium hypochlorite groups, the highest roughness value was found in the 30-minutes groups.

The statistical evaluation of the surface roughness values between the control and the other groups is shown in [Table/Fig-3]. A statistically significant difference was found between the control group and the 1% sodium hypochlorite (30 min), and 5% sodium hypochlorite (30 min) (p<0.05). There was no statistically significant difference between the other groups and the control group (p>0.05).

Statistical evaluation of the surface roughness values between the control and other groups’ Wilcoxon signed rank tests *(p<0.05 to be considered significant).

| Groups | Disinfection times (minute) | p-value |

|---|

| Control-1% sodium hypochlorite | 1 | 0.539 |

| 5 | 0.358 |

| 10 | 0.859 |

| 30 | 0.037* |

| Control-5% sodium hypochlorite | 1 | 0.575 |

| 5 | 0.959 |

| 10 | 0.505 |

| 30 | 0.017* |

| Control- quaternary ammonium-based | 10 | 0.475 |

| 30 | 0.059* |

[Table/Fig-4] shows the statistical evaluation of the surface roughness of the samples with different concentrations of sodium hypochlorite and the same times. In evaluating the surface roughness between similar application times but different concentrations, a statistically significant difference was found between the groups with 1% and 5% sodium hypochlorite concentrations applied for 30 minutes (p<0.05). There was no statistically significant difference between the other 1% and 5% sodium hypochlorite concentration groups (p>0.05). No statistically significant differences were observed between the quaternary ammonium-based disinfectant groups applied for 10 and 30 minutes (p>0.05).

Statistical analysis of the surface roughness between the groups’ Wilcoxon signed rank tests (p<0.05).

| Comparison within groups | Disinfection times (minute) | p-value |

|---|

| 1% and 5% sodium hypochlorite | 1 | 0.767 |

| 5 | 0.574 |

| 10 | 0.507 |

| 30 | 0.021* |

| Quaternary ammonium-based | 10 and 30 | 0.358 |

Discussion

When taking impressions, pathogens in the mouth can be transmitted to the external environment. To prevent the spread of infectious diseases due to cross-contamination, measuring materials are disinfected. Different impression disinfectant materials have been used by researchers [3,6,7,9,21-24]. In this in-vitro study, the effect of a light-body elastomeric impression material, sodium hypochlorite with two different concentrations and a quaternary ammonium-based disinfectant for 10 and 30 minutes on surface roughness was investigated.

Elastomeric impression materials are most commonly used in dentistry because they transfer surface details well, have good physical properties and exhibit high clinical performance. Whether the waiting time affected the surface roughness of the impression material was evaluated in the present study. Data regarding different concentrations and durations of sodium hypochlorite disinfectant application were obtained. In addition, data regarding different waiting times of another chemical disinfectant, quaternary ammonium-based disinfectant was obtained.

Dental impressions must be disinfected after taking impressions. Beyerle MP et al., reported that the process of rinsing impression materials with water per single view removed only 40% of the bacteria in the materials [15]. In addition, before placing the materials directly on the impression disinfectants, they must be kept under flowing tap water to remove residues on the surface of the impression materials. McNeill MRJ et al., found that rinsing the impressions with water for 15 seconds reduced contamination by approximately 90% [25]. In their study on four different disinfectant agents on alginate, polyvinyl siloxane and polyether impression materials, Al-Jabrah O et al., reported that disinfectant materials provided an effective disinfection on each impression substance and that rinsing the impression materials with water significantly reduced the number of microorganisms but not the disinfected impression materials [24]. In this study, disc-shaped samples were obtained via contact with the shiny glass surface and directly exposed to the disinfectants, as there were no residues on their surfaces.

