Evaluation of Effect of Zirconia Surface Treatment, Using Plasma of Argon and Silane, on the Shear Bond Strength of Two Composite Resin Cements

Aswathy Kaimal1, Poojya Ramdev2, C S Shruthi3

1 Postgraduate Student, Department of Prosthodontics, M R Ambedkar Dental College, Bengaluru, Karnataka, India.

2 Reader, Department of Prosthodontics, M R Ambedkar Dental College, Bengaluru, Karnataka, India.

3 Professor, Department of Prosthodontics, M R Ambedkar Dental College, Bengaluru, Karnataka, India.

NAME, ADDRESS, E-MAIL ID OF THE CORRESPONDING AUTHOR: Dr. Aswathy Kaimal, Postgraduate Student, Department of Prosthodontics, M R Ambedkar Dental College, E, 1/36 Cline Road Cooke Town, Bengaluru-560005, Karnataka, India.

E-mail: aswathy.kaimal@gmail.com

Introduction

Yttria stabilised tetragonal zirconia opens new vistas for all ceramic restoration by the mechanism of transformation toughening, making it much stronger compared to all other ceramic materials. Currently, it is the most recent core material for all ceramic fixed partial dentures due to its ability to withstand high simulated masticatory loads.

Problems which have been reported with zirconia restorations involve the core cement interface leading to loss of retention of the prosthesis. Different reasons which have been reported for the same include the lack of adhesion between zirconia and commonly used cements due to absence of silica phase which makes zirconia not etchable. In addition, the hydrophobic nature of zirconia causes low wettability of zirconia surface by the adhesive cements which are commonly used.

Aim

The purpose of this in vitro study was to compare and evaluate the effect of two pre-treatments of zirconia, using plasma of argon and silane, on the shear bond strength values of two composite resin cements to zirconia and to evaluate the failure pattern of the debonded areas using stereomicroscopic analysis.

