Netra Pariseka/Seka (procedure for closed eye irrigation) is an ayurvedic treatment method of pouring a very fine stream of medicated liquid over the closed eyes from a height for a specified time period. This procedure is done to cure eye-related diseases through ayurvedic medicines. Presently this Seka procedure is done manually where there are chances for human errors. To override this, an automation system is introduced that includes flow control heat control and speed control.

Innovative seka technique, Netra pariseka, Pariseka machine

Introduction

Netra Seka, Netra pariseka or Netra Dhara is an ayurvedic treatment tradition of pouring medication fluids in the form of streams (Sukshma dhara) in and around the eyes (Pariseka). The quantity and temperature of the liquid to be poured depend on the illness effected to the eyes such as itching of eyes, watery eyes, conjunctivitis, burning eyes or dry eyes [1,2]. Treatment procedures are mainly divided into three steps-Purva karma (Pre-procedure), Pradhana karma (Main procedure) and Pashyat karma (Post-procedure).

In the Netra Seka procedure, a thin stream of liquid is poured around the eyes from a height of about four inches. Lukewarm medicated liquid is needed throughout the treatment procedure [3,4]. Duration of a single stretch procedure varies from 2 to 20 minutes. The time taken for different treatment procedures are not the same. The Seka procedure is repeated to 2-4 times depending on the severity of illness. To perform seka procedure manually, trained therapists are needed. Performing the treatment by the same therapist for the whole course of the treatment of a patient is practically difficult. Physical parameter of the medication throughout the treatment like temperature is difficult to maintain. After certain time of pouring, the temperature of the medication reduces.

