However, the main drawback with these types of ceramics is, chipping of the veneer porcelain from its core resulting minute fractures in the restoration [1,8]. To overcome this problem, Monolithic zirconia that is, solid zirconia which does not require veneering with porcelain has been introduced [9]. It is fabricated using state-of-the-art Computer Aided Design/Computer Aided Manufacturing (CAD/CAM) technology and is based on special chemistry as well as unique shading system [10]. Grinding may be required for chair side occlusal adjustments in these restorations also. When they are subjected such tensile stresses, it weakens the restoration. Hence, after grinding the surface needs either reglazing or polishing so as to make it smooth [11]. As monolithic zirconia is commonly used to fabricate long span posterior fixed partial dentures, knowing the flexural strength becomes important, especially after surface alteration.

Materials and Methods

Making the samples using CAD-CAM technology:

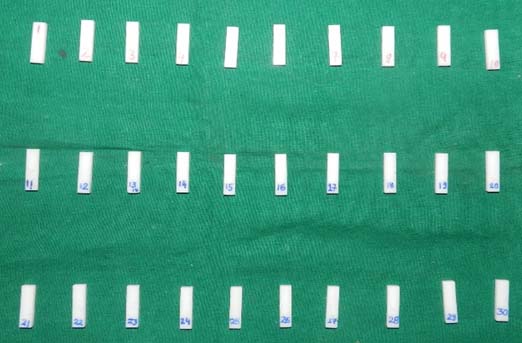

In this invitro study, monolithic zirconia blocks of Lava 3M ESPE were used. Study samples were designed using CAD software based on the digitized data and processed by a computer assisted milling machine [12]. Thirty samples were fabricated and divided into three groups according to the surface alteration treatment they were subjected to based on the data of previous studies [8,10,11] [Table/Fig-1]. The samples made were categorized as follows: Group 1 (n=10) – Control (no surface alteration), Group 2 (n=10) – Ground and Polished, and Group 3 (n=10) – Ground and Reglazed.

Milled Zirconia blocks by LAVA (3M ESPE).

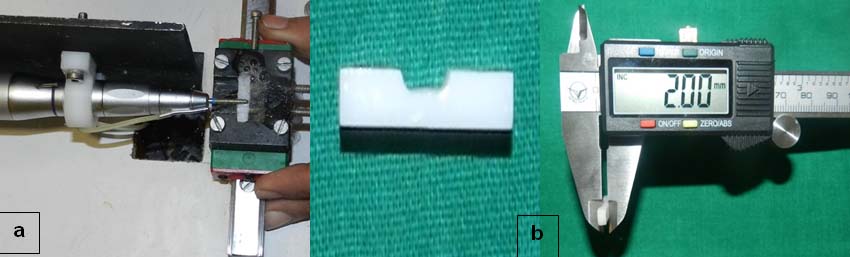

Each sample was made with wax replicas of standardized dimensions 20 mm(l)*5 mm(b)*3 mm(d) (l=length, b=width, d=thickness) according to ADA specification number 69, 1891 for flexural strength testing of dental ceramic [13] [Table/Fig-2]. For fabrication of samples, the wax replica was scanned by a digital scanner, followed by milling of the LAVA blocks with the help of CAD/CAM machine [12]. The samples were sintered to full density at temperatures between 1350°C and 1500°C for 7-8 hours. After milling the porous zirconia shrinks by 20%, it thus achieves its strength and final dimensions [14]. The bars were finished by soft cut polishers and the final dimensions were measured by digital caliper and glazed at 790ºC for 7-8 minutes.

Standardization of samples.

Surface alteration of samples: For standardized of grinding of the samples, a custom-made grinding apparatus was designed to mount the samples [Table/Fig-3] [15]. Air motor was clamped to a straight holding arm which was fixed on the apparatus. A metal holder with three screws, which carried the samples was attached to the apparatus. The straight handpiece was attached to the airmotor above the metal holder producing contact of the Zirconia bar with the rotating bur. The bur was oriented perpendicular to the long axis of the bars to the long axis of the bars. A linear guide was attached to the apparatus for constant linear forward and backward motion while grinding [Table/Fig-4a]. A constant load of 100 gm was used by applying free weight on the holding arm to maintain a light touch and prevent excessive grinding. Bars were marked at 5 mm distance length with permanent pen on the tensile surface so that all the specimens received the same length of surface treatment. Depth holes were made with 1 mm round bur by an airotor. Grinding was performed in a linear back and forth motion with a coarse grit diamond point until 1 mm reduction was achieved with continuous grinding under pressure of 40 lb/in2. Grinding points were changed after every four samples. This was performed on 20 samples of Group 2 and Group 3. The thickness of the ground sample between the 5 mm mark was 2 mm [Table/Fig-4b]. To remove the debris more effectively, the samples were placed in ultrasonic water bath and dried at room temperature.