Materials and Methods

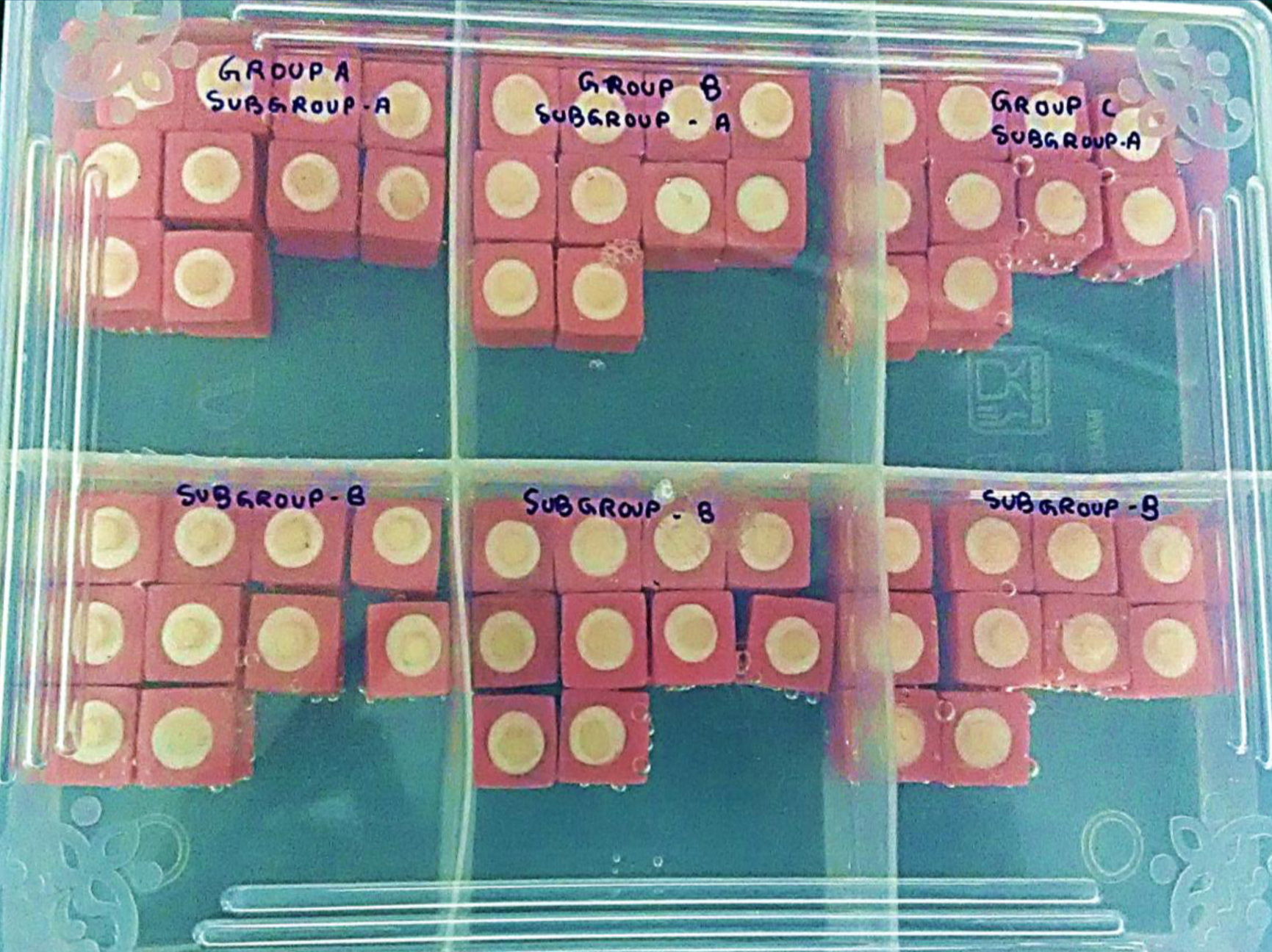

Sixty zirconia discs (10 mm×2 mm) were randomly divided into three groups (n=20), following surface treatment, with airborne particle abrasion, using 110 µm Al2O3: Group I (control), Group II (plasma of argon cleaning), and Group III (application of silane primer). Each group had two subgroups based on the type of resin cement used for bonding: subgroup A; Rely X Ultimate (3M ESPE) and subgroup B; Panavia F (Kuraray). In subgroup A, Rely X universal silane primer and in subgroup B Clearfil ceramic primer was used. Shear bond strengths were determined after water storage for one day and thermocycling for 5000 cycles. Data (megapascal) were analyzed using ANOVA and Bonferroni test. Specimens were subjected to stereomicroscopic analysis, for evaluation of failure pattern.

Results

Group III produced the highest shear bond strength followed by Group II and Group I. Subgroup A showed higher shear bond strength than Subgroup B. Stereomicroscopic analysis showed cohesive failure in Group III, while in Group I adhesive failure was seen.

Conclusion

Silane primer application caused maximum increase in shear bond strength due to increased wettability. Argon plasma treatment was less effective in comparison to silane treatment. Air abrasion when used alone resulted in lower bond strength values, thereby making it necessary to use a combination of surface treatments. Rely X Ultimate cement was superior to Panavia F in terms of adhesive bonding to zirconia.

Masticatory loads, Panavia F, Rely X Ultimate

Introduction

Zircon has been known as a gem since ancient times. Zirconia is a white crystalline oxide of zirconium. Zirconia is a well-known polymorph consisting of tetragonal, cubic and monoclinic phases at various ranges of temperature. This temperature dependent transformation of zirconia causes strain on transformation from tetragonal to monoclinic phase, which is accompanied by a volumetric increase of 3%-4%. This principle has been used for the strengthening of zirconia in order to prevent the propagation of cracks by partially stabilising the tetragonal phase of zirconia (Tetragonal Zirconia Polycrystalline-TZP) by the addition of 2%-3% mol yttrium oxide. This strengthening mechanism of zirconia is known as transformation toughening and it has been sometimes referred to as ‘ceramic steel’ due to this strengthening and toughening mechanism [1].

With the mechanism of transformation toughening, it was possible to create zirconia materials with high toughness and strength. However, the real breakthrough came with the innovations in CAD/CAM technology. Currently, it is the most recent core material for all ceramic fixed partial dentures due to its ability to withstand high simulated masticatory loads [2].

Problems which have been reported with zirconia restorations involve the core cement interface leading to loss of retention of the prosthesis. Different reasons which have been reported for the same include the lack of adhesion between zirconia and commonly used cements due to absence of silica phase which makes zirconia not etchable. In addition, the hydrophobic nature of zirconia causes low wettability of zirconia surface by the adhesive cements which are commonly used [3].