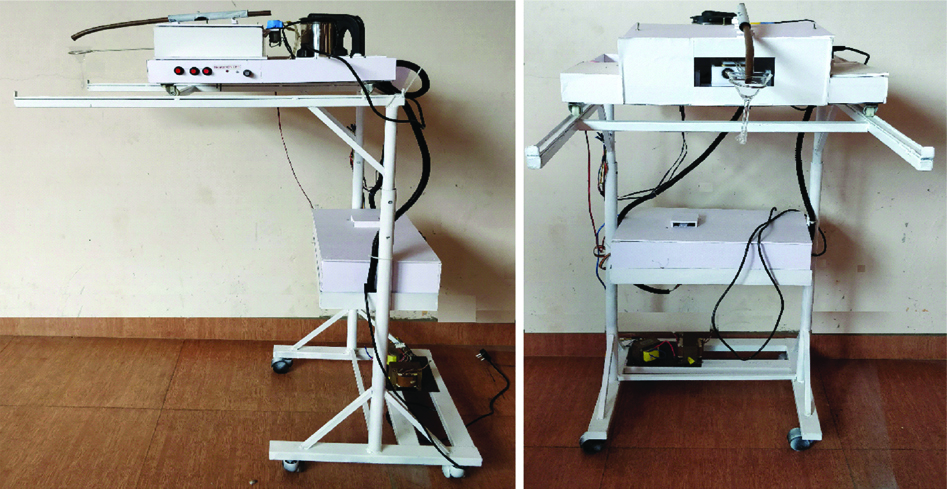

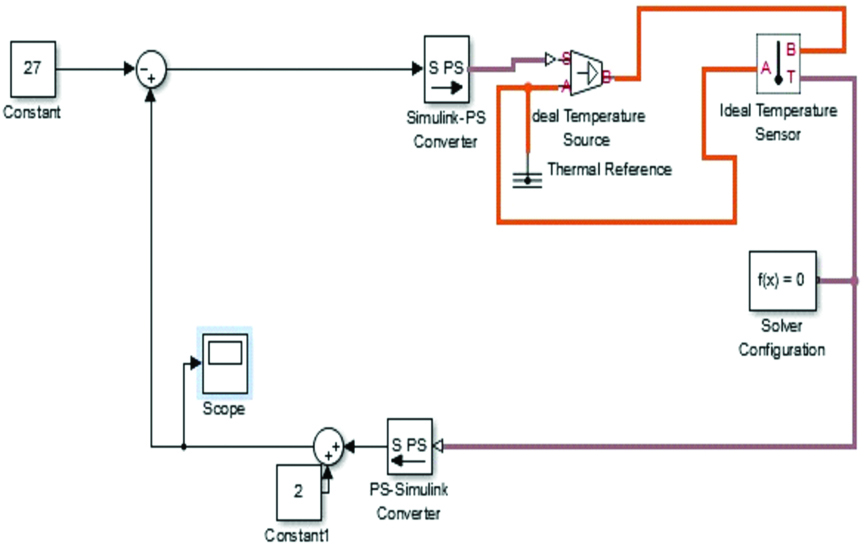

This paper explains about automation of the whole Netra Seka procedure. By automation, all these factors can be addressed and also manpower can be reduced. In order to automate the whole procedure, X-Y plotter with two stepper motor is required. By using the X-Y plotter principle, elliptical motion can be obtained and also if needed circular movement is possible. Thus, by keeping some funnel or steel tube, the medicated liquid can be poured around the eyes for the prescribed period of time. Proportional Integral Derivative gain (PID) based temperature control method is used so as to regulate the temperature of the medicated liquid to 37°C. The flow of the medicated liquid is controlled by means of a solenoid valve where the closing and opening of the valve is done by starting and stopping the X-Y plotter. The whole prototype of the implemented Netra Seka system are shown in [Table/Fig-1].

Prototype of the proposed ayurvedic drug delivery system.

System Description

The prototype of the proposed ayurvedic drug delivery system has a structure which is made of Galvanized Iron (GI) sheet and pipes. It is of the height of three feet and the height of the structure can be extended up to five feet. As shown in the [Table/Fig-1], power and control circuit of the whole system is fixed in the structure at a height of two feet from the ground level. The width of the tray carrying circuitry is of about 50 cm and breadth is about 27 cm. A rail is fitted at the top of the structure and it can be extended in vertical direction for the length of about 65 cm. Over the rail, a GI tray is placed and it moves through the rail in forward and backword motion using four wheels. By moving the GI tray in forward and reverse motion Ayurvedic Practitioner can adjust the position of drug delivery system and hence the point to pour the medicated oil on the patient. On this GI tray, the X-Y Plotter, vessel for meditative oil with heater to maintain the temperature of the medicative oil and peristaltic pump for delivery of meditative oil are placed. The whole structure is placed over four multidirectional wheels, by using which Ayurvedic Practitioner can easily carry the whole system from one place to another. The weight of the whole structure is about 6 Kg.

X-Y Plotter

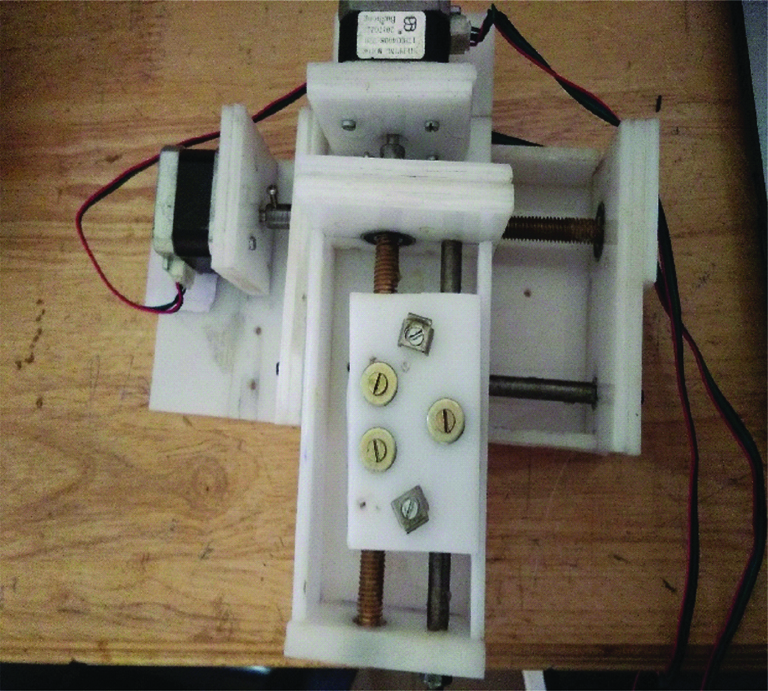

X-Y Plotter is designed with two stepper motors, where one motor operates for the movement along X-direction and the other for the movement along Y-direction. The motor, connected in the X-axis, drives the Y-axis motor with the help of a conveyor belt as shown in [Table/Fig-2].

Design model of the X-Y plotter.

The knob which holds the point of drug delivery is controlled by the Y-axis motor through a conveyer belt. Thus, by inputting the values of X and Y coordinates along with the radius of the path to be traced, circle or ellipse of different radii can be drawn. The stepping of the stepper motor can be done in two ways full stepping and half stepping mode. In full stepping, motor move 1.8 degrees and in half stepping 0.9 degrees [5-7]. The speed of the stepper motor can be controlled by controlling the duty cycle of the PWM signal, thus by varying the duty cycle of the PWM signal given to the motor drives the speed of the motor can be varied [8].