Sodium hypochlorite is one of the effective substances used for the chemical disinfection of impression materials. Estafanous EW et al., reported that disinfectant application by spray or immersion method stopped bacterial growth for 10 minutes [26]. In their study on the disinfection of alginate impression material by sodium hypochlorite and iodophor and the evaluation of antimicrobial effectiveness in the obtained gypsum models, Haralur SB et al., found that the antimicrobial effectiveness of sodium hypochlorite was higher [27]. Disinfectants with different concentrations and different waiting times have been applied to impression materials [23,24,28,29]. Researchers examined the dimensional changes as a result of the impressions’ exposure to the disinfectant materials. Carvalhal CIO et al., reported that the elastomeric impression materials exposed to 0.5% sodium hypochlorite and 2% glutaraldehyde disinfectants by immersion for equal time periods affected the dimensional changes [6]. Silva SMLMD and Salvador MCG indicated that condensation-type silicone impression materials’ exposure to 1% sodium hypochlorite and a 2% glutaraldehyde solution for 10 and 20 minutes did not cause a significant change in linear dimensions [30]. The chemical disinfection of impression materials is conducted using the immersion or spraying method. In the immersion method, the impression is immersed in a disinfectant solution [24]. This method is considered to be more effective and reliable [10]. In the studies carried out by these researchers, there are differences in application time and the concentration of the disinfectants used for impression disinfection.

Impression materials are replicated in detail and the dental cast models obtained reflect these records precisely. Sterilisation and disinfection processes should not cause changes in the surface roughness of impression materials. Various studies have been carried out to evaluate the surface roughness of impression materials. In their research on the sterilisation and disinfection effect on the surface roughness of elastomeric impression materials, Kotha SB et al., found that chemical disinfection and autoclave sterilisation did not significantly affect surface roughness [4]. Al Kheraif AA evaluated the surface roughness of a polyvinyl siloxane impression material after different disinfection processes and while they found no significant difference between the control group and the chemical disinfection and autoclaved sterilisation groups, they noted a significant difference in the microwave sterilisation group [31]. In this study, only chemical disinfection methods were applied. Compared to the control group, significant differences existed between the surface roughness in the sodium hypochlorite groups where a 30 minutes disinfection application time was applied.

Limitation(s)

While the impression samples are obtained, their surface is very smooth as the glossy glass provides contact with the surface. However, intraoral structures show a complex structure in shape. Accordingly, changes can be observed in the contact surface areas of the disinfectant substances. Differences can be seen between data obtained in-vitro and that of clinical trials.

Conclusion(s)

The application time of the 1% and 5% sodium hypochlorite impression disinfectant affects the surface roughness of a light body elastomeric impression material. The application time of the quaternary ammonium-based disinfectant did not significantly change the material’s surface roughness. However, long-term sodium hypochlorite disinfectant use affects the surface roughness of the light body elastomeric impression material’s surface which should not be forgotten in clinical use.

Author Declaration:

Financial or Other Competing Interests: None

Was Ethics Committee Approval obtained for this study? No

Was informed consent obtained from the subjects involved in the study? NA

For any images presented appropriate consent has been obtained from the subjects. NA

Plagiarism Checking Methods: [Jain H et al.]

Plagiarism X-checker: Apr 22, 2020

Manual Googling: May 18, 2020

iThenticate Software: Jun 13, 2020 (11%)

[1]. Mehtar S, Shisana O, Mosala T, Dunbar R, Infection control practices in public dental care services: Findings from one South African ProvinceJ Hosp Infect 2007 66(1):65-70.10.1016/j.jhin.2007.02.00817433494 [Google Scholar] [CrossRef] [PubMed]

[2]. Wu G, Yu X, Gu Z, Ultrasonically nebulised electrolysed oxidising water: A promising new infection control programme for impressions, metals and gypsum casts used in dental hospitalsJ Hosp Infect 2008 68(4):348-54.10.1016/j.jhin.2008.01.02418353501 [Google Scholar] [CrossRef] [PubMed]

[3]. Celebi H, Büyükerkmen EB, Torlak E, Disinfection of polyvinyl siloxane impression material by gaseous ozoneJ Prosthet Dent 2018 120(1):138-43.10.1016/j.prosdent.2017.09.00329310874 [Google Scholar] [CrossRef] [PubMed]

[4]. Kotha SB, Ramakrishnaiah R, Devang Divakar D, Celur SL, Qasim S, Matinlinna JP, Effect of disinfection and sterilisation on the tensile strength, surface roughness, and wettability of elastomersJ Investig Clin Dent 2017 8(4):01-06.10.1111/jicd.1224427782374 [Google Scholar] [CrossRef] [PubMed]