Untreated zirconia surfaces have low bond strength due to contamination of the surface during manufacturing process. Achieving sufficient bond strength is a major challenge in the long term clinical success of zirconia restorations. To improve the superficial adhesion, different pre-treatment methods have been suggested.

To increase the surface area for micromechanical bonding, airborne particle abrasion has been used. Air abrasion has proven to increase the surface energy and surface area for bonding and wettability. Studies have shown that similar surface roughness can be created with aluminium oxide airborne particle abrasion and silica coating methods. Air abrasion leads to the phase transformation of tetragonal to monoclinic phase which increases the flexural strength [4,5].

New innovative adhesive strategies combining new surface roughening procedures like Rocatec system using silica particles, selective infiltration etching techniques, laser treatment using Nd YAG laser and chemical bonding have been developed. Chemical bonding to zirconia involves the use of various couplers and silane primers containing acidic groups [6].

A newest approach is to use a combination of plasma treatment with argon plasma and 10 Methacryloyloxydecyl dihydrogen Phosphate (MDP) containing resin cements. Plasma treatment done using argon plasma increases the surface energy of zirconia resulting to an improvement of wettability. Also, it removes the organic impurities and thus enhances bonding of resin cements to zirconia [7].

Earlier zirconia restorations were luted using conventional zinc phosphate cement and resin modified glass ionomer cement. However, adhesive cementation with resin cements has shown to increase fracture resistance and improve the longevity of the restoration [6]. Panavia F and Rely X Ultimate containing phosphoric acid metharylates has been proven to provide a strong physical bond with the air abraded zirconia surface [8].

However, there is no universally accepted protocol regarding the cementation of zirconia and there is lack of clarity as to which surface conditioning method produces the most durable resin bond strength. Therefore, the purpose of this in vitro study was to compare and evaluate the effect of two pre-treatments of zirconia, using plasma of argon and silane, on the Shear Bond Strength (SBS) values of two composite resin cements (Rely X Ultimate and Panavia F) to zirconia and to evaluate the failure pattern of the debonded areas using stereomicroscopic analysis. The null hypothesis of this in vitro study was that there would be no significant difference in the mean SBS values among the various groups tested.

Materials and Methods

An in vitro study conducted at M R Ambedkar Dental College, Bengaluru, Karnataka, India.

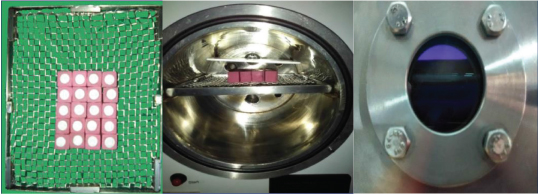

For this study, sixty sintered discs of zirconia (10 mm in diameter and 2 mm in thickness) were fabricated using CAD CAM technology [Table/Fig 1(a-g)]. Each zirconia disc were embedded in an aluminium mould (25 mm in length and 15 mm in width) with polymethyl methacrylate autopolymerising acrylic resin. All the sixty samples were divided into three different groups following air abrasion using 110 µm aluminium oxide for 10 seconds at an angle of 90° under 0.28 MPa air pressure, held at a distance of 10 mm from the specimen surface [Table/Fig-2] and all specimens were ultrasonically cleaned in distilled water for 10 minutes and air dried. Based on the surface treatment, all 60 samples were randomly divided into three groups. All three groups were further subdivided into two subgroups based on the resin cement used for bonding. Subgroup A was luted using Rely X Ultimate resin cement while subgroup B was luted using Panavia F resin cement.

Fabrication of Zirconia Discs a) Wax pattern of 10 mm diameter and 2 mm; b) Obtaining master cast of the wax pattern impression; c) Scanning of the pattern using ceramill mind software; d) Scanned pattern nested into zirconia blank for milling; e) Milling of zirconia blank in ceramill motion 2; f) Sintering of zirconia discs in ceramill therm 3. g) sintered 60 zirconia discs.

Sandblasting of zirconia specimens.

Group I-Twenty specimens received no surface treatment following air abrasion with 110 µm aluminium oxide and acted as control.

Group II –Underwent plasma of argon cleaning at 0.5 mb pressure and for a treatment time period of 20 minutes [Table/Fig-3].

Group II samples undergoing plasma of argon cleaning.