Temperature Control

To maintain the temperature level of the medicated oil in between 37°C to 38°C, PID based temperature control method was used. The temperature control was made by using the Arduino microcontroller board. The Temperature Sensor (DS18B20 Model) was calibrated and the output terminal of the sensor is connected to the Analog pin of the Arduino microcontroller board. The power supply for the temperature sensor was given through the Arduino microcontroller board. The relay control output from the Arduino microcontroller board is given through the digital port. The negative terminal of the 24 Volt supply of heater was connected to the common terminal of the relay, and the negative terminal of the heater was connected to the Normally Closed (NC) pin. When the temperature goes above 37°C, the relay goes to NC condition and thus the supply to the heater was cut-off and the heater stops heating. When the temperature of the medicated oil goes below 36°C, the relay goes to Normally Open (NO) condition and the heater gets turn ON. The heater ON and OFF condition was indicated by using two Light Emitting Diodes (LEDs). When the heater was in ON condition the red light glows and when the heater was in OFF condition green light glows.

Flow Control

Flow control of medicated decoction is done by using the peristaltic pump. A peristaltic pump was a drug dosing pump it actually used in medical applications and it can withstand high temperature. By using this peristaltic pump, maximum of 100 mL per minute of medicated decoction can be pumped. The connecting tube used along with the peristaltic pump was silicon tube, which was used in medical applications. The maximum current rating of the peristaltic pump was about 0.4 Amps. By using the variable resistor, the current flow of the pump can be controlled and thus the speed of the motor was controlled. By controlling the speed of the motor the flow rate of the liquid can be controlled. For ayurvedic reasons, the intake and delivery pipe of the medicated decoction uses silicon tube and final delivery was through copper tube until it was delivered over the infected area of eye by the small funnel.

System Operation

While switching on the power supply, the heater gets turned ON because the temperature of the kettle may be below 36°C. There have three settings available with the Arduino microcontroller board. This is used to set different time period: 15, 20, 25 minutes for delivery of meditative oil depending on the requirements. When any one of these switches gets pressed, the signal goes to the Arduino microcontroller. Now the relay goes to normally open condition, turn ON the peristaltic pump and start to pump the medicated decoction. Simultaneously the x-y plotter was powered and starts working.

