A Novel Complete Denture Impression Technique with Thermoplastic Stock Trays

Sivaranjani Gali1, Priyanka Aiyer2, Anoop Sharma3

1 Associate Professor, Department of Prosthodontics, Faculty of Dental Sciences, Ramaiah University of Applied Sciences, Bengaluru, Karnataka, India.

2 Postgraduate Student, Department of Prosthodontics, Faculty of Dental Sciences, Ramaiah University of Applied Sciences, Bengaluru, Karnataka, India.

3 Postgraduate Student, Department of Prosthodontics, Faculty of Dental Sciences, Ramaiah University of Applied Sciences, Bengaluru, Karnataka, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Sivaranjani Gali, Associate Professor, Department of Prosthodontics, Faculty of Dental Sciences, M S Ramaiah University of Applied Sciences, Bangalore-560054, Karnataka, India.

E-mail: nature79gali@gmail.com

Primary impressions in complete dentures are generally made with stainless steel stock trays. Conventional clinical procedures therefore, require additional patient appointments for primary and master impressions. We propose a unique single appointment technique of a thermoplastic stock tray for peripheral tracing and master impression for complete denture patients.

Dental impressions, Impression trays, Peripheral tracing

Technique

Stainless steel stock trays used for primary impressions are basically designed as vehicles to carry and support relevant impression materials. Plastic modelling compound and irreversible hydrocolloids are the materials of choice for primary impressions in complete dentures. The obtained primary casts are then used for the fabrication of custom trays for master impressions. Regular clinical practice involves patient appointments for both primary and master impressions. Massad earlier proposed the use of low temperature edentulous stock tray with putty as stoppers and used elastomeric impression materials for peripheral tracing and master impression [1,2]. Herein, we propose an original technique of a thermoplastic stock tray (KLARITY WhiteTM, Meditronix) with built in tissue stoppers and spacer design that can be adapted to the patient’s edentulous arch, to be further used for peripheral tracing and master impression, thus reducing the above mentioned additional appointments [3]. The present article will throw light on the procedure of customising the tray with peripheral tracing, master impression and the clinical challenges faced.

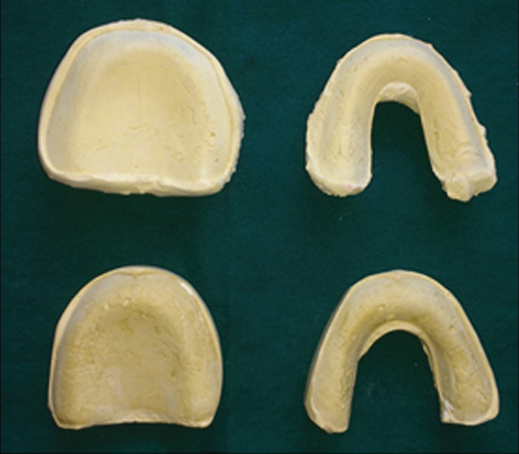

Construct dental stone casts from a standard size maxillary or mandibular stock tray as shown in [Table/Fig-1].

Dental stone casts prepared from available stainless steel stock trays.

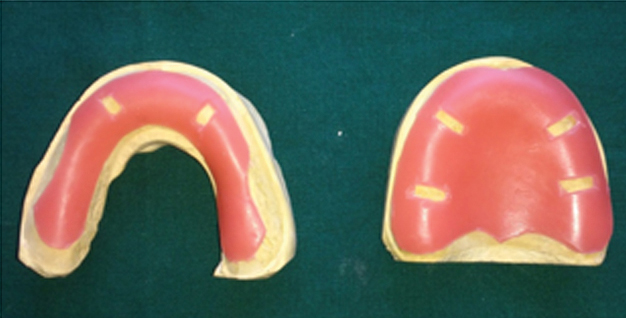

Place 4×4 mm tissue stoppers (Modelling wax, DPI) on the dental cast with a spacer (2 mm Modelling wax, DPI) design of choice (Boucher’s design), 4 mm short of sulcus.