GROUP III-Underwent application of silane primer using the silane primer specific for each resin cement used. In subgroup A samples, to be bonded to Rely X Ultimate resin cement, the zirconia specimens were treated using Rely X ceramic primer. Subgroup B samples, to be bonded with Panavia F resin cement, the zirconia specimens were surface treated using Clearfil ceramic primer.

Group I specimens were surface treated as follows: Airborne particle abrasion using 110 µm Al2O3 particles was performed for 10 seconds at an angle of 900 under 0.28 MPa air pressure, held at a distance of 10 mm from the specimen surface. Subsequently, all the specimens were ultrasonically cleaned in distilled water for 10 minutes and air dried.

Group II specimens were surface treated as follows: Air abrasion was done using 110 um at 0.28 MPa of air pressure for 10 seconds at an angle of 90° and at a distance of 10 mm from the specimen surface. The specimens were ultrasonically cleaned in distilled water for 10 minutes and air dried. Subsequently, all the specimens underwent plasma of argon cleaning. Plasma treatment was performed using a plasma reactor with argon plasma at 0.5 mb pressure and for a treatment time period of 20 minutes [7].

Group III specimens were surface treated as follows: Air abrasion was done using 110 um Al2O3 at 0.28 MPa of air pressure for 10 seconds at an angle of 90° and at a distance of 10 mm from the specimen surface. The specimens were ultrasonically cleaned in distilled water for 10 minutes and air dried. The specimens were treated with silane specific to each resin cement used. In subgroup A which consisted of ten samples, a single coat of Rely X ceramic primer was applied using a disposable applicator tip for 20 seconds on the exposed surface of zirconia disc to be bonded with the Rely X Ultimate resin cement following the manufacturer’s specifications. A gentle stream of air was used over the liquid for 5 seconds and surface of the disc was left to dry at room temperature. In subgroup B which consisted of ten samples, a single coat of Clearfil ceramic primer was applied using an applicator tip for 20 seconds on the exposed surface of zirconia disc to be bonded with the Panavia F resin cement. A gentle stream of air was used over the liquid for 5 seconds and surface of the disc was left to dry at room temperature following the manufacturer’s specifications.

A custom- made metal split matrix (5 mm internal diameter and 2 thickness) was placed on the center of the zirconia disc. The cement was dispensed according to manufacturer’s instructions and inserted into the matrix. In subgroup A, Rely X Ultimate cement was dispensed from the clicker dispenser onto the mixing pad. The base and catalyst was mixed for 2 minutes and 30 seconds following which it was applied onto the zirconia disc and light curing was performed for 20 seconds using light wave of 400-500 nm. In subgroup B, the Panavia F base and catalyst paste was dispensed onto a mixing pad and mixed for 20 seconds. The cement was then applied over zirconia disc. A glass slab and a weight exerting 500 g was placed on top of the cement to permit overflow of a slight excess of material and light curing was done for 20 seconds. The specimens were left undisturbed for 15 minutes and the excess cement was removed. All the specimens were stored in distilled water at 37°C for 24 hours [Table/Fig-4].

Specimens stored in distilled water.

All the samples were thermocycled 5000 times in water between 5°C and 55°C. The dwell time at each temperature was 30 seconds with a transfer time of 15 seconds between baths. The thermocycling conditions were based on the estimation that 5000 thermocycles would simulate the situation during 5 years in the oral cavity [9]. After thermocycling, the specimens were tempered to room temperature in a water bath prior to measuring SBS.

The specimens were then subjected to shear load of 1 KN with a universal testing machine (3345 model; instroncorp). A knife edge chisel apparatus (5 mm blade length) running at a cross head speed of 0.5 mm/minute was used to direct a parallel shearing load at the resin cement/zirconia interface. SBS values were recorded in megapascal (MPa). Following SBS testing, after debonding of the samples, the failure type was assessed and classified according to the failure origin by using a stereomicroscope (Lawrence & Mayo; Nsz 606, Lynx) at 10X magnification.

Statistical Analysis

The collected data were analyzed by 3- way Analysis of Variance test (ANOVA). When significant differences were found between the groups, Bonferroni test (post-hoc test) was applied. The level of significance was set at p-value ≤0.05.

