Use of Bubble Gum to Check Border Extensions of the Custom Tray Before Border Molding

Mohammed Shammas1, VT Abdurahiman2, Nawawi Ahmed Elaf Youssef3, Nasser Fawzi Maryam Nabeel4

1 Associate Professor, Department of Prosthodontics, Ibn Sina National College for Medical Studies, Jeddah, Saudi Arabia.

2 Associate Professor, Department of Prosthodontics, Ibn Sina National College for Medical Studies, Jeddah, Saudi Arabia.

3 Student, Ibn Sina National College for Medical Studies, Jeddah, Saudi Arabia.

4 Student, Ibn Sina National College for Medical Studies, Jeddah, Saudi Arabia.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Mohammed Shammas, Division of Prosthodontics, Department of Oral and Maxillofacial Rehabilitation, Ibn Sina National College for Medical Studies, Al Mahjar Street, Gulail District, PO Box 31906, Jeddah, Saudi Arabia.

E-mail: shammasm@hotmail.com; mshammas@ibnsina.edu.sa

Over-extension or under-extension of denture borders leads to loss of retention and to some extent stability of the removable prosthesis which is attributed to mistakes made during the border molding step. To check border extensions of the custom tray before border molding using bubble gum. Bubble gum is softened in warm water and adapted to the borders of the custom tray. The custom tray is inserted into the mouth and the usual functional movements that are done during border molding are done to check any over-extension. This technique is simple, convenient, and bubble gum is easily available.

Final impression, Removable prosthesis, Retention, Stability

Introduction

When making a removable prosthesis, all the clinical steps are extremely important. Objectives of impression making are important for a successful complete denture. These can be achieved by accurate border molding followed by making a precise final impression [1,2]. This procedure is a critical step which can take a very long time if proper techniques are not followed [2]. According to the Glossary of Prosthodontics Terms (GPT-9), border molding has two definitions:

1) The shaping of impression material along with the border areas of an impression tray by functional or manual manipulation of the soft tissue adjacent to the borders to duplicate the contour and size of the vestibule; 2) Determining the extension of a prosthesis by using tissue function or manual manipulation of the tissues to shape the border areas of impression material [3]. Although the custom tray is kept short of the sulcus by 2 mm on the primary cast by the technician, the clinician must verify this extent in the patient’s mouth [4]. This is time-consuming, particularly for a beginner student if it involves checking and trimming the tray extensions in the patient’s mouth multiple times [5]. In a quest to make this procedure easy many materials like wheat flour dough [6], play dough [7,8], and catalyst or base paste of polyvinyl siloxane putty material [8-10] have been advocated by various authors with each one having its advantages and disadvantages. An alternate technique to check border extensions of the custom tray using bubble gum is described here.

Procedure

Primary impressions were made using alginate impression material (Jeltrate Alginate Impression Material, DENTSPLY Caulk, Milford, DE) and primary casts were made in Type III dental stone (Silky-Rock, Whip Mix Corporation, Louisville, KY).

A custom tray with spacer was fabricated on this primary cast with visible light cure resin (Triad 2000, Dentsply Sirona, York, PA).

During the second clinical visit, the custom trays were checked in the patient’s mouth to check the space required for border molding. It was then removed and the borders were cleaned with gauze.

A piece of bubble gum (Baloona, Gandour, Jeddah, Saudi Arabia) was softened in warm water at about 45°C and was made into a roll of about 2-3 mm thick and a length that covers the entire borders of the custom tray. The roll was then adapted onto the borders of the custom tray [Table/Fig-1].

Softened bubble gum adapted to the borders of the custom tray.