[5]. Correia-Sousa J, Tabaio AM, Silva A, Pereira T, Sampaio-Maia B, Vasconcelos M, The effect of water and sodium hypochlorite disinfection on alginate impressionsRev Port Estomatol Cir Maxilofac 2013 54(1):08-12.10.1016/j.rpemd.2012.12.003 [Google Scholar] [CrossRef]

[6]. Carvalhal CIO, de Mello JA, Sobrinho LC, Correr AB, Sinhoreti MAC, Dimensional change of elastomeric materials after immersion in disinfectant solutions for different timesJ Contemp Dent Pract 2011 12(4):252-58.10.5005/jp-journals-10024-104322186859 [Google Scholar] [CrossRef] [PubMed]

[7]. Martin N, Martin MV, Jedynakiewicz NM, The dimensional stability of dental impression materials following immersion in disinfecting solutionsDent Mater 2007 23(6):760-68.10.1016/j.dental.2007.01.00417353045 [Google Scholar] [CrossRef] [PubMed]

[8]. Schleier PE, Gardner FM, Nelson SK, Pashley DH, The effect of storage time on the accuracy and dimensional stability of reversible hydrocolloid impression materialJ Prosthet Dent 2001 86(3):244-50.10.1067/mpr.2001.11775811552162 [Google Scholar] [CrossRef] [PubMed]

[9]. Rentzia A, Coleman DC, O’Donnell MJ, Dowling AH, O’Sullivan M, Disinfection procedures: Their efficacy and effect on dimensional accuracy and surface quality of an irreversible hydrocolloid impression materialJ Dent 2011 39(2):133-40.10.1016/j.jdent.2010.11.00321093528 [Google Scholar] [CrossRef] [PubMed]

[10]. Hiraguchi H, Kaketani M, Hirose H, Yoneyama T, Effect of immersion disinfection of alginate impressions in sodiumhypochlorite solution on the dimensional changes of stone modelsDent Mater J 2012 31(2):280-86.10.4012/dmj.2010-20122447063 [Google Scholar] [CrossRef] [PubMed]

[11]. Schmidt A, Häussling T, Rehmann P, Schaaf H, Wöstmann B, Accuracy of various impression materials and methods for two implant systems: An effect size studyJ Prosthodont Res 2018 62(2):245-51.10.1016/j.jpor.2017.10.00429191609 [Google Scholar] [CrossRef] [PubMed]

[12]. Chen SY, Liang WM, Chen FN, Factors affecting the accuracy of elastometric impression materialsJ Dent 2004 32(8):603-09.10.1016/j.jdent.2004.04.00215476954 [Google Scholar] [CrossRef] [PubMed]

[13]. Kalantari MH, Malekzadeh A, Emami A, The effect of disinfection with sodium hypochlorite 0.5% on dimensional stability of condensation silicone impression materials of speedex and irasilJ Dent 2014 15(3):98-103. [Google Scholar]

[14]. Lang BR, Lepe X, Johnson GH, Berg JC, Surface characteristics of polyether and addition silicone impression materials after long-term disinfectionJ Prosthet Dent 1995 74(2):181-86.10.1016/S0022-3913(05)80184-2 [Google Scholar] [CrossRef]

[15]. Beyerle MP, Hensley DM, Bradley Jr DV, Schwartz RS, Hilton TJ, Immersion disinfection of irreversible hydrocolloid impressions with sodium hypochlorite. Part I: MicrobiologyInt J Prosthodont 1994 7(3):234-38. [Google Scholar]

[16]. Thouati A, Deveaux E, Iost A, Behin P, Dimensional stability of seven elastomeric impression materials immersed in disinfectantsJ Prosthet Dent 1996 76(1):08-14.10.1016/S0022-3913(96)90338-8 [Google Scholar] [CrossRef]