Customized apparatus for grinding the samples.

a) Grinding procedure with the linear guide; b) Sample after grinding.

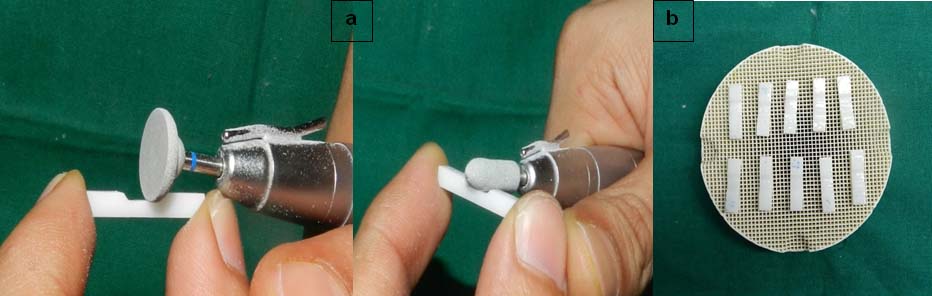

Finishing of samples using the polishing kit: Group 2 samples were polished with ceramic technique system kit (Shofu Inc. Kyoto Japan) as per manufacturer’s instructions at 25,000 rpm to give a flat polished surface [Table/Fig-5a].

a) Polishing with the help of ceramic technique Kit Dura green stone and silicon point (Shofu Japan); b) Samples after reglazing.

Finishing of samples by reglazing: Zirconia overlay porcelain powder was mixed with the glaze liquid and applied in a thin coat on the samples and reglazed at a final temperature of 790°C for seven to eight minutes [Table/Fig-5b].

Testing the samples: Flexural strength was determined by using a 3-point bending test performed in a Universal Testing Machine (UTM) at a cross head speed of 0.5 mm/min with a span length of 15 mm [16]. The ultimate load that caused specimen fracture was recorded [Table/Fig-6a-c]. Mean fracture strengths were calculated using the following equation as recommended by the ISO 6872 standard, 1995 [17].

a) Instron universal testing machine; b) Three point bend test for flexural strength testing; c) Samples after testing.

M= 3WI/2bd2 Where,

M=Flexural strength (Mpa), W=fracture load (N), I =test span (center to center) distance between support points (mm), b=breadth of specimen (mm), d=thickness of specimen.

Details of the test materials are given in [Table/Fig-7].

Details of test material.

| Brand of Materials | Type | Chemical Composition | Manufacturer | Lot No |

|---|

| LAVA | Monolithic Classic | Zirconium Dioxide | 3M ESPE | 4635090110974379067430281229f4919105688302880092258283993056649 |

Statistical Analysis

Quantitative data was presented in the form of mean, standard deviation and median [Table/Fig-8a]. Tests used were one-way ANOVA as per the results of D’Agostino and Pearson omnibus normality test [Table/Fig-8b] and [Table/Fig-9] Tukey’s multiple comparison test [Table/Fig-10].

Shows mean flexural strength values (in MPa) and Standard Deviation (SD) of all the three groups.

| GROUPS | Control | Polished | Glazed |

|---|

| Minimum | 335.1 | 446.8 | 459.3 |

| Maximum | 636 | 706.6 | 905.4 |

| Mean | 507 | 588.5 | 648.7 |

| Standard deviation | 83.27 | 93.46 | 148.4 |

| ANOVA test | SS | DF | MS | F(DFn,DFd) | p-value |

|---|

| Treatment | 101238 | 2 | 50619 | F (2,2.7)= 4.030 | P=0.0294 |

| Residual | 339158 | 27 | 12561 |

| Total | 440396 | 29 | |

where SS= sum of squares, DF= degree of freedom, MS=mean square, DFn =degree of freedom numerator, DFd=degree of freedom denominator, p-value= calculated probability

D’Agostino and Pearson omnibus normality test.

| Test used | Control | Polished | Glazed |

|---|

| K2 | 1.938 | 1.140 | 2.375 |

| p-value | 0.3795 | 0.5655 | 0.3050 |

| Passed normality test (alpha=0.05) | Yes | Yes | Yes |

| p-value summary | Ns | Ns | Ns |

Ns – non-significant, K2 – D’Agostinos test for normality

Details of Tukey’s multiple comparison test and results of the test

| Test Details | Mean 1 | Mean 2 | Mean Diff. | SE of diff. | n1 | n2 | q | DF |

|---|

| Control vs. Glazed | 507.0 | 648.7 | -141.8 | 50.12 | 10 | 10 | 4.000 | 27 |

| Control vs. Polished | 507.0 | 588.5 | -81.52 | 50.12 | 10 | 10 | 2.300 | 27 |

| Glazed vs. Polished | 648.7 | 588.5 | 60.25 | 50.12 | 10 | 10 | 1.700 | 27 |

| Test Results | Mean Diff. | 95% CI of diff. | Significance |

| Control vs. Glazed | -141.8 | -266.0 to -17.49 | S |

| Control vs. Polished | -81.52 | -205.8 to 42.76 | ns |

| Glazed vs. Polished | 60.25 | -64.03 to 184.5 | ns |

(where q= studentized range statistic, DF= degree of freedom, S Indicates p ≤ 0.05 (significant), ns indicates p > 0.05 non significant)