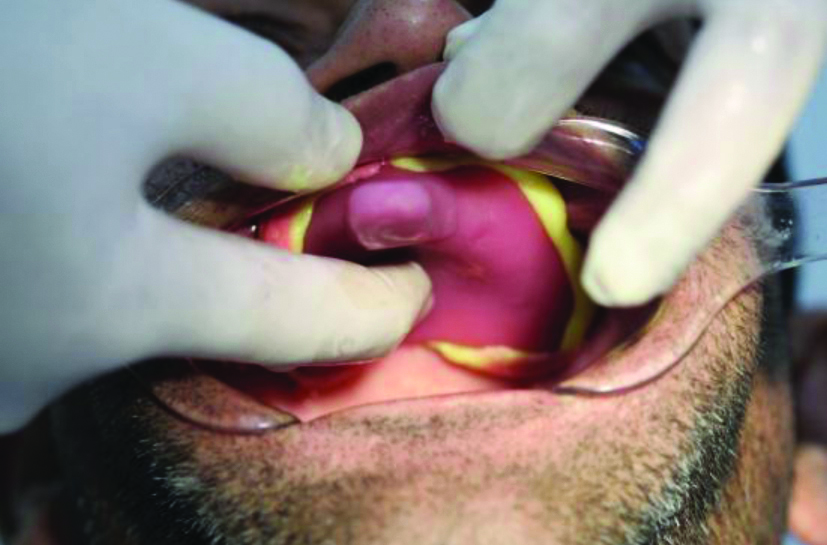

The tray was placed in the mouth and the same manipulation for border molding was done [Table/Fig-2].

Maxillary custom tray with bubble gum placed in the mouth and border molding procedure carried out;

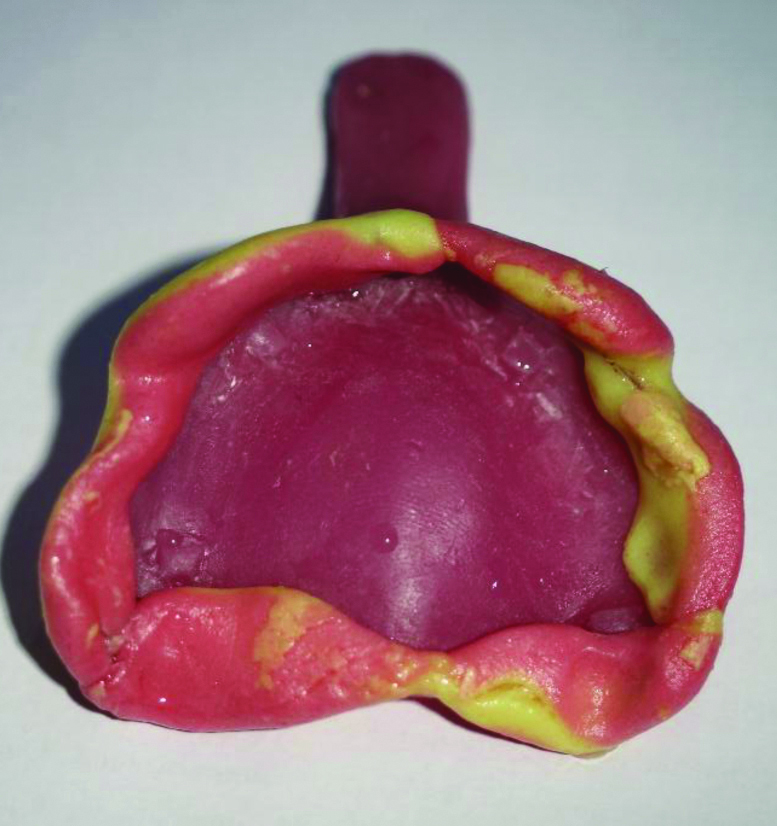

The custom tray was removed from the mouth and was checked for any exposures [Table/Fig-3].

Maxillary custom tray removed from the mouth after border molding with bubble gum showing exposed tray;

The exposed areas on the tray were trimmed using a bur and micromotor handpiece after removal of the bubble gum.

Again the same bubble gum was softened in warm water and was adapted onto the tray and the same functional movements were performed as mentioned above. The procedure was repeated until the desired height and thickness of about 2-3 mm was seen and was verified by using a periodontal probe [Table/Fig-4].

Maxillary custom tray showing adequate height and thickness of 2-3 mm of bubble gum indicating that it is ready for border molding.

Once it was considered satisfactory, the bubble gum was removed and the borders of the custom tray were cleaned with the gauze.

The border molding procedure was carried out conventionally and a final impression was made.