[17]. Ulgey M, Gorler O, Yesilyurt G, Importance of disinfection time and procedure with different alginate impression products to reduce dimensional instabilityNiger J Clin Pract 2020 23(3):284-90.10.4103/njcp.njcp_481_1932620724 [Google Scholar] [CrossRef] [PubMed]

[18]. https://www.zhermack.com/public/uploads/F121027_19-06_Zeta_Hygiene_EN_low.pdf [Google Scholar]

[19]. Johnson GH, Lepe X, Aw TC, The effect of surface moisture on detail reproduction of elastomeric impressionsJ Prosthet Dent 2003 90(4):354-64.10.1016/S0022-3913(03)00429-3 [Google Scholar] [CrossRef]

[20]. Peracini A, Davi LR, de Queiroz Ribeiro N, de Souza RF, da Silva CHL, Paranhos HDFO, Effect of denture cleansers on physical properties of heat-polymerised acrylic resinJ Prosthodont Res 2010 54(2):78-83.10.1016/j.jpor.2009.11.00420083448 [Google Scholar] [CrossRef] [PubMed]

[21]. Jha A, Jha S, Kumar A, Das R, Jha A, Singh SS, Assessment of effect of disinfection methods on the dimensional stability of elastomeric materialsJ Adv Med Dent Scie Res 2019 7(8):240-42. [Google Scholar]

[22]. Samra RK, Bhide SV, Efficacy of different disinfectant systems on alginate and addition silicone impression materials of Indian and international origin: A comparative evaluationJ Indian Prosthodont Soc 2010 10(3):182-89.10.1007/s13191-010-0040-y21886411 [Google Scholar] [CrossRef] [PubMed]

[23]. Poulis N, Prombonas A, Yannikakis S, Karampotsos T, Katsarou MS, Drakoulis N, Preliminary SEM observations on the surface of elastomeric impression materials after immersion or ozone disinfectionJ Clin Diagn Res 2016 10(12):01-05.10.7860/JCDR/2016/20330.894928208993 [Google Scholar] [CrossRef] [PubMed]

[24]. Al-Jabrah O, Al-Shumailan Y, Al-Rashdan M, Antimicrobial effect of 4 disinfectants on alginate, polyether, and polyvinyl siloxane impression materialsInt J Prosthodont 2007 20(3):299-307. [Google Scholar]

[25]. McNeill MRJ, Coulter WA, Hussey DL, Disinfection of irreversible hydrocolloid impressions: A comparative studyInt J Prosthodont 1992 5(6):563-67. [Google Scholar]

[26]. Estafanous EW, Palenik CJ, Platt JA, Disinfection of bacterially contaminated hydrophilic PVS impression materialsJ Prosthodont 2012 21(1):16-21.10.1111/j.1532-849X.2011.00788.x22040354 [Google Scholar] [CrossRef] [PubMed]

[27]. Haralur SB, Al-Dowah OS, Gana NS, Al-Hytham A, Effect of alginate chemical disinfection on bacterial count over gypsum castJ Adv Prosthodont 2012 4(2):84-88.10.4047/jap.2012.4.2.8422737312 [Google Scholar] [CrossRef] [PubMed]

[28]. Hemalatha R, Ganapathy D, Disinfection of dental impression-A current overviewJ Pharm Sci Res 2016 8(7):661-64. [Google Scholar]

[29]. Mostafavi A, Koosha S, Amjad M, Effect of disinfection on the surface roughness of dental casts retrieved from addition silicone ımpressionsJ Res Dentomaxillofac Sci 2018 3(1):27-33.10.29252/jrdms.3.1.27 [Google Scholar] [CrossRef]

[30]. Silva SMLMD, Salvador MCG, Effect of the disinfection technique on the linear dimensional stability of dental impression materialsJ Appl Oral Sci 2004 12(3):244-49.10.1590/S1678-7757200400030001621049261 [Google Scholar] [CrossRef] [PubMed]

[31]. Al Kheraif AA, Surface roughness of polyvinyl siloxane impression materials following chemical disinfection, autoclave and microwave sterilisationJ Contemp Dent Pract 2013 14(3):483-87.10.5005/jp-journals-10024-134924171994 [Google Scholar] [CrossRef] [PubMed]