Results

The SBS values were evaluated for each group in comparison with their respective subgroups [Table/Fig-5]. The mean SBS and standard deviation for surface treatment methods and bonding resin cements was calculated [Table/Fig-6,7].

Comparison of the shear bond strength (MPa) values.

| Sl. No. | Group I A Shear bond strength (MPa) | Group I B Shear bond strength (MPa) | Group II A Shear bond strength (MPa) | Group II B Shear bond strength (MPa) | Group III A Shear bond strength (MPa) | Group III B Shear bond strength (MPa) |

|---|

| 1 | 5.724286 | 4.285681 | 8.756988 | 7.101667 | 16.76578 | 9.863918 |

| 2 | 4.868319 | 4.000629 | 7.999895 | 8.952254 | 11.15576 | 11.3209 |

| 3 | 4.900323 | 3.00683 | 6.623453 | 7.830648 | 12.06001 | 12.39214 |

| 4 | 4.436861 | 3.999739 | 11.7194 | 8.952254 | 13.54381 | 13.51676 |

| 5 | 3.108761 | 4.662117 | 9.00262 | 7.101667 | 12.74054 | 9.374153 |

| 6 | 4.994773 | 3.237742 | 7.679805 | 8.113354 | 13.54381 | 9..847121 |

| 7 | 4.084858 | 3.599743 | 8.970892 | 8.185433 | 11.15576 | 8.065405 |

| 8 | 5.376575 | 3.791143 | 9.999872 | 7.102345 | 12.41278 | 11.30834 |

| 9 | 4.298679 | 3.009721 | 8.112392 | 7.312754 | 13.12082 | 13.51347 |

| 10 | 3.74942 | 3.657243 | 8.112082 | 6.376328 | 12.51204 | 8.060512 |

Mean shear bond strength (MPa) values with respect to surface treatment.

| Group | Mean | Standard deviation |

|---|

| 1-Control | 4.14 | 78 |

| II- plasma of argon | 8.20 | 1.24 |

| III-silane primer | 11.81 | 2.09 |

Mean shear bond strength (MPa) values with respect to resin cement.

| Subgroup | Mean | Standard deviation |

|---|

| A-Rely X Ultimate | 8.72 | 3.69 |

| B-Panavia F | 7.38 | 3.17 |

ANOVA test was performed to compare the mean SBS values in different groups [Table/Fig-8]. Highest mean SBS was recorded in Group III (11.81± 2.09 MPa) followed by Group II (8.20 ±1.24 MPa) and control Group I (4.14 ±78 MPa) [Table/Fig-6]. The difference in mean shear bond strength among the groups was found to be statistically significant (p<0.001). In order to find out among which pair of groups there exist a significant difference, Bonferroni test (post hoc test) was applied [Table/Fig-9].

ANOVA test for the groups.

| Source | df | Sum of Squares (SS) | Mean SS | F | p-Value |

|---|

| Surface Treatment (group I, II, III) | 2 | 589.570 | 294.790 | 173.500 | <0.001* |

| Bonding (Subgroup A and B -type of cement used) | 1 | 26.650 | 26.650 | 15.690 | <0.001* |

| Surface Treatment x Bonding based on type of cement used | 2 | 5.380 | 2.690 | 1.580 | 0.214 |

| Error | 54 | 91.750 | 1.700 | --- | --- |

| Total | 59 | 713.360 | --- | --- | --- |

denotes significant difference

Bonferroni test for different groups.

| (I) Surface treatment | (J) Surface treatment | Mean Difference (I-J) | p-Value | 95% CI for Mean diff |

|---|

| Lower Bound | Upper Bound |

|---|

| Control | Plasma of Argon | -4.060 | <0.001* | -5.08 | -3.04 |

| Silane Primer | -7.674 | <0.001* | -8.69 | -6.66 |

| Plasma of Argon | Control | 4.060 | <0.001* | 3.04 | 5.08 |

| Silane Primer | -3.614 | <0.001* | -4.63 | -2.60 |

| Silane Primer | Control | 7.674 | <0.001* | 6.66 | 8.69 |

| Plasma of Argon | 3.614 | <0.001* | 2.60 | 4.63 |

denotes significant difference

Among the air abraded specimens, a consistent amount of adhesive fractures (between zirconia and cement) was found [Table/Fig-10]. Controversially among the silane treated and plasma treated groups, most detachments were pure cohesive (within the cement) or mixed with part of cement remaining attached to the zirconia.