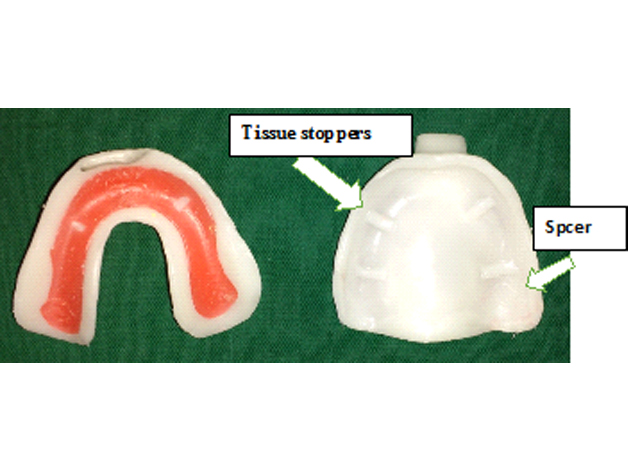

Typical property of a thermoplastic polymer is its ability to be moulded with temperature. Manually mold the softened thermoplastic sheet (KLARITY WhiteTM, Meditronix) to even thickness on the prepared cast using Bunsen Burner at a temperature of 85°C and temperature at 45°C in warm water bath as shown in [Table/Fig-2,3] as a prefabricated tray [3]. Further adapt the material for fabricating handle on the tray using Bunsen flame and warm water bath.

Tissue stoppers and spacers adapted on the stone casts.

Thermoplastic mandibular and maxillary trays with built in tissue stoppers and spacers (Boucher’s design).

Adapt the prefabricated thermoplastics tray at a temperature of 45°C (warm water bath) to the patient’s edentulous arches and cool the tray in water bath at room temperature as shown in [Table/Fig-4].

Thermoplastic tray being adapted in the patients’ maxillary and mandibular arches.

Trim the trays 2 mm short of the sulcus in the patient mouth to accommodate for peripheral tracing modelling compound.

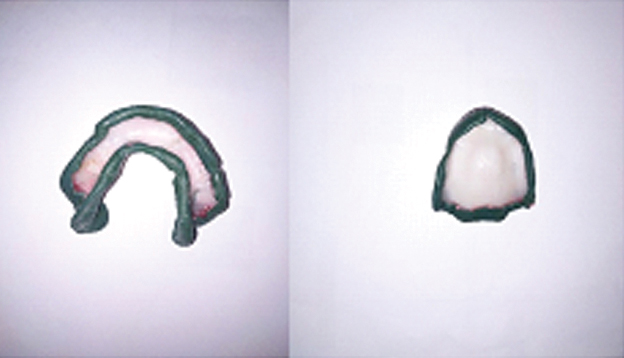

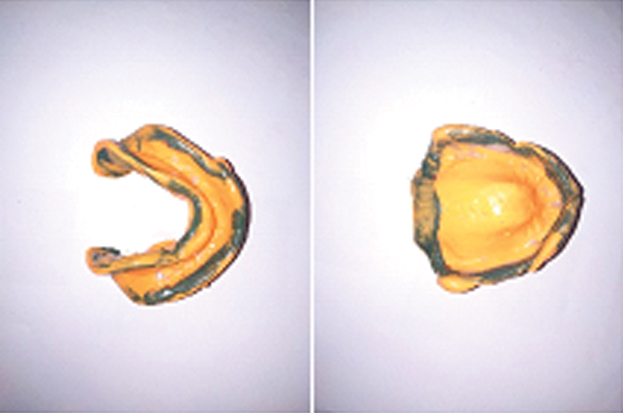

Follow the conventional procedure of peripheral tracing and master impression with elastomeric or zinc oxide eugenol impression paste as shown in [Table/Fig-5,6,7].

Tracing performed on the thermoplastic tray (maxillary).

Peripheral tracings on the maxillary and mandibular thermoplastic tray.

Secondary impressions made from maxillary and mandibular thermoplastic trays.

Discussion

The thermoplastic material used in the technique is a styrene based epsilon caprolactone polymer with cross-linking agents and fillers, used mostly to support artificial limb prosthesis [4]. A number of thermoplastic materials are used in dentistry such as modelling compounds, thermoplastic waxes including baseplate and pattern waxes, and reversible hydrocolloids. Thermoplastic material, as prefabricated stock trays can be readily adapted as custom trays in the patient’s mouth compared to the conventional procedures of stock and custom trays. The uniqueness of the proposed impression technique unlike earlier techniques, is the idea to incorporate the philosophy of selective pressure technique in the prefabricated thermoplastic stock tray. This will enable the clinician to select the prefabricated trays with tray designs based on the examination and diagnosis of the patient’s mucosal and ridge condition at the first appointment [5]. Therefore, there are advantages of reduced appointment time and material cost compared to the conventional procedures.