Simulation Results

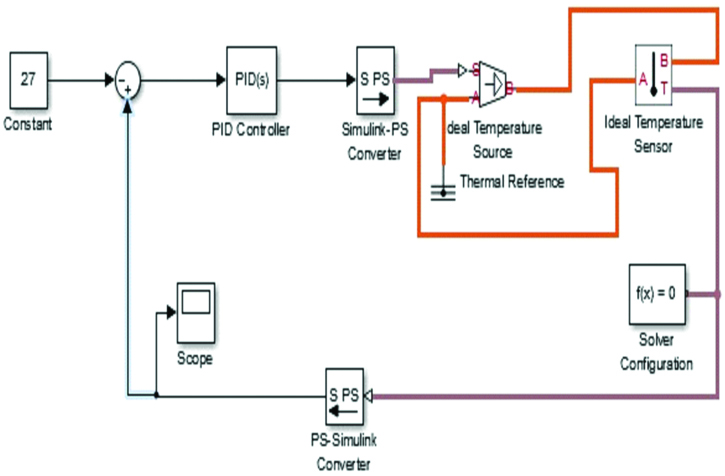

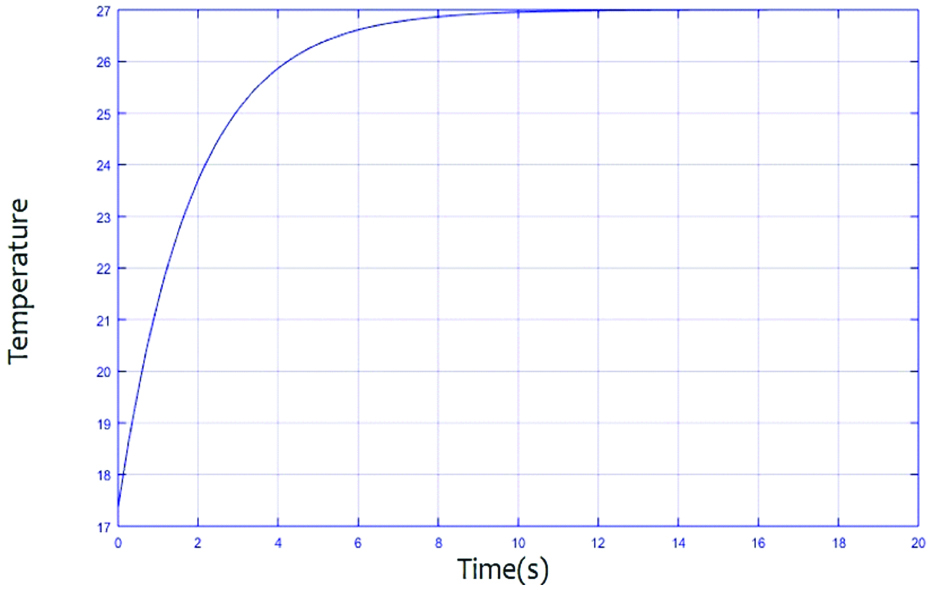

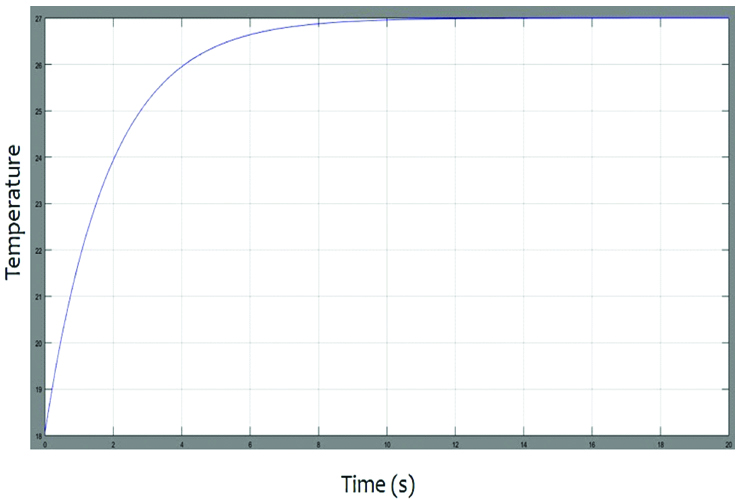

The [Table/Fig-3] shows the temperature control closed loop simulation where a PID controller was used to controlling the temperature range at a particular level. From the [Table/Fig-3] it was clear that if the given input reference temperature value is 27 and the temperature was sensed by using an ideal temperature sensor, then the sensed value was compared with the reference value and then the error signal passed through the PID controller. From the [Table/Fig-4], it can be observed that within a particular period of time, the temperature becomes constant for the range of 27°C.

Temperature control without external disturbance.

Temperature control output without disturbance.

[Table/Fig-5] shows a simulation system with external disturbance included in the feedback path and the corresponding performance of the control system shown in [Table/Fig-6]. From the results, it was observed that the PID controller was working properly and the external disturbance was not affecting the performance in maintaining of temperature at a particular level.

Temperature control simulation with disturbance.

Temperature control output with disturbance.

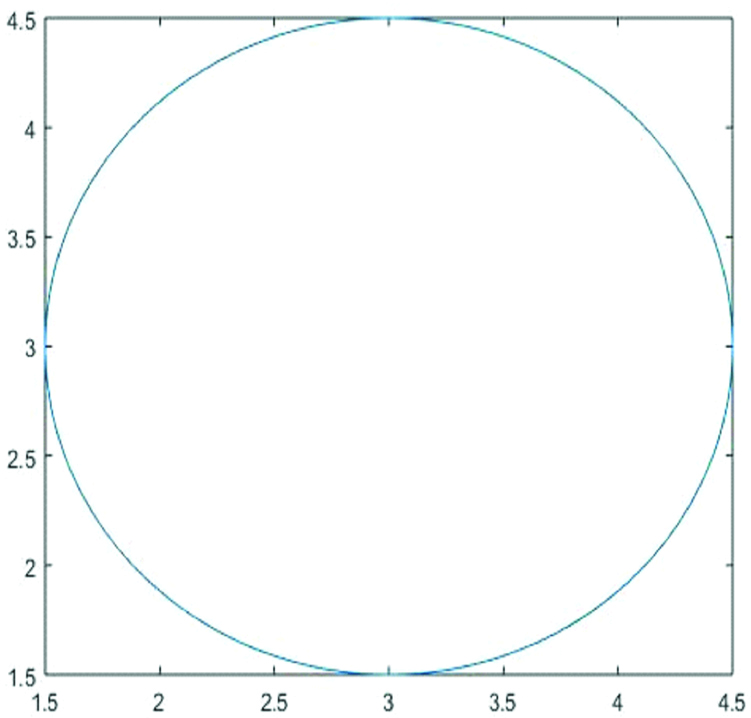

[Table/Fig-7] shows the simulation result of the x-y plotter, where the x and y co-ordinate values were given to the simulation code and by including the circle formula that to the code, authors got the output just as for the diameter of 3 cm.