Frequeny distribution of the failure pattern as determined by stereomicroscopic analysis.

| Group | Adhesive(%) | Mixed(%) | Cohesive(%) |

|---|

| IA | 28.0 | 13.0 | 59.0 |

| IB | 33.0 | 12.0 | 55.0 |

| 2A | 67.0 | 31.0 | 2.0 |

| 2B | 45.0 | 45.0 | 10.0 |

| 3A | 63.0 | 35.0 | 0 |

| 3B | 55.0 | 39.0 | 6.0 |

Discussion

The results in this study concluded that among the various surface treatments done, the highest mean SBS was recorded in Group III (11.81±2.09 MPa) followed by Group II (8.20±1.24 MPa) and control Group I (4.14±0.78 MPa). Among the two subgroups of resin cements used, subgroup A had the highest SBS (8.72±3.69 MPa) and subgroup B showed lower bond strength value (7.38±3.17 MPa)

The Group III specimens which were abraded with 110 µm Al2O3 particles followed by treatment with silane primer of the respective resin cements used, produced the highest SBS values. Air abrasion with 110 µm Al2O3 particle roughened the surface which increased its surface area for bonding. The application of silane on this surface hence resulted in improved wettability of the resin cement. Also, the stereomicroscopic results showed the absence of pure adhesive failure in the silane treated group, suggesting that the increase of the SBS in silane treated group is due to a stronger zirconia-cement interface bonding. Combining air abrasion with silane results in association of micromechanical with the chemical retention via siloxane bonds. Silane also has the property of increasing the wettability of cement, thus improving the ability of the zirconia to adhere to the resin cement [10,11].

Group II which underwent plasma of argon cleaning following air abrasion with Al2O3 showed bond strength values lower than the silane treated group. The values were significantly higher than the control group which was only air abraded. This signifies the importance of combining air abrasion with other surface treatment modalities, plasma argon cleaning effectively cleaned the air abraded surface of the zirconia, thus reducing the surface contamination and increased the surface energy. Studies have also shown thatplasma argon cleaning reduced the carbon based contaminants and eventually created super hydrophilic surfaces [12,13]. Since MDP present in both the resin cements used directly interacts with zirconia, a deeply cleaned surface with increased wettability from plasma cleaning treatment might have allowed for superior primer behavior. The results are in agreement with similar study which concluded that plasma argon cleaning is effective in increasing the adhesion between zirconia and composite cement [10].

In Group I, samples which were only airborne particle abraded using 110 µm Al2O3, the bond strength values were found to be the least. The results are in agreement with a study which concluded that zirconia with surface abrasion only and no chemical bonding showed low bond strength and ultimately resulted in adhesive failures [14].

Among the two subgroups in all the three groups, highest bond strength values were obtained in subgroup A which was bonded using Rely X Ultimate resin cement in comparison with subgroup B which was bonded using Panavia F resin cement. Though, both the cements contained acidic phosphate group, MDP studies have revealed higher bond strength values for Rely X cement when compared with Panavia F cement [8]. Hence, the results of this study was in agreement with various other researchers [8,15].

The significant improvement in SBS was because of combined mechanical treatment using airborne particle abrasion and chemical treatment using silane primer. Therefore, it can be concluded that silane treatment of zirconia is a prerequisite to ensure a stronger and more durable bond between zirconia and resin cement from this study.

The results of this study rejected the null hypothesis, since the surface treatment produced SBS values significantly greater than the control group.

In day to day clinical practice, zirconia crowns are most often luted with resin cements without prior application of primers available with the resin cement. This study has proven the significance of using a primer containing silane that can effectively improve the bonding of resin cement. Application of silane primers to zirconia must be employed in day to day clinical practice. The use of air abrasion of the zirconia crowns before cementation will improve the microroughness and ensure better wettability of the primers used. Hence, air abrasion is a prerequisite for bonding and must be used in combination with primer application for a better chemical and mechanical bonding.

Limitation

SBS of resin cement to zirconia was the only factor used for assessing the strength of the bond. Bond strength will be significantly affected based on the oral environment which could not be simulated in the study being an in vitro study and long term longevity could not be evaluated. Future studies taking into consideration the effect of intraoral conditions need to be done.