Discussion

Materials like wheat flour dough have many disadvantages as it is not available readily and requires extra armamentarium and manipulation to convert it into a usable form [7]. The use of play dough has its own limitations like, the need to lubricate the material with petrolatum before border molding to facilitate easy removal without adhering to the tissues [7] and some brands of play dough are toxic and are not biocompatible to the oral tissues. The use of catalyst or base of putty consistency of poly-vinyl siloxane material is expensive and also, any contact with the lips and cheeks should be avoided during insertion and removal of the tray to minimize the displacement of the material. A long-time contact inside the patient’s mouth may lead the material to sag over the borders [9].

Some of the advantages of using bubble gum to check the border extensions are that it is easily available in stores, less time consuming, inexpensive, and it has patient acceptance. It sticks to the custom tray nicely but does not stick to the oral tissues and it is easy to clean from the custom tray. The disadvantages of this technique includes the need for a kettle to heat the water and the tendency to become soft and unusable if it is placed in water which is more than 45°C. The material should be placed in the mouth without any contact with the lips and cheeks, otherwise distortion of the material will occur. The trial border molding should be gentle to avoid sagging of the material.

Conclusion(s)

Border molding procedure requires time and patience from the clinician and also patient cooperation is a must. Repeated insertion of the tray in the mouth to check the space and exact retraction of the tissues requires a learning curve for a beginner student. The use of bubble gum which is easily available is simple, convenient and faster. It also saves chair side time for the clinician and can enhance patient cooperation.

Author Declaration:

Financial or Other Competing Interests: None

Was informed consent obtained from the subjects involved in the study? Yes

For any images presented appropriate consent has been obtained from the subjects. Yes

Plagiarism Checking Methods: [Jain H et al.]

Plagiarism X-checker: Dec 16, 2019

Manual Googling: Feb 21, 2020

iThenticate Software: Feb 29, 2020 (12%)

[1]. Yarapatineni R, Vilekar A, Kumar JP, Kumar GA, Aravind P, Kumar PA, Comparative evaluation of border molding, using two different techniques in maxillary edentulous arches- An in vivo studyJ Int Oral Health 2013 5(6):82-87. [Google Scholar]

[2]. Qanungo A, Aras MA, Chitre V, Coutinho I, Rajagopal P, Mysore A, Comparative evaluation of border molding using two different techniques in maxillary edentulous arches: A clinical studyJ Indian Prosthodont Soc 2016 16(4):340-45.10.4103/0972-4052.19129127746597 [Google Scholar] [CrossRef] [PubMed]

[3]. Glossary of Prosthodontic Terms- 9th EditionJ Prosthet Dent 2017 117(5S):e1-105.10.1016/j.prosdent.2016.12.001 [Google Scholar] [CrossRef]

[4]. Arora AK, Goyal I, Sehgal M, Comparative evaluation of reproducibility of peripheral tissues produced by different border molding materials in edentulous patients: An in vivo studyJ Indian Prosthodont Soc 2015 15(2):102-10.10.4103/0972-4052.15503026929495 [Google Scholar] [CrossRef] [PubMed]

[5]. Smith DE, Toolson LB, Bolender CL, Lord JL, One-step border molding of complete denture impressions using a polyether impression materialJ Prosthet Dent 1979 41(3):347-51.10.1016/0022-3913(79)90022-2 [Google Scholar] [CrossRef]

[6]. Namratha N, Shetty V, A technique to evaluate custom tray border extensions before peripheral moldingJ Prosthet Dent 2014 112(6):1603-04.10.1016/j.prosdent.2014.06.00825134997 [Google Scholar] [CrossRef] [PubMed]

[7]. Aggarwal H, Kumar P, Comments regarding Namratha N, Shetty V. A technique to evaluate custom tray border extensions before peripheral moldingJ Prosthet Dent 2015 114:01-02.10.1016/j.prosdent.2014.09.03025794905 [Google Scholar] [CrossRef] [PubMed]

[8]. Alhajj MN, Evaluation of custom tray border extensions before final peripheral molding using two different materialsInt Dent J Stud Res 2016 4(1):32-34. [Google Scholar]

[9]. Alhajj MN, Marquez JR, Simple technique to evaluate denture border extensions using silicone impression materialJ Ir Dent Assoc 2016 62(4):213-14. [Google Scholar]

[10]. Bhat V, Shetty S, Kamath J, Shenoy KK, A simple method to check the border extensions of custom trayAnn Int Med Den Res 2016 2(1):31-32. [Google Scholar]