Results

[Table/Fig-8a] showing the mean flexural strengths of the three groups. The strength of the reglazed group was found to be higher as compared to other groups.

Discussion

Studies have shown that grinding can introduce compressive stresses which inhibit crack propagation increasing the flexural strength of zirconia [15]. Studies on this aspect have proven that restoration of surface damage improved the flexural strength of zirconia specimens [14]. Grinding promotes tetragonal to monoclinic (t to m) form transformation. Monoclinic being a more stable form of zirconia, causes an increase in the strength of zirconia. However, few studies have revealed that fine polishing lowers the mean flexural strength by removing the layer of compressive stresses [7,18]. This explained why greater strength was not found for the polished specimen. The results of this study are similar to previous studies in which the influence of grinding and polishing on the flexural strength of zirconia was investigated [16].

Chang I et al., stated that overglazed group had significantly higher flexural strength than self-glazed and polished group, whereas there was not much difference between the glazed and polished group [19]. The high flexural strength in the overglazed group may have been due to two possible explanations. First one was due to the overglazed layer filling the surface flaws and subsequently blunting the flaw tips thereby increasing the strength. Second could be due to the fact that overglaze layer has a lower thermal expansion coefficient than the leucite-rich interior. This places the outer surface in compression when cooled. Applying this knowledge to zirconia based ceramics, the current study was performed, in which the strength of the reglazed group increased as compared to the control group.

Iseri U et al., concluded that all grinding procedures decreased the flexural strength [20]. In their study, temperature obtained by micromotor grinding was significantly higher than high-speed handpiece grinding because low speed produce more heat. Lesser the heat more is the flexural strength due to retention of the monoclinic phase. Hence, grinding zirconia with low speed handpiece decreased flexural strength whereas high-speed caused the least reduction in strength. In the current in vitro study, a water spray was used as a coolant reducing the temperature thus decreasing the effect of temperature variations on the strength.

Iseri U et al., concluded that although grinding influenced the flexural strength of zirconia, it was not statistically significant [14]. Nakamura Y et al., also performed a study in which they concluded that the mean flexural strength of the glazed group was the highest, while that of the polished groups was low [21]. The crack inhibition phenomenon was responsible for this result. However, Yener ES et al., in their study investigated the effect of glazing and concluded that glazing decreased the flexural strength significantly [22]. Unglazed specimens had more flexural strength than that of glazed. They gave two possible explanations for their conclusion. One was the manufacturing process causing compressive stresses on the surface which was relieved by heat treatment and veneering. Other would be due to monoclinic to tetragonal (m to t) phase transformation or change in particle size during heat treatment or veneering.

Aboushelib M et al., observed variations in their study in which they concluded that strength increased statistically in polishing as the fine surface flaws were eliminated [15]. Glaze porcelain caused less regain in strength because of poor wetting ability and high viscosity failing to seal the deep flaws. The research hypothesis for this in vitro study was that there was no difference in the flexural strength after surface alterations. However, this hypothesis was rejected following the study, since there were statistically significant differences after surface alterations.

Limitation

The effect of temperature variations, sand blasting, heat treatment, variable speeds and ageing were not taken into consideration. This study was performed only on one brand but further studies including more number of brands along with long term clinical trials are required to substantiate the results obtained in this study.

Conclusion

Flexural strength was found to be increased after reglazing and polishing treatment as compared to the control. The effect of glazing on the flexural strength of zirconia was found to be statistically significant and that of polishing was non-significant. Clinicians can provide improved, high strength restorations to the patients without fearing the reduction in strength after performing any alterations. Accurate impression techniques, precise fabrication and lab finishing procedures would reduce the effort of chairside alterations thus decreasing the complications associated with fractured restorations. High translucency monolithic zirconia is also developed recently which could be used in anterior restorations without fearing the opacity of conventional zirconia.

where SS= sum of squares, DF= degree of freedom, MS=mean square, DFn =degree of freedom numerator, DFd=degree of freedom denominator, p-value= calculated probability

Ns – non-significant, K2 – D’Agostinos test for normality

(where q= studentized range statistic, DF= degree of freedom, S Indicates p ≤ 0.05 (significant), ns indicates p > 0.05 non significant)