The philosophy of selective impression technique is fundamentally based on loading the denture bearing areas that can withstand pressure and relieving areas that cannot withstand the functional load [6]. The concept of selectively applying pressure is based on the variance in histology of the denture bearing mucosa. It is the underlying anatomic structures supporting and limiting the prosthesis that determine the success of complete dentures [7]. There are an array of customised tray designs proposed to follow the principle of selective pressure technique. The present technique follows Boucher’s concept of spacer design, of placing 1 mm baseplate wax all over the maxilla except the posterior palatal seal area and Sharry’s concept of placing four tissue stops 4 mm in width in the molar and cuspid region extending from palatal aspect of the ridge upto the vestibule [8].

Prefabricated trays of thermoplastic material with built in tissue stoppers (Sharry design) of 4×4 mm (Baseplate wax, DPI) at the cuspid and molar region and spacers (Boucher’s design) were fabricated in our laboratory [8]. It is important to adequately soften the thermoplastic material at the recommended temperature of 85°C and adapt the material closely onto the cast with even thickness for the fabrication of tray with the spacer and stopper design. The spacers appear as debossed areas and the tissue stoppers appear as embossed areas in the stock tray. It is also essential, to shape the moulded tray meticulously to the patient’s denture bearing and limiting structures, without injuring the tissues at the suggested temperature of 45°C during the procedure. The tray was adapted to the patient’s posterior palatal seal area and border extensions of the tray were trimmed accordingly. Thermal properties of the tray material (KLARITY White TM, Meditronix) such as high melting point above 140°C and low softening point (below 100°C, ~85°C) enabled the use of low fusing modelling compound (~55°C) for peripheral tracing without the risk of deformation [4]. Technically, we assumed the adaptation of the thermoplastic tray in patient’s mouth may be difficult due to the presence of saliva. However, use of Bunsen flame followed by tempering eased the tray adaptation in the patient mouth.

Limitation

Limitations of the present technique concerns to the retention of thermoplastic properties following chemical sterilisation of trays for re-use, and skill of the operator in controlling the tray thickness during the manipulation.

Conclusion

A single appointment impression technique of thermoplastic stock trays with tissue stoppers and custom tray designs can be effectively adapted to patient’s edentulous arches and further used for peripheral tracing and master impression.

[1]. Chairside Custom Impression Trays. Massad® Edentulous Low Temp Impression Trays [Internet]. Star Dental Lab, 2804 Great Valley Dr. Cedar Park, TX. 78613. Available from: http://www.stardentallab.net/Massad_Edentulous_Arch.pdf [Google Scholar]

[2]. Zest Dental Solutions [Internet]. 2875 Loker Avenue East, Carlsbad, CA, USA [Accessed 9th Oct 2017, Updated 2017]. Available from: https://www.zestanchors.com/media/wysiwyg/pdf/chairside/L8032-ma_rev_a_01-16.pdf [Google Scholar]

[3]. Zhang Z, Low temperature thermoplastic material and preparing method thereofUnited States Patent. 8,859,691 B2 2014 [Google Scholar]

[4]. Michael J. Borroff, Donald A. Willstead, United States Patent. 4,661,535 1987 [Google Scholar]

[5]. Devan MM, Basic principles in impression makingJ Prosthet Dent 2005 93(6):503-08.10.1016/j.prosdent.2005.02.00715942607 [Google Scholar] [CrossRef] [PubMed]

[6]. Duncan JP, Raghavendra S, Taylor TD, A selective-pressure impression technique for the edentulous maxillaJ Prosthet Dent 2004 92(3):299-301.10.1016/j.prosdent.2004.06.00115343168 [Google Scholar] [CrossRef] [PubMed]

[7]. Jacobson TE, Krol AJ, A contemporary review of the factors involved complete dentures. Part III: SupportJ Prosthet Dent 1983 49(3):306-13.10.1016/0022-3913(83)90267-6 [Google Scholar] [CrossRef]

[8]. Shetty S, Nag PVR, Shenoy K, The selective pressure maxillary impression: A review of the techniques and presentation of an alternate custom tray designJ Indian Prosthodont Soc 2007 7(1):08-11.10.4103/0972-4052.32509 [Google Scholar] [CrossRef]