X-Y Plotter Simulation output.

Discussion

In Ayurveda, most of the procedures and also the medicines needed for are prepared manually. Any variations in these will alter the treatment outcome and human errors are inevitable. The properties of the medicines are important in selecting them for the treatment so also the form and the method of application.

Here are some points to highlight certain physical parameters and their importance.

Importance of maintaining height: Water is the most flexible medium for producing the thermic and mechanical effects desired and can be applied to a limited area or to the whole-body surface. The mechanical effect of the flow of the decoctions stimulate the nerve impulses at the skin deeper into the body, where they are instrumental in stimulating the immune system, invigorating the circulation and digestion, encouraging blood flow and lessening pain sensitivity.

Importance of maintaining the flow: According to Bhavamisra, sara gunam stimulates other substances to move or act. Flowing substances helps in the removal of vata and other vitiated doshas from the affected site. The stream should not be thin or thick. It should be continuous flow and not as drops to get the proper effect.

Importance of maintaining the temperature: Ushna gunam is the main property of tejo mahabhuta which helps to regulate dhatvagni mandhya and also has pachana effect bringing the Nethra gata amavasta into nirmavasta. Therapeutic application of heat of any substance, adds heat of the body tissues. A 1° increase in tissue temperature is associated with a 10-15% increase in the local tissue metabolism. This increase in metabolism aids the healing process by increasing both anabolic and catabolic reactions needed to degrade and remove metabolic by products of tissue damage and provides milieu to tissue repair.

Conclusion

By incorporating automatic flow control, temperature control and position control of the stepper motors, the whole Netra Seka procedure is automated. By automating the whole procedure, manual difficulties are eliminated. Future research may attempt to reduce the size of the system and implement accurate flow control of medicated decoction. This will make the system more efficient in future.

[1]. Dhiman KS, Agarwal R, Gopinathan G, Shukla VJ, Optimization of Parisheka kriyakalpa (procedure for closed eye irrigation) 3: A clinical study on acute conjunctivitis with Triphala decoctionIndian Journal of Traditional Knowledge 2017 16(1):107-12. [Google Scholar]

[2]. Srikantha Murthy, Sarngadhara samhita of sarngadhara, 13th chapter, 7 sloka 2010 VaranasiChaukhambha Sanskrit Sansthan:259 [Google Scholar]

[3]. Vardhan P, Dhiman KS, Clinical study to assess the efficacy of Keshanjana and Netra Parisheka in the management of Shushkakshipaka (dry eye syndrome)Ayu 2014 35(3):27710.4103/0974-8520.15374426664237 [Google Scholar] [CrossRef] [PubMed]

[4]. Srikantha Murthy, Sarngadhara samhita of sarngadhara, 13th chapter, 2 sloka 2010 VaranasiChaukhambha Sanskrit Sansthan:258 [Google Scholar]

[5]. Gaan DR, Kumar M, Sudhakar S, Real-time precise position tracking with stepper motor using frequency modulation based microsteppingIEEE Transactions on Industry Applications 2018 54(1):693-701.10.1109/TIA.2017.2753158 [Google Scholar] [CrossRef]

[6]. Kim W, Shin D, Chung CC, Microstepping with nonlinear torque modulation for permanent magnet stepper motorsIEEE Transactions on Control Systems Technology 2013 21(5):1971-79.10.1109/TCST.2012.2211079 [Google Scholar] [CrossRef]

[7]. Clout P, Johnson PN, The application of stepper motors to the control of scientific apparatusNuclear Instruments and Methods 1978 152(1):151-54.10.1016/0029-554X(78)90255-0 [Google Scholar] [CrossRef]

[8]. Chen C, Microcomputer speed control of stepper motorIEEE Control Systems Magazine 1982 2(1):17-20.10.1109/MCS.1982.1103690 [Google Scholar] [CrossRef]