Conclusion

The techniques that can be employed in clinical practice to increase the SBS at the resin–zirconia interface were investigated. Air abrasion with alumina particles provided greater surface area for bonding and increased the micromechanical retention of the resin cement to zirconia. Plasma treatment with argon plasma effectively enhanced and cleaned the zirconia surface considerably removing the smear layer which led to increase in SBS values.

The silane primer promoted a significant increase in the adhesive bonding of resin cement to zirconia. Highest SBS values were yielded by Group III specimens (silane treated group) followed by Group II (plasma of argon cleaning) and Group I specimens (control). The SBS values for Groups III and Group II were more than 5MPa which satisfied the ISO requirements.

Highest SBS values were obtained with Rely X Ultimate resincement when compared to Panavia F resin cement. Lowest SBS values were yielded by control Group I (only air borne particle abraded) followed by Group II (plasma argon cleaning). The SBS values for control group were less than 5MPa and hence was not suitable for clinical situations. Stereomicroscopic analysis showed cohesive failure among the silane treated group signifying a stronger resin cement zirconia bonding with use of silane treatment.

*denotes significant difference

*denotes significant difference

[1]. Kelly JR, Denry I, Stabilized zirconia as a structural ceramic: An overviewDent Mater 2008 24:289-98. [Google Scholar]

[2]. Raigrodski AJ, Contemporary materials and technologies for all-ceramic fixed partial dentures: A review of literatureJ Prosthet Dent 2004 92:557-62. [Google Scholar]

[3]. Manicone PF, Iommetti PR, Raffaelli L, An overview of zirconia ceramics: Basic properties and clinical applicationsJ Dent 2007 35:819-26. [Google Scholar]

[4]. Magne P, Paranhos MPG, Burnett LH, New zirconia primer improves bond strength of resin-based cementsDent Mater 2010 26:345-52. [Google Scholar]

[5]. Hallmann L, Ulmer P, Lehmann F, Wille S, Polonskyi O, Johannes M, Effect of surface modifications on the bond strength of zirconia ceramic with resin cement resinDent Mater 2016 32:631-39. [Google Scholar]

[6]. Tzanakakis EGC, Tzoutzas IG, Koidis PT, Is there a potential for durable adhesion to zirconia restorations?A systematic reviewJ Prosthet Dent 2016 115:09-19. [Google Scholar]

[7]. Canullo L, Micarelli C, Bettazzoni L, Koci B, Baldissara P, Zirconia composite bonding after plasma of argon treatmentInt J Prosthodont 2014 27:267-69. [Google Scholar]

[8]. Kumbuloglu O, Lassila LVJ, User A, Vallittu PK, Bonding of resin composite luting cements to zirconium oxide by two air- particle abrasion methodsOper Dent 2006 31(2):248-55. [Google Scholar]

[9]. Fischer J, Grohmann P, Stwawrczyk B, Effect of zirconia surface treatments on the shear bond strength of zirconia/veneering ceramic compositeDent Mater J 2008 27:448-54. [Google Scholar]

[10]. Kern M, Wegner SM, Bonding to zirconia ceramic: adhesion methods and their durabilityDent Mater 1998 14:64-71. [Google Scholar]

[11]. Matinlinna JP, Heikkinen T, Ozcan M, Lassila LVJ, Vallittu PK, Evaluation of resin adhesion to zirconia ceramic using some organosilanesDent Mater 2006 22:824-31. [Google Scholar]

[12]. Valverde GB, Coelho PG, Janal MN, Lorenzoni FC, Cravalho RM, Thompson VP, Surface characterization and bonding of Y-TZP following non-thermal plasma treatmentJ Dent 2013 41:51-59. [Google Scholar]

[13]. Lee MH, Min BK, Son JS, Kwon TY, Influence of different post-plasma treatment storage conditions on the shear bond strength of veneering porcelain to zirconiaDent Mater J 2014 35:425-26. [Google Scholar]

[14]. Jevnikar P, Krnel K, Kocjan A, Funduk N, Kosmac T, The effect of nanostructured alumina coating on resin-bond strength to zirconia ceramicsDent Mater 2010 26:688-96. [Google Scholar]

[15]. Yang B, Barloi A, Kern M, Influence of air-abrasion on zirconia ceramic bonding using an adhesive composite resinDent Mater J 2010 26(1):44-50. [Google Scholar]